This was too easy. There were no hidden screws, no hidden tabs snapping off, no tricky disassembly order, no blood and no cursing at all, so by definition its more like a take-apart than a teardown.

Please Help! If you can, help me figure out what other projects I could make out of these parts! I will be happy to take more pictures, like of the large caps. I would like to keep it all, but will eventually have to reduce the size :(

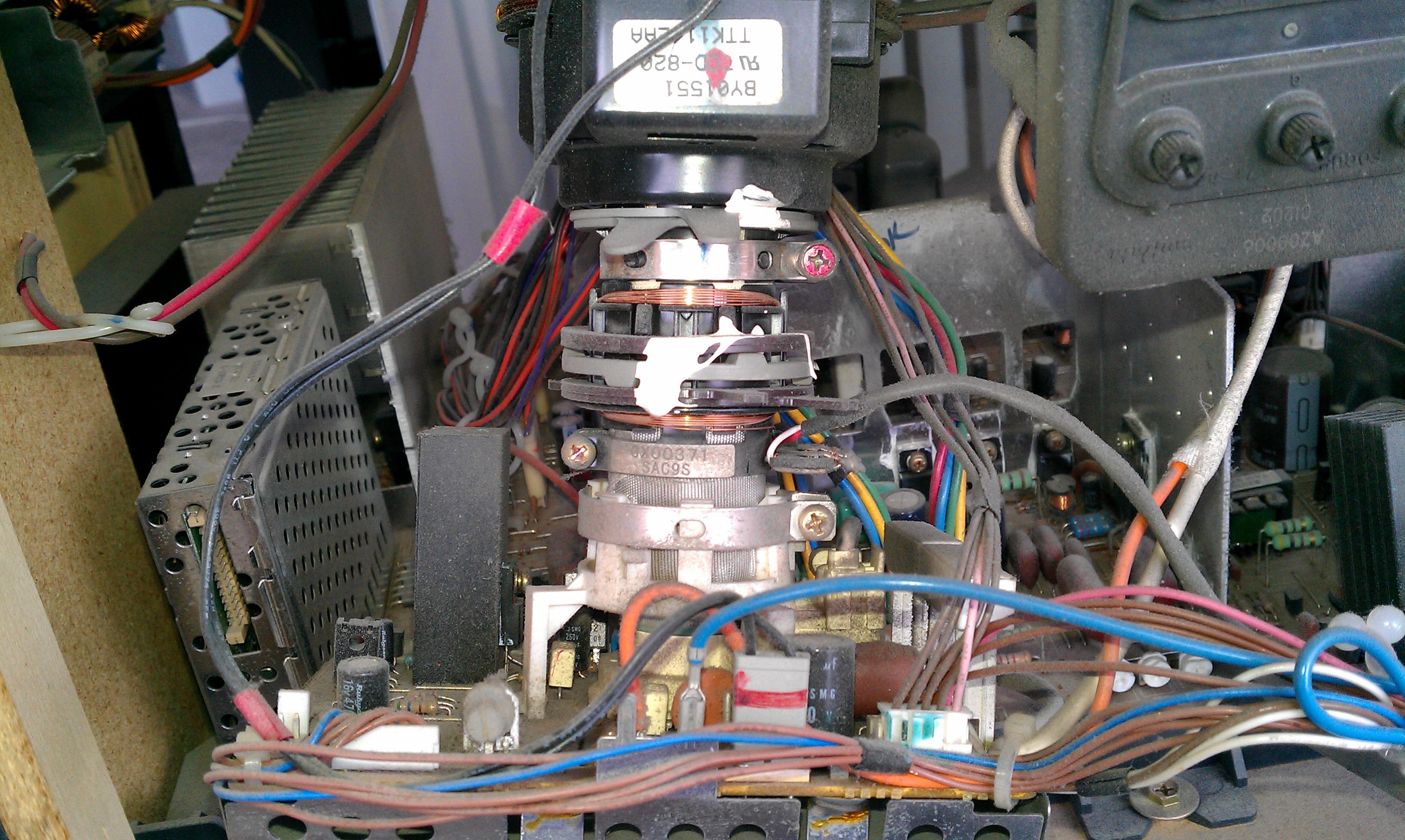

Preliminary Focal Point Information:

- Screen: 43" diagonal, about 34.5" x 26"

About 109cm diagnal, 87cm x 66cm

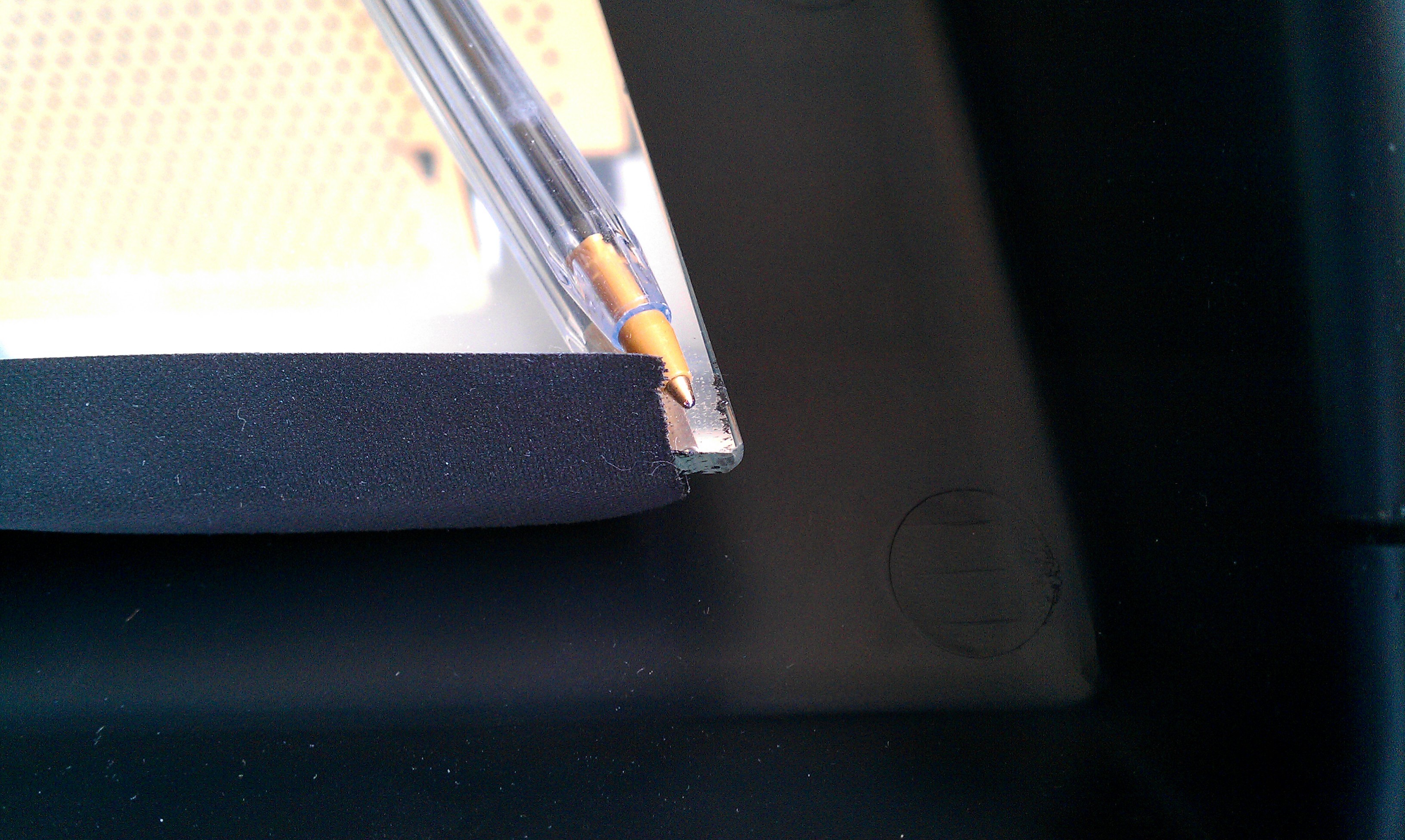

- Focal point 26" from the lens. (66cm)

Closer than I imagined, so smoke on the lens will be a bigger problem.

- Common vertical slit shaped point

About 4" high and 0.5" wide in the middle (about 10x1cm).

I was hoping for a small spot, even though it was a long shot, but this is much better than an unfocused blob some get.

