-

The race for the perfect speaker

12/31/2019 at 07:03 • 0 commentsThe lion kingdom had run with a dedicated speaker battery for years, having never found an affordable DC-DC converter which could power them reliably. They would all disconnect after a short time. These speakers could all run on a common USB cable & charger, but taking out the battery & giving them 4.2V through the battery leads made them so much lighter. It was only after accidentally plugging an Auvio into 12V & blowing it up did the solution reveal itself.

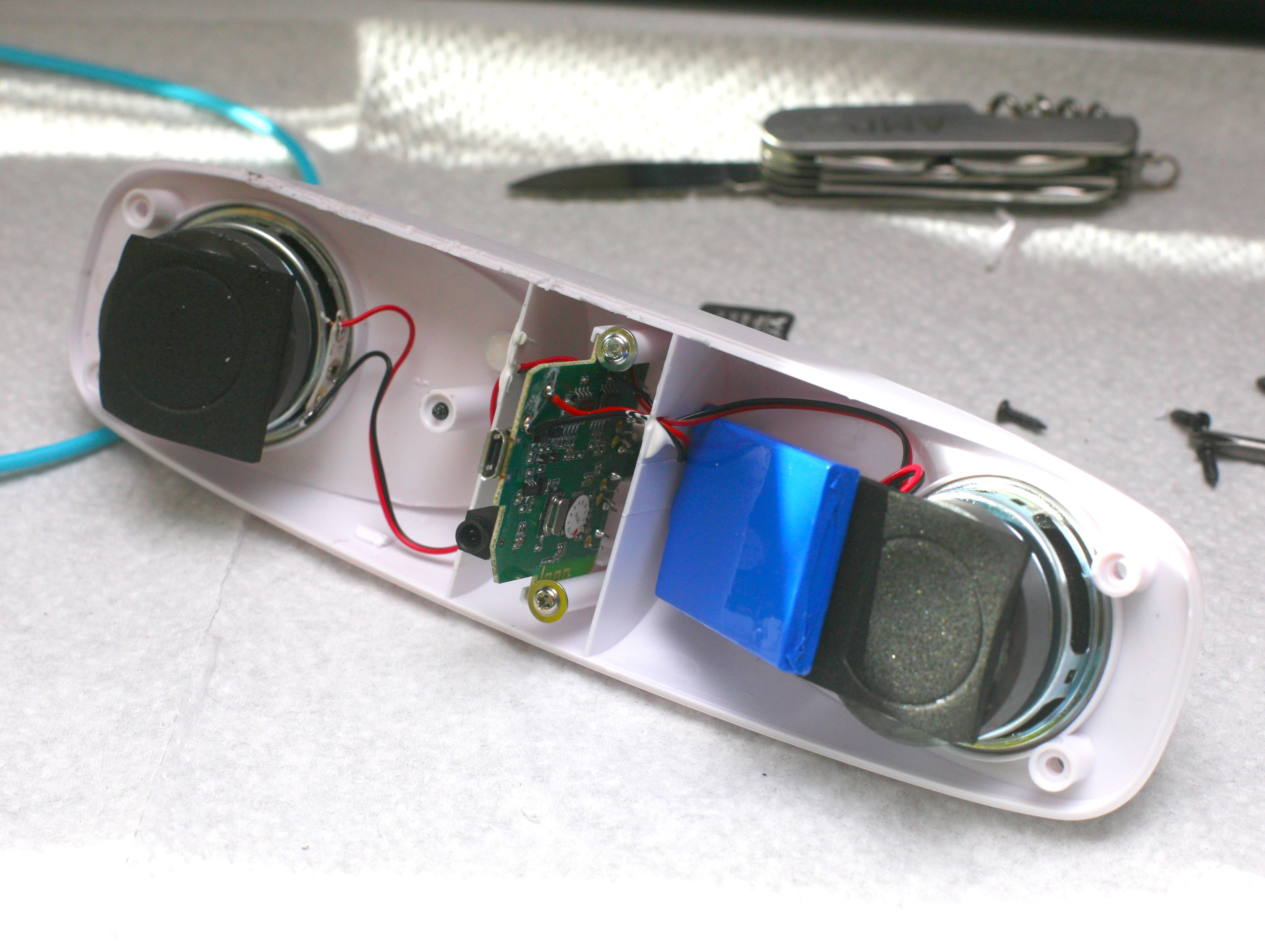

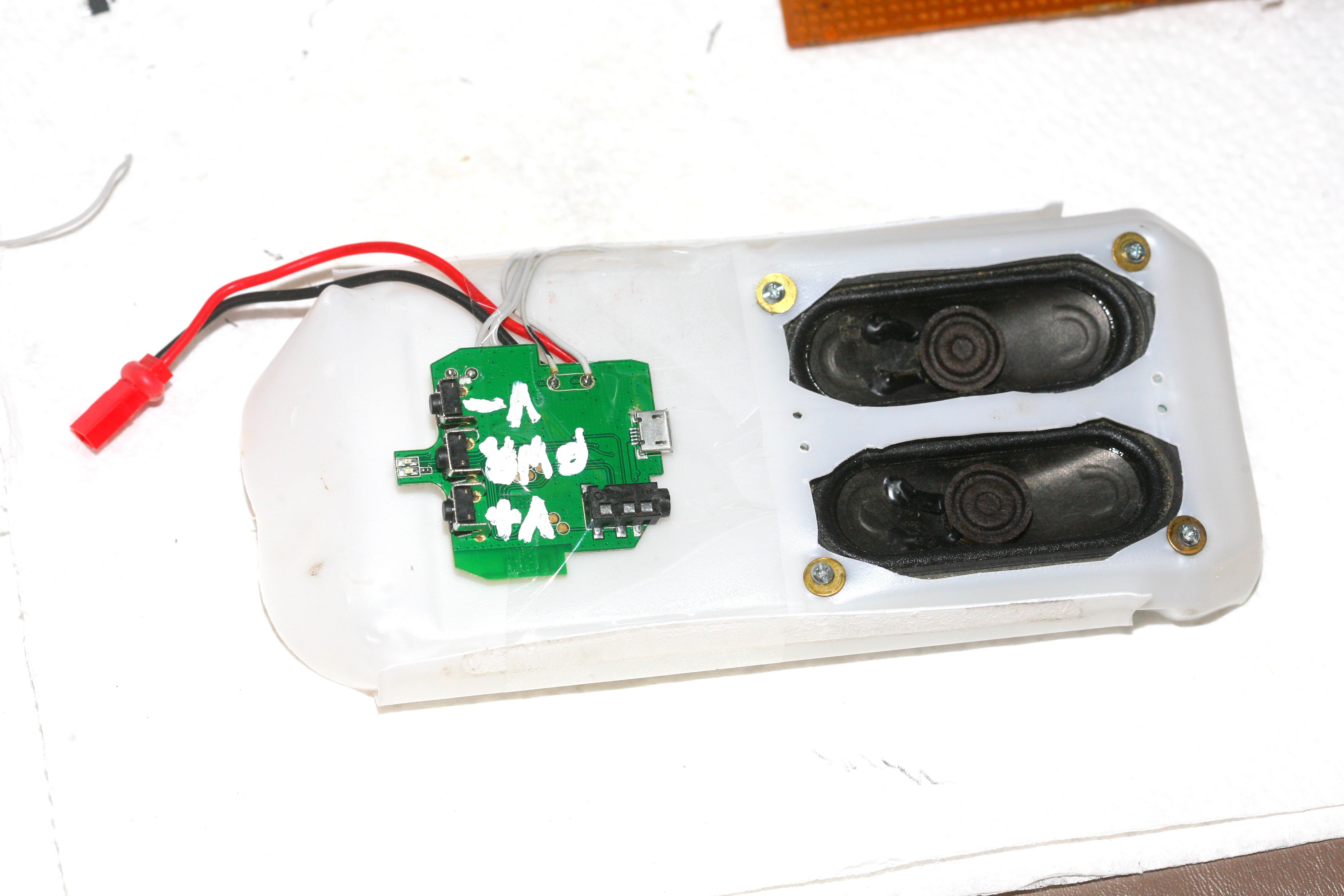

Fortunately, it only blew up the amplifier chip, a HT6871. The radio & leds were still intact. It would take 1 month to order a new amplifier from China, so went ahead & got a new speaker. With this experience, it was decided to put in different connectors for the 12V side than the 4.2V side on the DC-DC converters.

The Auvio was such a good speaker during its 3 year lifespan, the lion kingdom pondered putting in a different amplifier chip & finding other uses for it. The only amplifier chips sold outside China are obsolete class B chips from 1980 which cost more than a new speaker.

