-

Tire wrapping

05/31/2019 at 04:39 • 0 comments![]()

The new front tires were last year's old rear tires. After a few rotations, they were done after no more than 200 miles. The nylon wrapping was the same as before, gluing 1/3 at a time & holding it until it stiffened slightly, then gluing around a 2nd time. This time, a bead was laid on the 2nd day to try to make the irregularities slap around less.

![]()

![]()

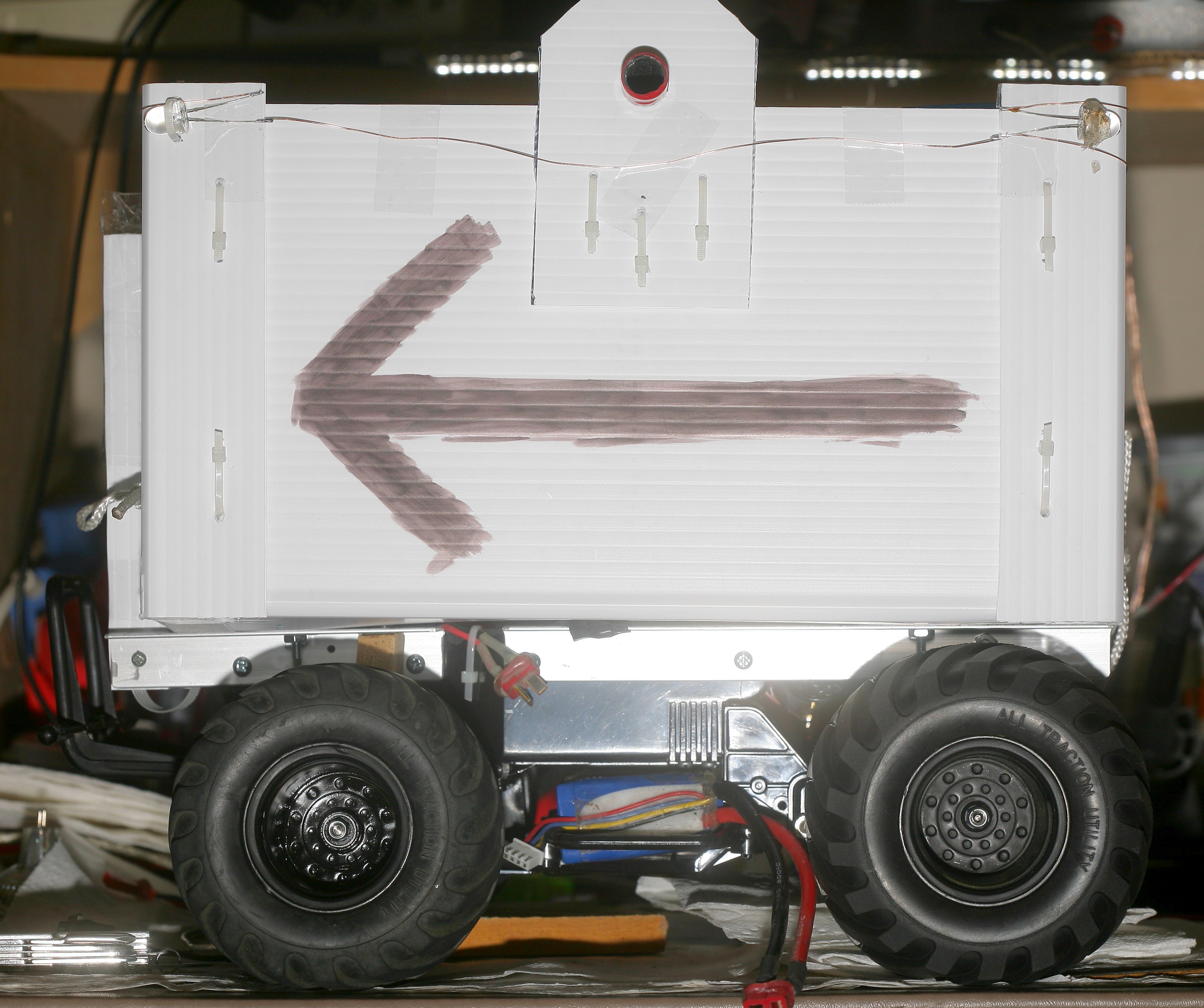

The handle strap proved to have another use besides making the handle removable. It allowed easily strapping stuff on top of the container. It was top heavy but a game changer.

-

The removable handle

04/02/2019 at 05:05 • 0 commentsThe transmission was extremely noisy for its 1st 20 miles, despite lubrication & the sound damper. Despite the noise, the efficiency was a record high of 240mAh/mile empty. 2200kV is a better speed than 2400kV. The hall effect sensor worked without any firmware changes. It actually manetaned the same speed going downhill. There's no brake modulation, so it would have to always deliver the minimum power rather than brake.

A 14 mile drive with 4.5 miles at 10mph & the heavy speaker pulled it up to 300mAh/mile. The speaker at 6mph only pulled 270mAh. Drove at high speed to try to break in the transmission & make it quieter, but it made no difference. The latest theory is the motor is making the noise.

The slightly enlarged cargo compartment was a huge improvement. There's definitely incentive to upgrade the old vehicle. Another idea gaining traction is a return to trying to make the handle removable. Removing the tape & relying on the stiffness of the coroplastic to keep it on was a failure.

A hose clamp could go on the handle.

https://www.walmart.com/ip/10-Constant-Tension-Band-Hose-Clamps-5-8-23-32/123944532

They're expensive, too tight, & would scratch the carbon fiber.

There's wrapping rubber bands on the handle. They would be too lose.

There's cutting a notch in the plastic & adding a key to the handle. The coroplastic is too soft to retain the notch shape. It would just become a larger hole for the handle to slide through.

There's augmenting the handle with a big rubber band. It would be soft enough to not crush the plastic, yet have enough tension to keep the sides in.

The leading idea was simply augmenting the handle with string to pull the coroplastic in. It would be a pain to remove, but it would work. The string could use a fastener or a simple shoelace knot.![]()

The string idea worked quite well. There are points of wear, like the coroplastic bending, the tape giving way, & the ends of carbon fiber delaminating. This allowed the largest single items to be transported.

