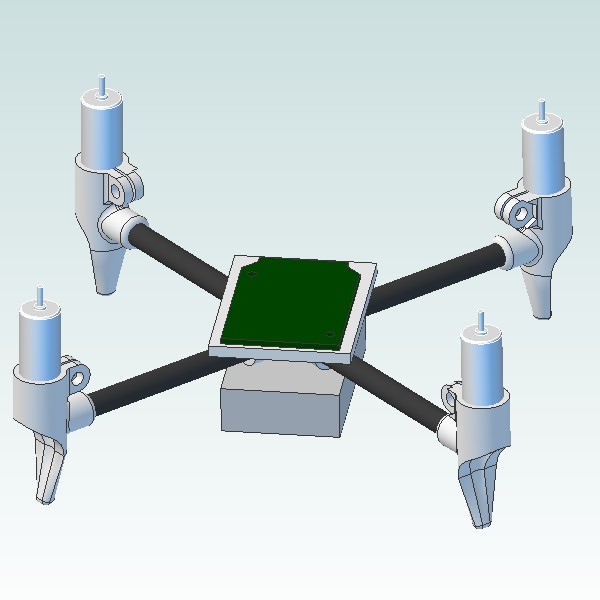

I haven't putzed about with the v0.1 base at all, but I think I've got a motor mount design that I like. It's got the split bolt setup for securing the motor (including a cutout for holding a 2-56 nut), and the legs are cool lofted dealies. Lots of radii and impractical features that don't cost anything more to 3D print (the machinist in me is cringing), but look somewhat cool!

Cutouts at the end save a bit of weight and give me access to thread the motor wires through the CFRP tubes. Based on measurements of the original X4 frame (and a bit of trig), I figured out that each motor is actually angled in 1 degree or so; maybe this has a similar effect to toe-in on a car in terms of stability. Either way, I included that feature here--the angle between the CFRP rod and the motor is 89 degrees. Right now the wall thickness of the mounts is 1mm which is the Shapeways minimum.

Think the parts will be strong enough? Any better ideas for feet? I might try to figure out some sort of rubber pad setup to prevent skittering off of tables during slow takeoffs.

zakqwy

zakqwy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Feet: a dab of hot glue works wonders!

Are you sure? yes | no

Great idea! I especially like the fact that I don't have to plan ahead too much for that. Done and done.

Are you sure? yes | no

At most you'd want to make the 'feet' concave and fill that with hot glue for better adhesion.

Are you sure? yes | no