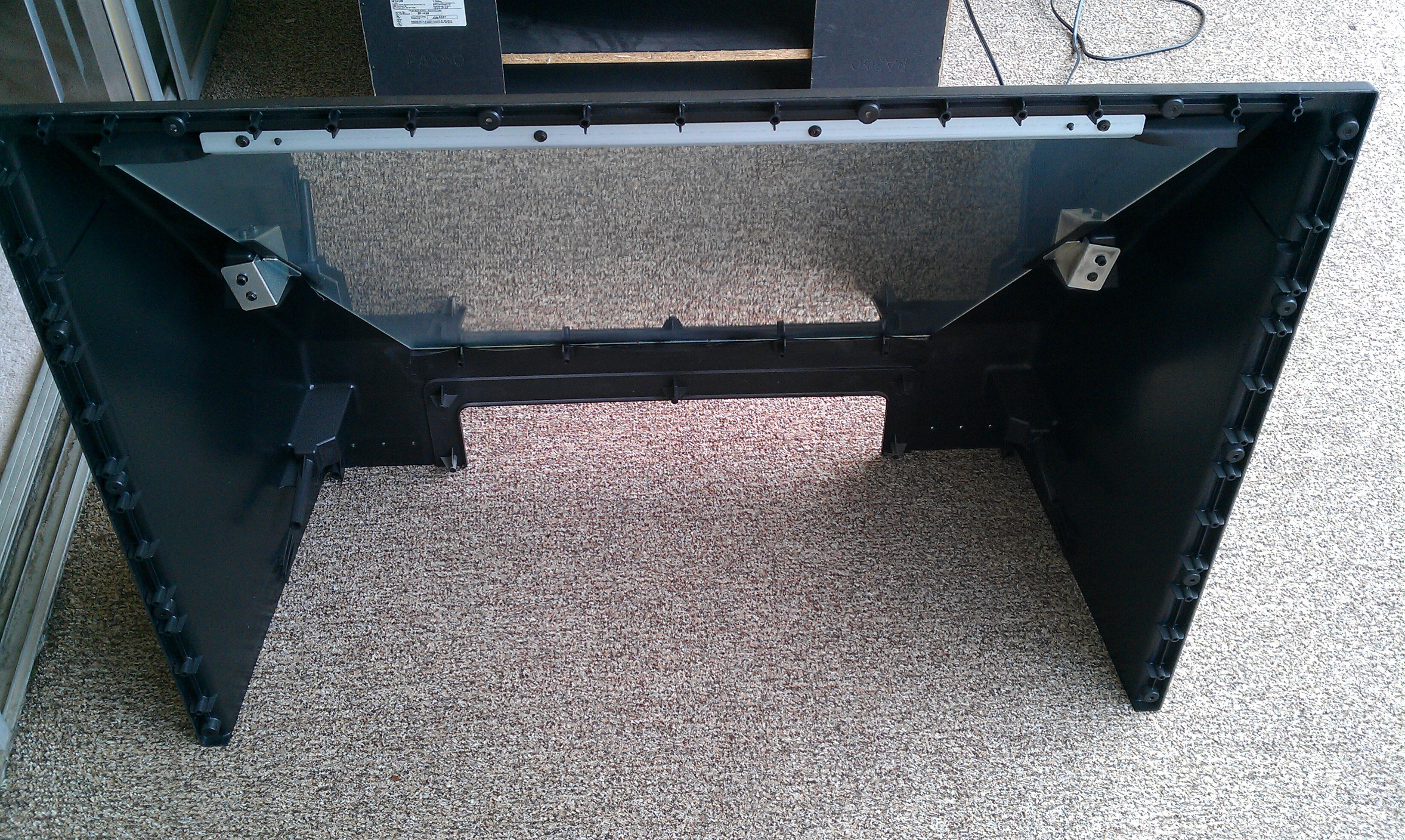

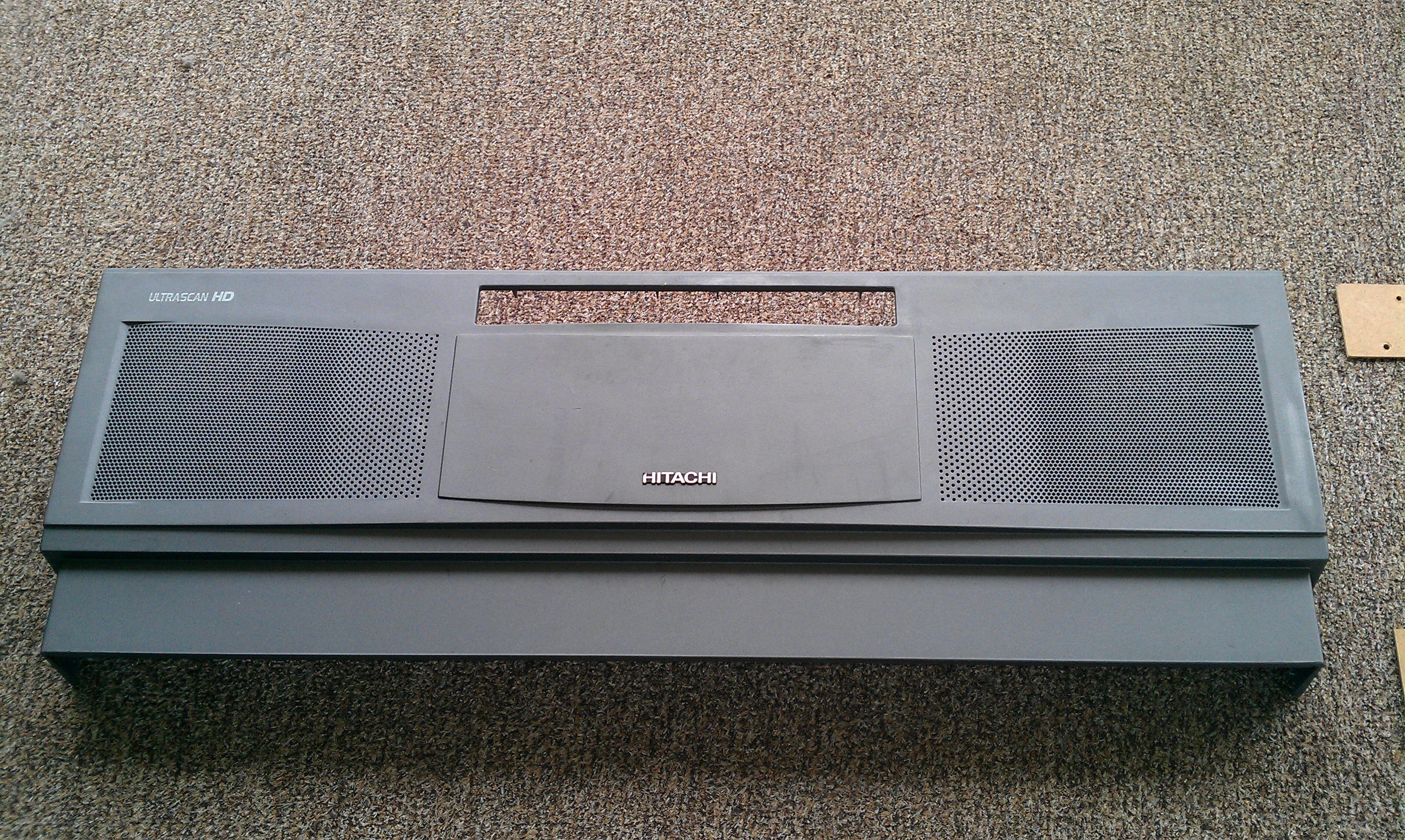

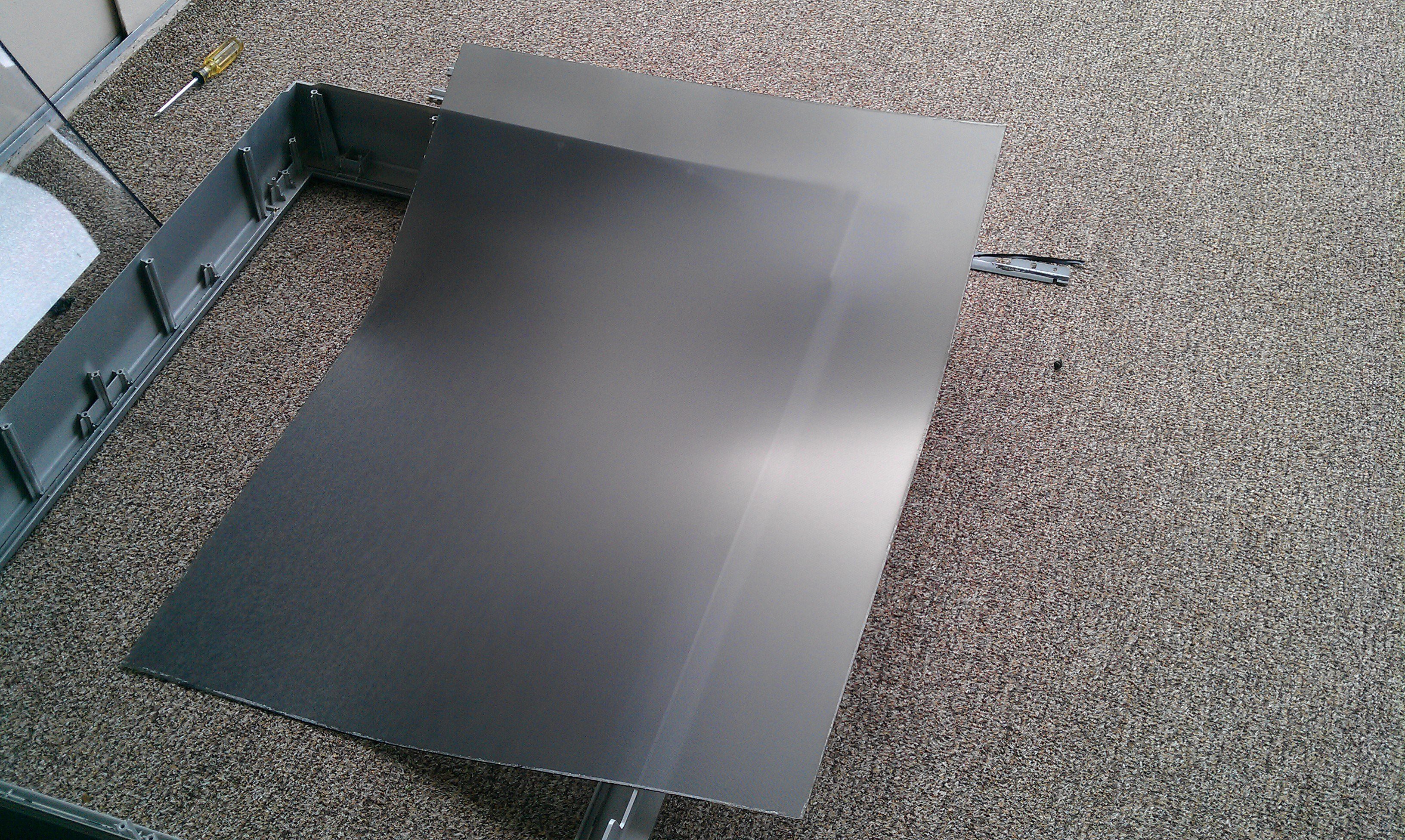

Lets start with the back.