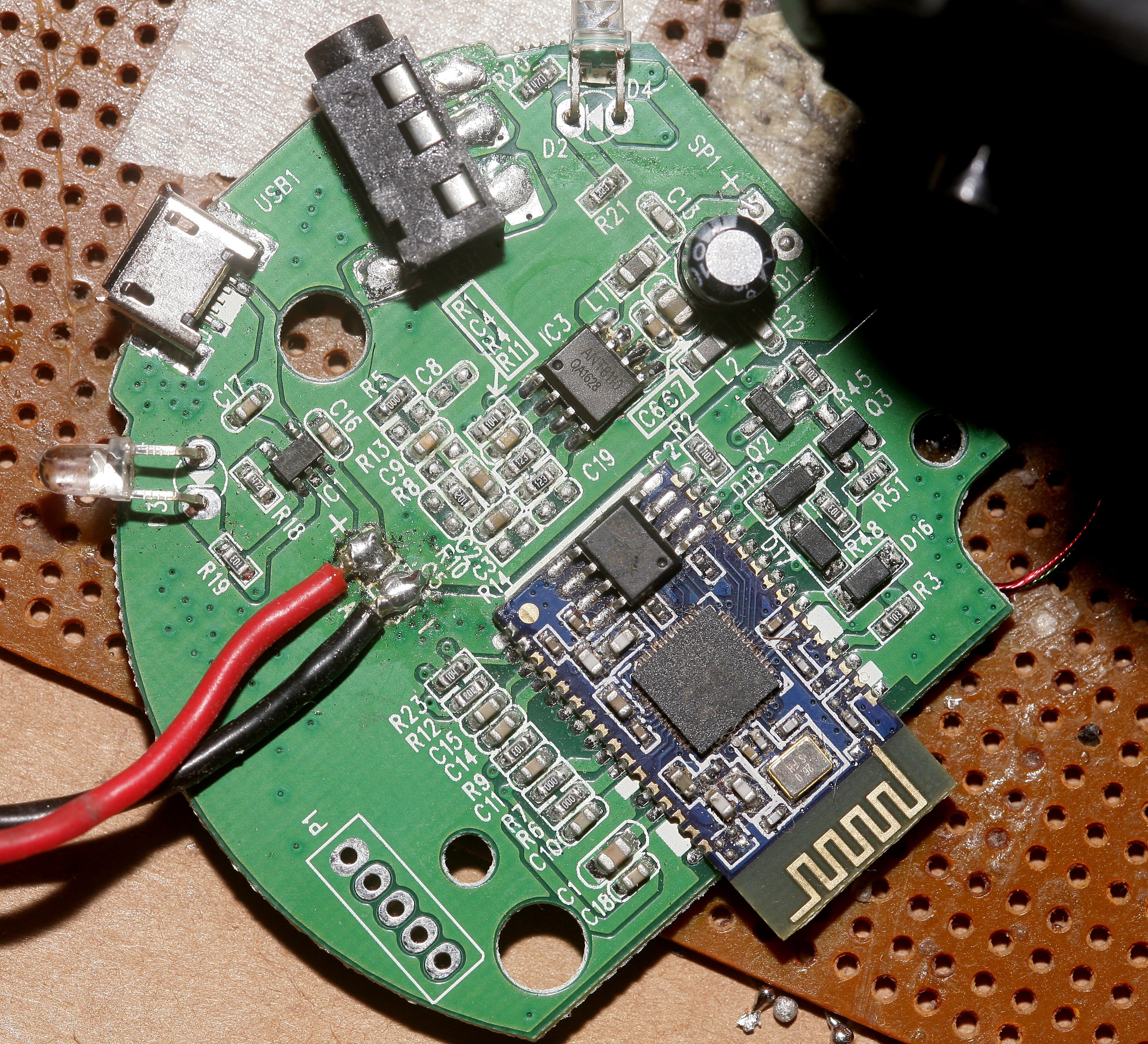

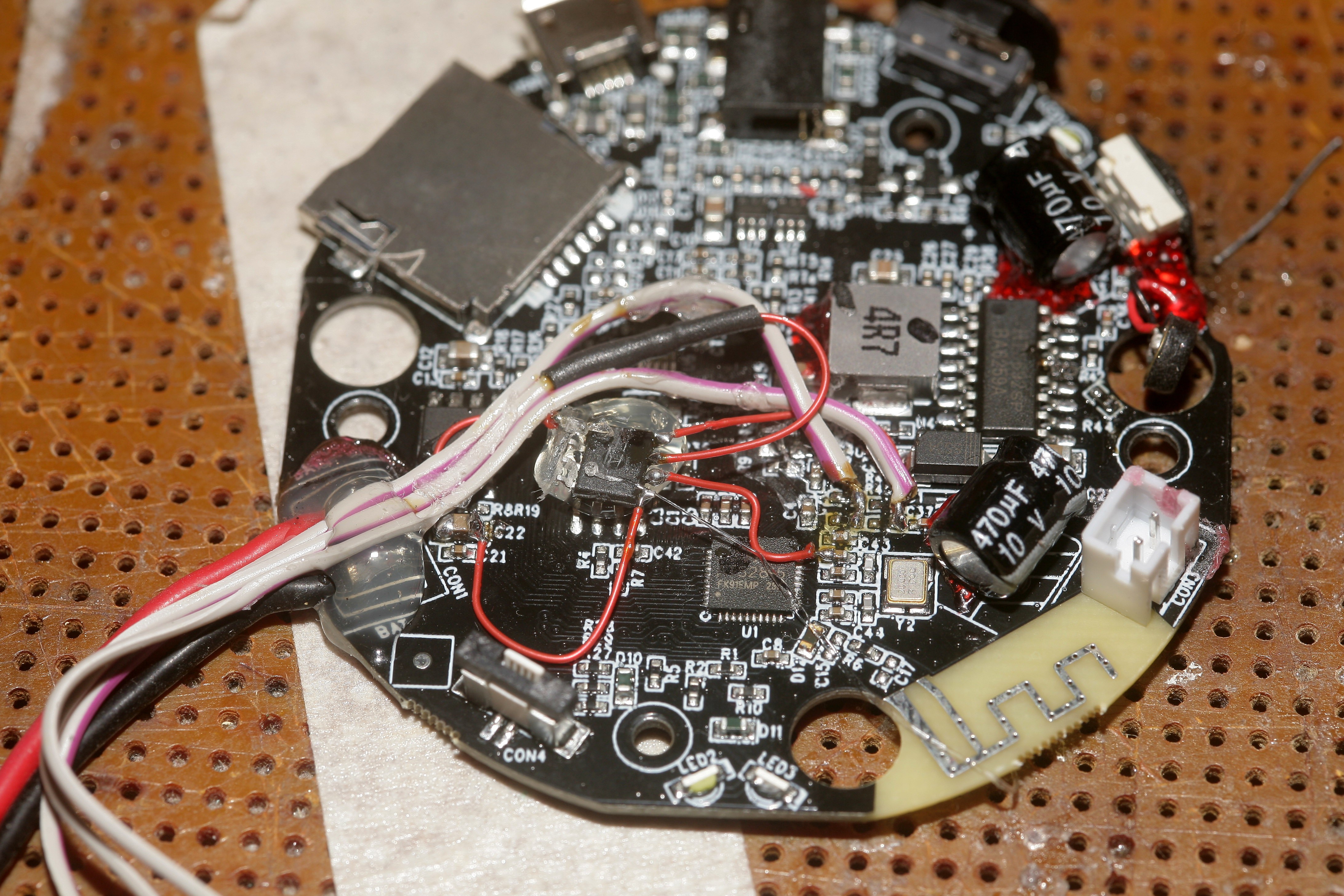

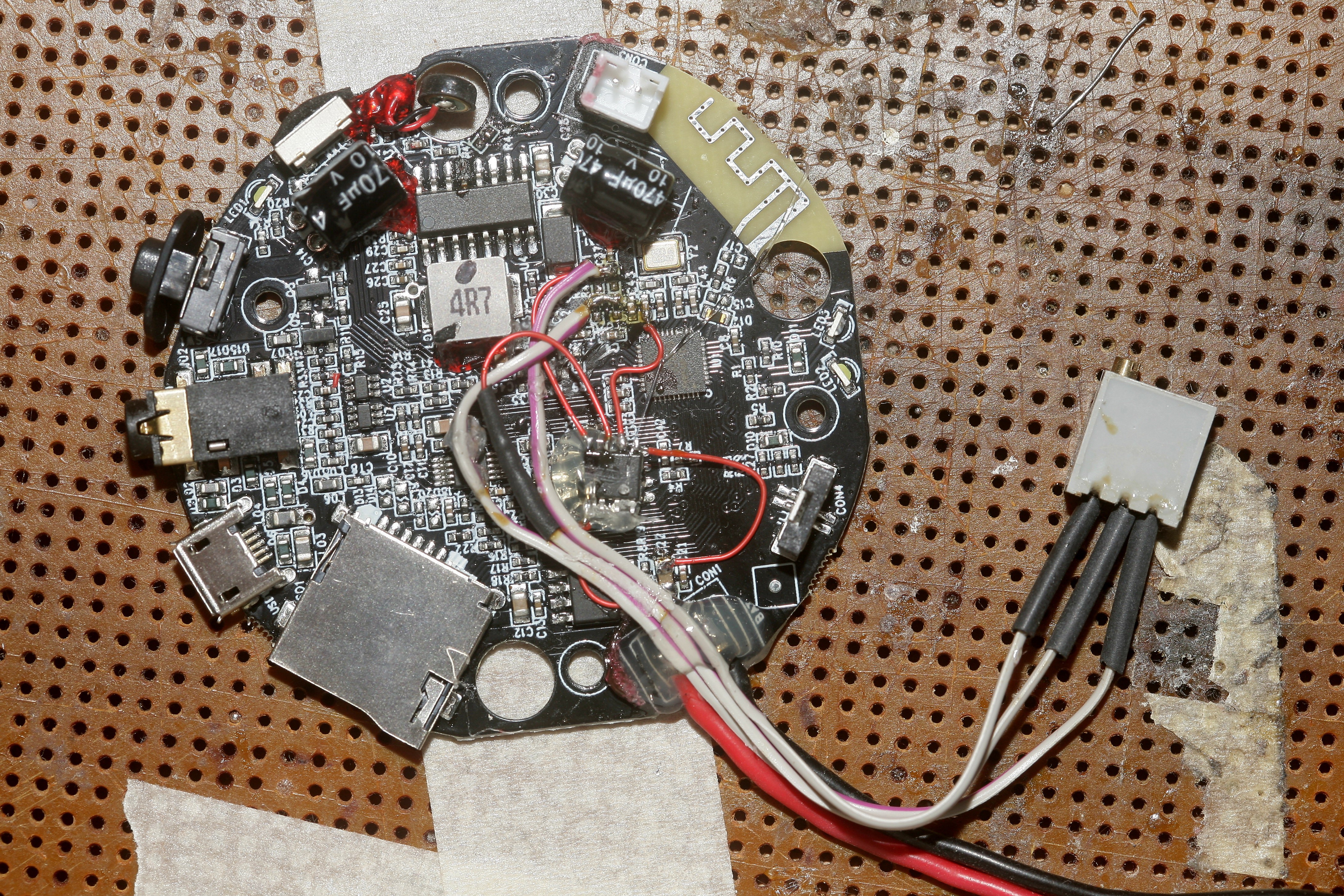

There was also swapping an amplifier chip from another bluetooth speaker.

![]()

It turned out the amplifier from the very 1st speaker, an ANT8110, had the same pinout & worked. It just had a higher gain.

While reviewing the datasheets, it became clear that all current speakers had separate amplifier & radio chips. The amplifiers were all rated for 6V & the radio chips were all using voltage regulators which could take in 12V. The speakers could run off a cheap 5V USB charger instead of an expensive 4.2V buck converter.

2A USB chargers had just become available for $1, so the lion kingdom started using those. After years of 1A buck converters failing, the 2A USB chargers finally managed to power the speakers. It was the amperage rather than the ripple or motor noise that made the difference.

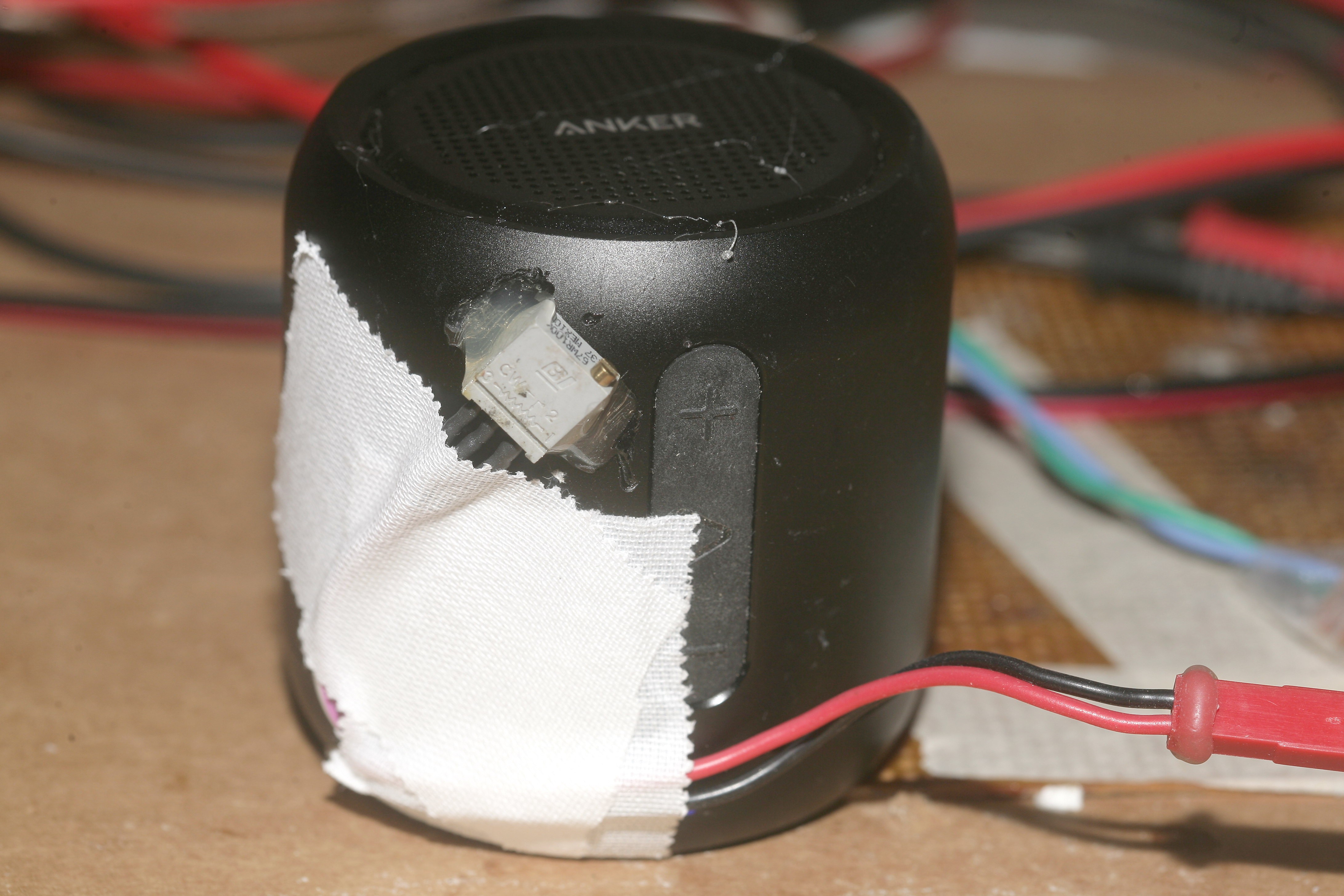

An Anker came in to replace the burned out Auvio & it didn't take long for the lion kingdom to realize it was running hundreds of miles in silence. The Anker was no louder than a phone speaker. There are 2 ways to make a bluetooth speaker louder. The HT8692 amplifier in the Anker has a gain adjustment resistor, but it has a very low maximum gain. Anything below 65k made no difference.

