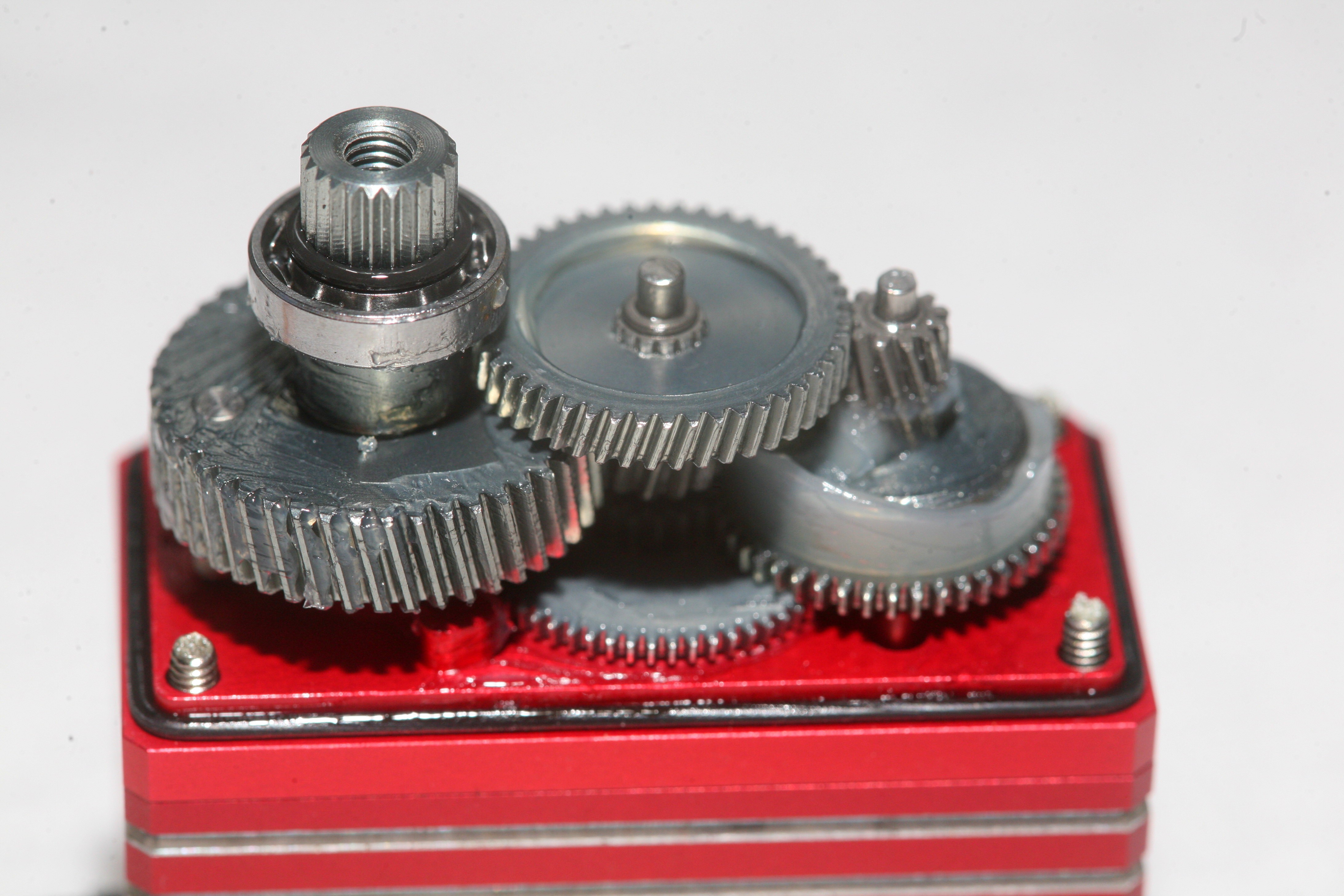

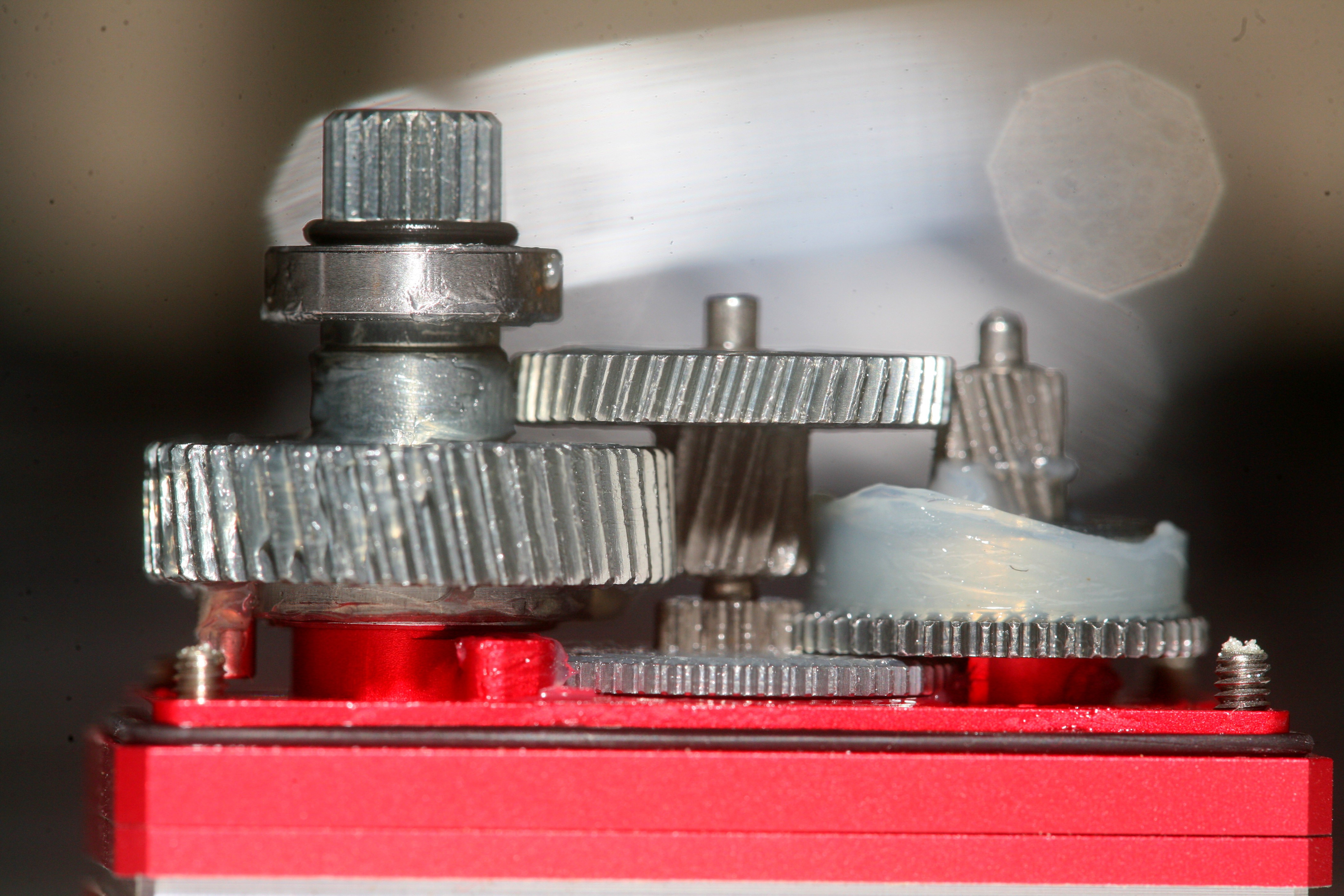

The $60 TS-940HG was the only one in stock. They sure made a big deal about the helical gears.

It's heavy, but fast. Standby current is no different than normal servos.