The front screen lens assembly is held on inside by four metal bars screwed into the front plastic frame.

Flash lens reflection.

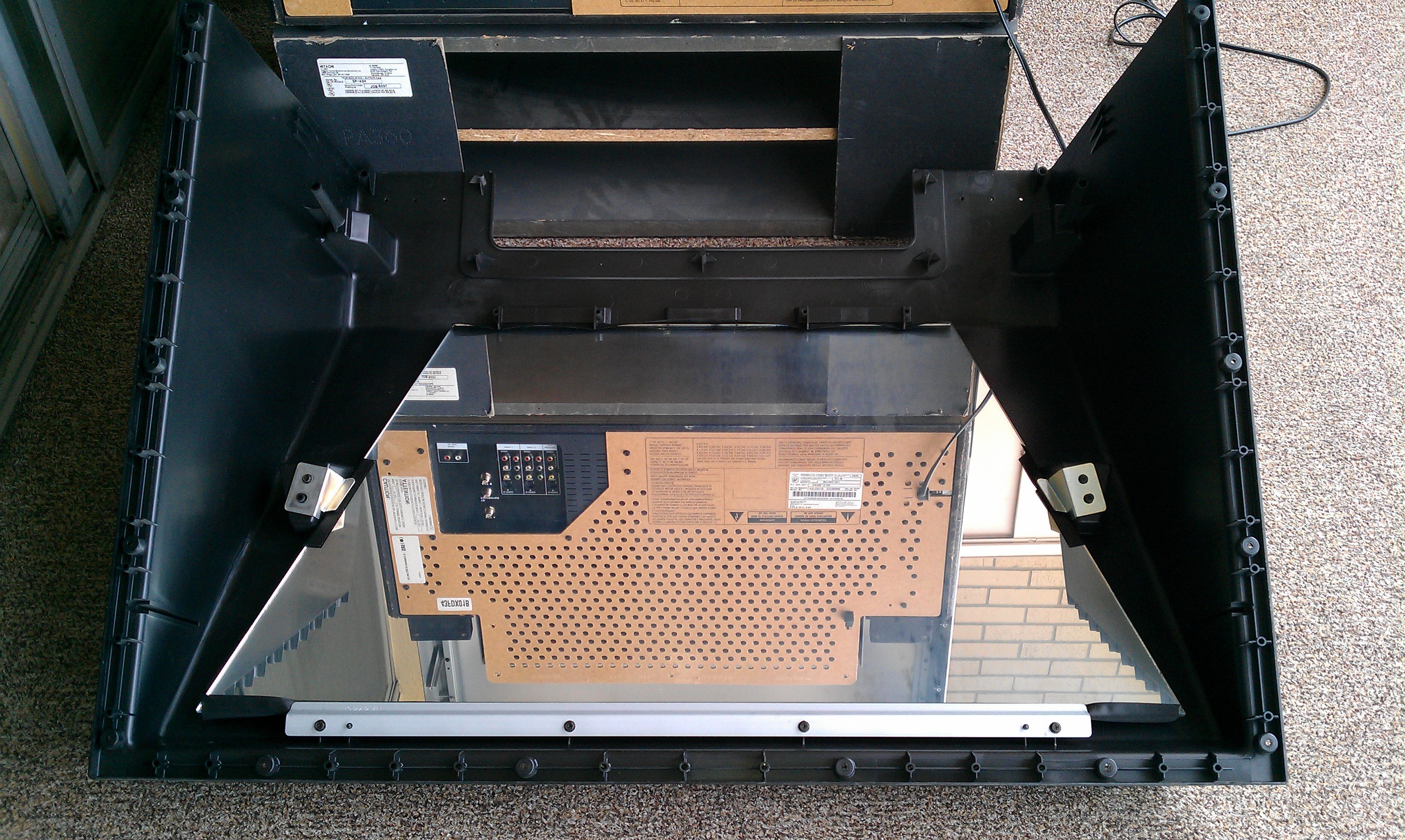

Back cover mirror.

Very trapezoidal.

The mirror is nice and thick, but the backing is a thin coating. You can see a little flaking at the edge, but you cant see the hazy streaks from age in these pictures.

Someone spilled coffee in from the front (we are calling it coffee).