![]()

![]()

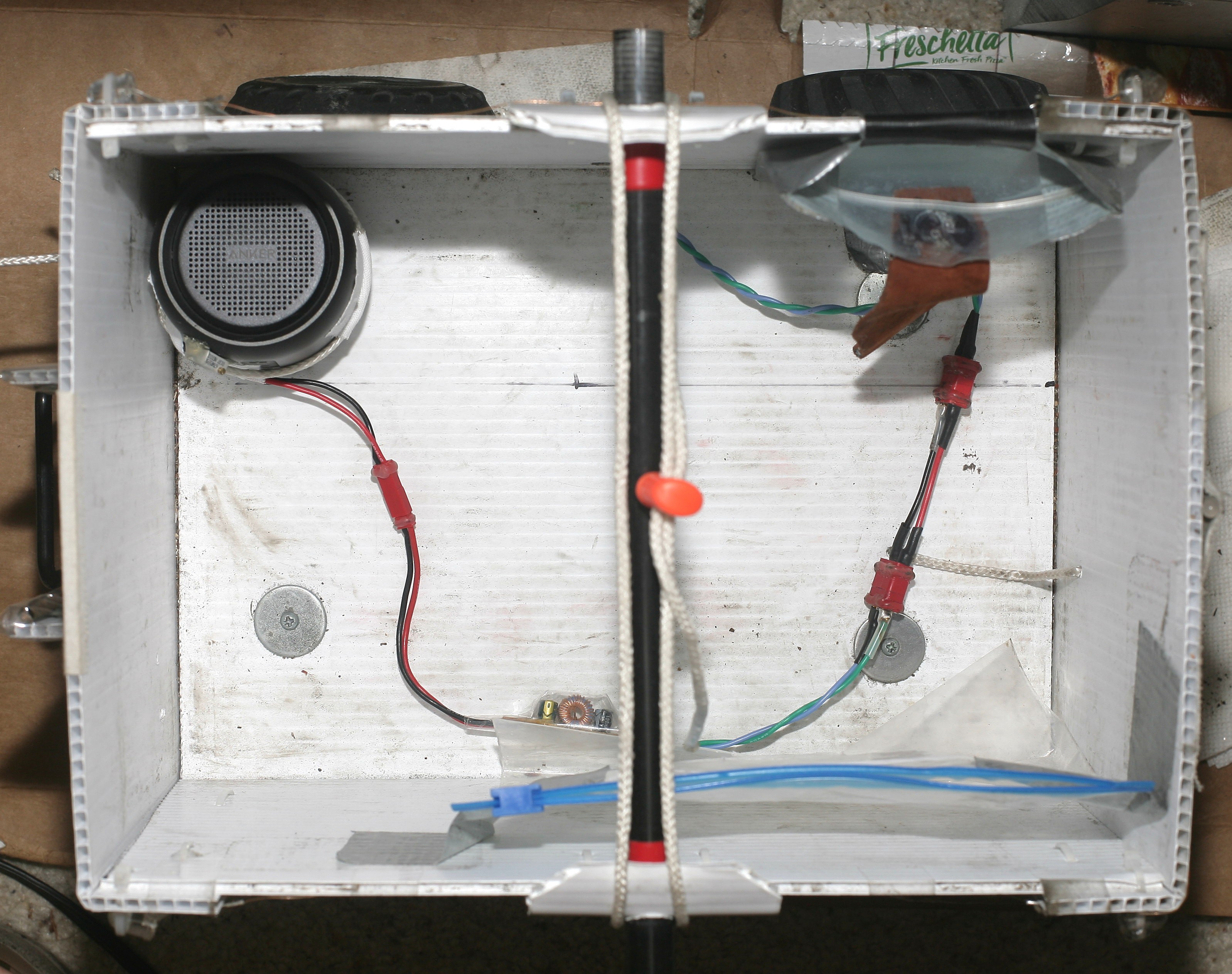

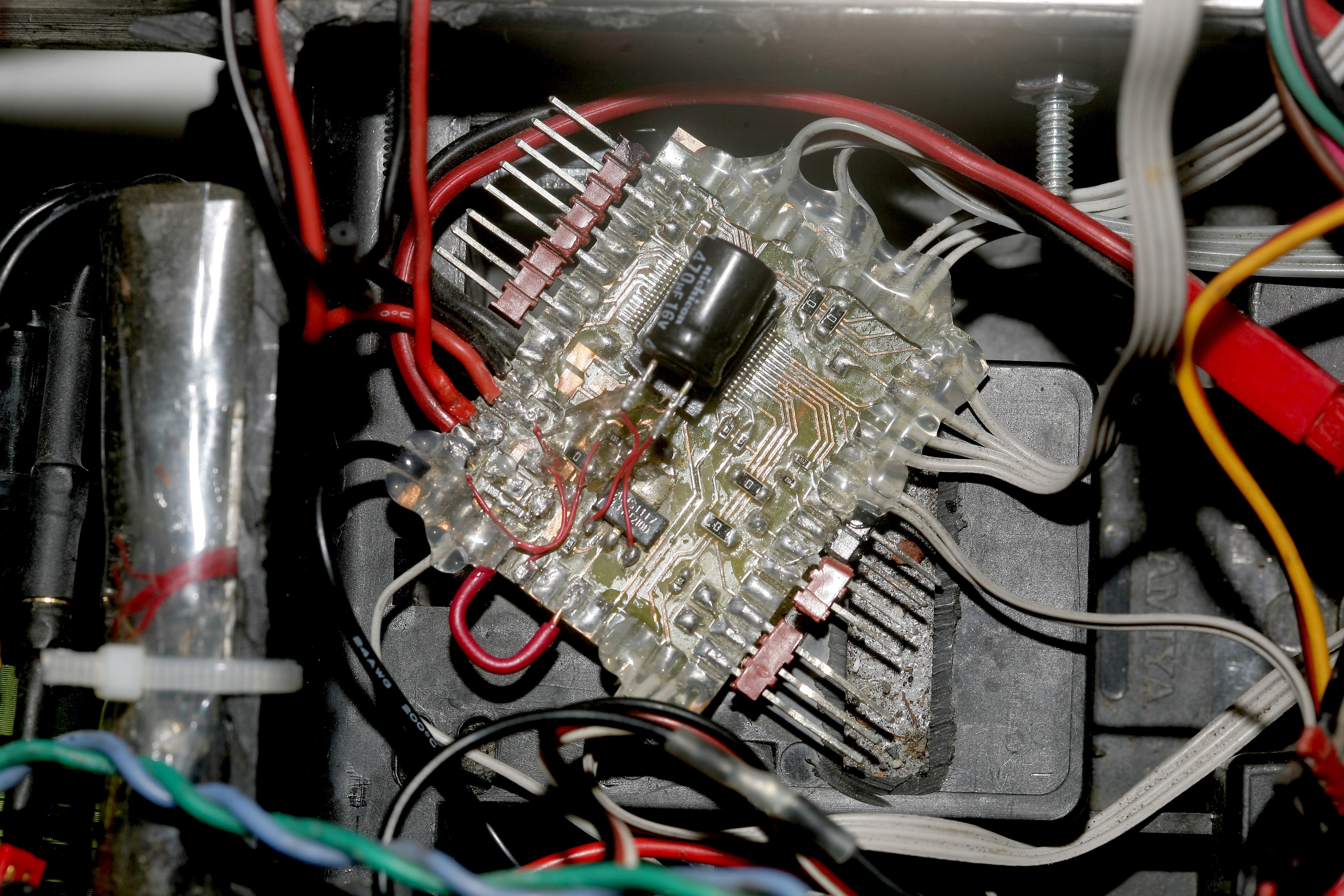

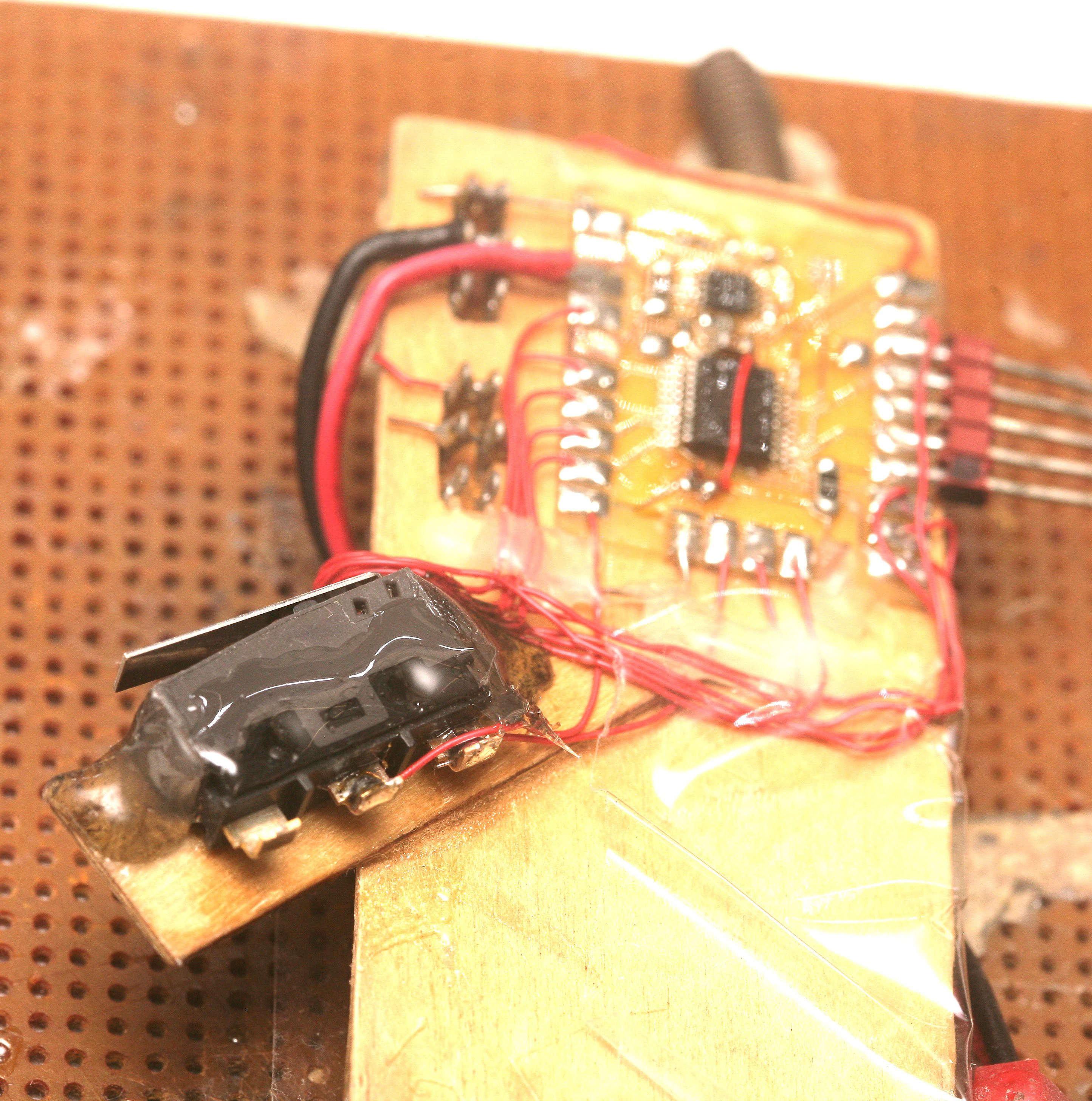

The next step was putting an op-amp between the ATS2815 radio & amplifier. All it took was a bare LF353 with a gain pot. The Anker provides a virtual ground & dividing resistors to combine the 2 channels.

![]()

The maximum gain of this circuit was limited by the input offset voltage of the op-amp. Above the maximum gain, the DC offset of the output mutes the signal. The lion kingdom tuned it just below the maximum gain & relied on the phone volume to limit distortion.

![]()

Lions have now gone through 5 speakers, originally directly wired & then bluetooth. The 1st one was directly wired & arrived in Aug 2016. Before then, lions spent 6 years running in silence, using painful earplugs meant for humans, or hearing the faint crackle of a phone speaker.