-

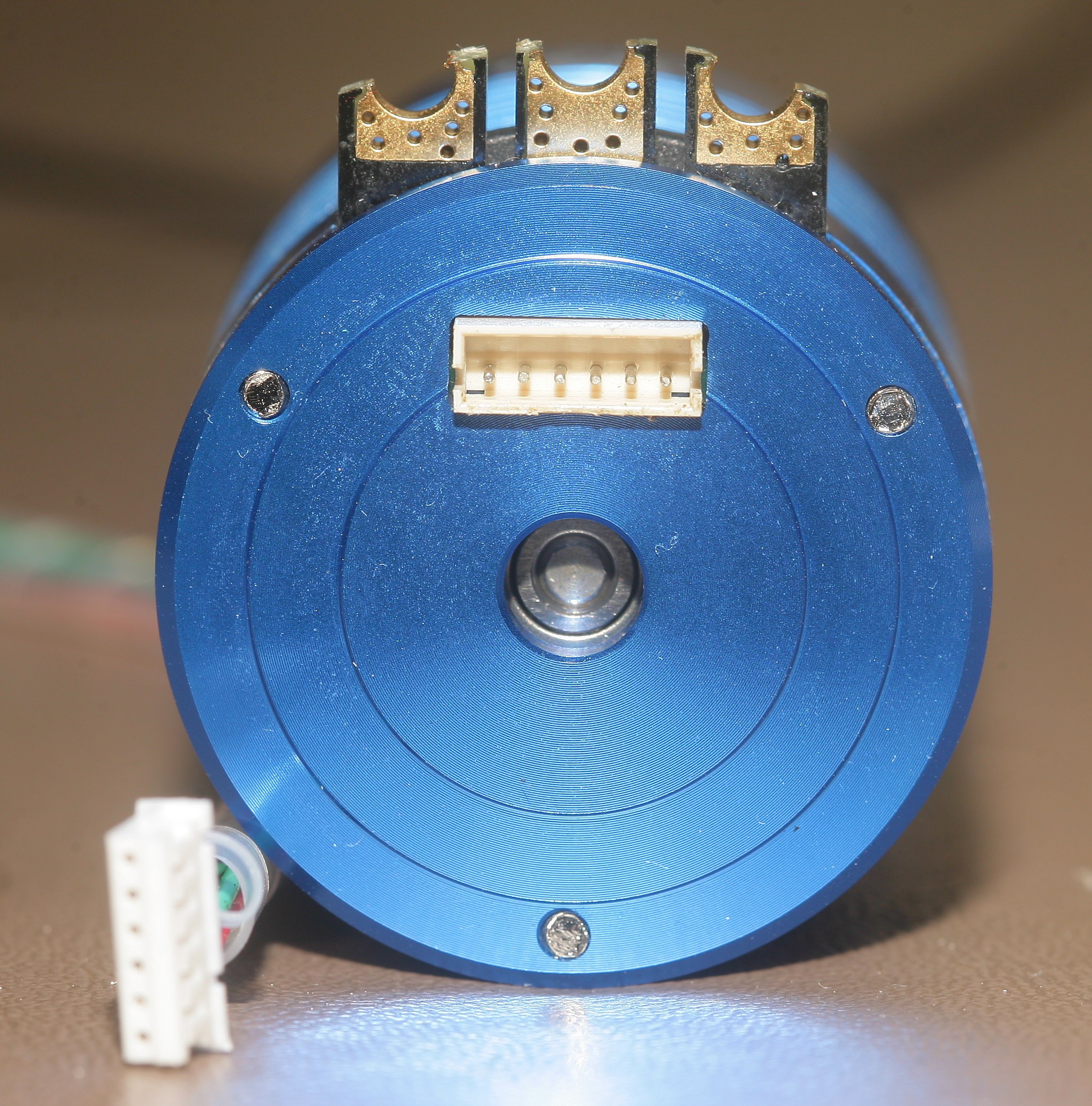

New motor 2

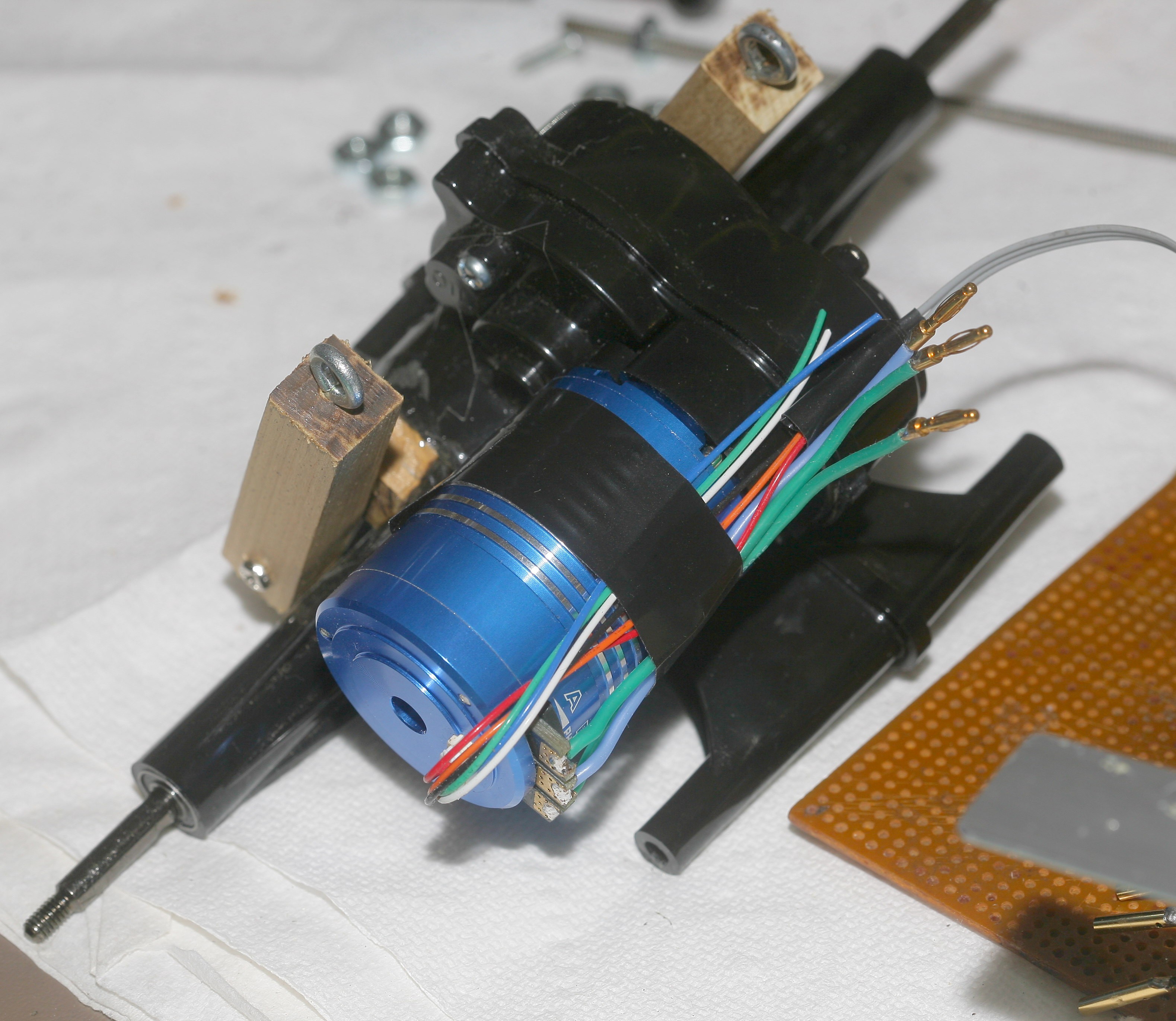

03/24/2019 at 20:09 • 0 commentsThe next motor was a

SODIAL(R) High Efficiency 540 17.5T 2200KV Sensored Brushless Motor for 1/10 RC Car Truck

https://www.amazon.com/gp/product/B075LFGCK9/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

After arriving 4 weeks later, this one finally fit.

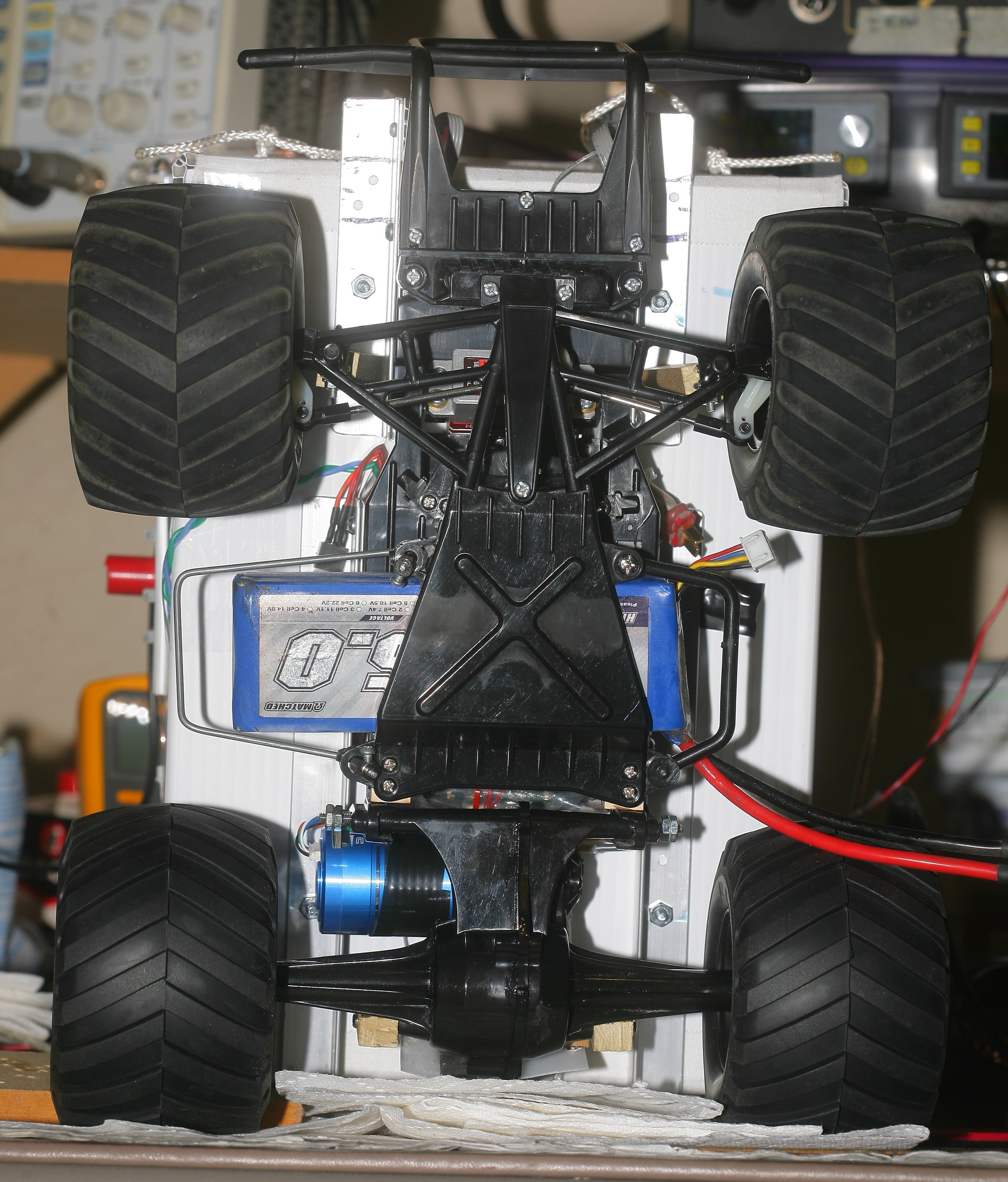

![]()

![]()

![]()

Most intriguing was the hall effect sensor connector. It could allow speed control while coasting. Sensorless motors just go out of control while coasting. It would require depotting the ESC, routing 3 more wires from the ESC to the motor.

![]()

Takes a lot more wires to access the hall effect sensor.

![]()

A 1.7k was put in series with the hall effect output to lower it to 3.3V. The 5V was extracted from the ESC. Sadly, the hall effect sensors proved very fragile. Just connecting 5V or GND to the signal line fried one. The motor was down to 2.

