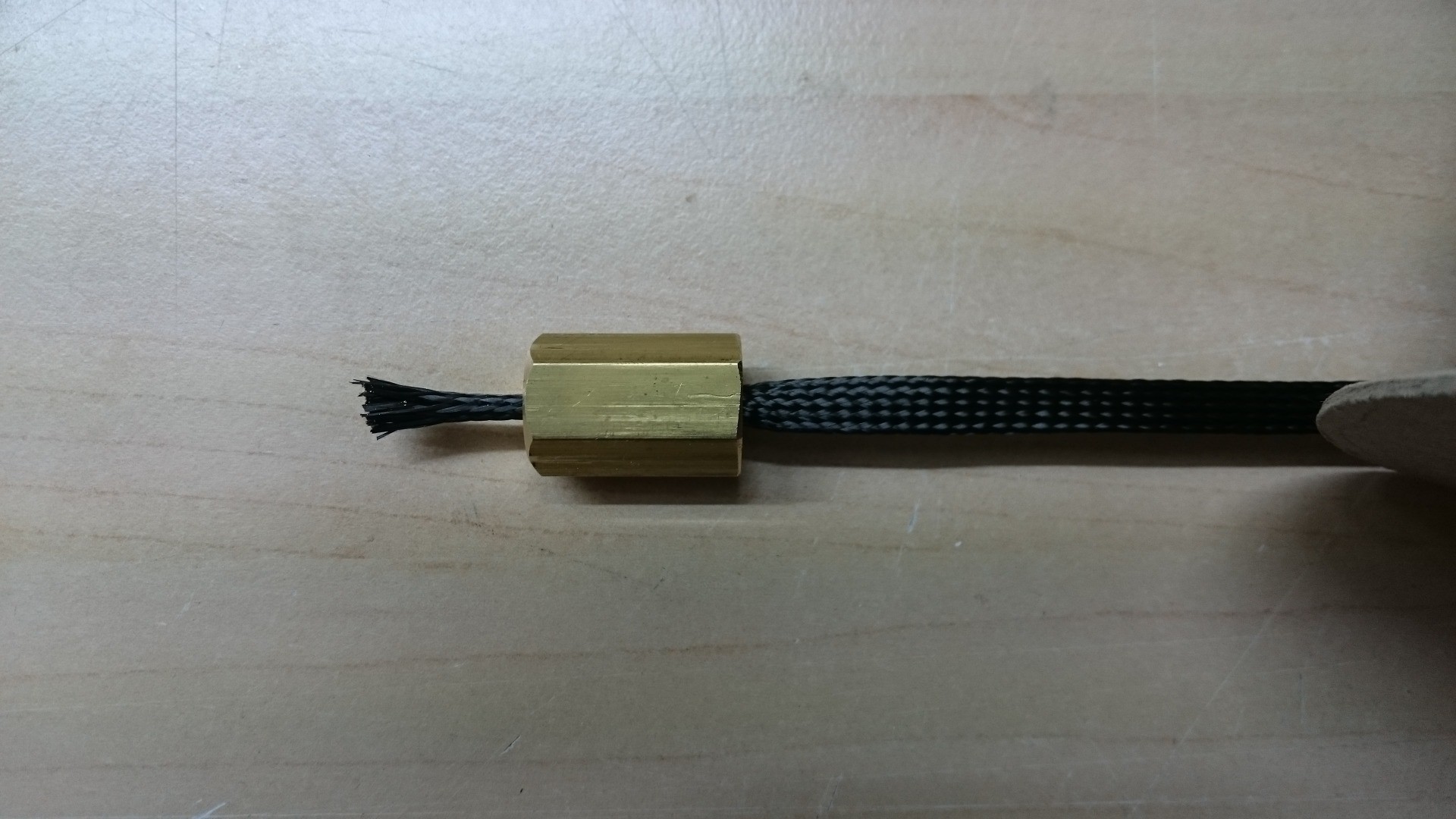

Using the brass nozzle makes the task of inserting carbon tube into a cable end sleeve easier by a felt order of magnitude:

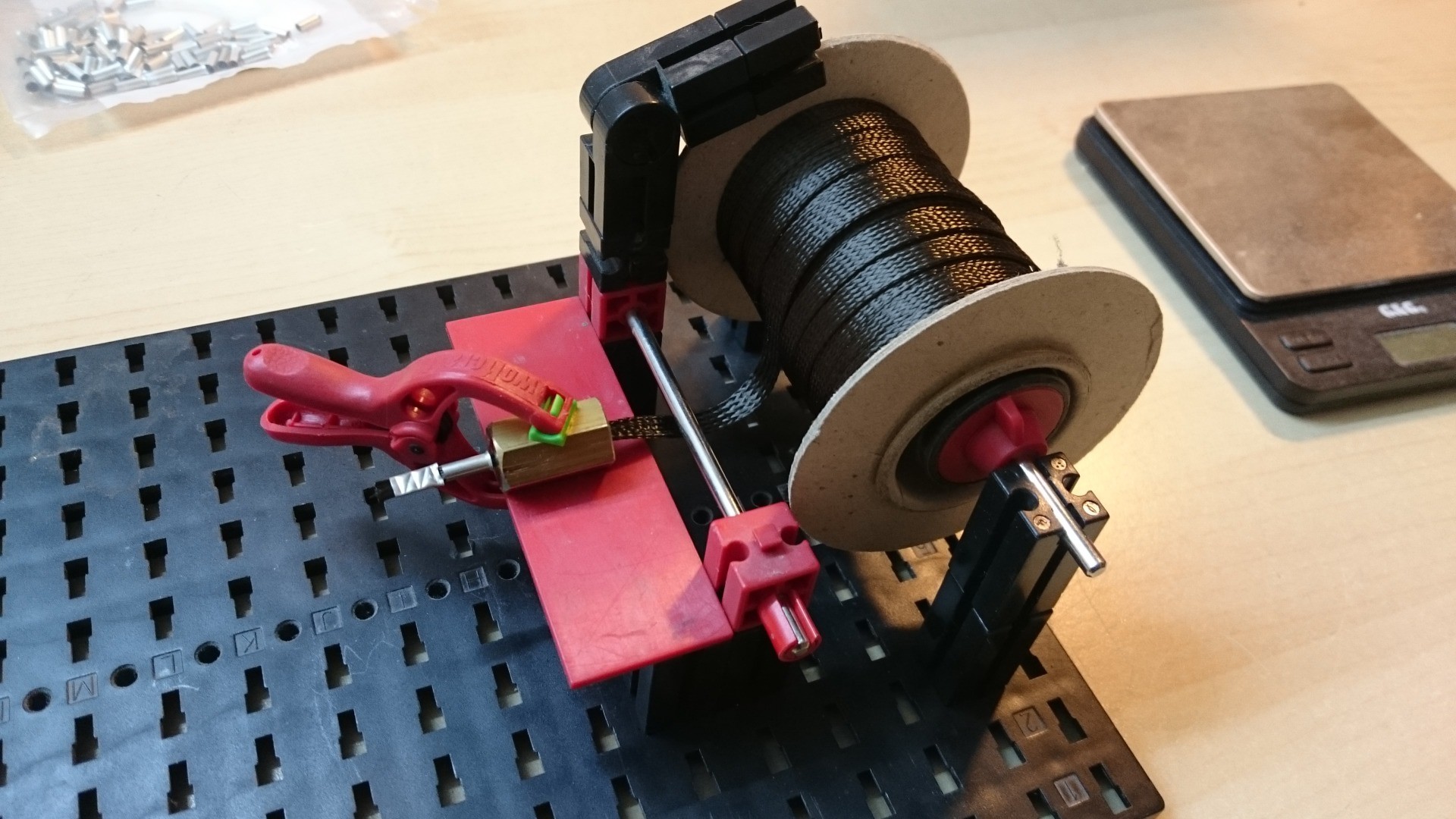

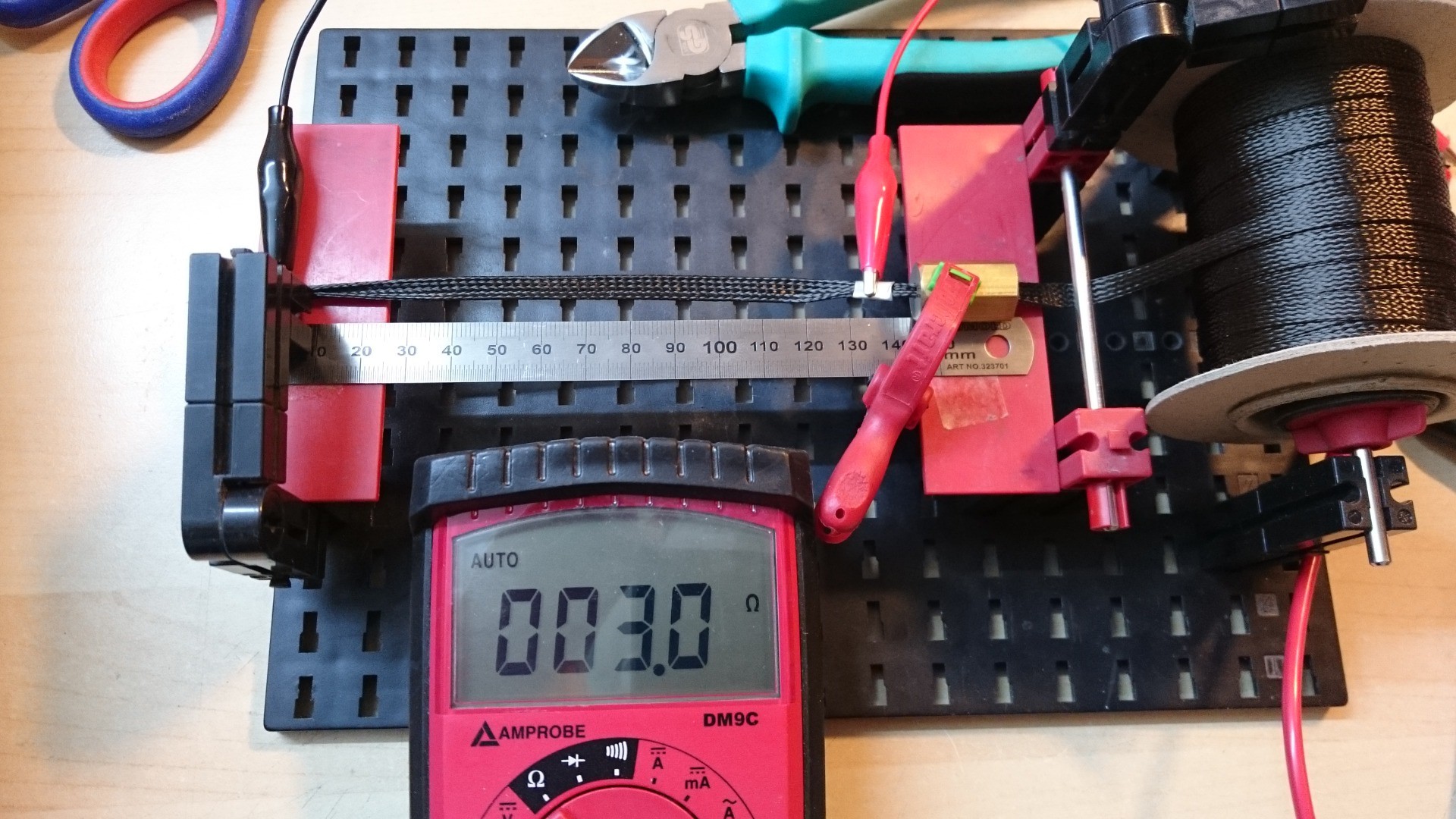

The cool thing about the tube is that it has a variable diameter (or width when flat). Making it wider also makes it shorter, but its resistance doesn't change significantly. Then resistance per length can therefore be adjusted a bit, leaving some room for fine-tuning when I'm past the more-power-is-better stage.