![]()

![]()

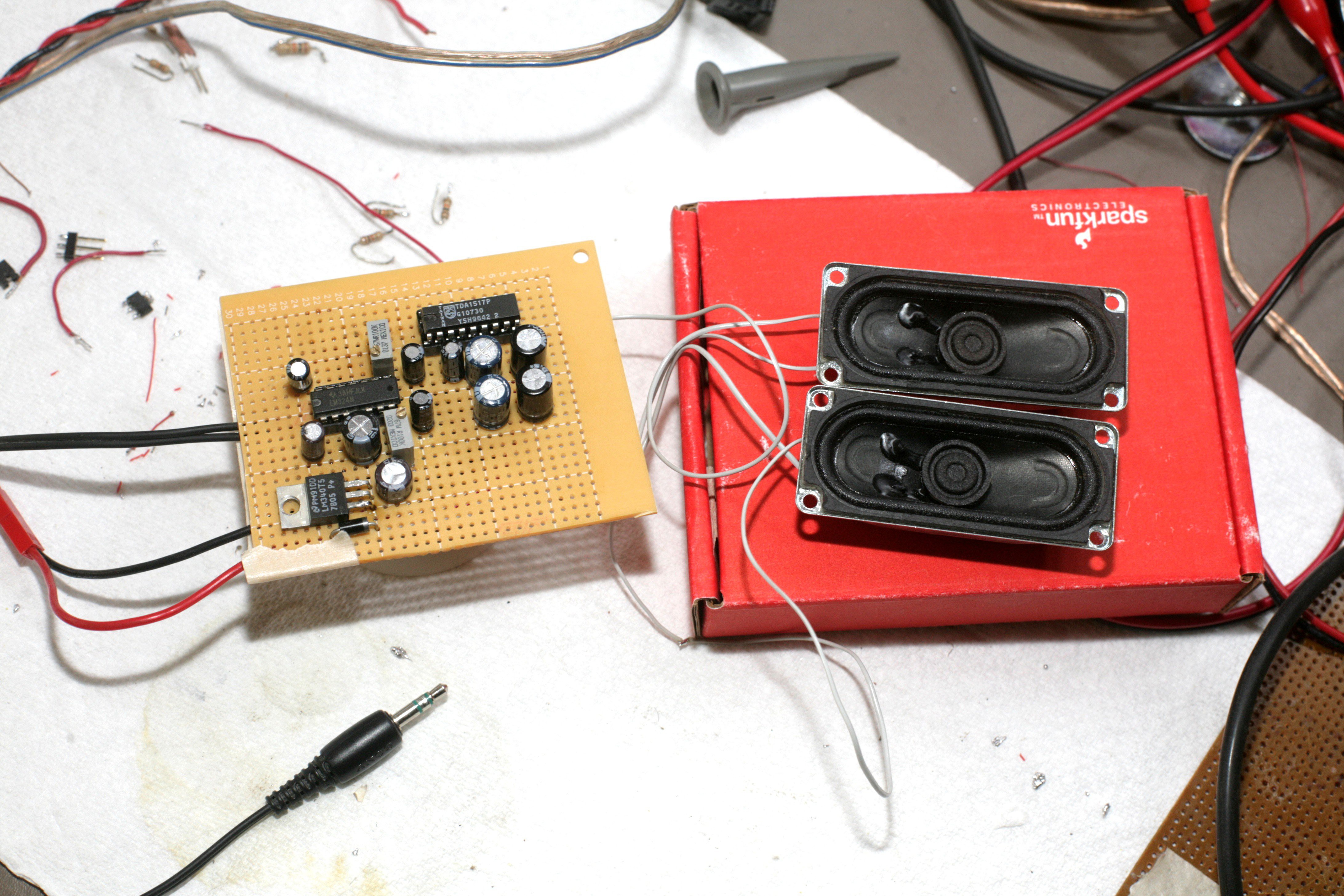

The 1st speaker used an amplifier from a soundblaster 16 & speakers from a TV. It needed 12V, but the vehicle it ran in had only 8.4V, so it still needed a spare battery. It sounded terrible but got the lion through 1.5 years. The running robot was like a city on wheels, with its speaker.

![]()

![]()

![]()

The next speaker & 1st bluetooth experience arrived in Jan 2017. It was too heavy to put in the robot, so its amplifier replaced the soundblaster 16 in the 1st speaker. It still sounded terrible, but was more convenient. Here, lions became familiar with the constant dropouts of bluetooth audio.

![]()

In Feb 2017, the Auvio with its future burned out amplifier arrived. There were finally 2 speakers for lions to have audio at the day job & home. The home robot was top heavy & couldn't fit much food, but it sounded better than the day job robot with its TV speakers.

![]()

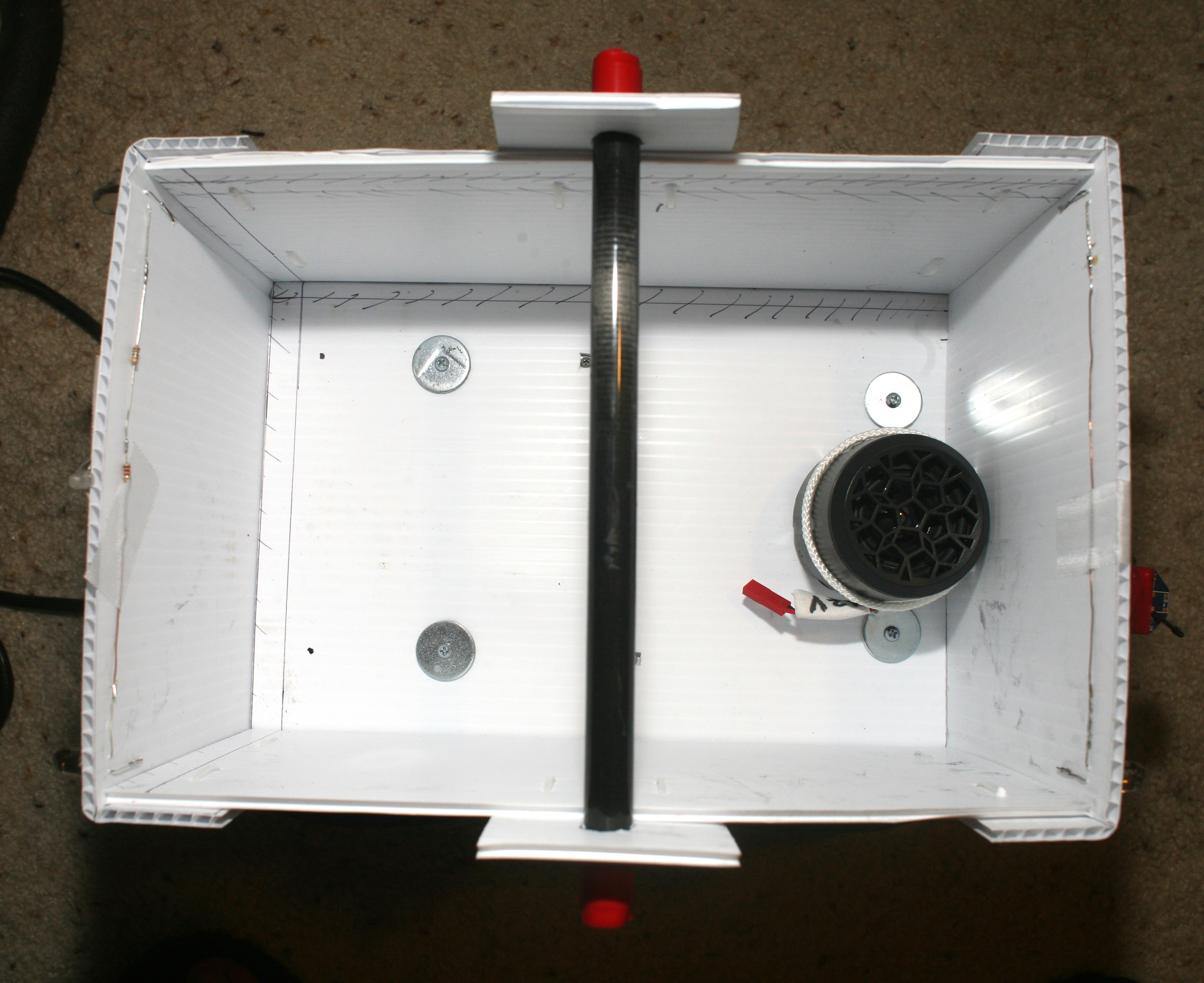

Larger containers & larger vehicles soon enabled an influx of better bluetooth speakers for both the day job & home, finally culminating in using power from the vehicle instead of a spare battery.

![]()

It's amazing how much power these speakers have put out, over the last 5 years, without blowing up.

-

Robo Rudulf year 2

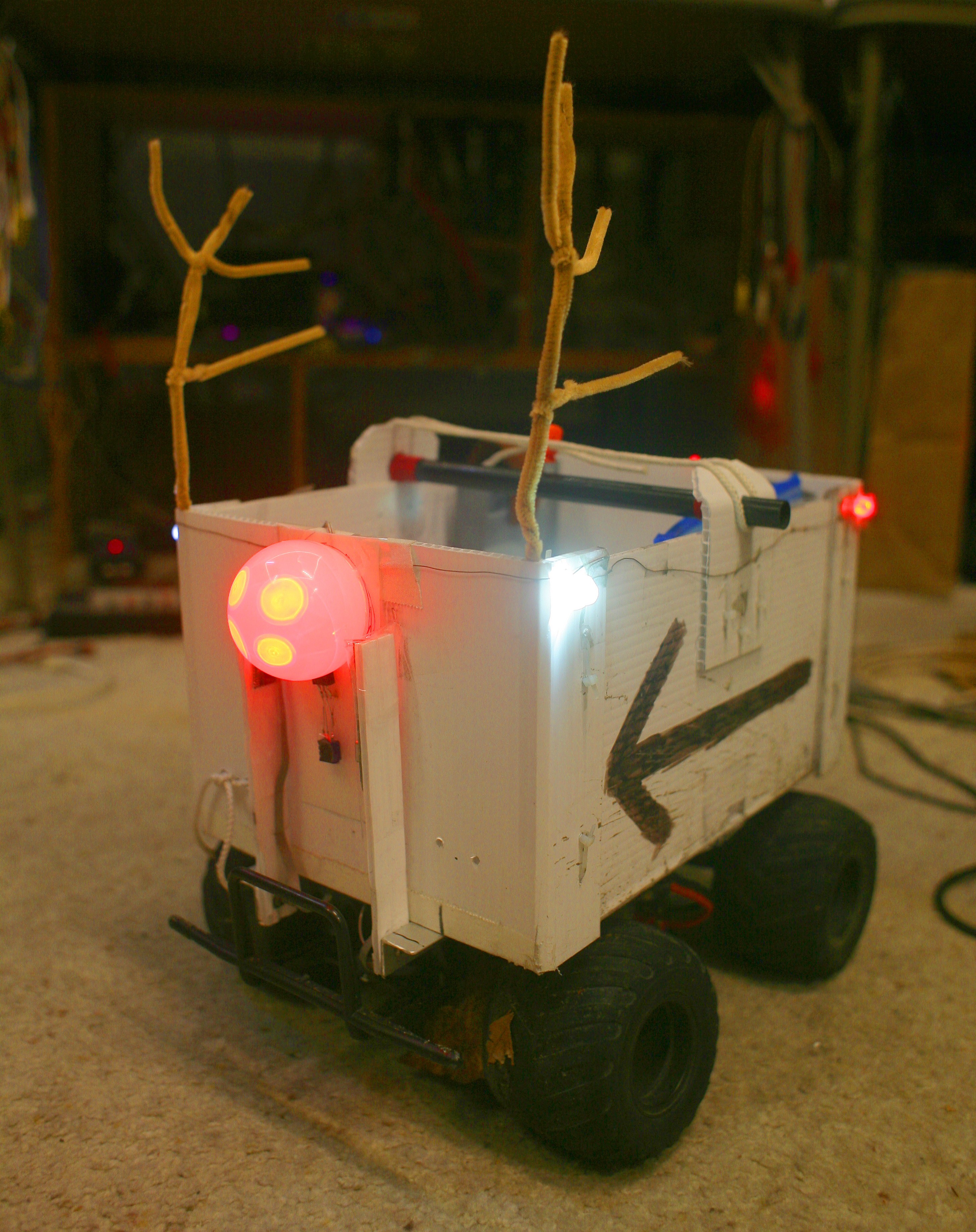

12/23/2019 at 01:08 • 0 comments![]()

![]()

The decorations keep getting better, with the discovery of brown pipe cleaners at Hobby Lobby & the order of giant red LEDs for the LED animation.

