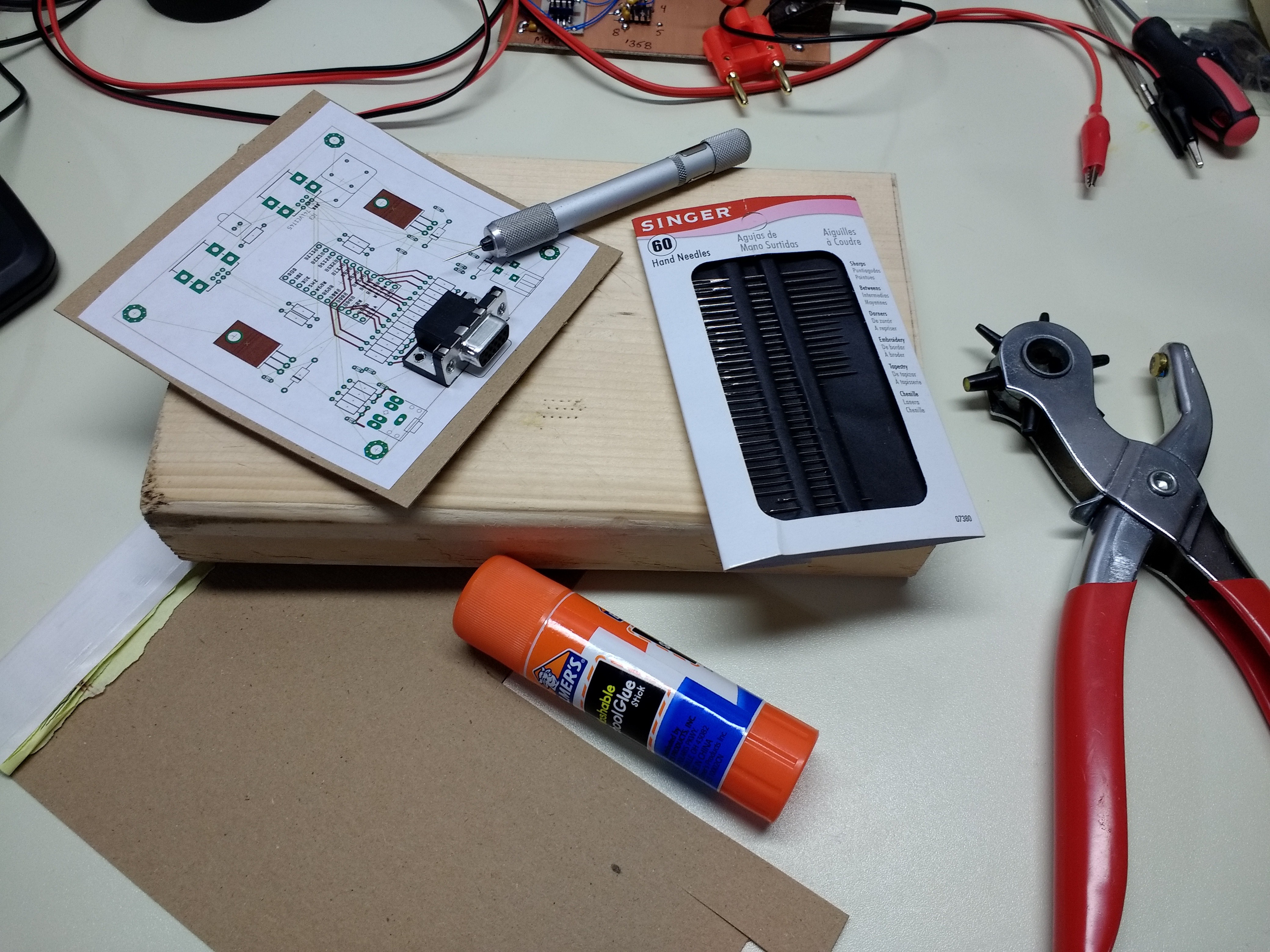

The mechanical drawing of the VGA connector included on the datasheet left me a bit puzzled, so I decided to mock-up the PCB to double-check the footprint before sending out the gerbers. I made a cardboard mock-up of the board to check things.

I printed out an image of the layout, glued it to a piece of cardboard from the back of a legal pad, then poked holes for the pins with a sewing needle held in a pin vise. I used a paper punch to make the mounting holes for the connector. The result: a perfect fit. I had properly deciphered the datasheet.

I used to make these a lot more often, especially when I used to etch my own boards. There are two gotchas - first, printers are typically more dimensionally accurate in the horizontal than vertical directions. This is caused by paper slippage and eccentricity of the rollers. So, the spacing may not be very accurate in one dimension. The second problem is caused by the paper warping when saturated with glue. I previously used white glue for these, but have found warping to be much less of an issue with a glue stick.

Ted Yapo

Ted Yapo

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

"Old School." XD

Prototyping done properly. :-) Remember the original HP Deskjet? Most accurate printer I ever had, hard to buy a good one now.

Are you sure? yes | no

I'm still using a 25 year old Laserjet 4P (when I don't need/want color). It works as well now as it did when it was new. One piece broke about five years in - a bracket that held the paper tray in place - and HP sold me an improved part to fix it.

Are you sure? yes | no

Odd they stayed out of the 3D printer market at the beginning, they could have eaten that whole and sold you plans for that part today. I dont know what happened, but HP's support stopped being legendary more than a few years ago lol.

Yeah, that was another great machine built before the industry cottoned on to market saturation...

Are you sure? yes | no

I say cardboard forever :-)

Are you sure? yes | no

Hmm. Maybe I should try to wire it up on there ;-)

Are you sure? yes | no

:-)

Are you sure? yes | no

Can I point out that both copper and polyolefin tapes will go through a laserjet, stuck to backing paper. Careful choice of backing paper that survives the etching process means you CAN literally print cardboard circuits. I wish I could afford a laser printer, never mind a vintage one. ;-)

Hey Mark lol

Are you sure? yes | no

I did this a ton for my senior project when my professors insisted everything work perfect in a single rev.

Are you sure? yes | no

Yeah, I'm spoiled these days. When I had to deal with etching my own, it seemed worth the time to go through this exercise. Today, it's so much easier just to send the PCBs off to be made, then re-do them if they're wrong. For a lot of problems, you can re-work the PCBs anyway. With the high-density d-sub VGA connector, if I got the pins wrong, I'd be stuck.

Are you sure? yes | no