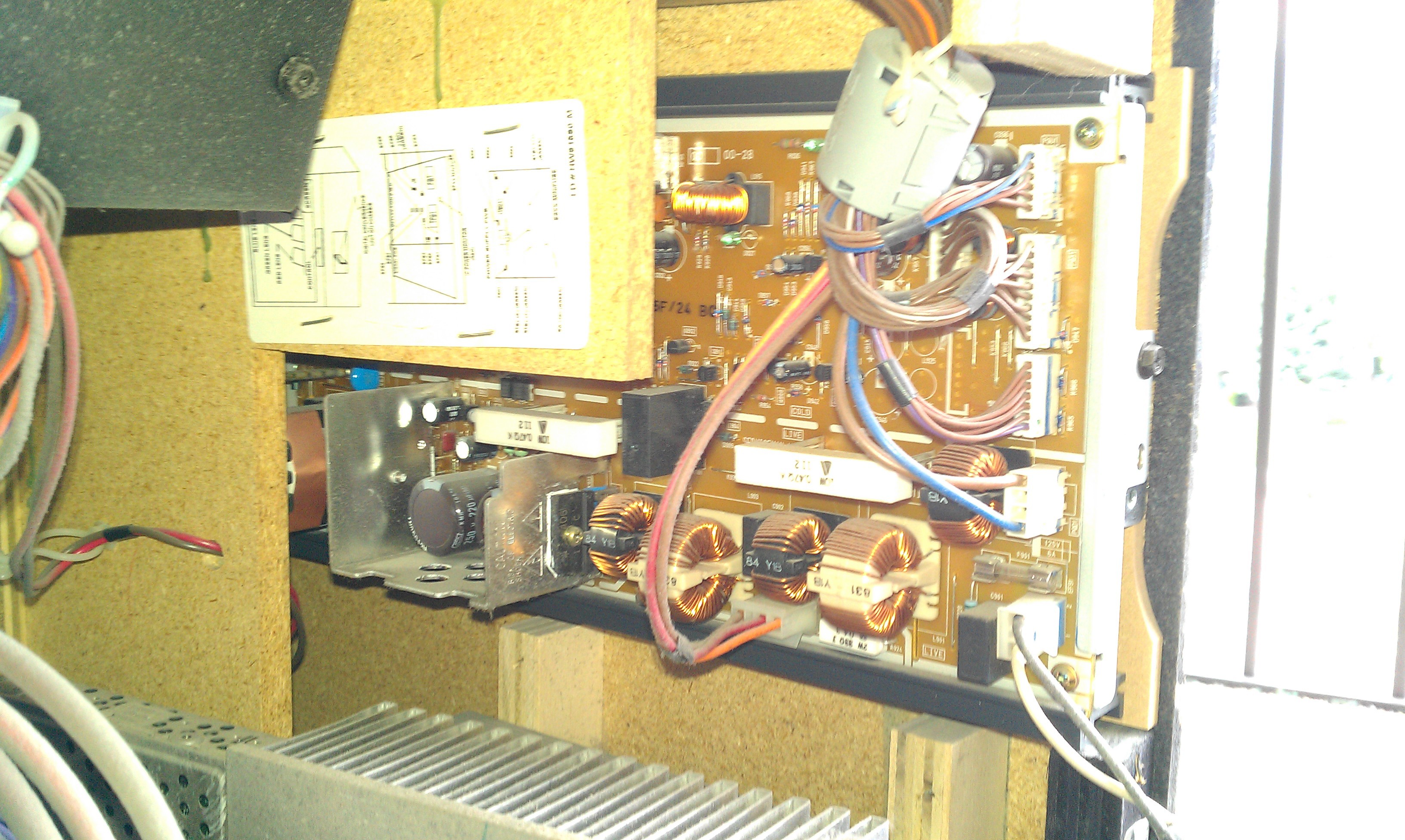

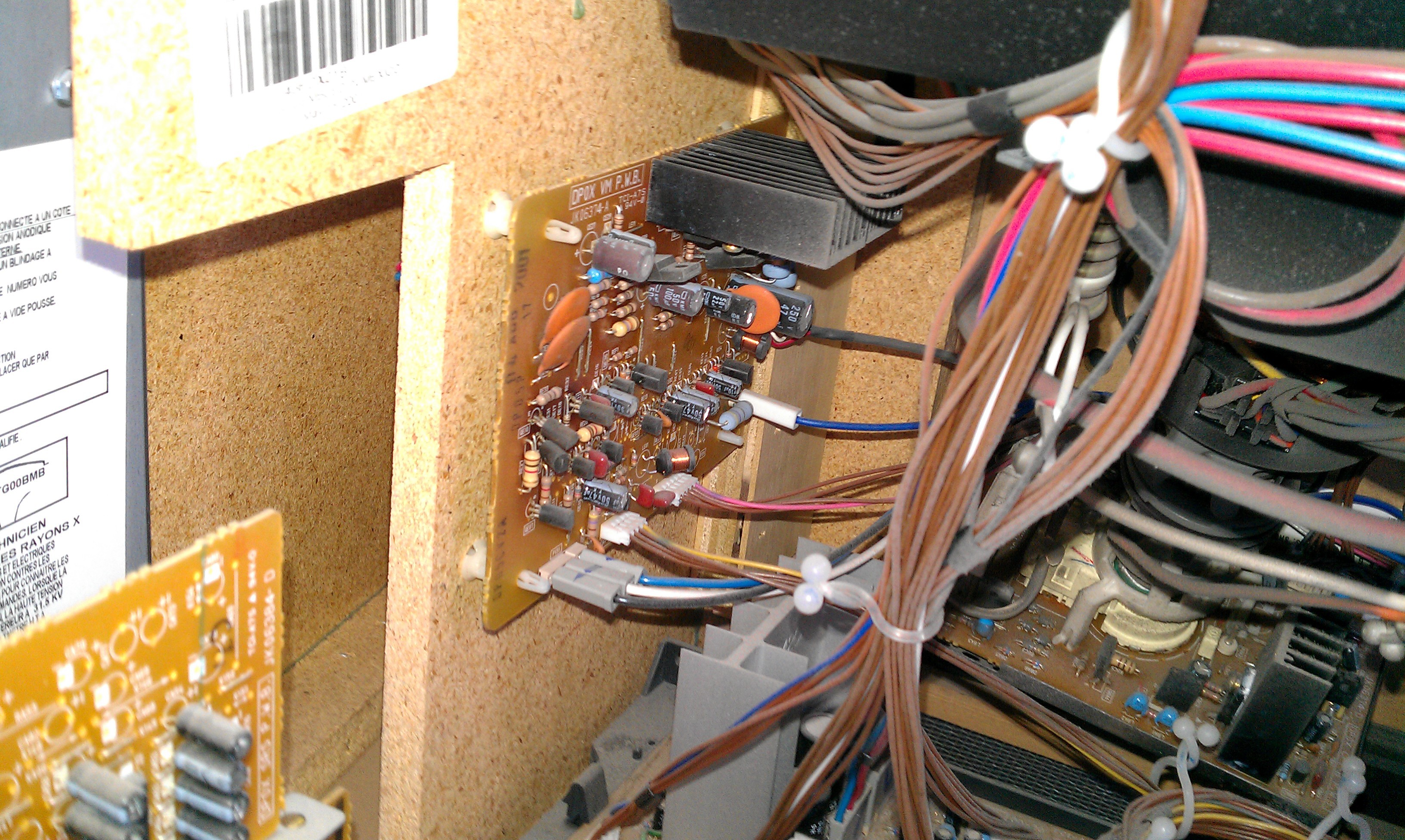

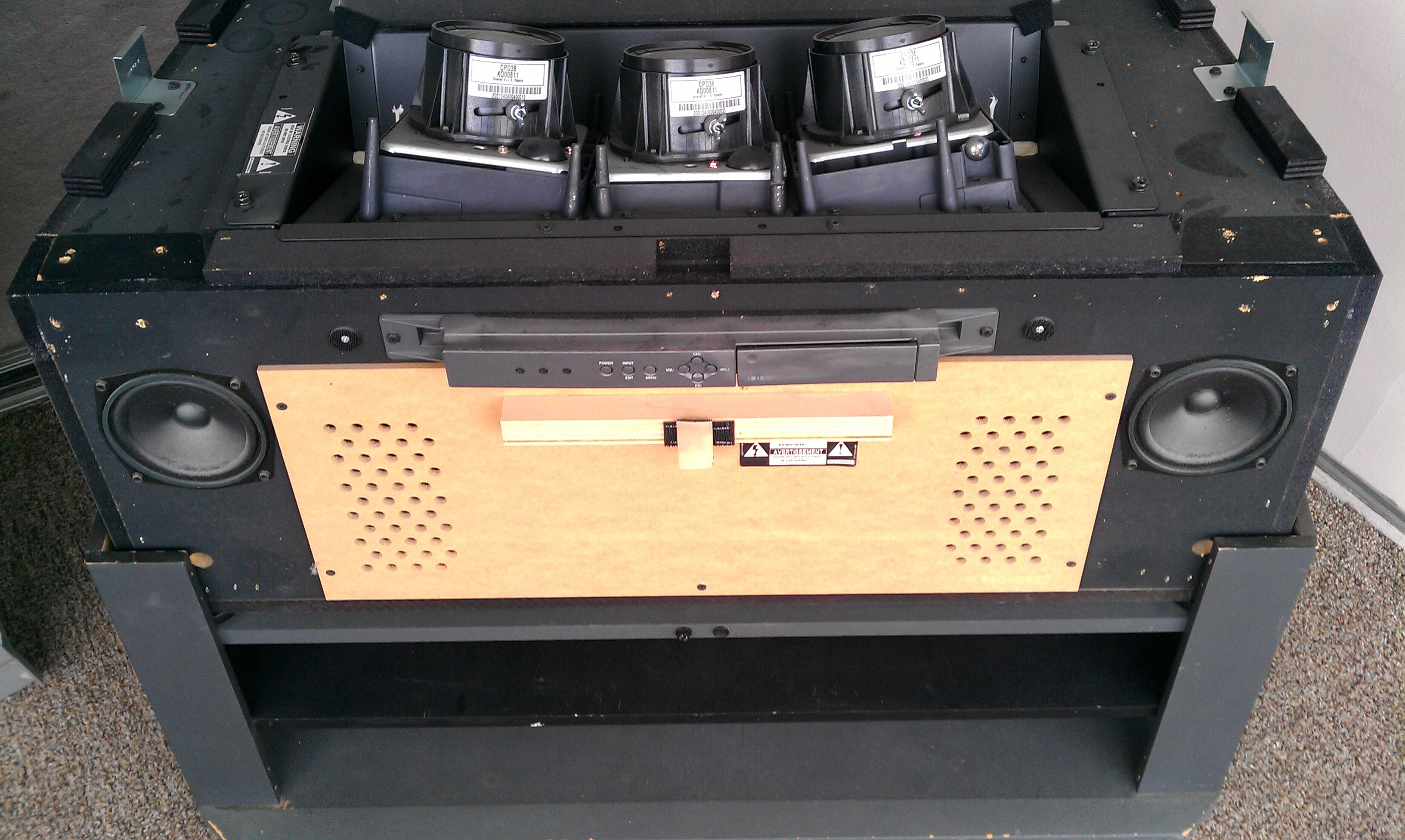

Most people would imagine a high tech inside, but most of the craftsmanship in this thing is in the woodworking!