-

Refurbing vehicle 1 & phone holster tweeking

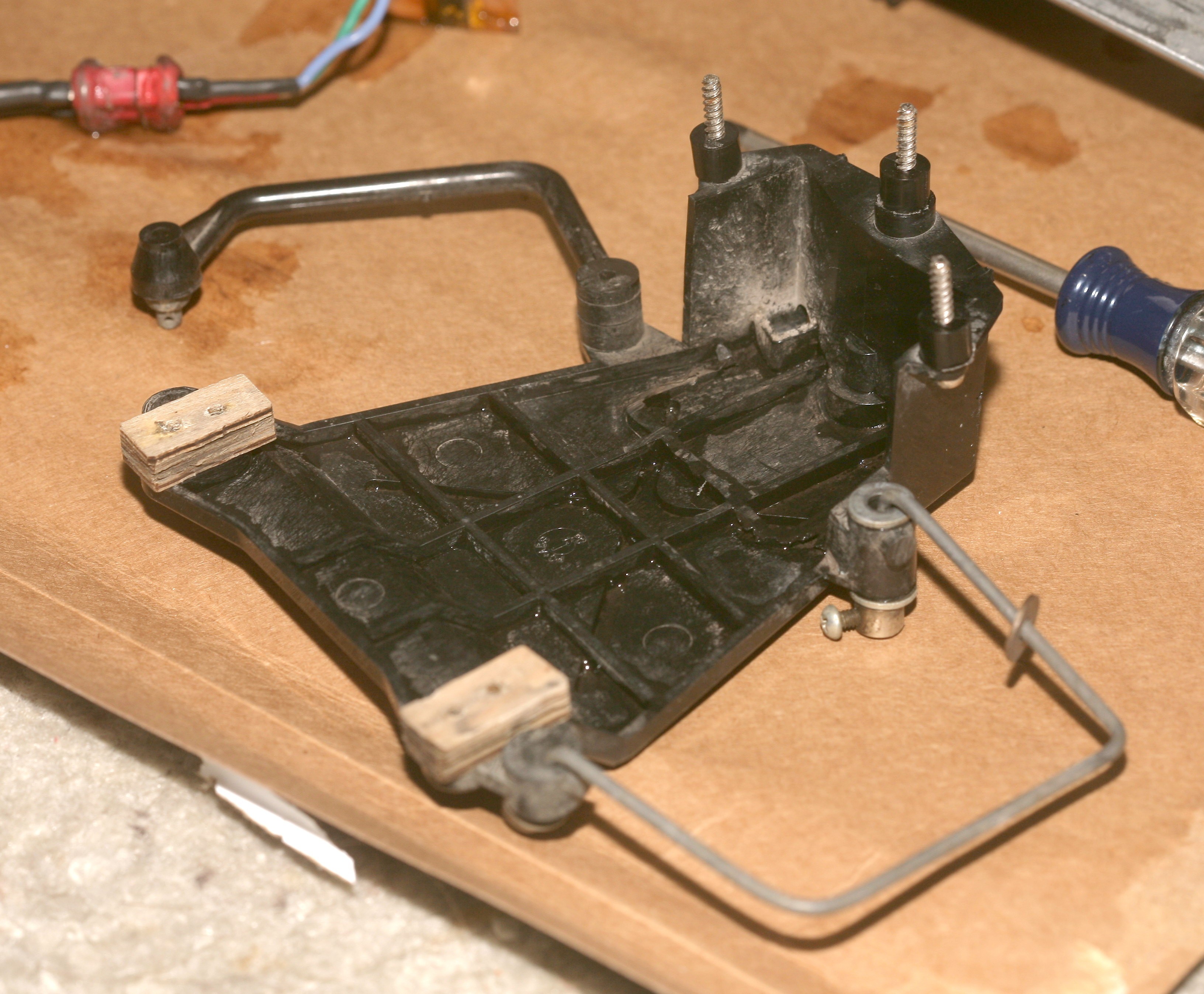

11/30/2019 at 05:38 • 0 commentsAfter 6 months, it was time again. The transmission was dry & just lubed instead of rebuilt. Other changes were lowering the front suspension to try to shorten the steering pushrods, grinding out access ways to more easily remove the transmission.

![]()

The battery compartment got taller standoffs to make room for puffing.

![]()

The struts got washers to prevent indentation.

![]()

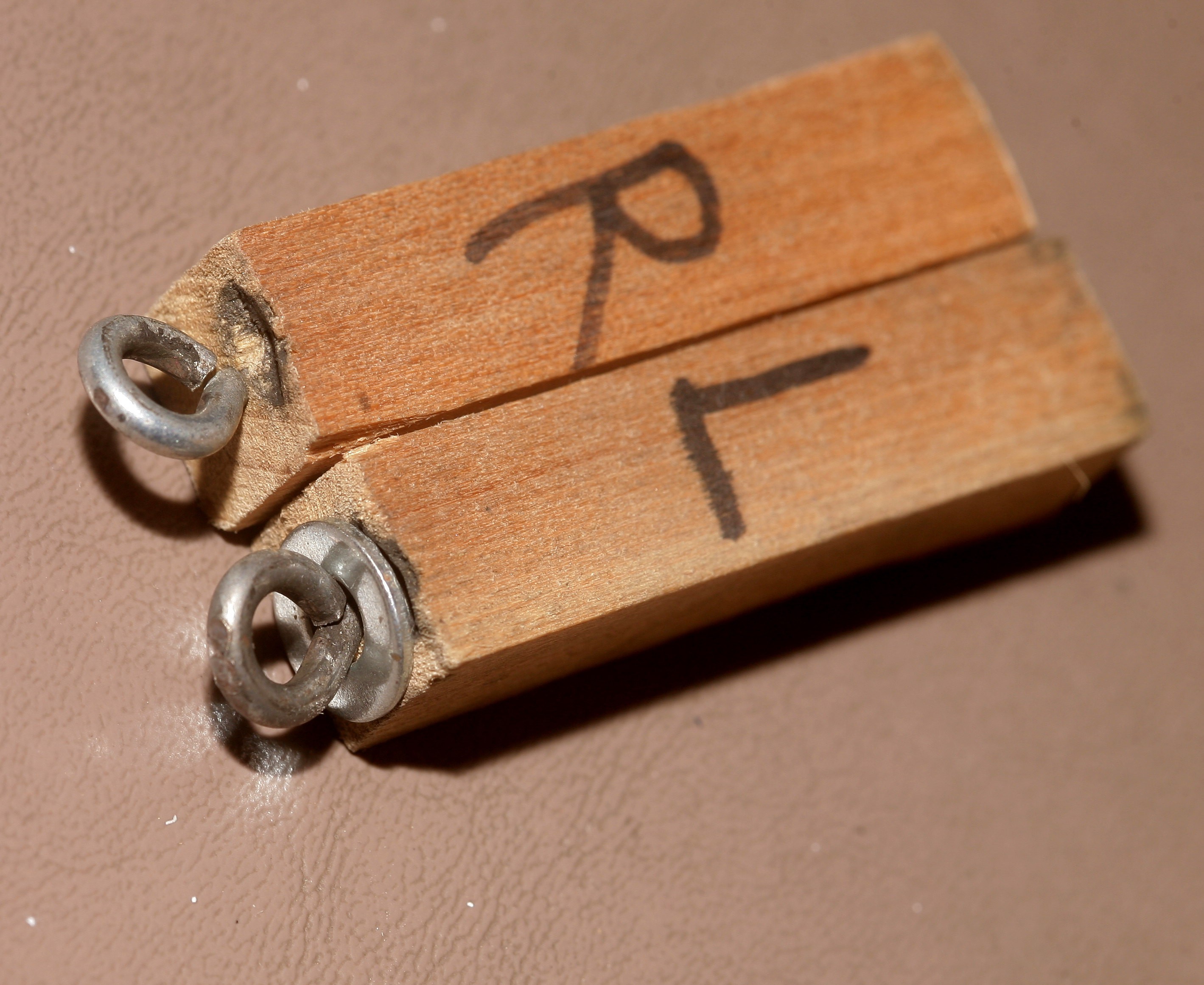

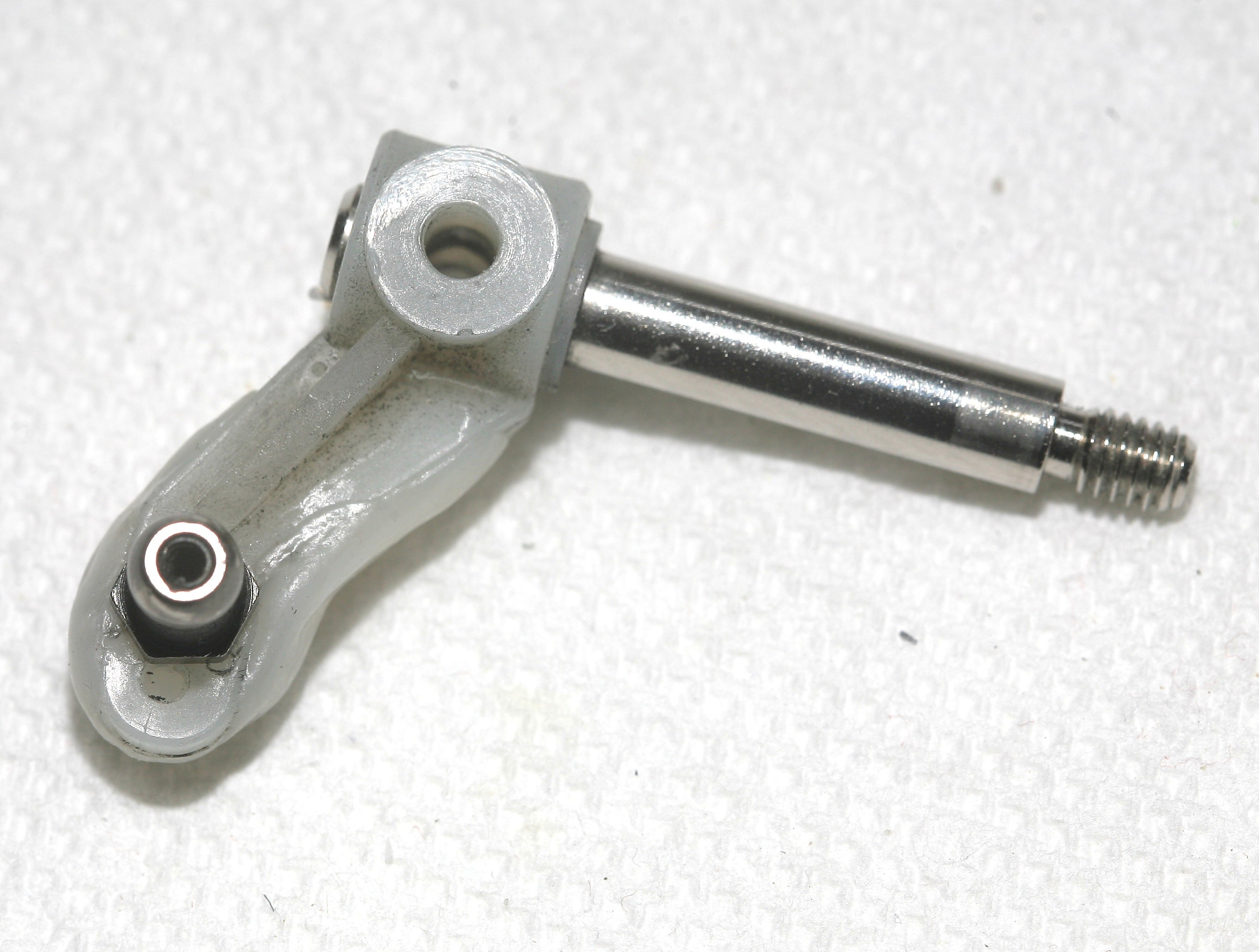

Wheels got aluminum knuckles & the pushrods had to be realigned again. Some attempts were made to try to improve the steering, but the right wheel needs a custom pushrod to do the job.