![]()

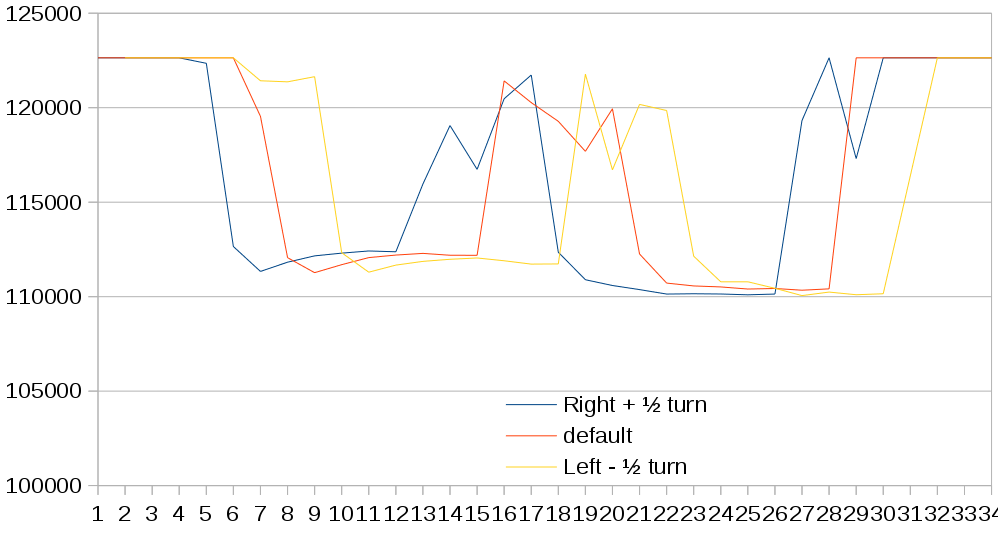

Some past telemetry was restored for viewing radio packet rates, throttle PWM, & RPM. For the 1st time, the app would record PWM to a file.

![]()

This revealed the slight throttle changes from changing the wheel alignment. The lower the PWM, the higher the power. The changes were also caused by the battery draining, but there was hope the battery drain changed it less than the alignment. The current alignment was copied with caliper measurements. More precise wheel alignment would still require many long drives.

![]()

High quality, weatherproof, color coded LED connectors. The frame is 7V, but the lion kingdom figured it wouldn't matter.

![]()

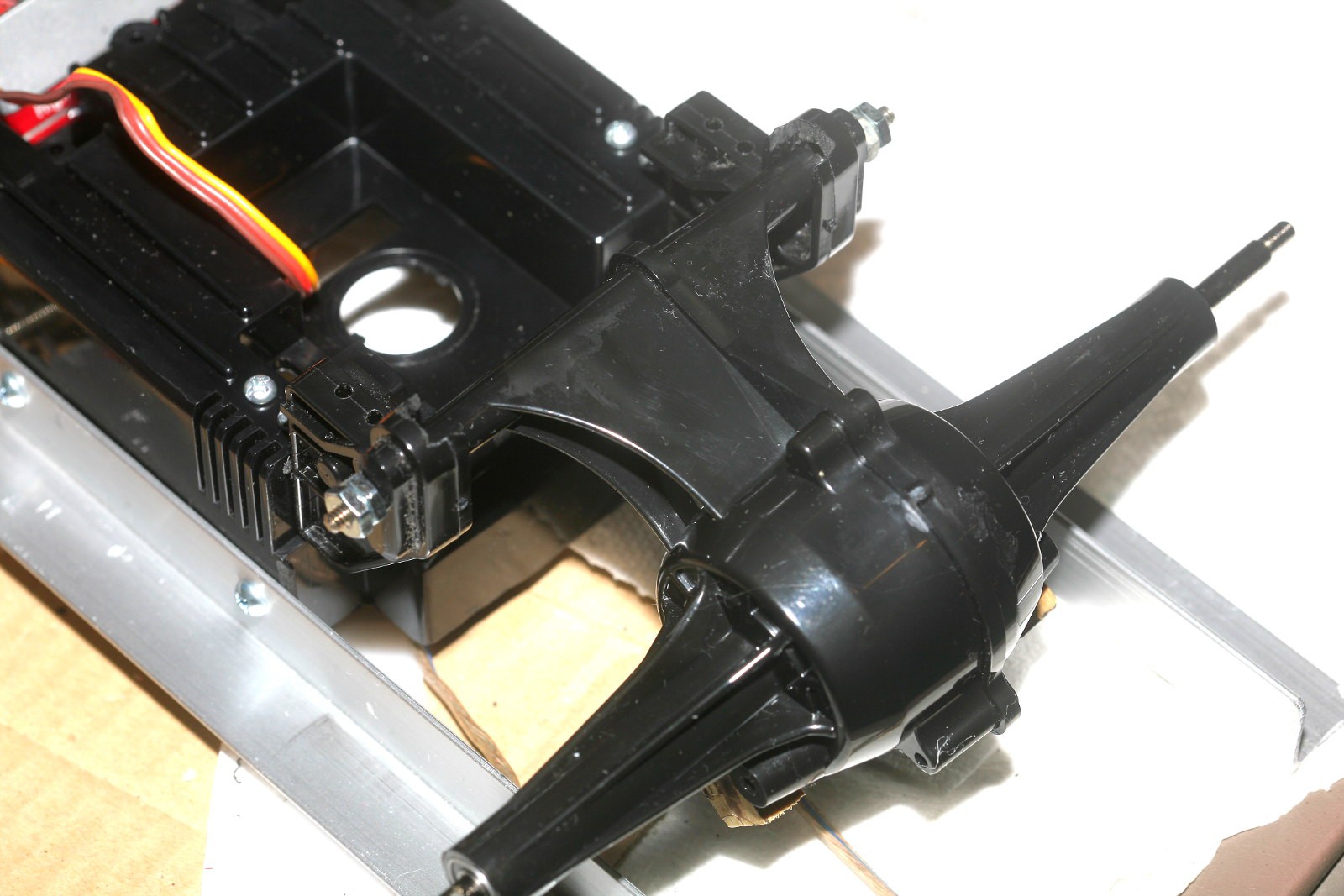

Oil cover installed & transmission lubricated. Struts are still not threadlocked, but it only needs 1 to finish a drive.

![]()

![]()

Old rear tires were installed as front tires to wear them down before installing nylon wrappers.

![]()

-

New motor

02/28/2019 at 17:43 • 0 commentsIn a common theme with limited ordering time between long commutes & worthless currency, another wrong part arrived from China. The 2848 designator on the Tacon 2848-2400kv does not symbolize diameter & length while it does on the B28-47-17S Brushless Inrunner 2300kv, so the required diameter is not 28mm but 35mm. Another motor won't arrive from China until April.

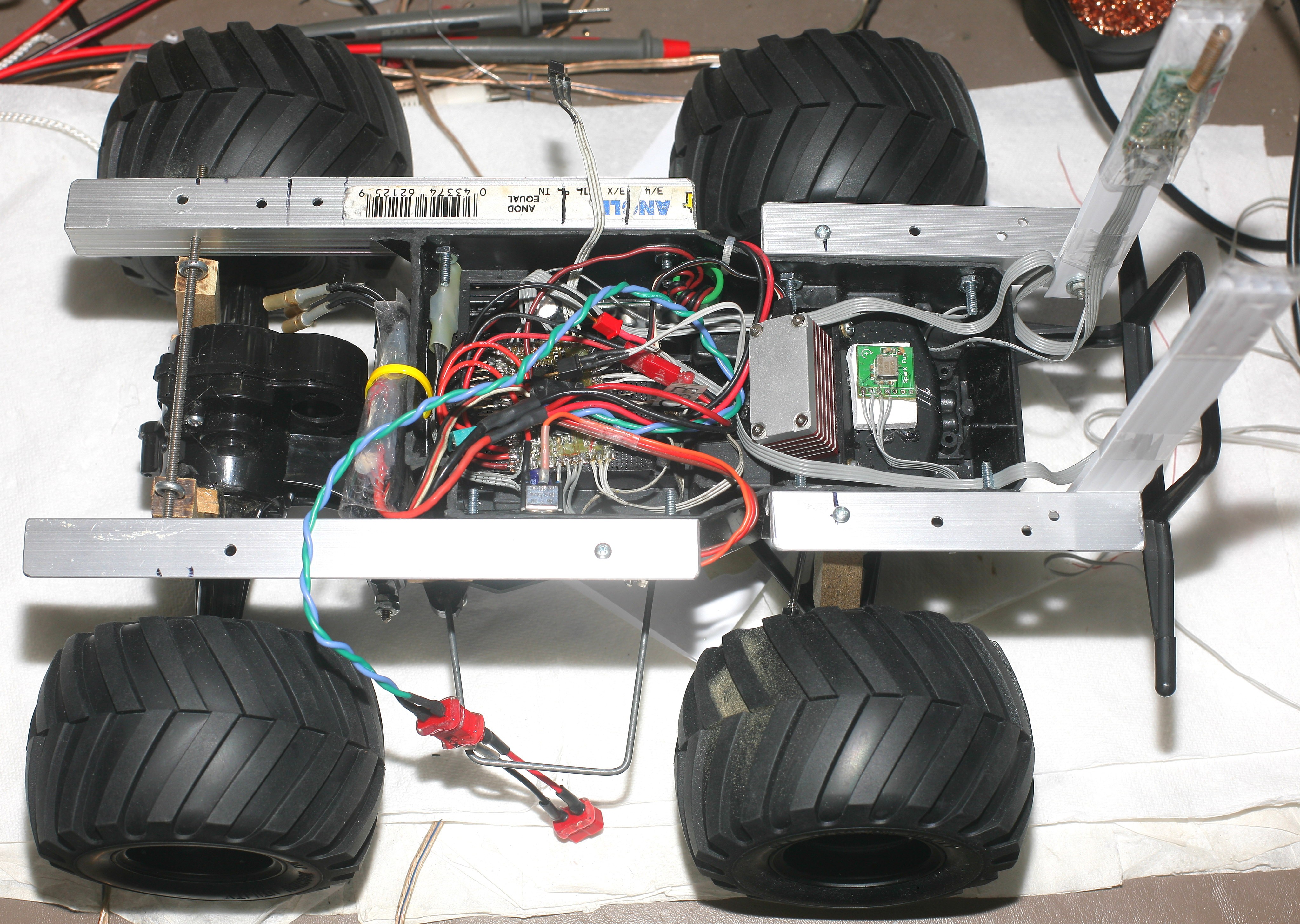

A large collection of useless servos & motors has accumulated.After much soldering, the electronics without the motor were finished & the cargo bolted on.