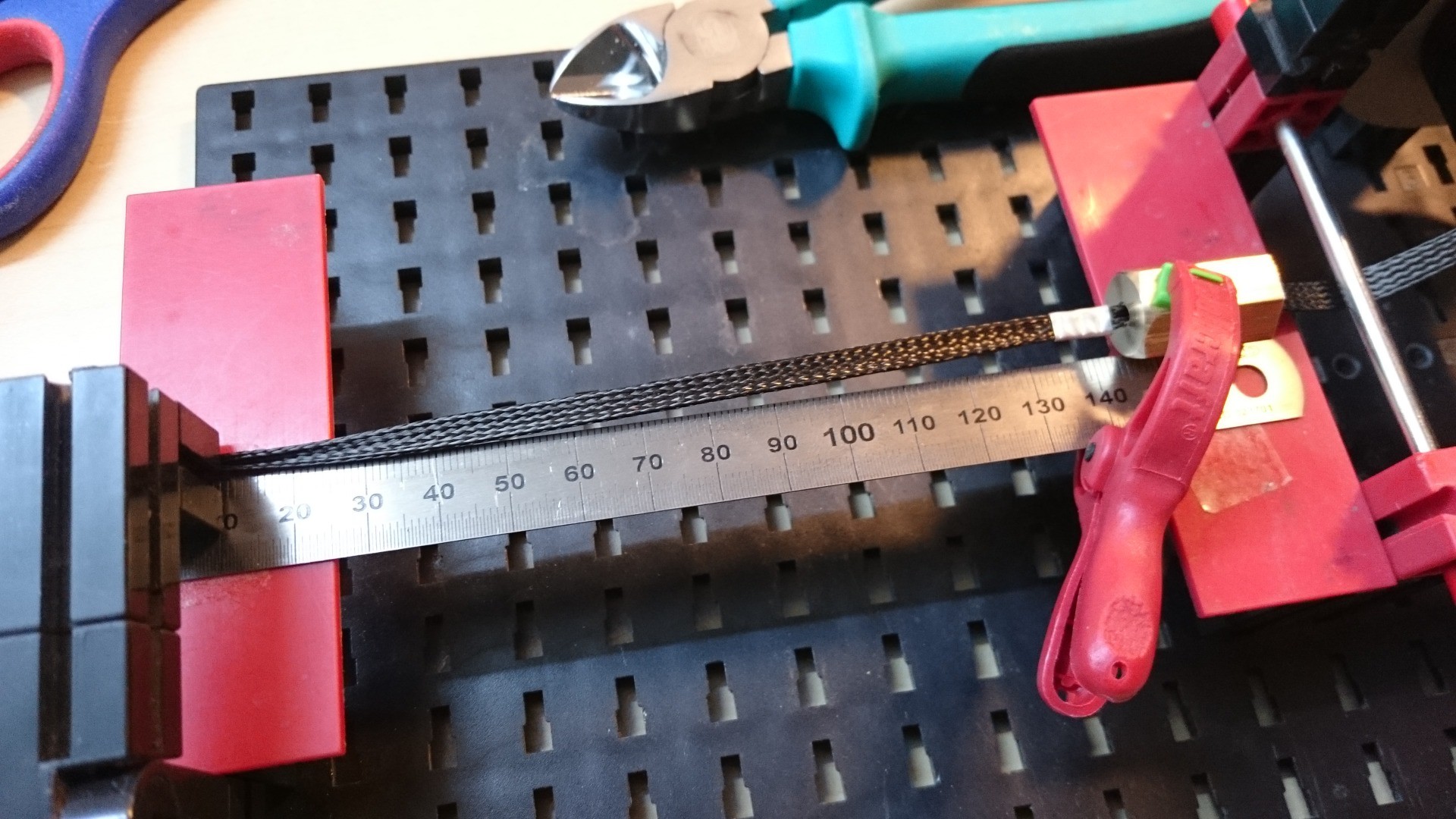

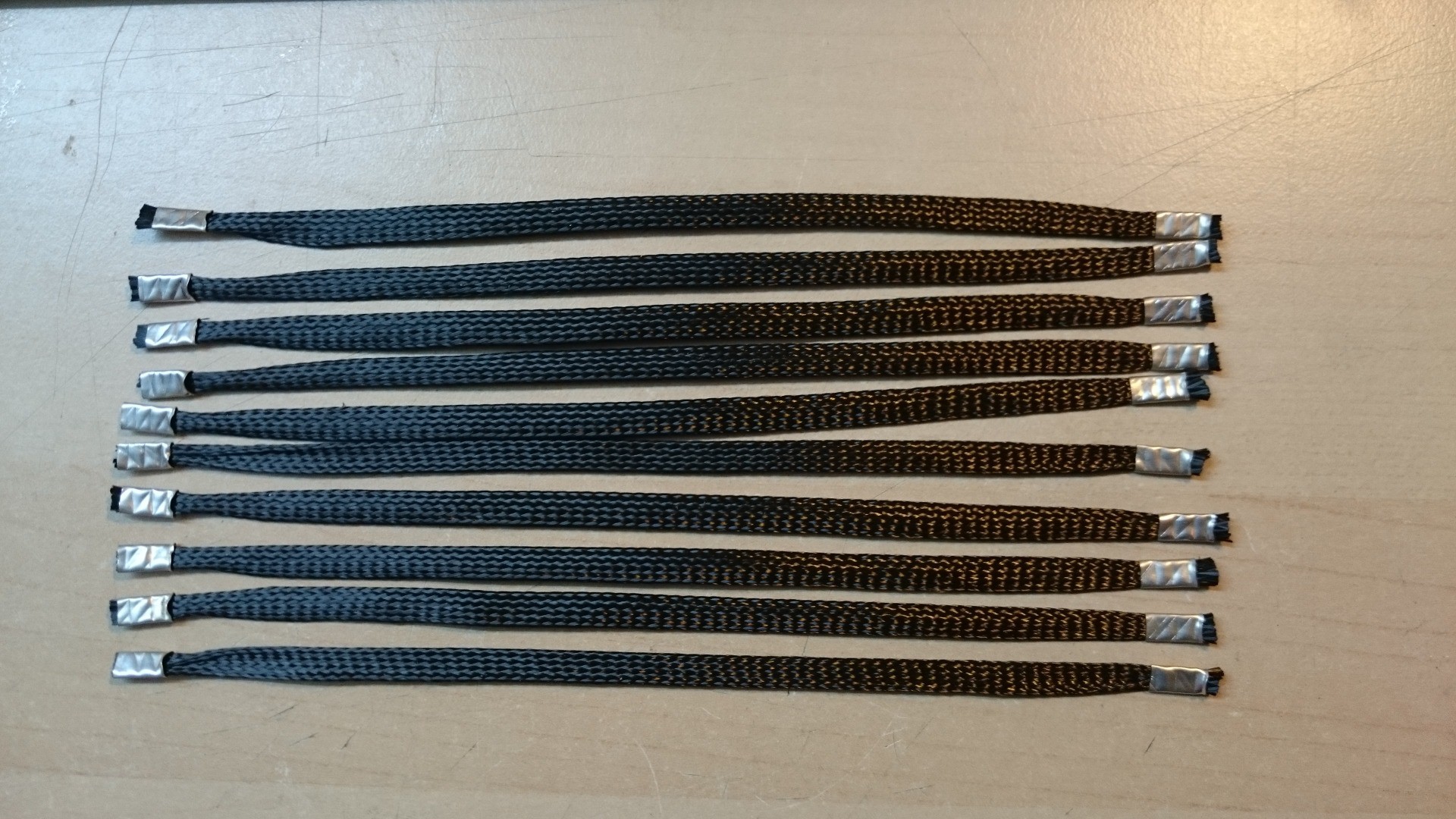

Made ten of these in 20 minutes:

Christoph

Christoph

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.