![]()

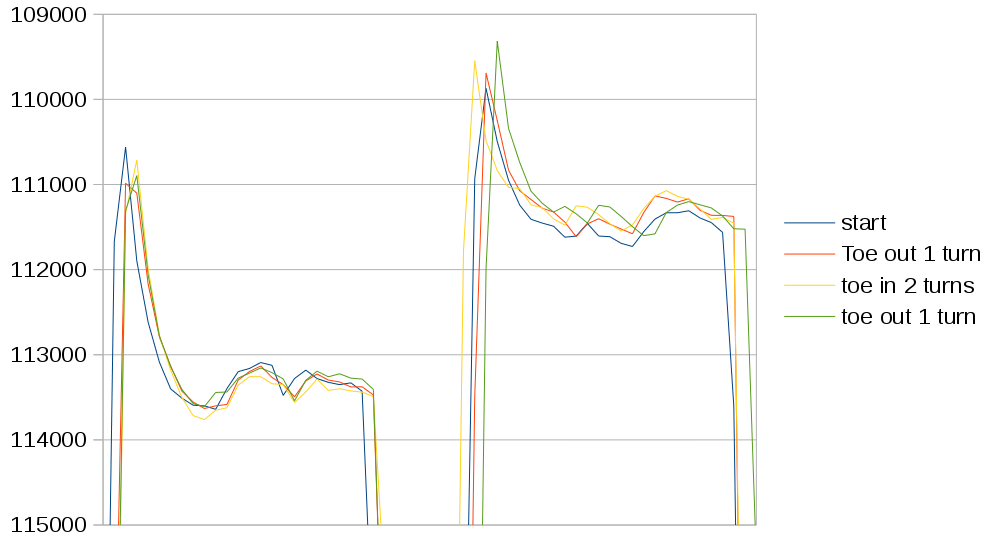

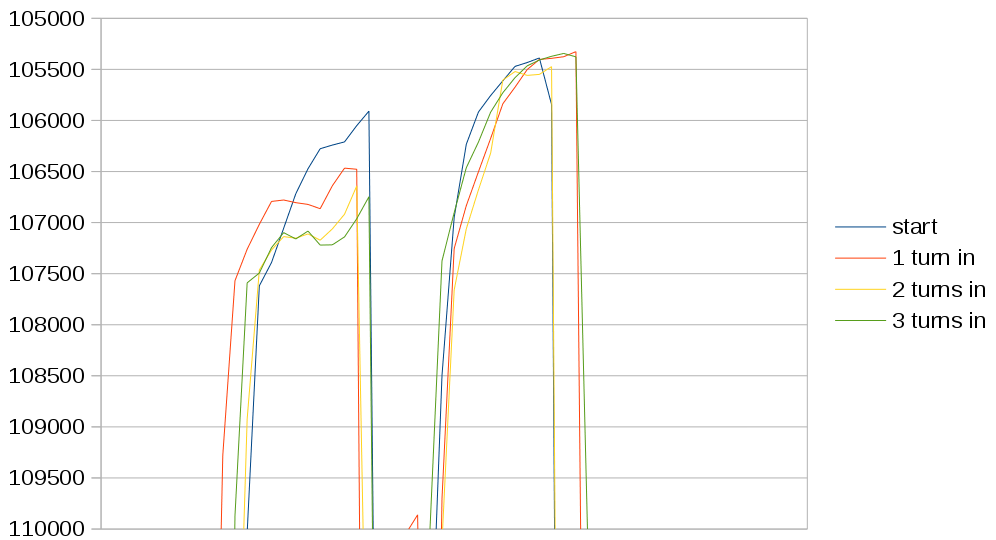

Green & blue were the same alignment. Orange was toed out. Yellow was toed in. There's no way both toing out & in could give lower power usage than the start. All of them were within the error bounds. Hopefully, it just means lions are good enough at aligning by eye that they didn't need any pushrod adjustments. Noticed the uphill direction was more variable because it was going into the wind.

![]()

Electronicals got some hot glue for strain relief.

![]()

Phone got some hot glue to try to stop the scratching.

![]()

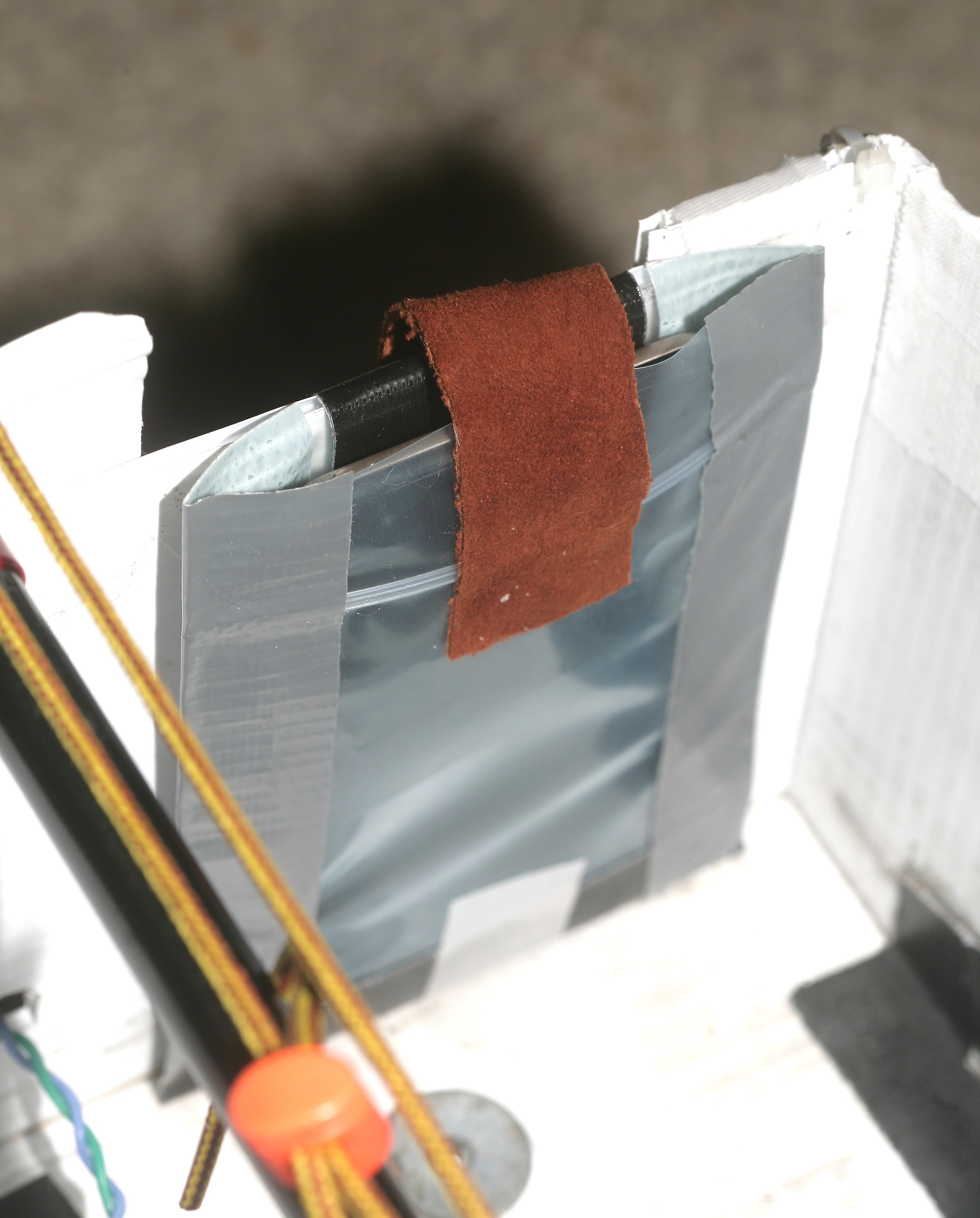

With velcro busted, it was time for a magnet wrapped in suede. Plastic falls apart very quickly & scratches the phone. The hope is an entire holster made of suede, but it's quite heavier than plastic.

Notice all the LEDs got the zip tie treatment. This has worked best for LED mounting.

![]()

The mane concern is the hot glue coming undone.

-

Steering failure

10/15/2019 at 05:07 • 0 comments![]()

It broke after only 6 months. The only replacement part is the fabled Tamiya Shaft Bag 58347, long out of production. There are aluminum ones in China with a 6 week waiting time. Lacking any replacement parts, the lion kingdom attempted a teflon repair. The bolt isn't long enough to reach through the teflon. Teflon is softer than the original nylon.![]()

![]()

During this process, it became clear the steering rods could be 1 hole shorter, so the wheels would have to be realigned for the teflon repair & aligned again next year when the China shipment arrived. All this wheel alignment had the lion kingdom searching for a better way. Lions traditionally aligned the wheels by driving a mile, recharging the battery, & measuring the charge. The charge depended on the wheel alignment as well as the battery temperature & how charged it was yesterday.

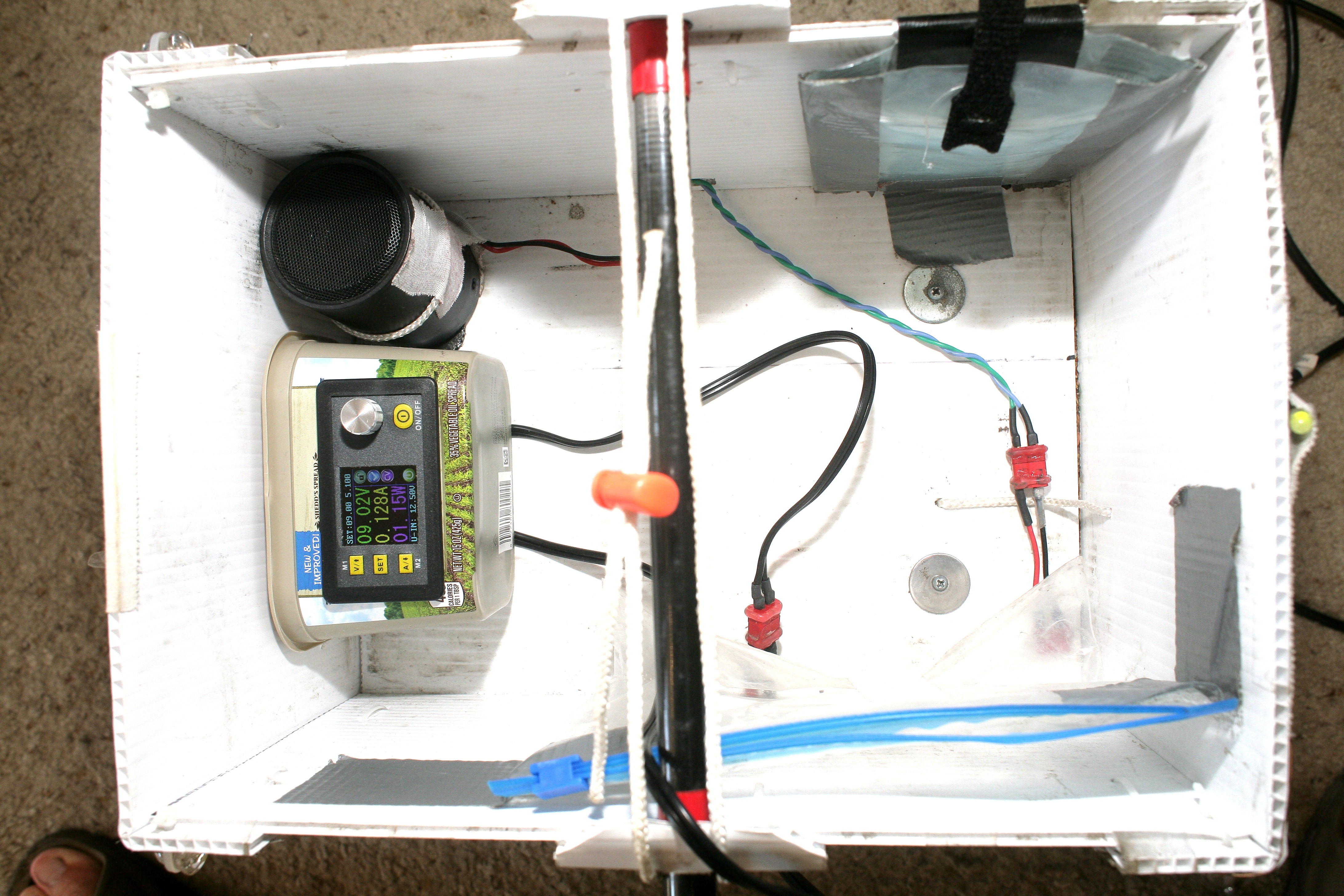

The ideal way is to drive a certain distance & record the PWM, but this requires a constant battery voltage. A Rudeng/RIDEN voltage regulator is still the ideal solution for getting a portable, constant voltage. Getting one is another 6 week China shipment.It was while searching for a voltage regulator that lion kingdom realized this was what Sparkfun sold, 15 years ago. What did Sparkfun sell nowadays? Dumbed down educational kits for large schools, big ticket items for corporations, & some standard connectors. Their power supply offerings where now the laptop bricks office supply stores sold 20 years ago instead of the bare boards they used to sell.