![]()

The lights got much higher quality connectors. Most of the other connectors were replaced by point to point soldering. All the soldering was a bit better.

![]()

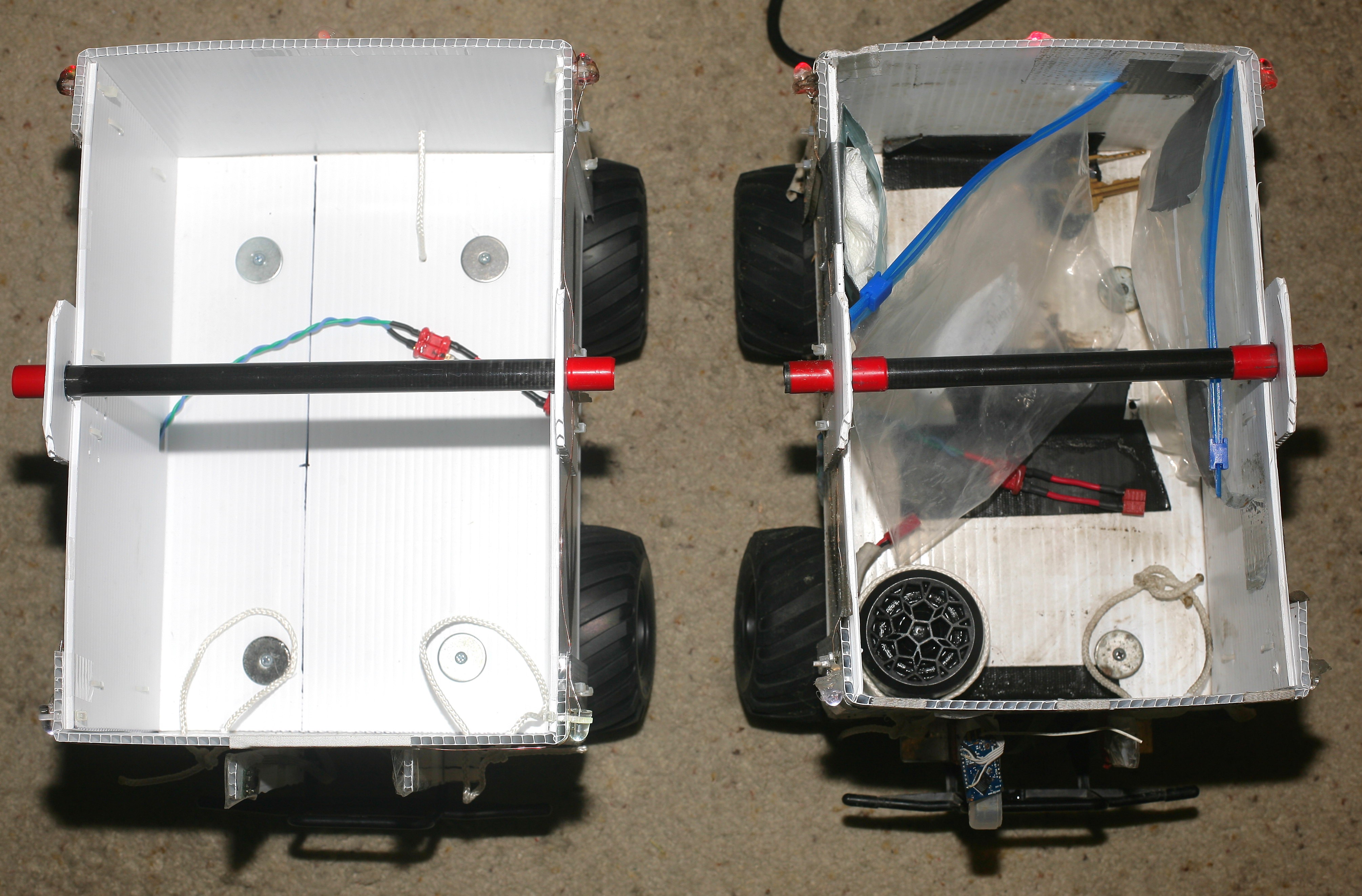

Being a rare new build of a finished design that evolved to handle extreme abuse, it felt like a very high quality, commercial product from Japan. The paint smelled fresh. Everything fit together tightly. The battery loading door was still stiff. All the corners were still right angles & flat surfaces were still flat. Lions never saw this design made out of virgin plastic.

![]()

The size increase was significant. The lion kingdom desperately wanted more room. It made it much harder to plug in the battery. It'll wear out the front tires faster. Dual speaker straps were added, to try to wear the tires more evenly. The previous camera tower won't work, because it's taller.

![]()

![]()

![]()

There's still installing the motor in April, doing a final transmission lube, threadlocking the nuts, doing the final rear wheel installation, installing the oil cover, modifying the firmware for the gyro being right side up, fine tuning the wheel alignment, reinforcing the front tires, waterproofing the radio. Wearing down the old rear tires as much as possible before putting them on the new front wheels. The new front tires will go on the old rear wheels.

-

Vehicle #6 begins

02/13/2019 at 21:49 • 0 commentsThe total for the next vehicle ended up being around $320. Should note the rising price of the lunchbox kit. Lions have now built 5 vehicles. Lions don't eat up robots. Years of experience have shown 2 lunchbox derived vehicles to be the required fleet.

Hobbyking required using a chrome browser to enable shipping. After 20 years, Firefox still can't render javascript, but doesn't lock up. Chrome renders javascript but constantly locks up. Nothing will ever be as fast as page loads in 1997. That year, the backbone 1st lept ahead of demand while clockspeeds lept ahead of the static pages of the time.

![]()

![]()

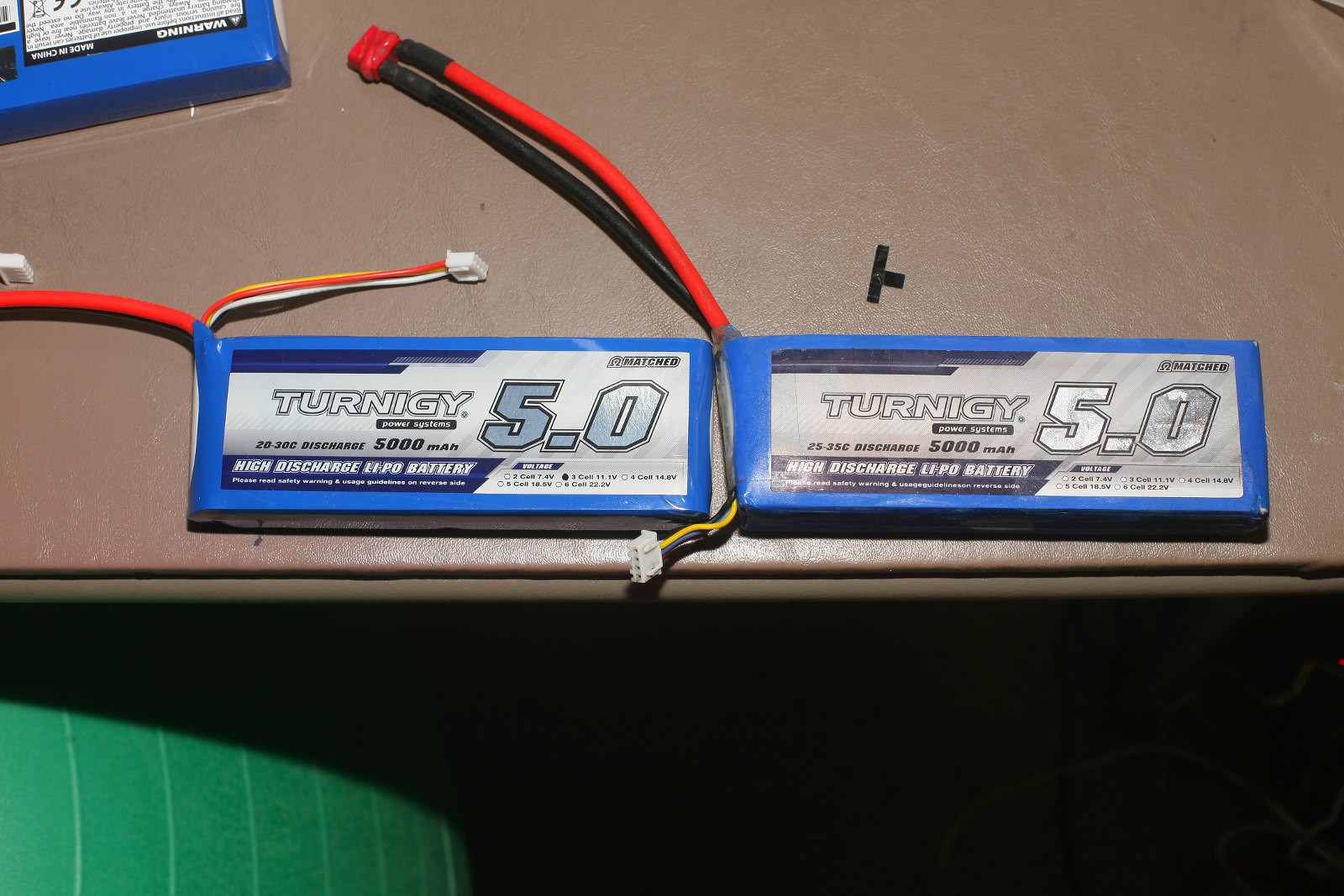

The journey began with 2 batteries. Note China has shrunk the size, despite a negligible decrease in current. Innovation ahead of refinancation.

