Cura doesn't handle bridging very well. If a bridged area is wider than you set your wall thickness to, it is more than happy to start printing in thin air.

However, you can still force it to get a clue with some tweaks to your model.

Cut the bottom of a bridged area into smaller long segments and make the segment width a multiple of your nozzle size. It will then do the right thing.

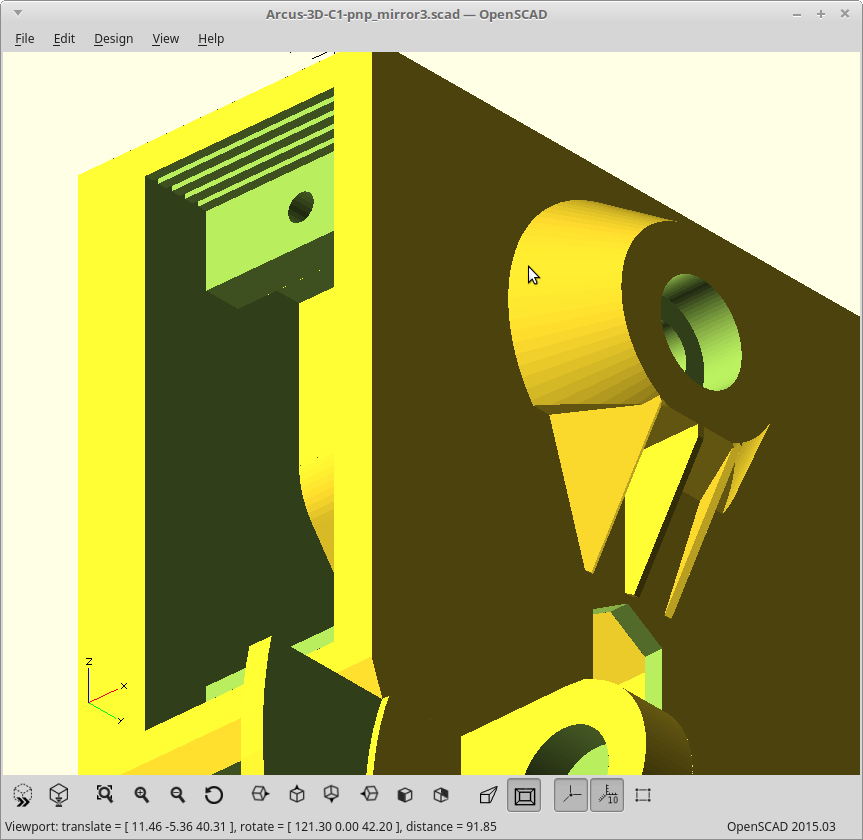

This is visible here as the ribbed area in the servo pocket.

The cuts only need to be about 3 layers deep for this to work.

Similarly if you have a large flat section which doesn't attach on both ends, make it.

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.