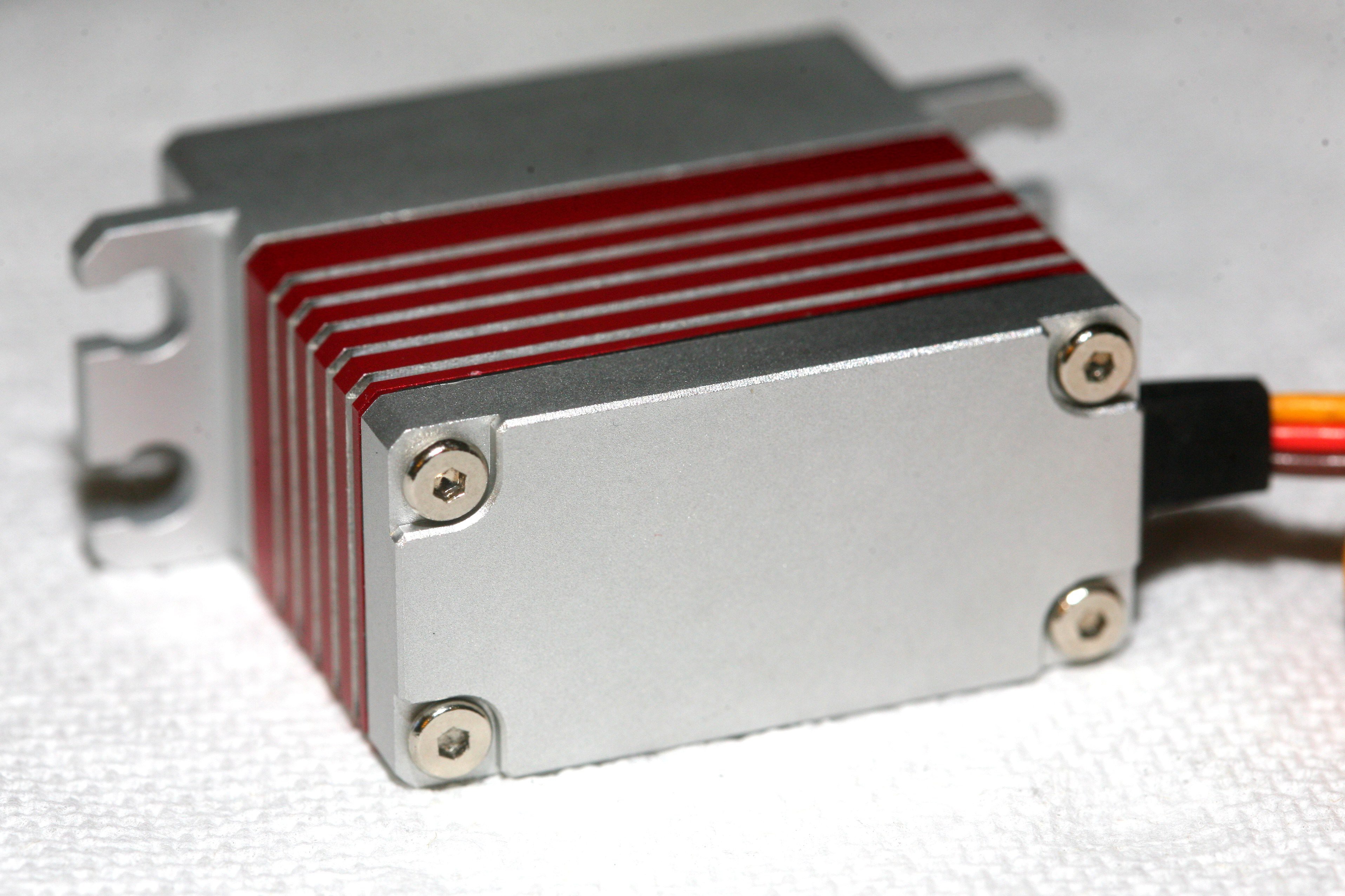

CNC milled case.