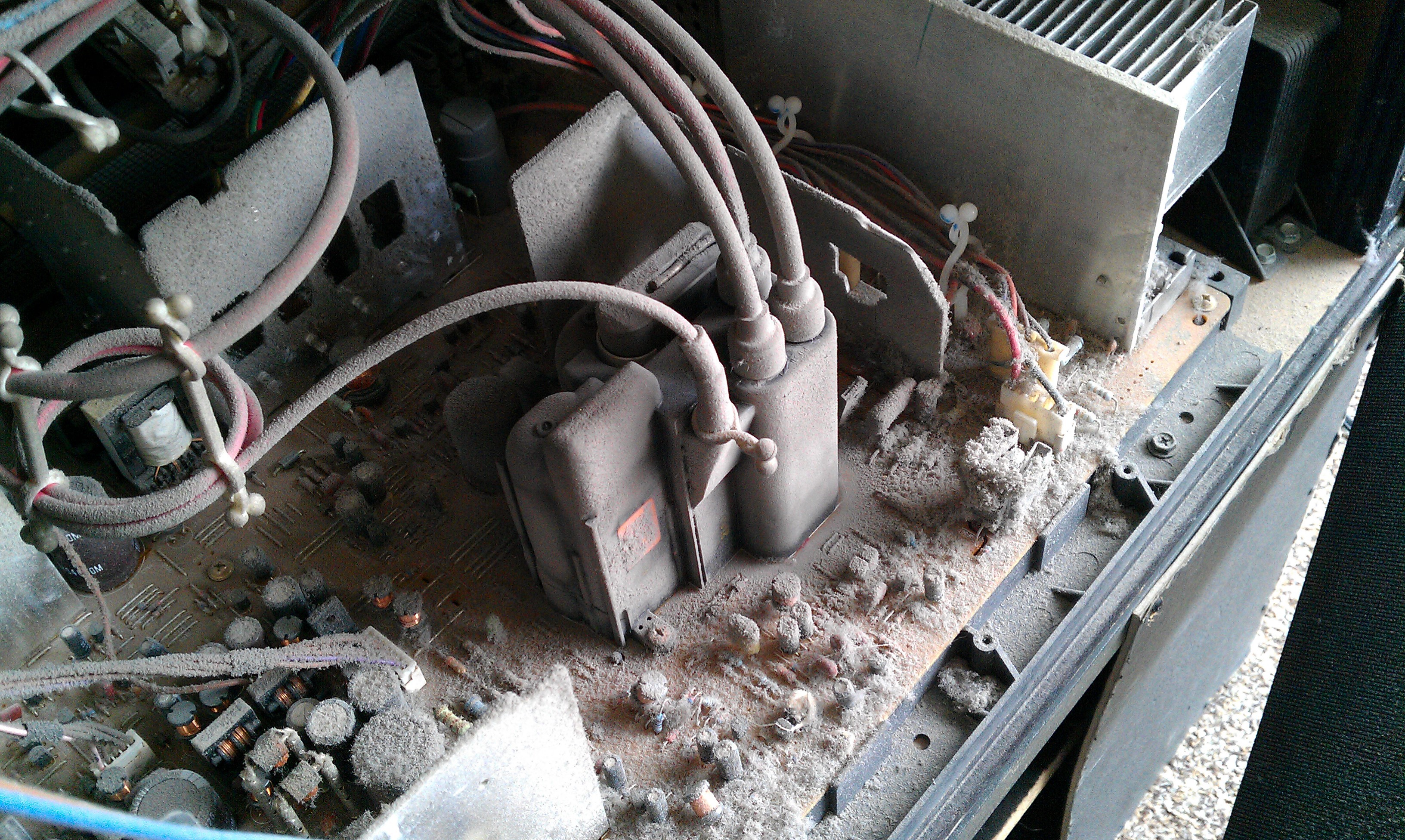

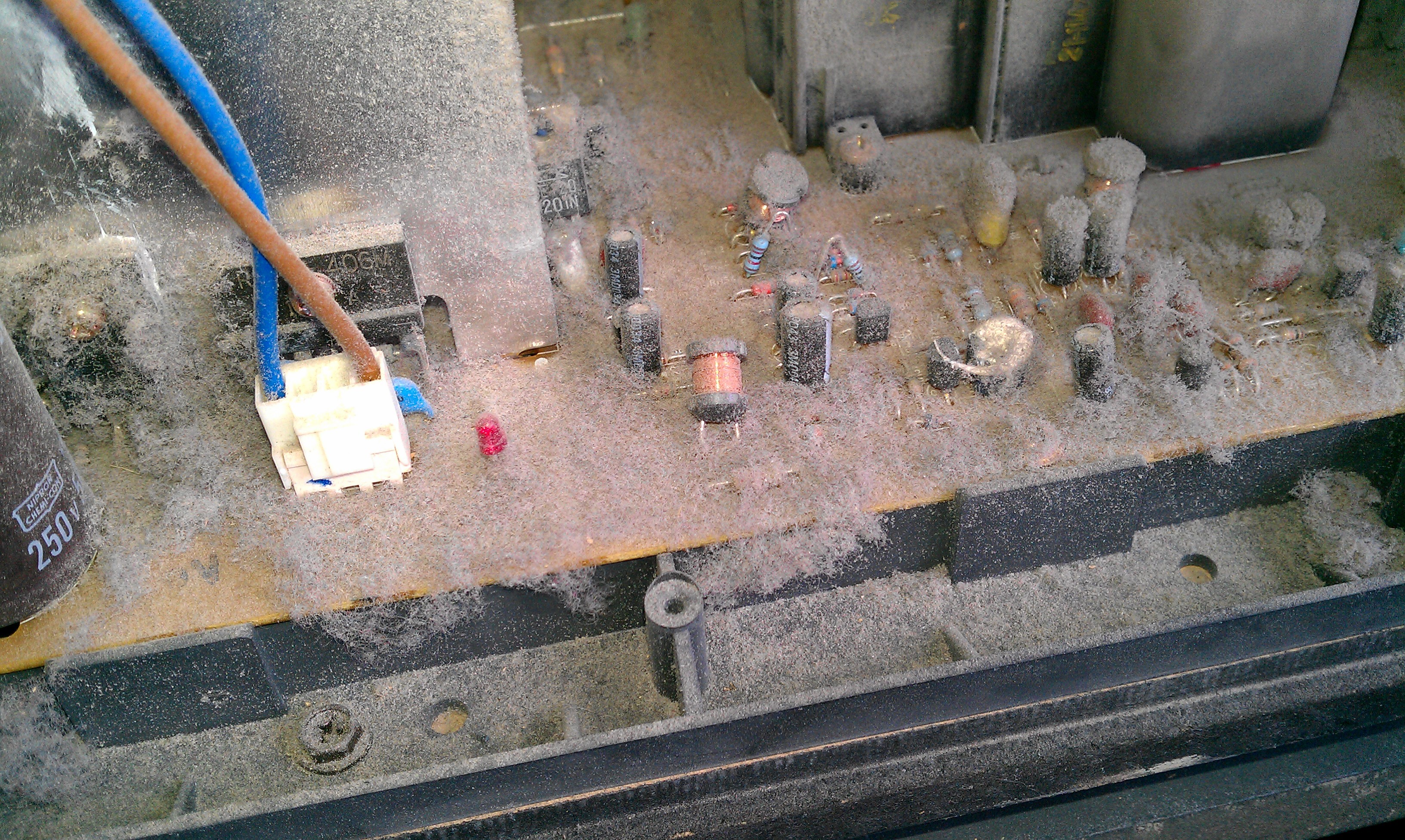

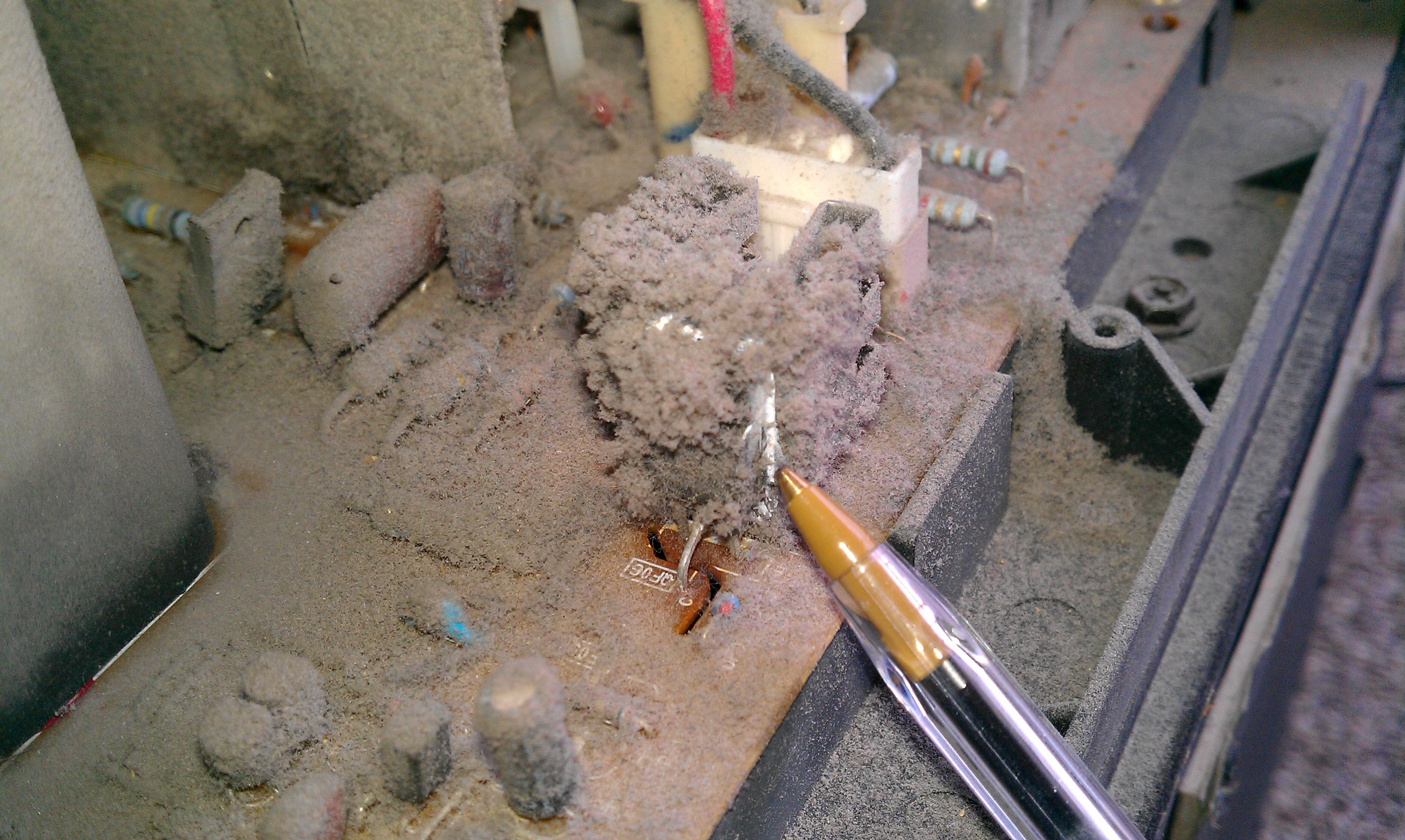

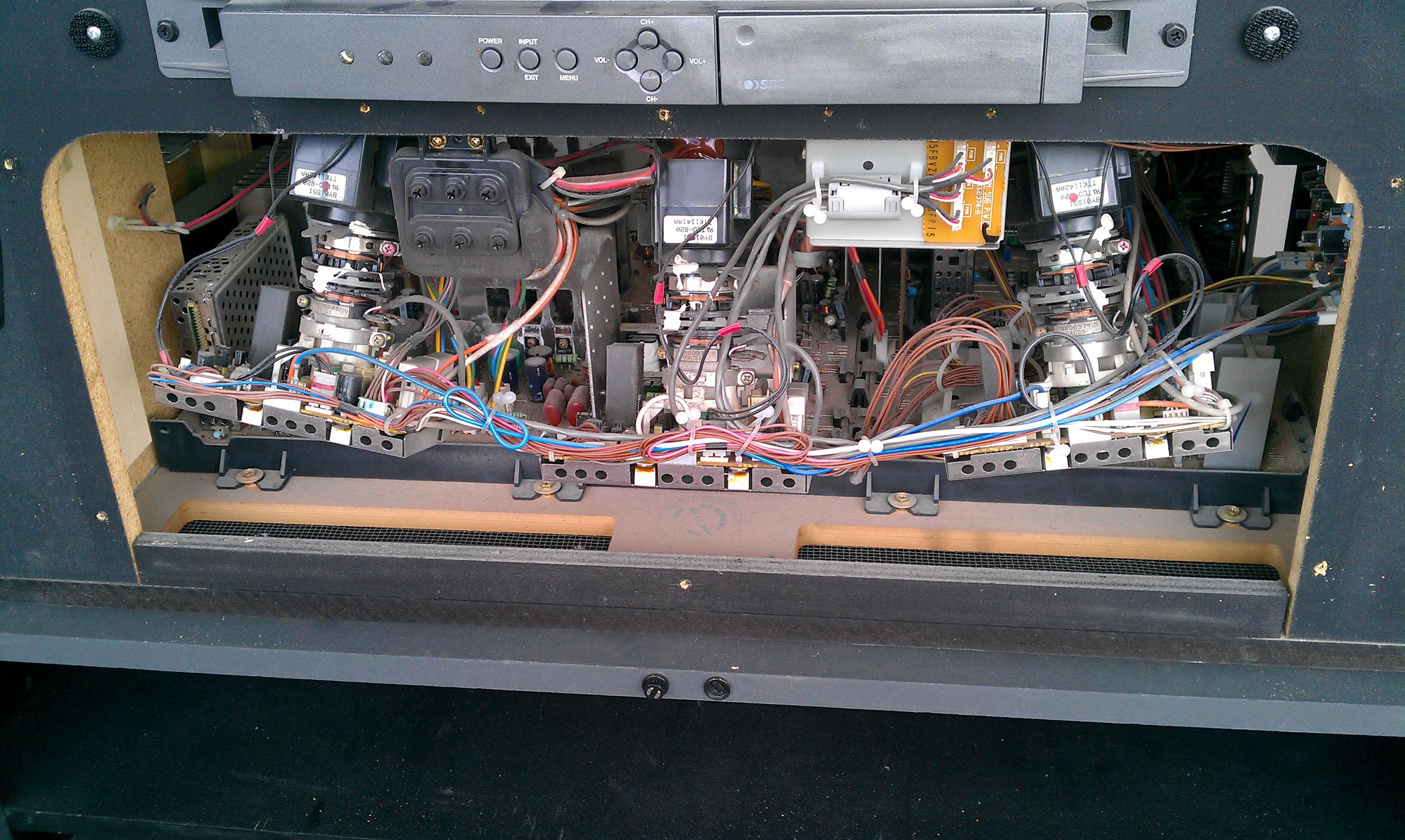

100 years worth of dust. I'm sure glad I always remember to teardown outside. I only found one dead bug.

Make that 200 years worth.