![]()

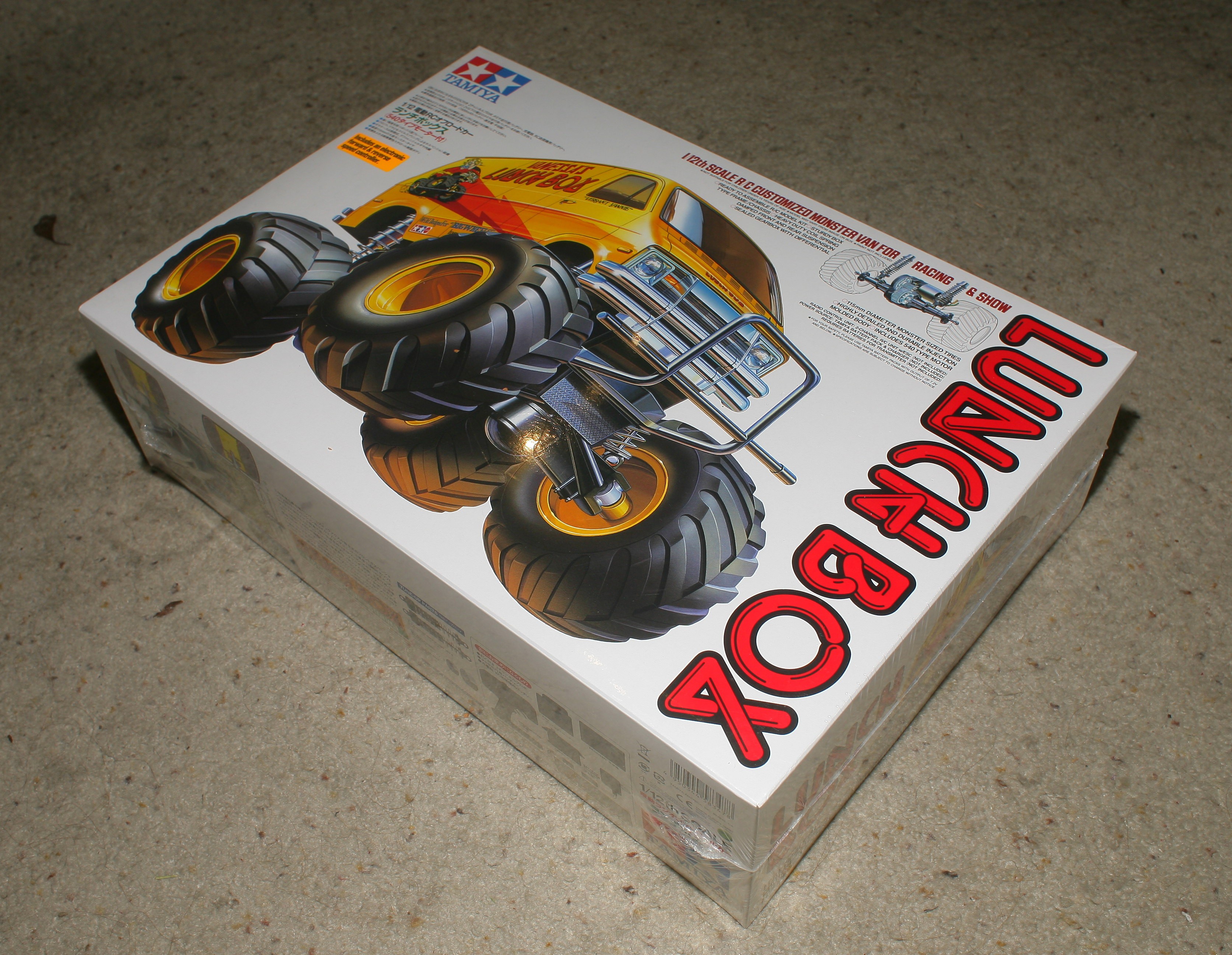

The new, higher priced kit arrived. Remember how marvelous these boxes looked in hobby shops 20 years ago & how they're manely discarded now.

![]()

Parts to be discarded & parts to be used are separated.

![]() Front wheels are strengthened with shapelock.

Front wheels are strengthened with shapelock.![]()

![]()

![]()

Paint is applied to all exposed surfaces. Very important to install plastic bushings as temporary masks.

![]()

Servo is pre threadlocked.

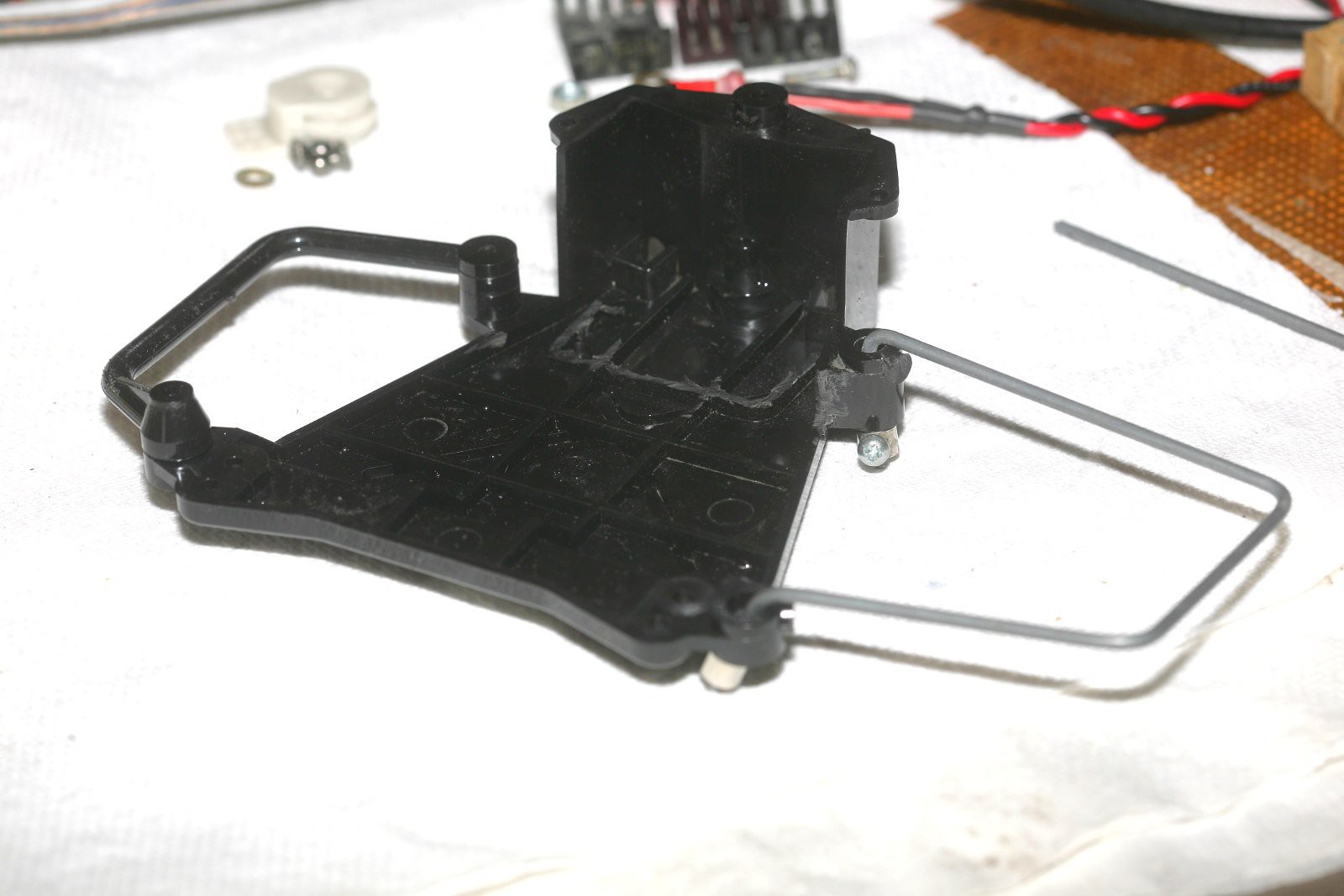

![]() Battery tray is modified.

Battery tray is modified.![]()