Exotic parts for starving college students & programmers are now only available in China. There's no money to be made in exotic parts just for building other things, partly because Chinese aren't allowed to use imported hardware in their own products.

![]()

A Rudung was sacrificed. The lion kingdom can remember no time when it needed 2 power supplies simultaneously. They were only used for remembering different settings or having different connectors. Manely, they were hoping for a future need that never came.

![]()

The new butter surprise created a stable 9V from a 12V battery. It had a 0.5V dropout.

![]()

![]()

Subjectively, the results were more realistic than without a regulated voltage. There was a steep drop in PWM for the 1st turns, then a leveling off. Finer precision was still a matter of complete drives & measuring charge.

The 1st 9.2 mile drive burned 246mAh/mile. -

Tire adhesive

09/28/2019 at 07:42 • 0 comments![]()

Lions run in hotter conditions than they did before. The wheels tend to spin inside the tires. When it's hot, the tires expand & they never move. The 1st attempt was hot gluing the tires on. That failed. The 2nd attempt was rubber cementing them on. The next attempt will be epoxy resin. The ideal adhesive would be tree sap.

After 34 miles of hard stop & go driving, the rubber cement was still holding. The motor definitely cogs more when the tires don't slip.

-

Button & switch failures

09/02/2019 at 03:08 • 0 commentsSo the throttle switch failed on, on the 900Mhz vehicle. The 400Mhz vehicle which was modified had no further problems. The stronger pullup resistor & lamination of the switch would have to be done to the 900Mhz vehicle.

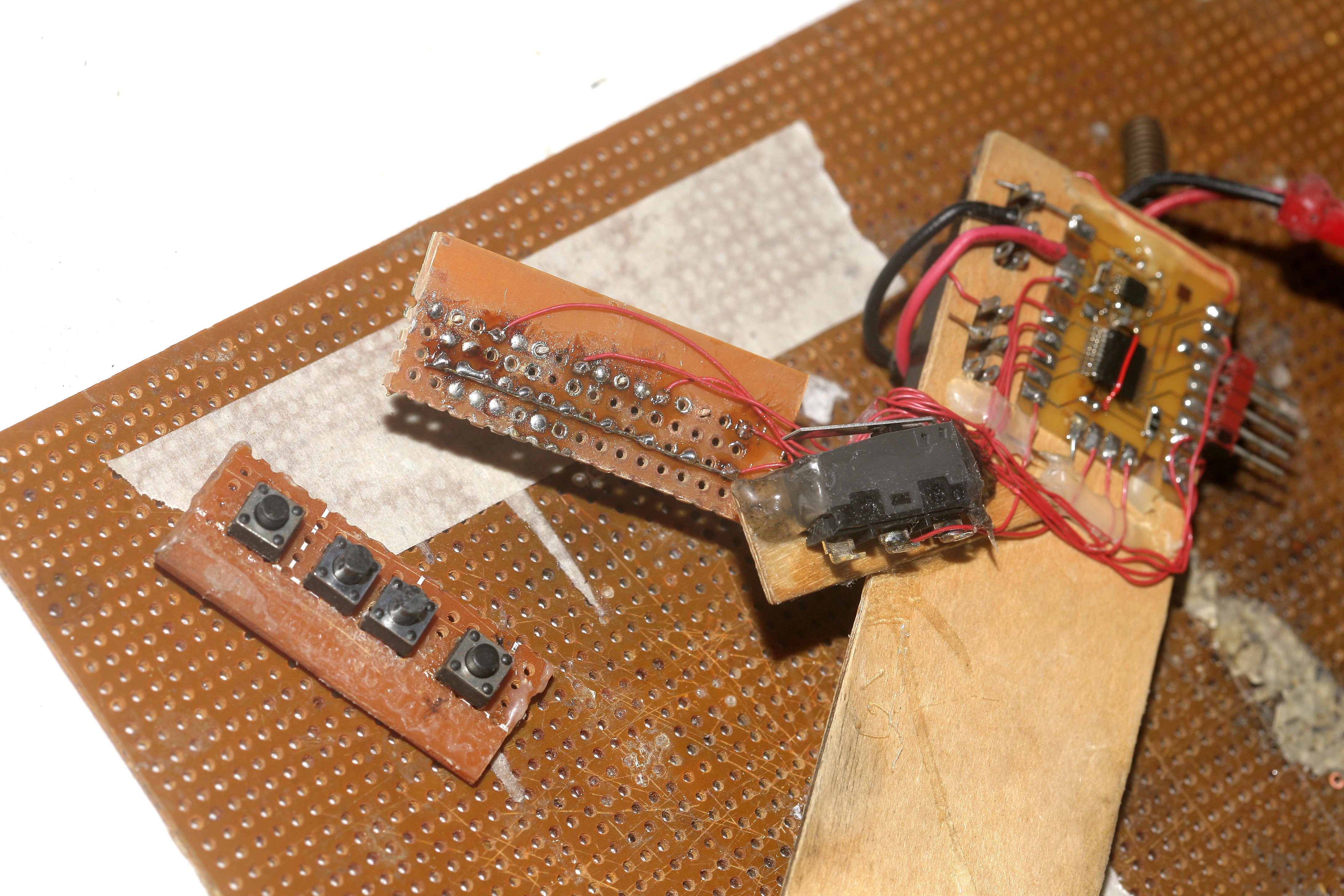

![]()

The next problem was the steering buttons. These have to be replaced every year. They got some life extension through wrapping in packing tape. The last wear comes from sweat which manages to get around the packing tape, holes in the packing tape, & the amount of abuse. They's constantly banged for minor steering adjustments. Eventually, getting good contact requires pressing the buttons sideways. Later on, they lose their springiness.

Attempts to make the steering buttons more tactile involved making the center buttons closer together. This provided clues as to what buttons were in the center., but it meant they couldn't be pressed sideways. A new idea is to space all the buttons enough to press them sideways, while grinding the buttons at different angles to indicate which button they are.

-

sweat + switches don't mix

08/12/2019 at 02:55 • 0 commentsThe same throttle switch had been used for many thousands of miles, since it was built in 2015. It gradually started failing on, when the lion got real sweaty. It finally failed hard & drove into an intersection on its own. When that happens, you can either kill the transmitter & wait 1 second for the watchdog timer to stop the motor, flip it into reverse, or steer it into a curb. The fastest move is to steer it into a curb. For the 2nd time in uncontrolled drives into roads, there happened to be no traffic. It's a good example of the kind of durability required in an electric scooter.

After failing for a few more miles & stopping by running into curbs, it started failing off & wouldn't go. The lion kingdom long believed the problem was salt water getting into the switch, but didn't know of a foolproof solution or why it started failing off. There was also the chance of salt water shorting pins.

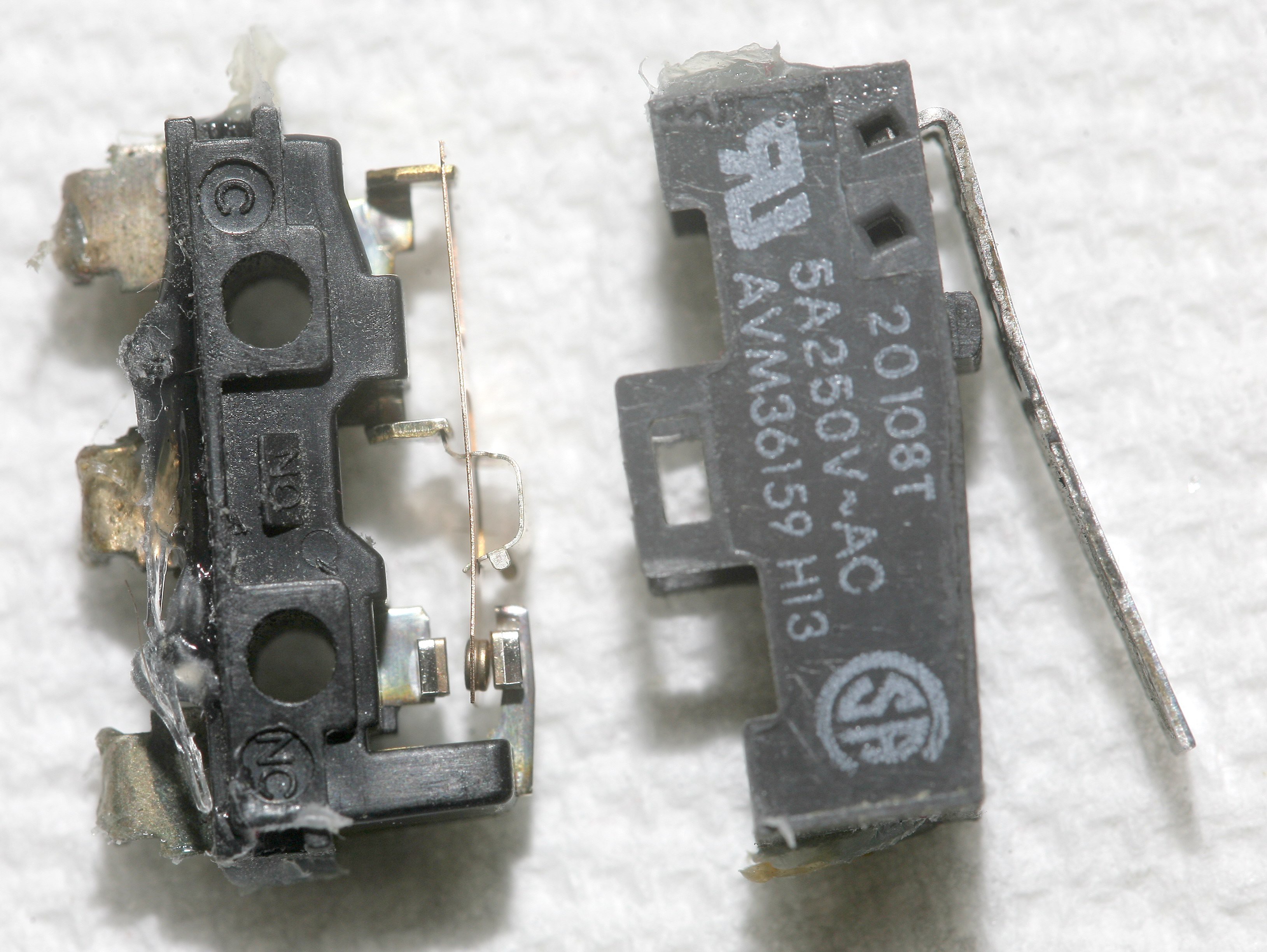

![]()

