-

Swing arm bias.

02/26/2018 at 20:48 • 0 commentsThis thing is normally made for pressure. Switching the valve around to make it do vacuum ends up putting a different kind of load on the arm that it wasn't designed for.

As the arm is pulled in by the diaphragm contracting from the increasing vacuum, it actually gets pulled out of the strongest area of the swinging magnetic field and vacuum performance then drops off.

So I realigned the magnet to correct for this by bending the arm out away from the diaphragm.

Now under maximum vacuum, we are still within the stronger area of the field. The arm can generate more force, and the maximum attainable vacuum increases.

If I was starting over, this is probably the only change I would make now. I'll take the increased pumping volume the Neodymium magnet gave me, but a higher vacuum is more useful in the end. Just bending the arm is a lot simpler too..

-

A tale of two magnets.

02/04/2018 at 04:46 • 0 commentsThe original ceramic magnets in the pump were decent as far as ceramic magnets go, but they were not even close to the pull of the N42 Neodymium magnets I had.

I could actually completely overwhelm the ceramic magnets and stick the neo magnets right to them in any orientation. This led to just trying to augment the existing magnets by sticking the neo one to the back. No significant change, so I opted to try to replace one of them.

I drilled out the brass rivet and then the glue still holding it on was easily split with a well placed screwdriver twist.

I then proceeded to glue a 12mm disc magnet I had to the arm.. several times.

Gluing Neodymium magnets is actually kinda tricky. Epoxy doesn't stick very well, and superglue isn't strong enough on it's own unless you have two perfect mating surfaces. So I used both. That worked for a while, but eventually failed under the duress of a small impact event. The third try had me grinding off the positioning tabs, wet sanding the steel for a perfectly flat surface, super-gluing to that, and then bridging the back/around the sides with a generous amount of UV cure resin. Thankfully, that has held up.

The 12mm magnet did not work... at all. The field lines were too concentrated and so as soon as it swung to one side it stayed there. The electromagnet just wasn't strong enough to push it away.

So that got replaced with a larger 18mm magnet. That is actually about 5mm larger than the ceramic one I removed.

That worked, I believe because it was large enough to pull on both sides of the electromagnet evenly. It still tended to want to stay deflected when I capped off the vacuum though and so performance was not very good at all. That turned out to be fixable though. More to come..

-

Three weeks eariler..

02/02/2018 at 01:29 • 0 commentsAgain, now that I've reached the end, time to go back to the beginning.

To build the pick and place machine requires a vacuum source. I actually had a tiny 12v vacuum pump, but it was pretty pathetic. It was loud, didn't have carbon brushes so it would wear out pretty quickly, and the actual performance was terrible.

I recalled seeing a video about converting an aquarium pump to vacuum. Not finding the video right now, but there is actually a really good instructable on that also, so I won't go into detail. Just follow his instructions.

So I did that. It worked.

That was too simple.

Of course I couldn't stop there.

The first mod beyond that was the simplest, required no additional parts, and improved performance by about 5%.

I took an angle grinder and removed some of the excess weight from the swing arm. It was still plenty strong and it would now visibly swing a bit farther. This should increase the volume also, but I failed to measure that before moving on to changing the magnet as well so no data...

Note: It's a really good idea to wrap the magnet end in tape before you start grinding on the arm so it doesn't collect all the stray metal shavings you are about to create.

Before:

![]()

After (ignore the magnet mod):

![]()

5% isn't much, but it was a start.