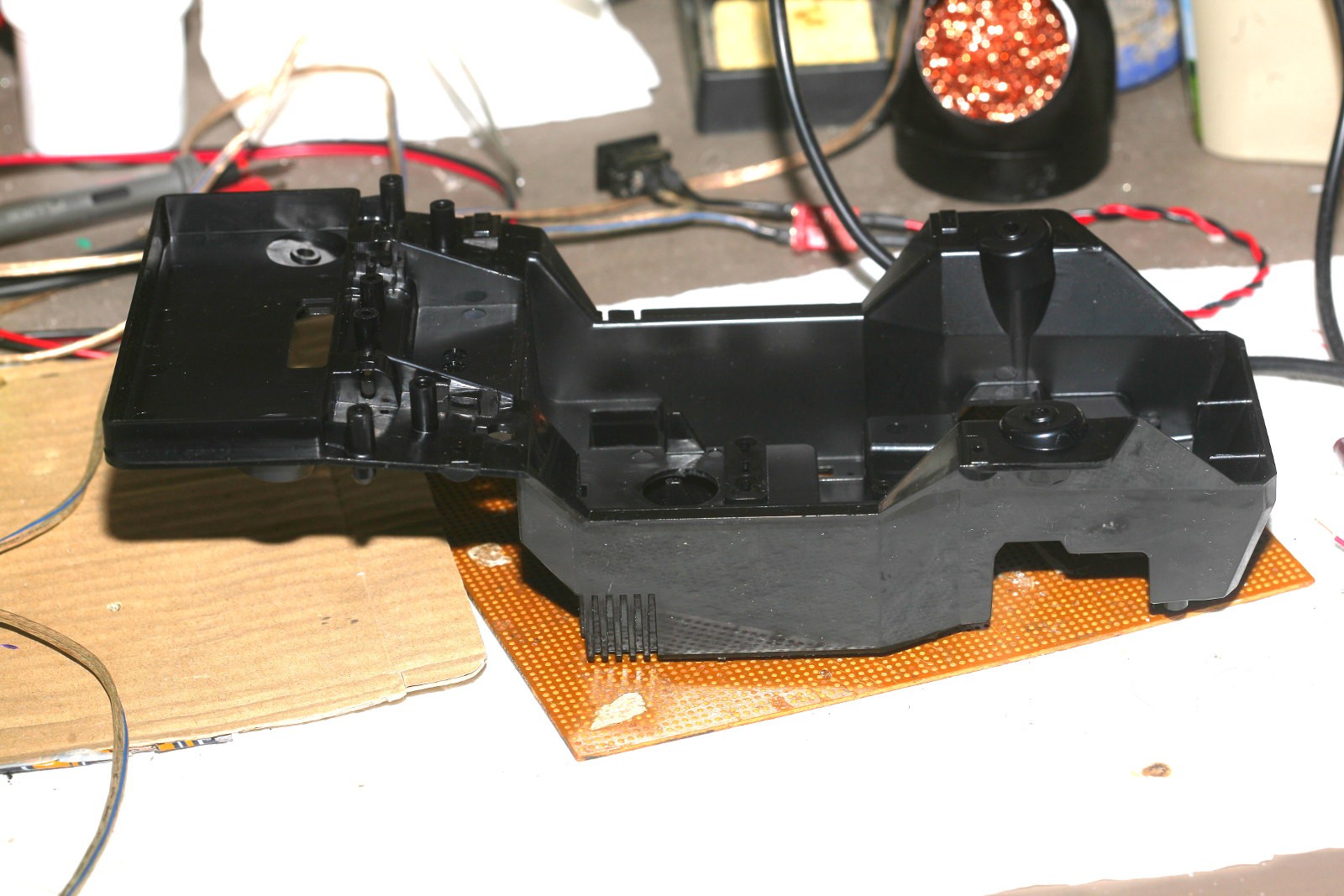

![]() The chassis is ground down, the hardest part of customizing this $150 kit.

The chassis is ground down, the hardest part of customizing this $150 kit.![]()

Chassis modification.

![]()

![]()

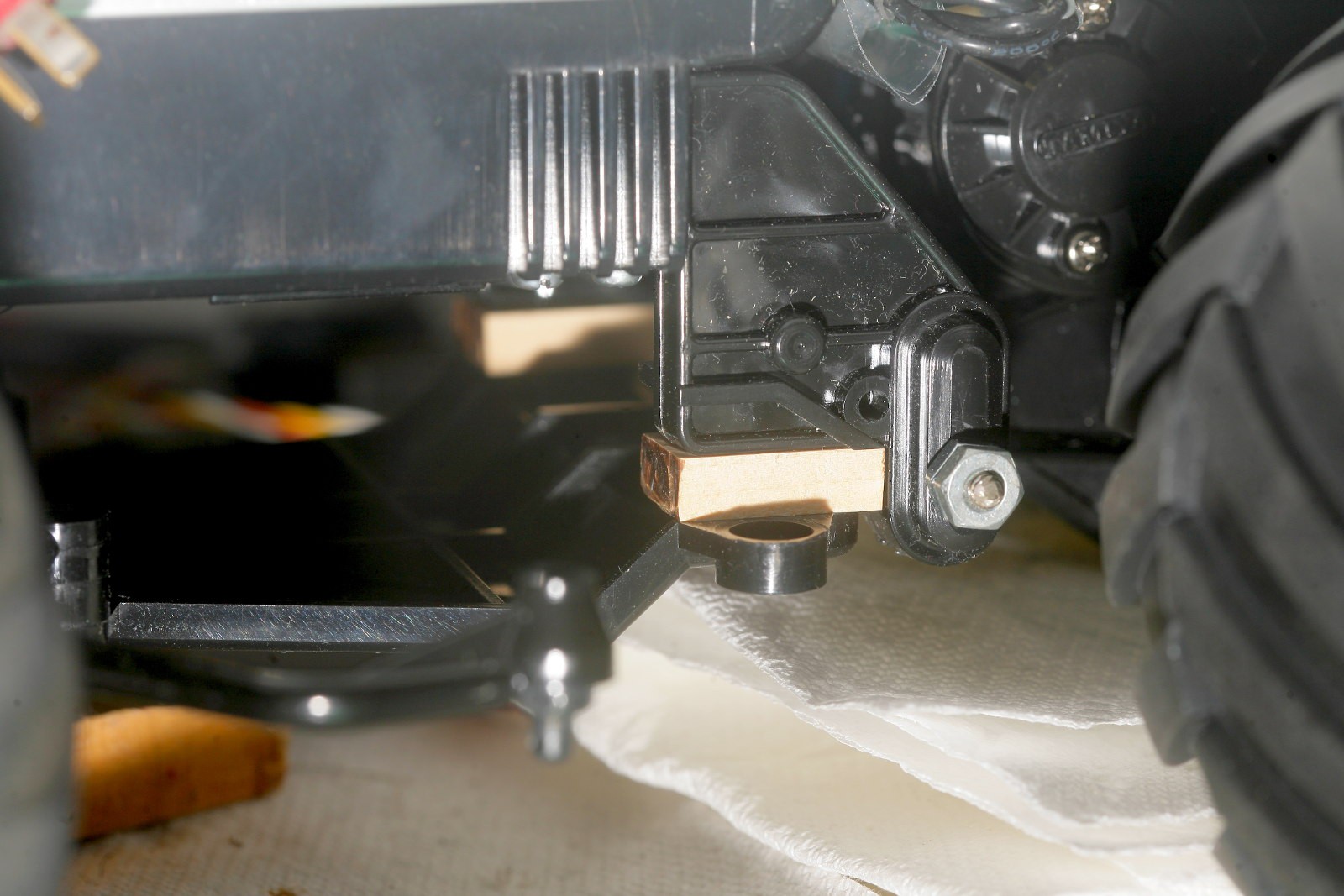

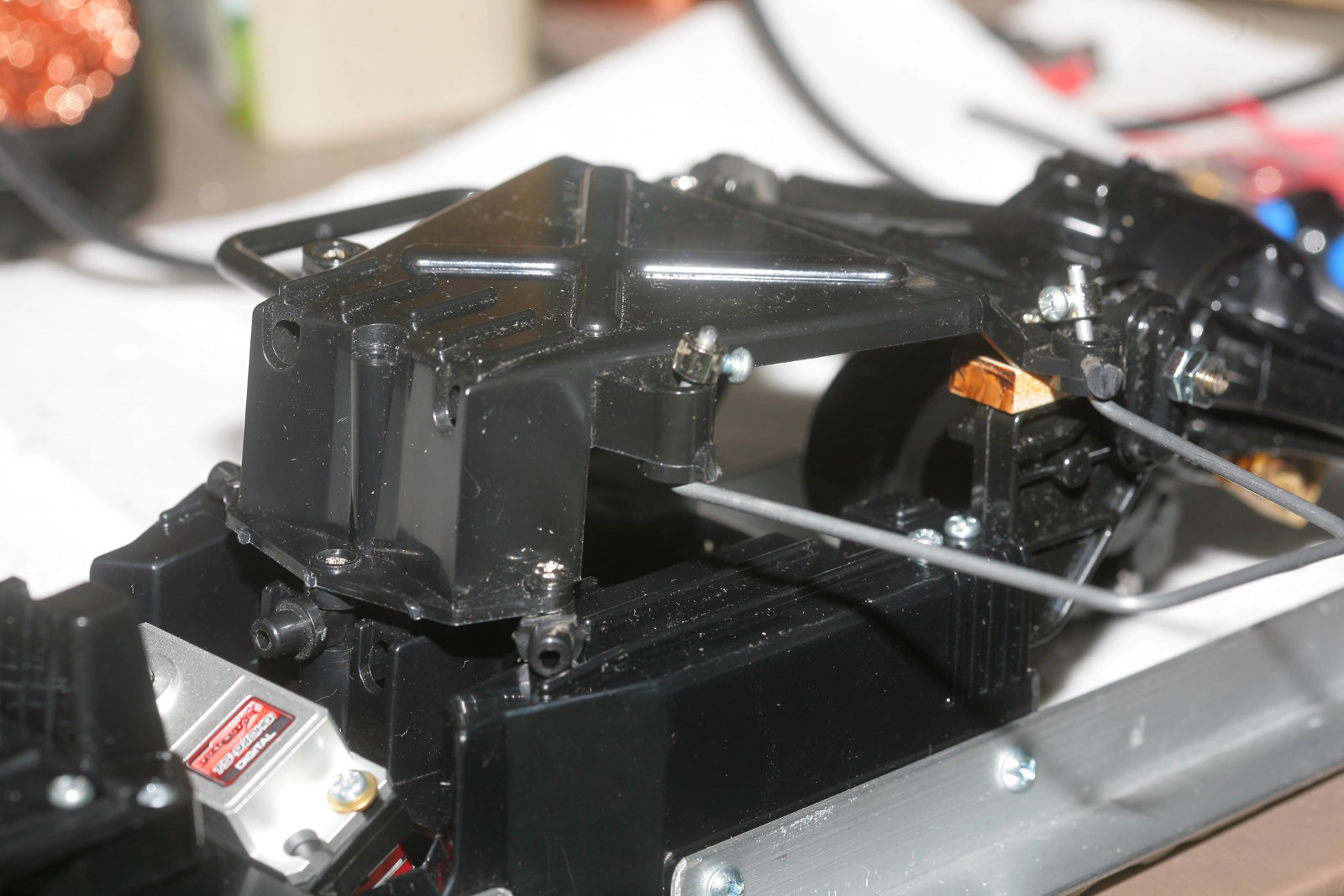

A key modification was allowing the transmission to be removed without disassembling the entire chassis.

