Everything fit, but my gears for nozzle rotation didn't mesh properly.

To line things up and make the cutouts for where the servos were going to sit I had two different models. One was the actual servo model, and one was the negative I used to generate the pocket it would need. The negative one was a little oversized with exaggerated depth for the flanges and pegs to generate the screw holes. It worked well.

Well it seems over the course of the project I accidentally modified the cutout version and changed the depth from the output shaft to the mounting flanges. I've flipped the side of the flange I was going to use a couple times so I can understand how it happened..

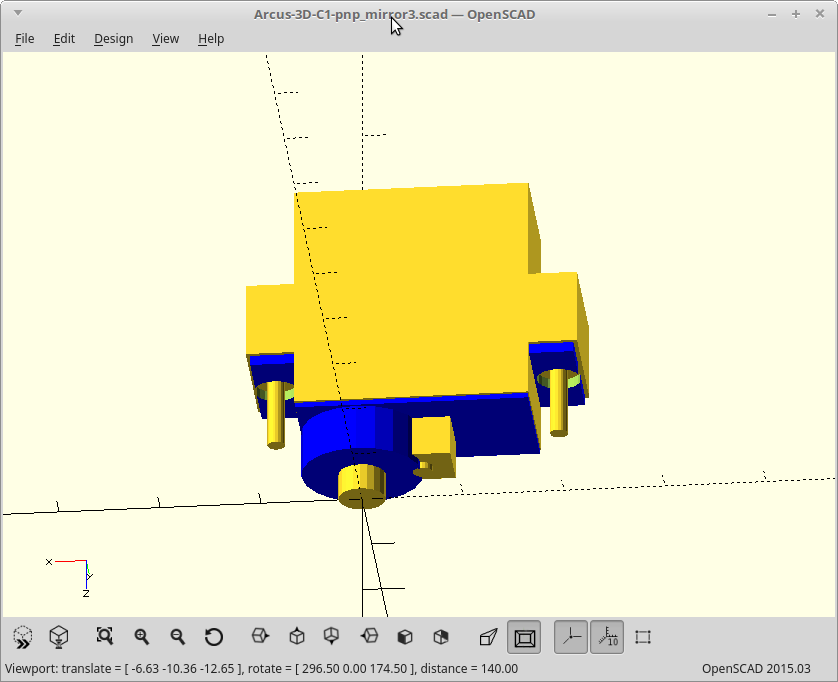

Blue is the original, yellow is my cutout.

Depth is kinda important for a right angle drive, so now the gears don't mesh. Fixing.

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.