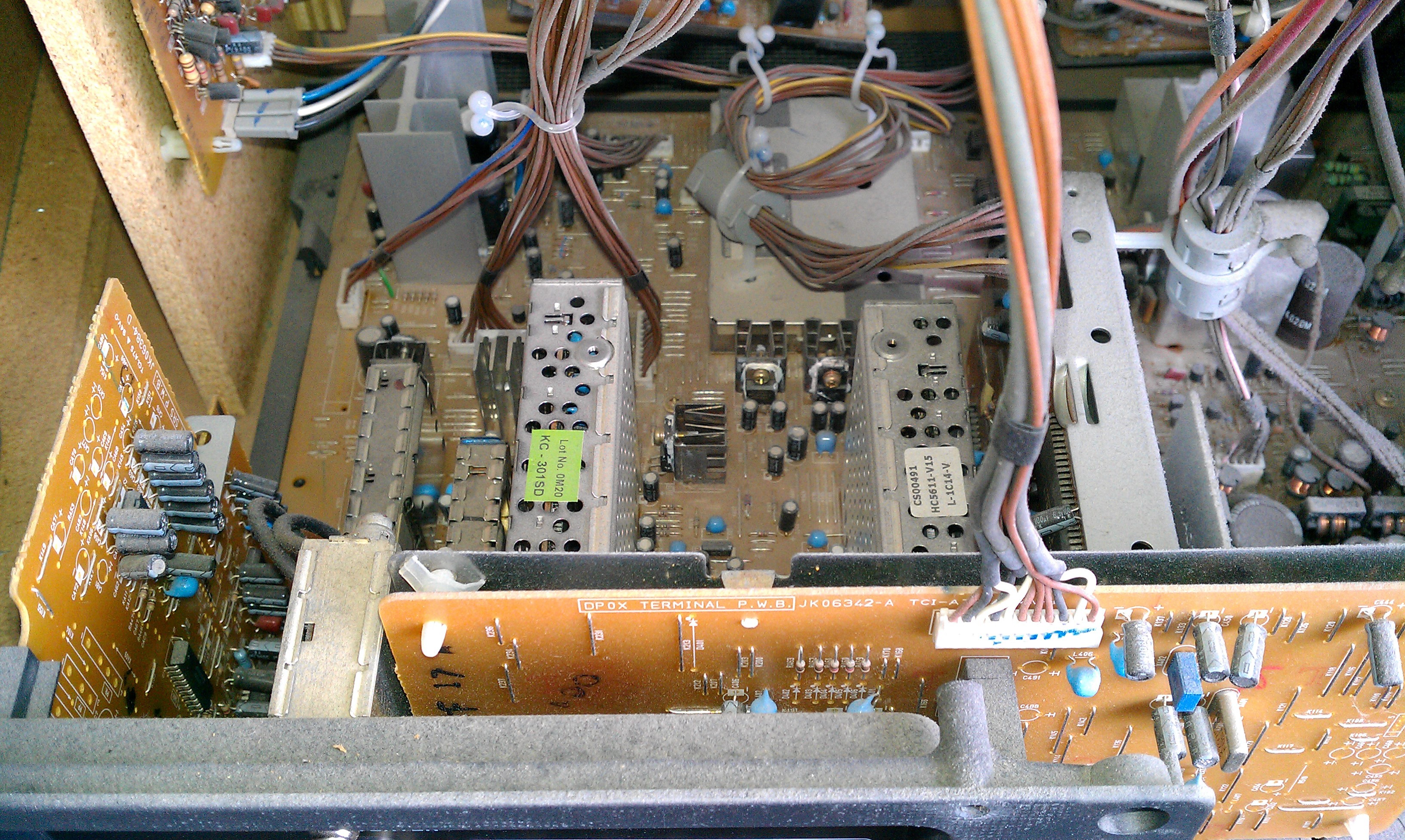

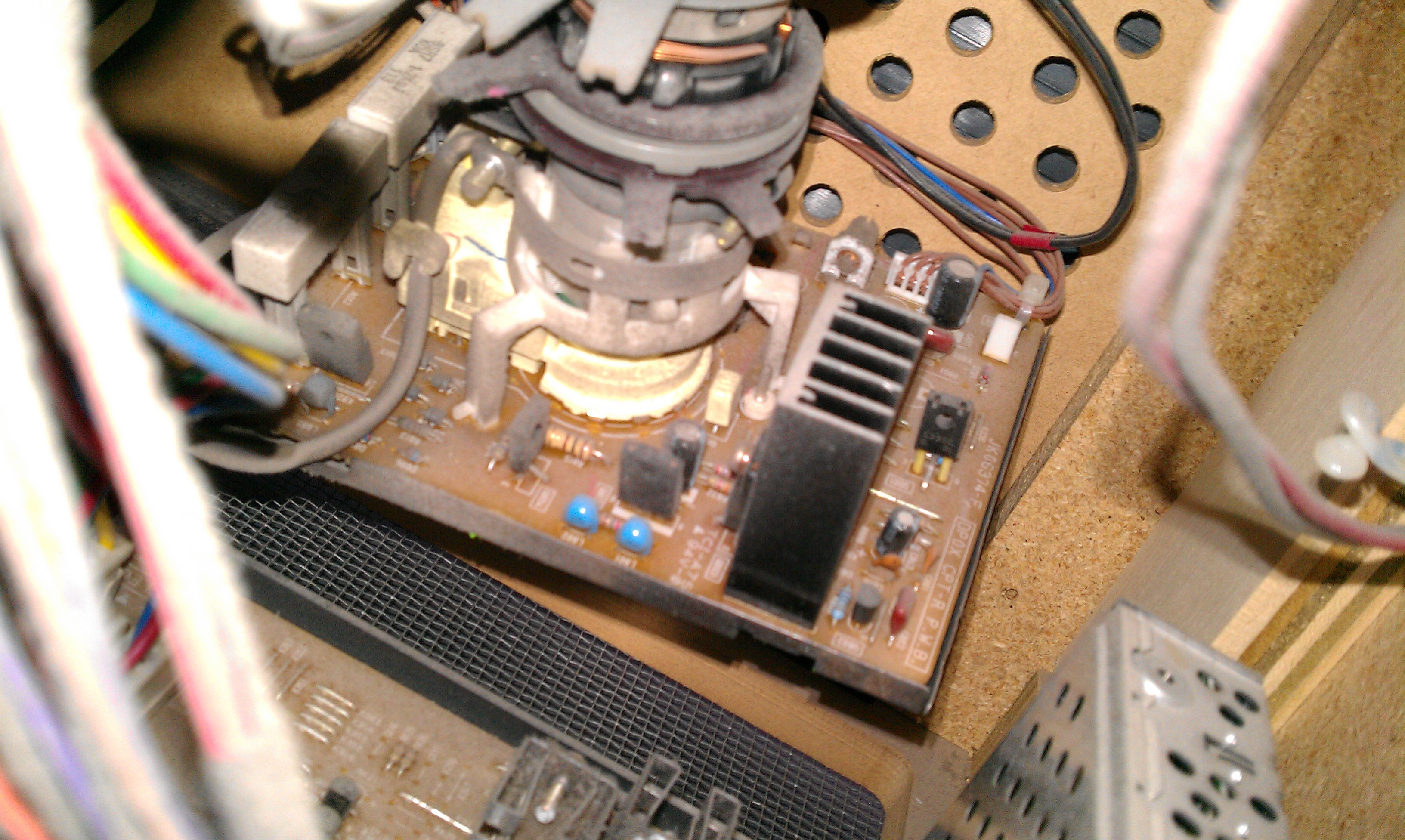

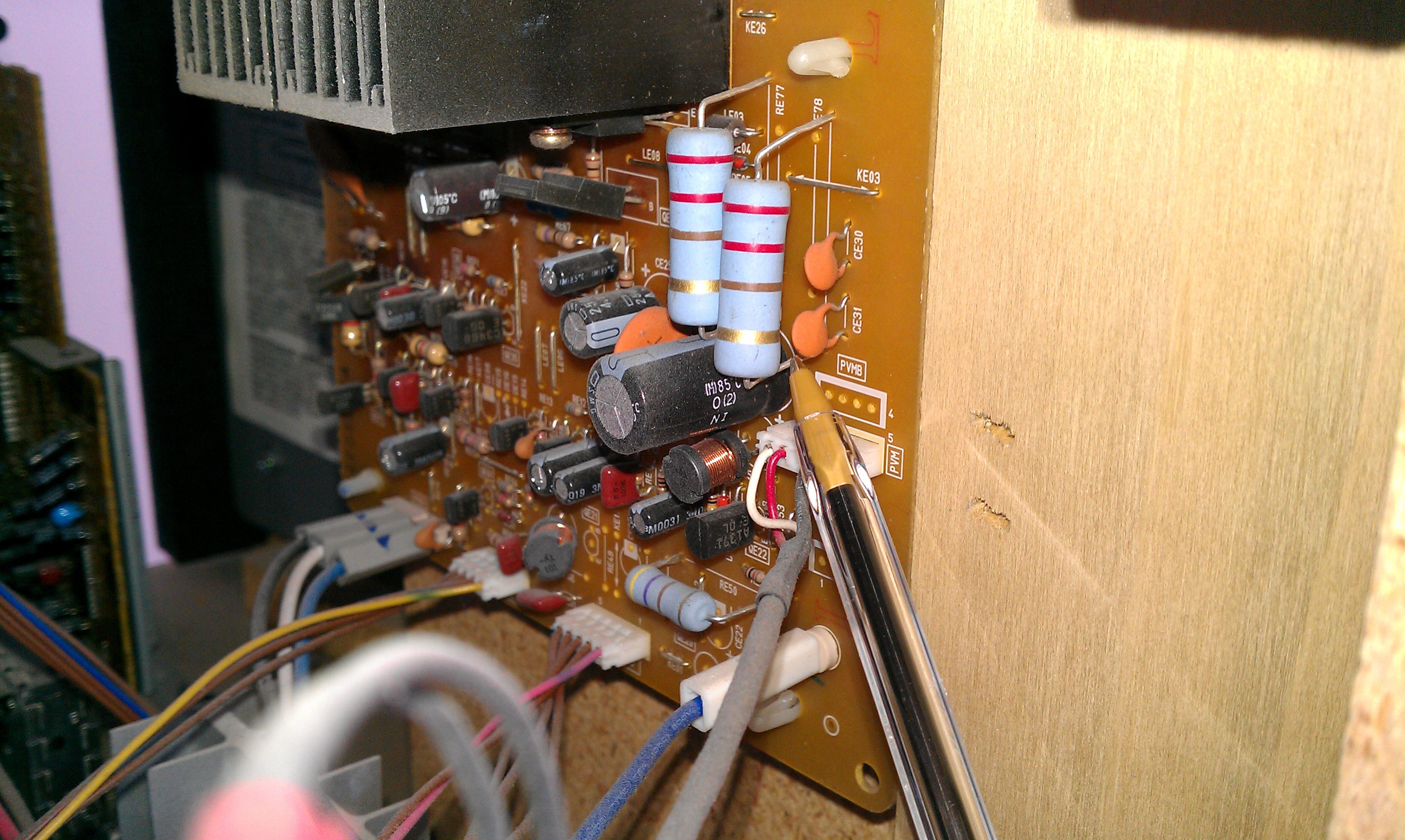

Lots of shielded boxes all over.