![]()

Battery tray receives 1/4" spacers.

![]()

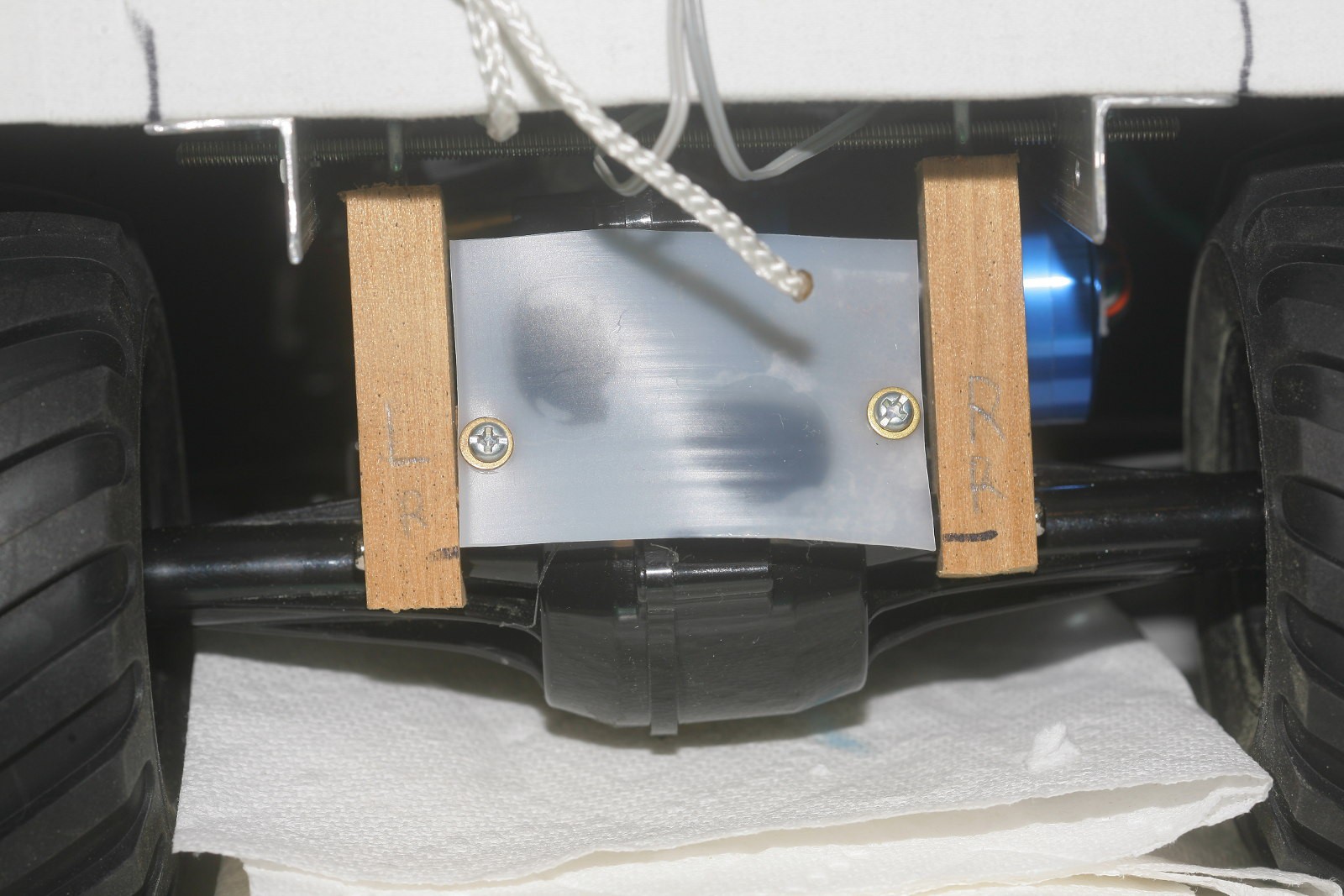

Transmission receives wood blocks to attach an oil cover.

![]() Wood struts are installed.

Wood struts are installed. -

Tire wear & Plans for another vehicle

02/07/2019 at 03:10 • 0 comments![]()

The 1st 2 nylon wrapped tires suddenly disintegrated after an extended period of good robustness, maybe from driving more on sidewalks instead of the bike path, so the 2nd set came together with gloves. Lions hate wearing gloves, but this operation is the 1st mess of carcinogenic adhesive big enough to leave no choice.

Though the problem is friction rather than tensile strength, there definitely should be an experiment with kevlar. Kevlar, gloves, & some dogs would make it TSA compliant.

With long commutes forecasted, plans for a new vehicle began. The new vehicle will be exactly the same as the existing lunchbox. The mane problem is the number of custom parts which must now be fabricated is quite high. Custom tires are just the beginning. Reinforced front wheels, suspension struts, chassis modification, cargo bay, ESC reprogramming & potting, headlights, handle, battery spacers, battery cage, transmission lubrication, radio stands, battery cables, all make you realize what it's like to be Chinese & create the modern world from nothing.

-

Laws covering robotic exercise coaches

01/24/2019 at 07:01 • 0 commentsSomething needs to be done about the law banning robotic exercise coaches from the bike trail. It's just a daunting task. The lion kingdom assumed 6 years ago, robotic exercise coaches would abound by now & there would have been enough industry pressure to legalize their use. Yet, there's still just 1 lion using them.

The lion kingdom wouldn't know where to begin. A lot of people would have to agree on amending the law. All the women who told lions to get lost for the last 40 years live in the east bay. Not even sure if the needs of 1 lion would be enough to motivate any change.

The laws aren't passed by voters, but a board of directors. The e-bike pilot program was a precedent, but it took a long time to implement & only lasted a year. There are board meetings where the public is supposed to address the board, but it's like jury duty. There's paperwork. You have to talk real fast. -

Battery swelling margins

01/18/2019 at 07:05 • 0 comments![]()

After 4 years of water causing the wood to shrink, the battery spacers were expanded to 1/4". Extra space is required to account for battery swelling. Since the days when battery swelling was considered doom, it's become the standard aging process. Products have extra space to account for battery swelling. Unfortunately, this battery is down from 5Ah to 4Ah capacity or only 14 mile range. Over 2400 miles with most of the discharges down to 33% capacity took their tole.