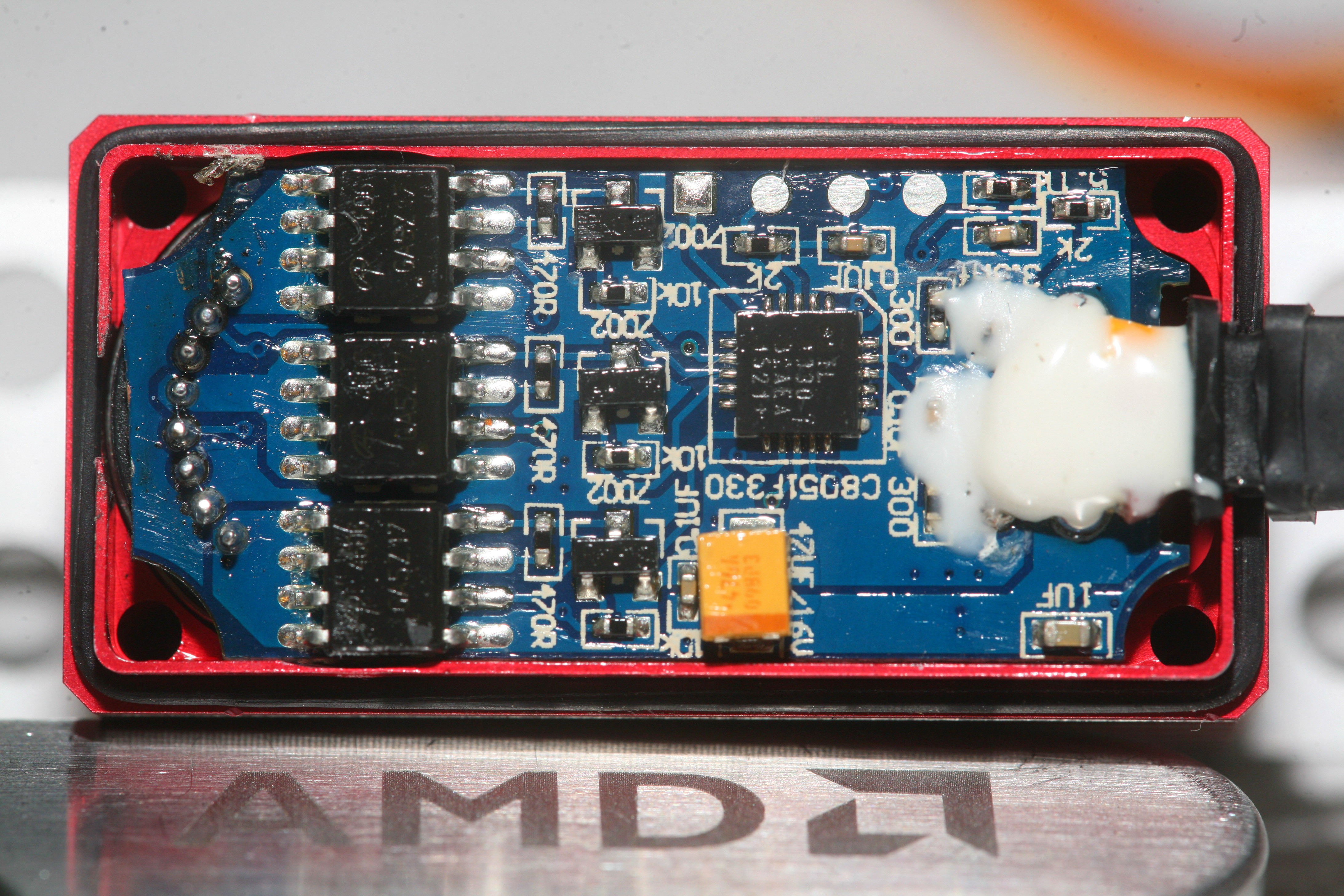

A 3 phase motor with 3 hall effect sensors, but not anything you can get separately.

The servo saver was the only thing which fit & could reach the pushrods. There were no changes needed in the feedback.

Instead of electrical tape, applied duct tape to the transmission with small electrical tapes just over the holes. This gave good protection without contaminating the oil.

In other news, the nylon straps were a failure. They were too wide & inflexible to get around the conical wheel shape. A conical section from a sheet of fabric would do it. Back to shoe laces.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.