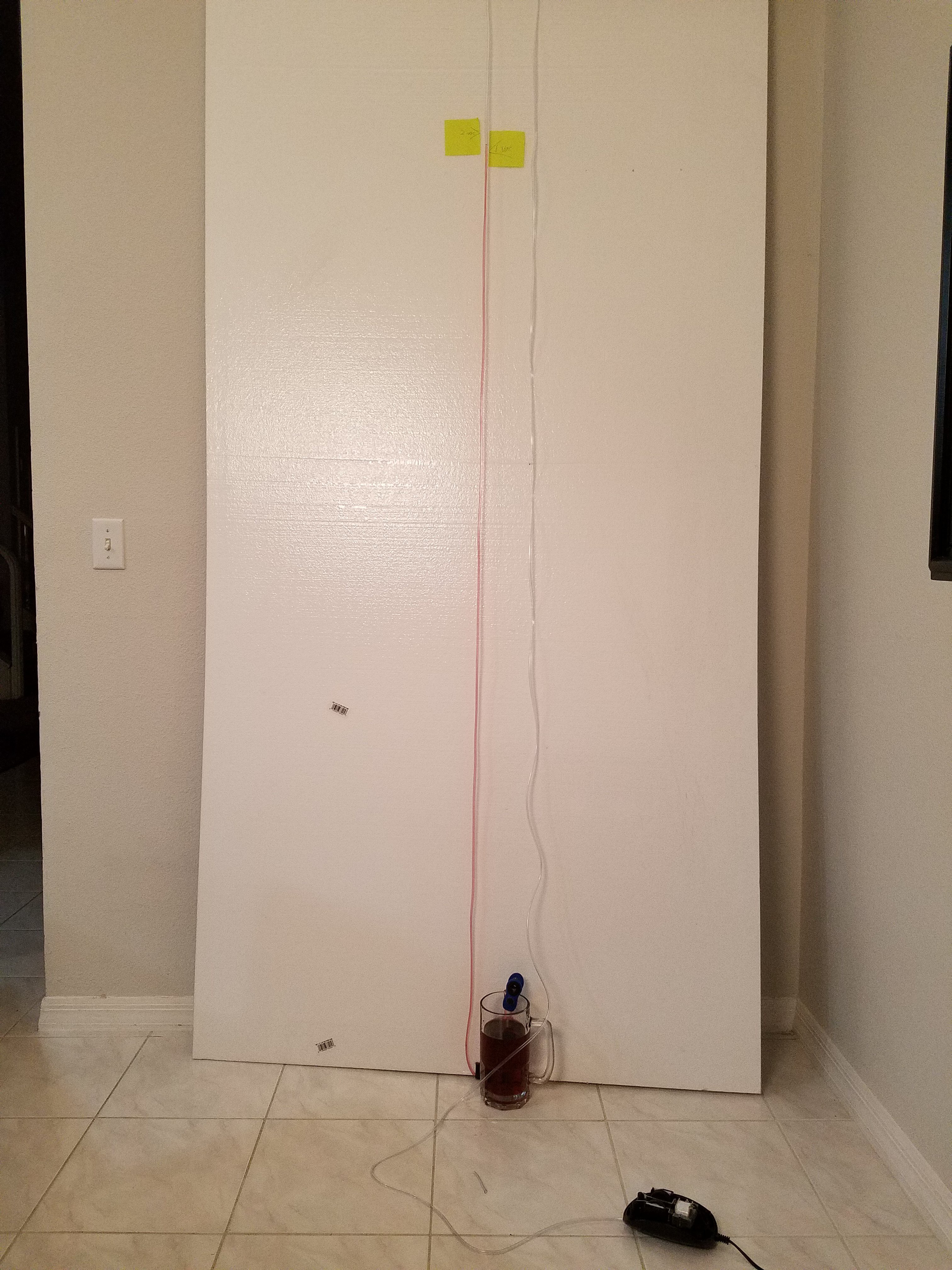

You may be asking, how did I quantify my results? Gravity. Specifically, a water column.

![]()

The post-it on the left was both diaphragm pumps in parallel, whereas the one on the right was just one.

Adding the second diaphragm did little to increase the overall vacuum, but it did reach that vacuum more quickly. Makes sense. Twice the volume pumped, same overall static pressure.