-

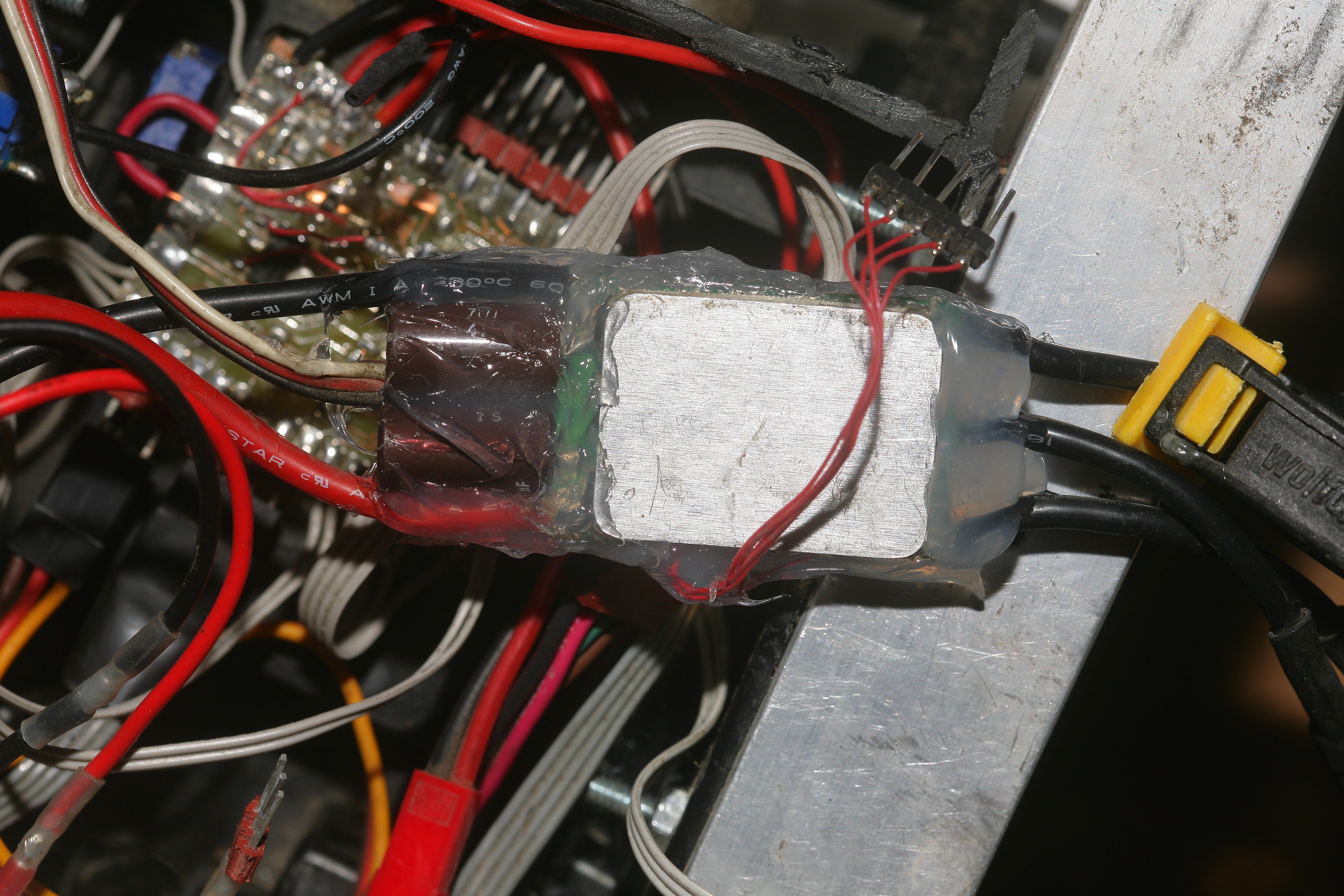

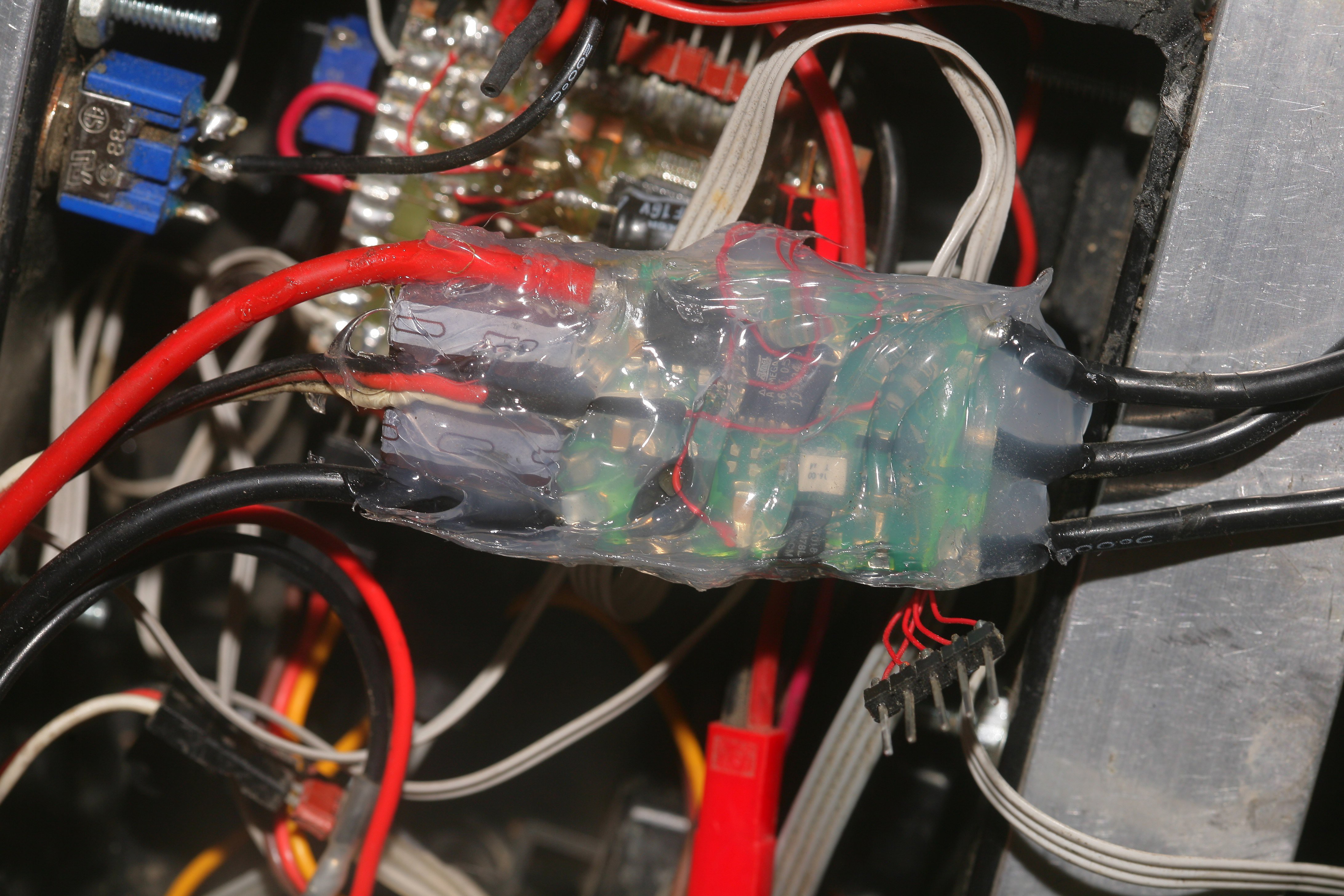

Wet ESC explosion

12/15/2018 at 21:42 • 0 commentsFor the 1st time, an ESC blew up from getting wet. All 3 PFETs blew up. They had been flown in rain, flown from wet fields, but never blew up before. Dunking in puddles finally got one wet enough to do the job. Potted it in aquarium sealer. It's not reworkable anymore.

![]()

![]()

![]()

![]()

-

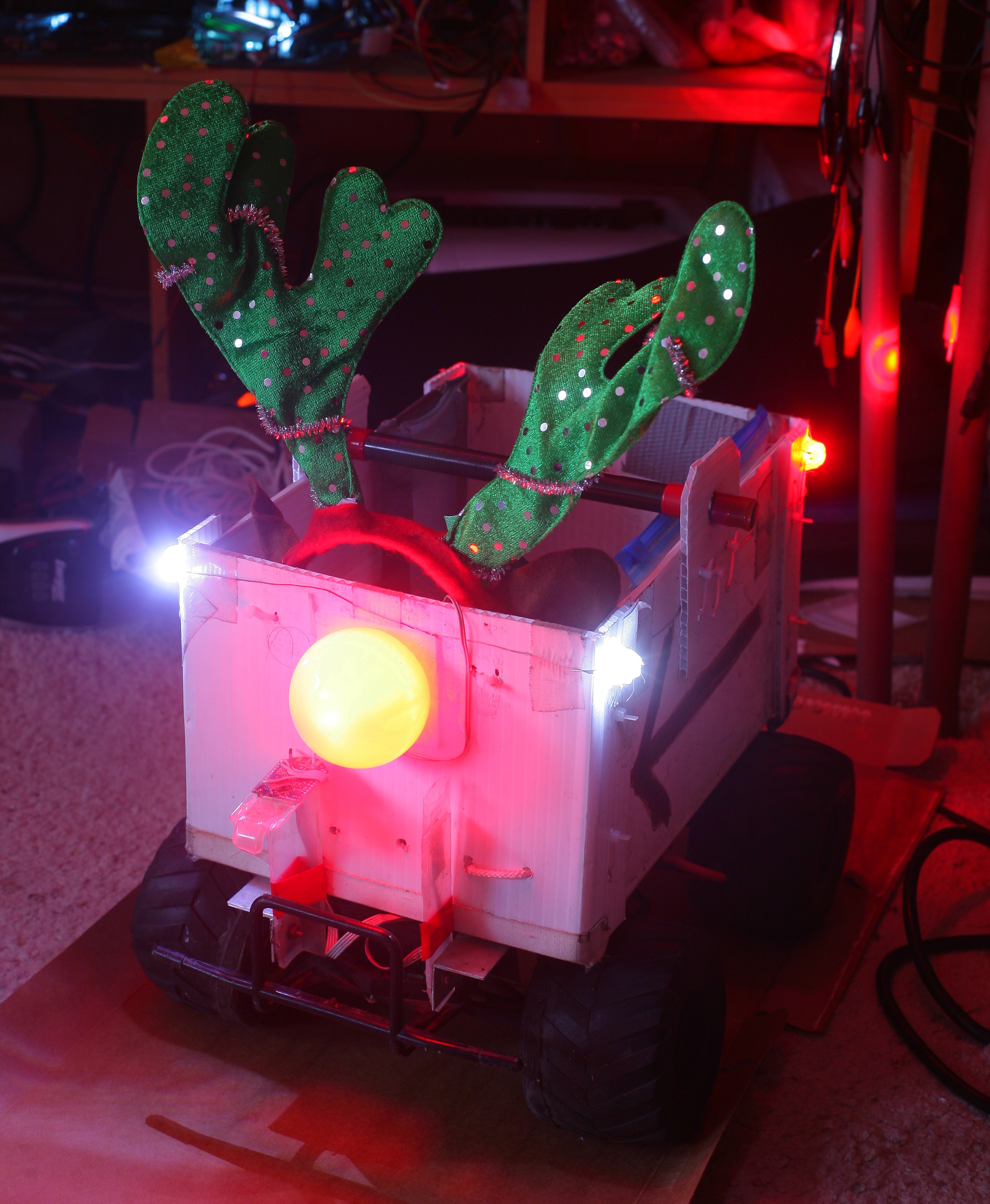

Robo Rudolf

12/15/2018 at 04:36 • 0 comments![]()

![]()

To make the miles more interesting, the decision was made. Originally wanted to discard the ears & just use the antlers, but didn't have the stomach to tear it all apart, despite being $1. The intact antlers are easier to break down. The nose was an LED light bulb with a red LED replacing the white LEDs. The red LED needed a diffusing cover in the form of translucent heat shrink which is no longer made.

lion mclionhead

lion mclionhead

Front wheels are strengthened with shapelock.

Front wheels are strengthened with shapelock.

Battery tray is modified.

Battery tray is modified.

The chassis is ground down, the hardest part of customizing this $150 kit.

The chassis is ground down, the hardest part of customizing this $150 kit.

Wood struts are installed.

Wood struts are installed.