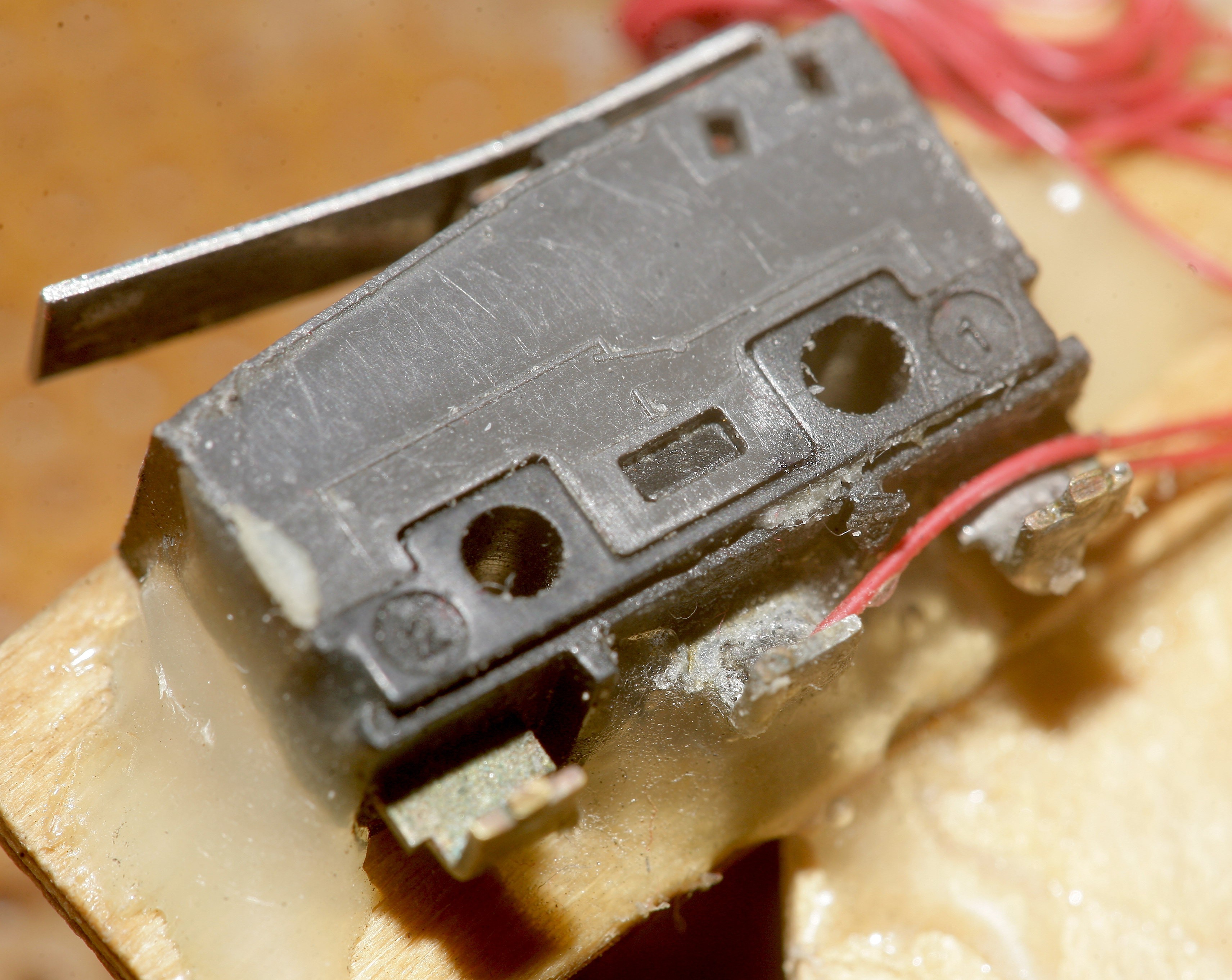

The outside was covered in salt & hot glue from a re gluing 2 years ago. It actually resumed service in 2016. Its previous life was a boundary sensor on the DVD robot from 2002-2009.

![]()

The teardown revealed a clean spring with good tension, despite its mileage. It makes sense since the switch is rarely toggled. A 10 mile run with no traffic can be done in only a single button press. The steering buttons take the most beatings.

![]()

The problem was the wear on the conductor. This clearly would have trouble conducting when it was dry. It was more like arcing wear it could have experienced in a former life. To fail on, a water drop must have formed in the tiny gap. The pullup resistor was only 50k. Unfortunately, there was no evidence of salt water anywhere inside the switch. This leads to the failures coming from shorted pins.

Another unlikely option is the spring getting weaker over time, until it would engage the conductor but not disengage it, in hot enough weather. The only force available to move the conductor is the spring tension & not the operator. There were still definite click sounds of the spring disengaging.

The switch was acquired around 2001 & it was already over 20 years old by then. It was now over 40 years old. Lions only used it in low current applications, as a boundary sensor.

Technology connections funnily enough made a video about switches on the day of the failure.

The mane idea is the force on the conductor comes entirely from a spring. No amount of pressing on the switch makes the conductor move more forcefully. They use a spring to make the switch bounce & arc as little as possible.

![]()

A layer of E6000 was added to the new switch, to try to seal it from water. The circuit board got another layer of polyurethane.

-

More gopro 7

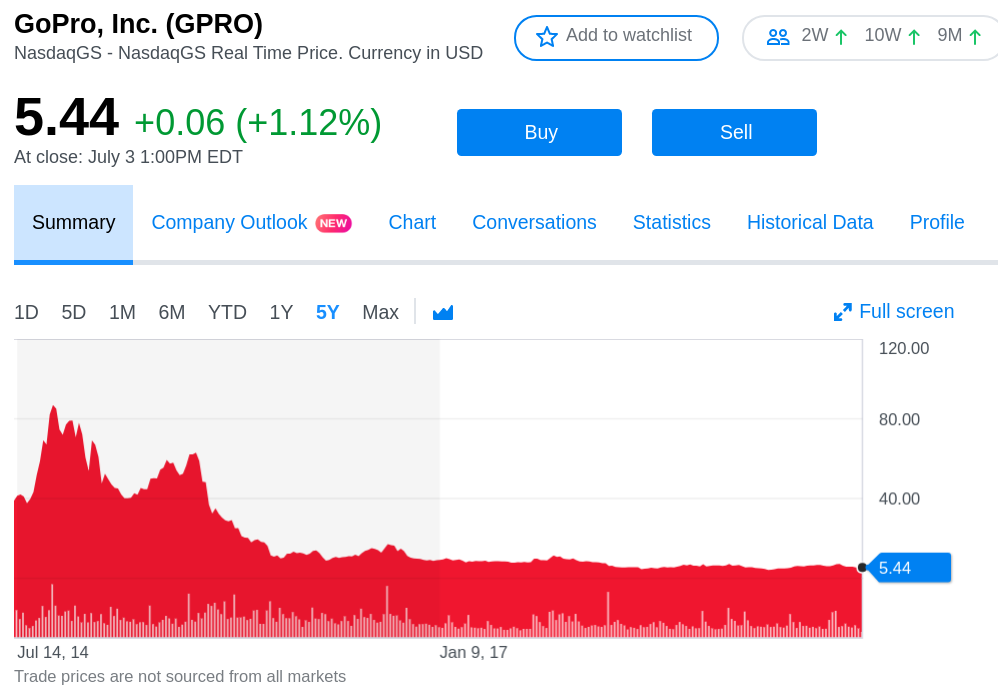

07/04/2019 at 21:45 • 0 commentsBased on a more complete picture of the features from Rainmaker Guy & the limited teardown information, the gopro7 is the same as the 6 except for the DDR being doubled. Doubling the DDR was the key to improving the stabilization.

The stabilization sauce is implemented in Japan by socionext.com. The 2 key innovations in the last 5 years are read ahead stabilization & rolling shutter correction. Lions lived in a time when the 1st single chip encoder for H.264 came out, just 13 years ago. It was a stretch just to encode 720p on a single chip. It took 2 chips to encode 1080p.

Today, the Socionext SC2000 encodes 4k 60fps in H.265 while also doing read ahead stabilization, rolling shutter correction, & camera stitching. It was only a year ago that lions still had a computer with 2GB of DDR taking up a stick on a motherboard.

All the image stabilization is driven by an IMU with a samplerate of 6400Hz. The fastest lions used in quad copters years ago was 1khz. At 6400Hz, they get 106 readings in each frame. It can easily detect changes in motion at different points in the scanning of the sensor. The memories of jello are gone. If only DSLR's implemented rolling shutter correction with gyros.

The key to stabilization was pioneered at Google for stabilizing gootube videos. They realized buffering several seconds of video into the future allowed the algorithm to anticipate future motion out of the sensor area. The algorithm could begin panning the video projection sooner rather than after motion was already out of bounds, giving much smoother results. The same thing is done for limiting audio loudness, but here it's done with video. The effect of read ahead stabilization is quite dramatic, with no significant increase in sensor size.![]()

Cautionary tale for stock pickers. Lions never bought any stock & weren't liked by their hiring manager, but despite all that going against them, the results from these cameras were always a cut above.

-

More gopro 7

07/04/2019 at 21:40 • 0 commentsBased on a more complete picture of the features from Rainmaker Guy & the limited teardown information, the gopro7 is the same as the 6 except for the DDR being doubled. Doubling the DDR was the key to improving the stabilization.

The stabilization sauce is implemented in Japan by socionext.com. The 2 key innovations in the last 5 years are read ahead stabilization & rolling shutter correction. Lions lived in a time when the 1st single chip encoder for H.264 came out, just 13 years ago. It was a stretch just to encode 720p on a single chip. It took 2 chips to encode 1080p.

Today, the Socionext SC2000 encodes 4k 60fps in H.265 while also doing read ahead stabilization, rolling shutter correction, & camera stitching. It was only a year ago that lions still had a computer with 2GB of DDR taking up a stick on a motherboard.

All the image stabilization is driven by an IMU with a samplerate of 6400Hz. The fastest lions used in quad copters years ago was 1khz. At 6400Hz, they get 106 readings in each frame. It can easily detect changes in motion at different points in the scanning of the sensor. The memories of jello are gone. If only DSLR's implemented rolling shutter correction with gyros.

The key to stabilization was pioneered at Google for stabilizing gootube videos. They realized buffering several seconds of video into the future allowed the algorithm to anticipate future motion out of the sensor area. The algorithm could begin panning the video projection sooner rather than after motion was already out of bounds, giving much smoother results. The same thing is done for limiting audio loudness, but here it's done with video. The effect of read ahead stabilization is quite dramatic, with no significant increase in sensor size.![]()

Cautionary tale for stock pickers. Lions never bought any stock & weren't liked by their hiring manager, but the results from these cameras were always a cut above.

-

Gopro 7 stabilization

06/27/2019 at 22:41 • 0 comments![]()

Gopros had advertised stabilization for years, but only the marginal amount found on camcorders 20 years ago. The mighty Yi 4k was a change in form factor with little improvement. The gopro 7 was the 1st to advertise enough stabilization to approach gimbals. The DJI action cam just looked like junk, cropped more than the gopro & had lousier color.

Suddenly, the goo tubes lept ahead of the lion kingdom in terms of stabilization & the quest for improved stabilization got more intense. The lion videos were truly shaky relics in a world of rock solid videos.

The lion kingdom got by with software stabilization for 20 years & never really matched today's standards. The lion kingdom was so desperate to capture decent footage of its mane, the decision was made.

In reality, the gopro stabilization doesn't work in 4k wide mode. It works in 4k linear & all modes below. The most aggressive gimal-like stabilization only works in the "linear" modes. The fisheye/wide modes offer minimal camcorder stabilization from 20 years ago. There's no difference between 4:3 & 16:9 modes, so pick 4:3.

It doesn't change the cropping to enable stabilization & there's no way to manually crop the modes to vary the stabilization. In unstabilized modes, the sensor area is thrown away. It's disappointing that the amount of cropping can't be adjusted to adjust the amount of stabilization.

The integrated video screen is a bulky, fragile, heavy, slow, battery draining pain. There is no longer a way to use it without the screen. Many methods have been tried to keep it from shattering. The enclosure provides some protection, but lions often use it out of the enclosure.

Like the other gopros, it uses the battery to record 4K, despite USB being plugged in.

There's no way to turn off the screen manually, only set the timeout as short as possible & reduce the brightness. The GUI is so slow, it's like 2007 again before Steve Jobless showed everyone how to do it.The front lens cover is replaceable & the lion kingdom wishes it knew all the lenses were replaceable, 4 years ago.

25" has been the maximum height for a camera pole with significant reduction in maneuverability & very shaky results. Compare the stabilized gopro 7 with the unstabilized 4.

Stabilized:

Unstabilized:

The 1st run video was amazing. The stabilization on the robot wasn't steadicam grade & slightly behind gimbal grade, but far ahead of the footage on the other goo tubes. Would call it slightly behind the steadycam & maybe equivalent to the 1980's Star Wars footage. It was worth $330 for that level of improvement. The cropping cut off the lion's head for most of it. You either have to stand farther back or aim it carefully.

They dramatically increased the saturation. Audio is heavily processed to remove wind noise. It's so processed & stabilized, it's like more of the information is coming from the software than the sensor.

lion mclionhead

lion mclionhead