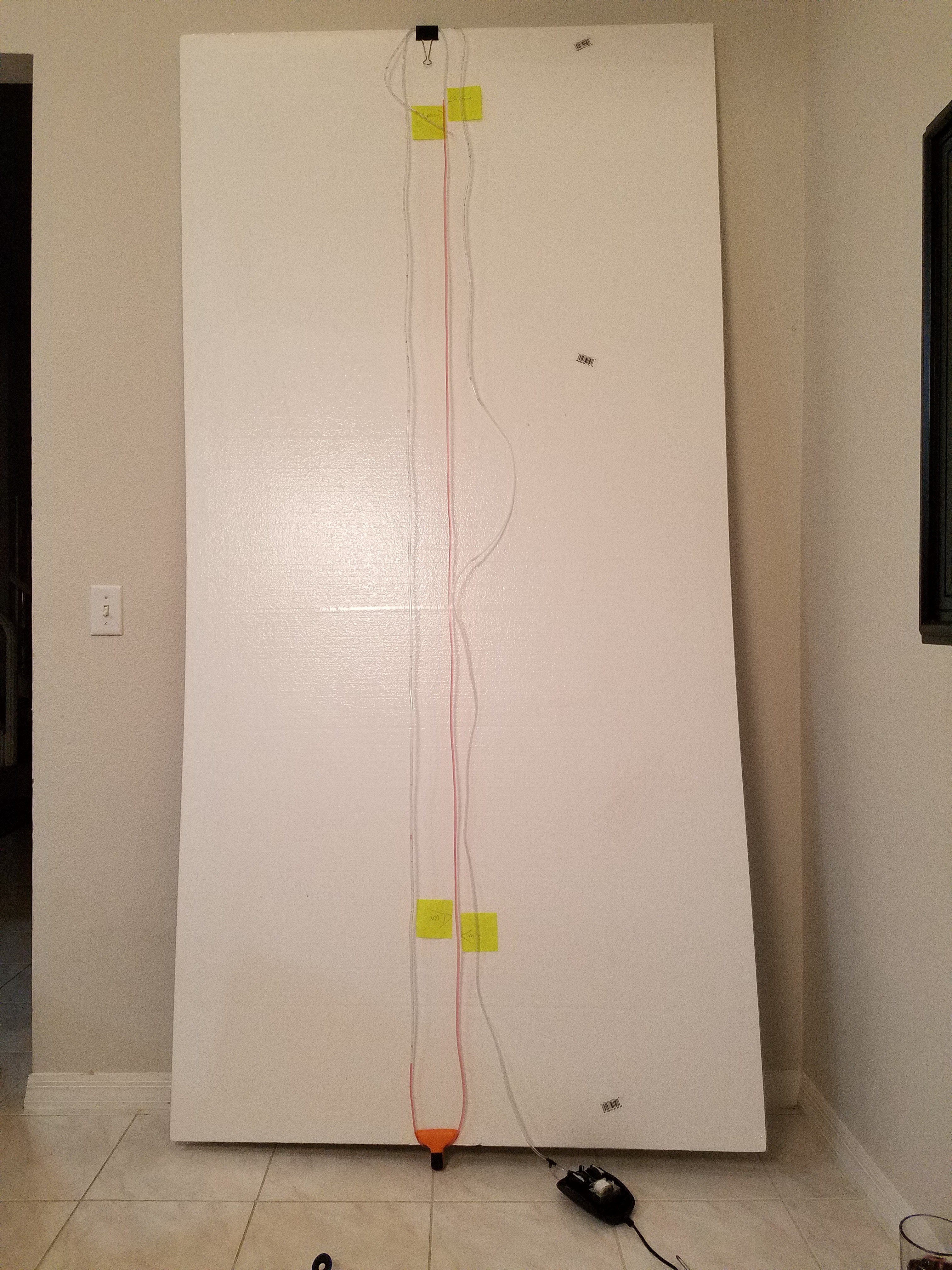

I also switched the valves back and tested pressure by how far it could raise a column of water.

![]()

The results were very similar with the pump being able to deliver about 10% more in pressure than it could in vacuum. I discounted the pressure and single versus double diaphragm results for the remainder of the tests.

-

It don't mean a thing if it ain't got that...

02/01/2018 at 23:16 • 0 commentsMovement of the arm with the Neo magnet. Much further swing.

P1 - Aquarium to vacuum pump conversion

The now classic conversion of an aquarium pump, and what you probably shouldn't do too..

MasterOfNull

MasterOfNull