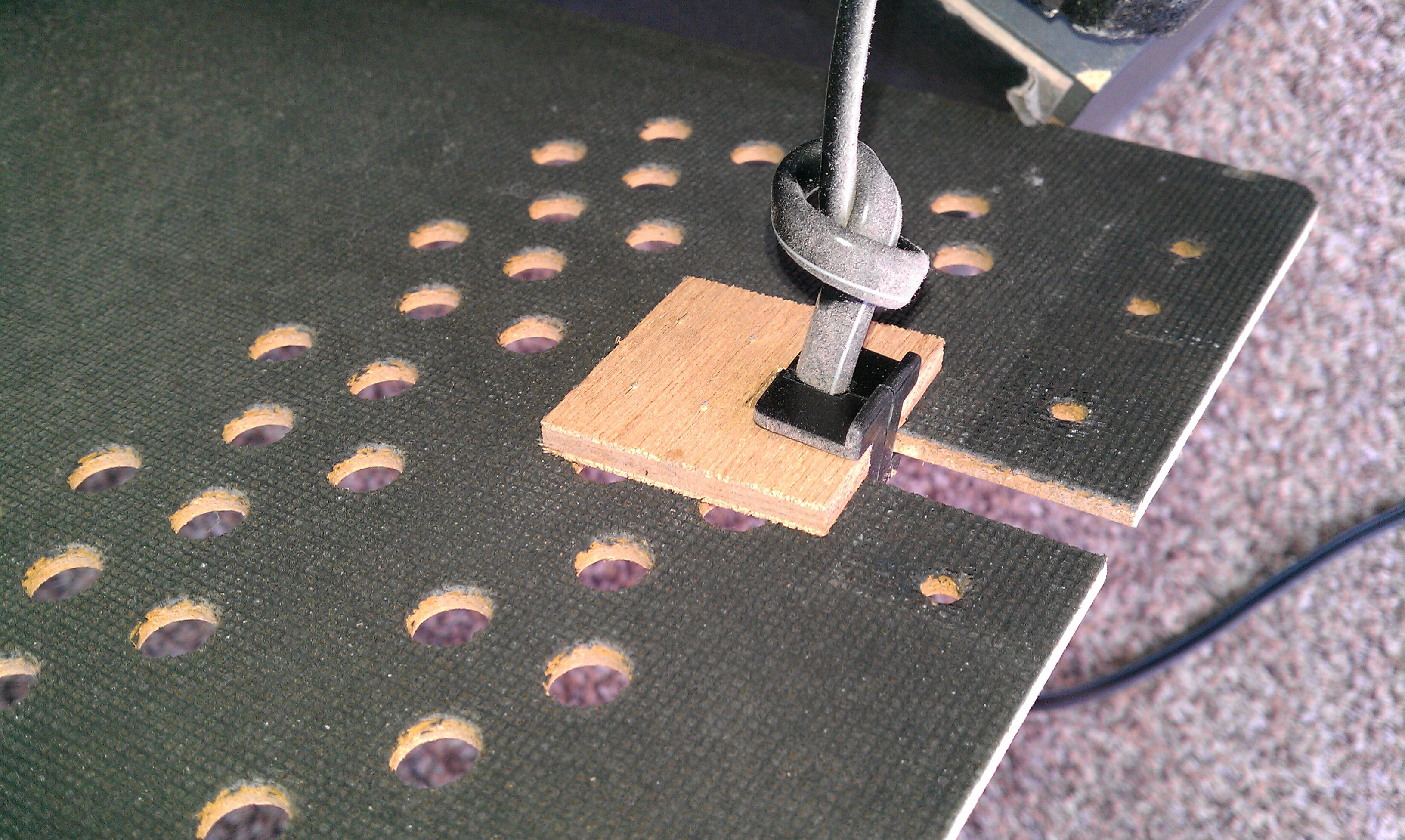

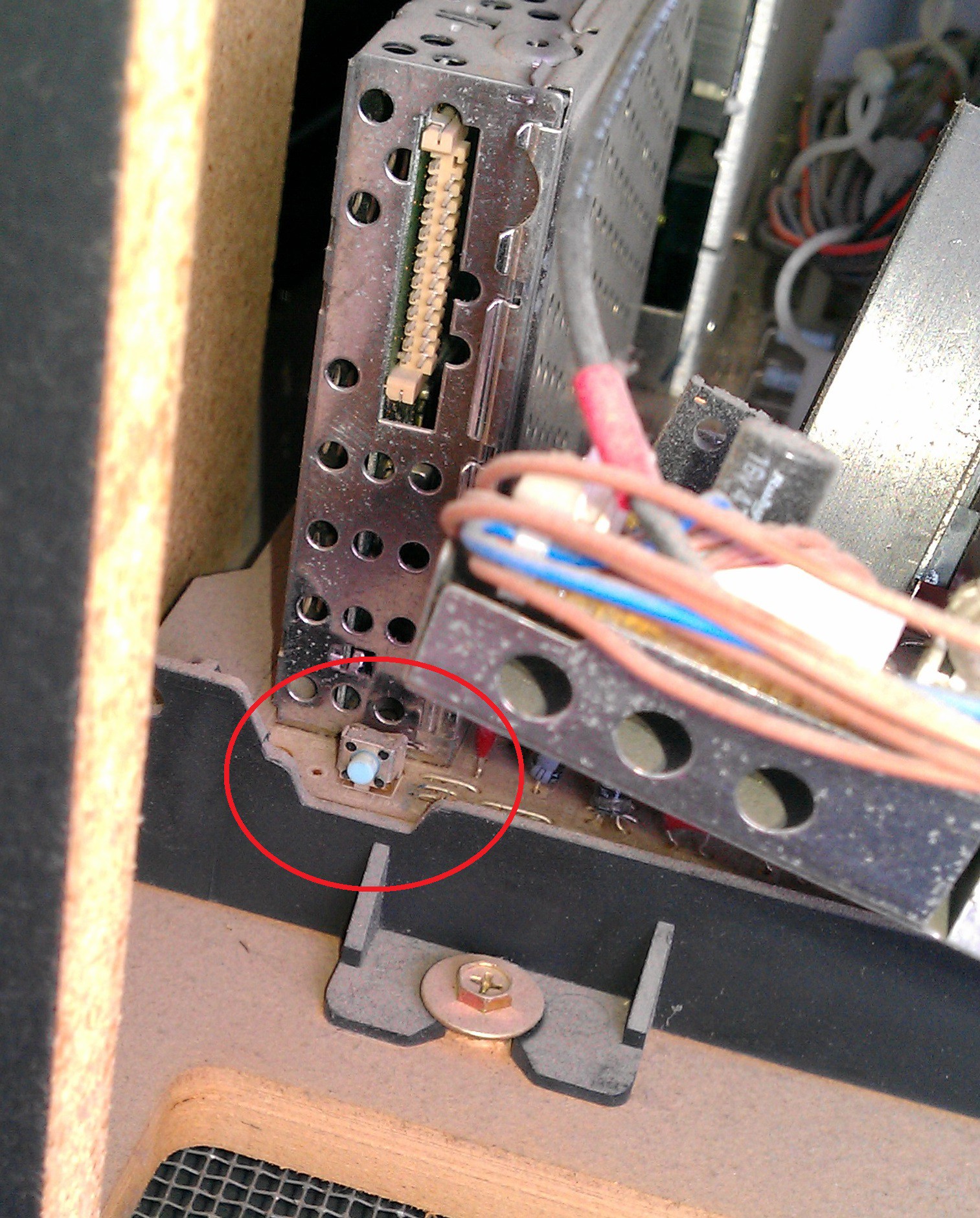

Original handmade wood strain relief.

Engineer 2: "Don't worry. It will hold for 30 years."

Yep, it still held for 30 years. Unfortunately the velcro glue backing specs had to be lowered for cost...

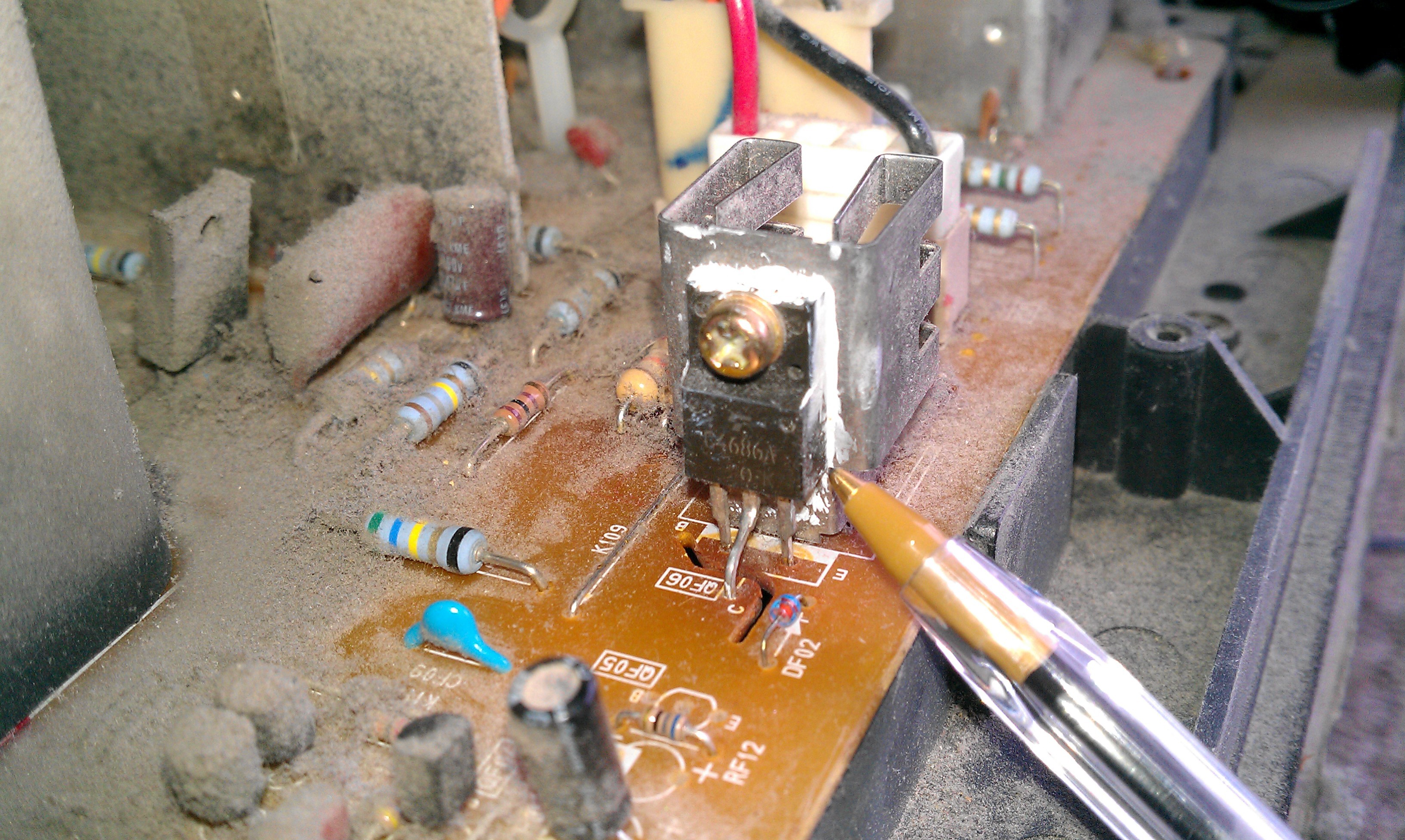

I finally found the reset button! Its right below that 90,000V line in the foreground. How convenient.

The focus test (26") was quickly disrupted by rain and a quick clean up before the wife comes home to a mess and kills me. It only focuses in direct light, so weather permitting, maybe I can get some pictures of the focused slit tomorrow.

frankstripod

frankstripod

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hmm, If you don't have one, get a desoldering Iron from ebay like this one http://www.ebay.com/itm/30W-desoldering-iron-electronic-pump-sucker-removal-soldering-welding-solder-/111669941651?pt=LH_DefaultDomain_71&hash=item1a000c1593 they are cheap, but you can get some of those caps and other parts off the boards, that might interest you. I don't think you'd get something useful out of it in one piece/board anyway. Just search ebay on worldwide for desoldering iron and sort by price+shipping and "buy it now". (if it's not helpful for you, it might be for someone else reading this :) )

Thanks for converting to metrical by the way :)

Are you sure? yes | no

Thanks Dave! Getting the parts off won't be a problem for me. I was really hoping for project ideas for some of the more odd parts, With all

those caps and coils I think there might be a coilgun hack in there, but I am not interested in projectiles and high voltage right now, I don't have the space.

Nice link! I have used plunger style removers before, but never seen it w/ the iron built in. I am hoping to save up for a desoldering station with a pump (don't get me started on awish list,) but until then I prefer to put what little money I have into having fun with projects for now.

(I wish the US would switch to metric.)

Are you sure? yes | no

I'm on an EEVblog marathon and Dave Jones is ringing in my ears, spending proper money on proper tools :D Makes sense to put a desoldering station with a pump to your wishlist, when you'd use it quite often or being serious about fixing stuff etc. - there actually is an episode about those machines. I had no "handy mechanical pump syringe thingy" and saw this thing somewhere else. Totally worth it's 15 bugs for desoldering caps, resistors and DIP stuff from salvaged boards. Hm, or is it? You could compare it to those 10 bugs sandwich makers where you know they'll break sooner or later. I'm crossing off made sandwiches to have a "cents spend per sandwich" statistic :D So far I've freed just some chips and caps - might not have yet reached it's value in parts.

Are you sure? yes | no

Ha! "cents per sandwich".

I saw the EEVblog on proper tools. It was great! I should watch more of those. I will need a marathon also :)

Are you sure? yes | no