-

16th August - Further work

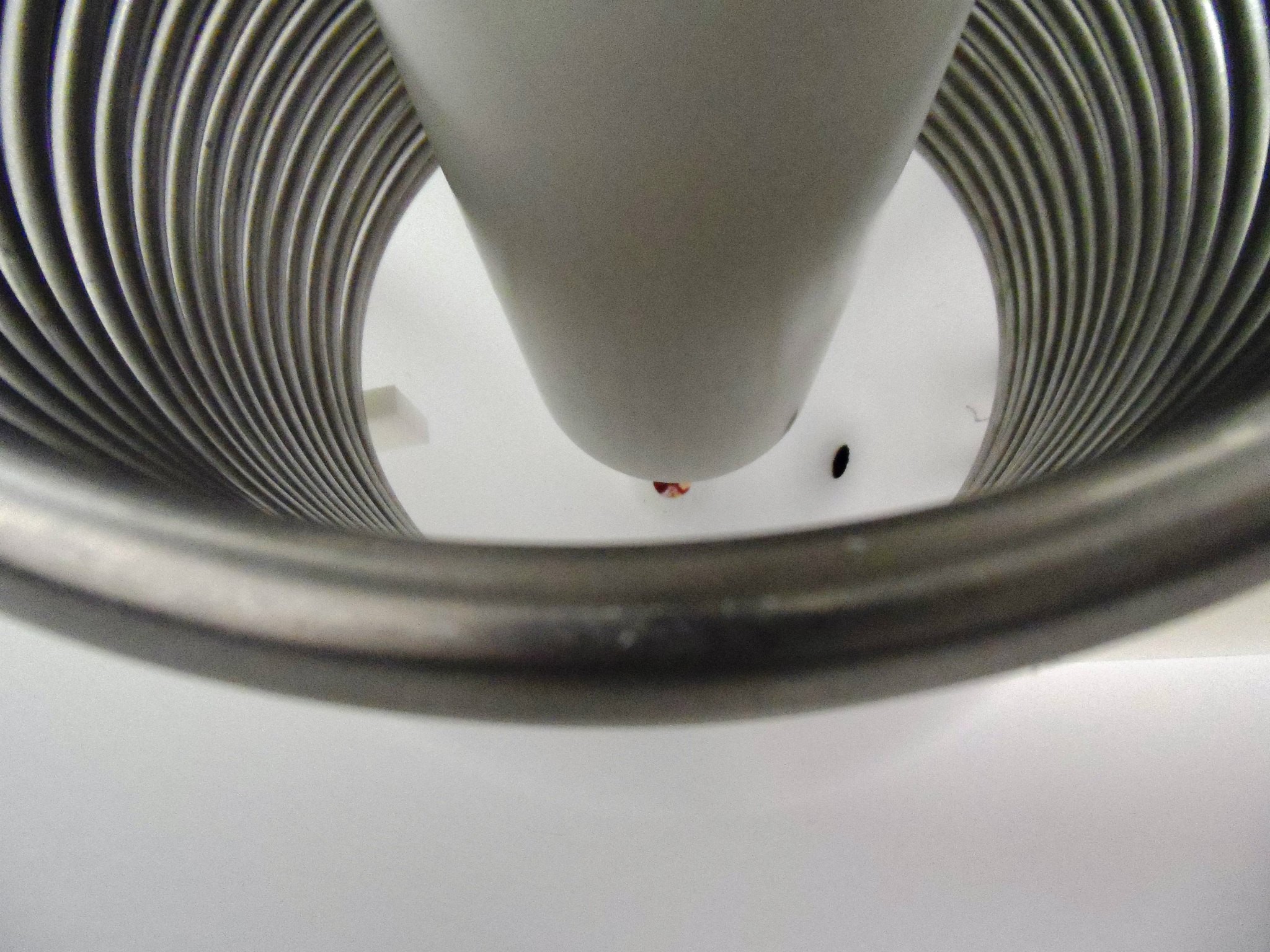

08/16/2015 at 10:58 • 0 commentsI'm quite sure there could be many improvements in the condensation side, but it's a prototype that works with a mixture of hacked off-the-shelf parts. Its all about using a 0 to 200W DC supply that is highly variable (solar) and storing coolant to use at a better time of the day. The filter is both for particulates and to drop air pressure suddenly inside the vessel forcing moisture out of the air coming in.

The design also crudely creates turbulence (vortex) around the condenser coil, this could do with some work. Other areas of improvement include: Insulating the vessel and a smaller condenser coil as the liquid coolant heats back up to room temperature quickly ~4-6 hours. The vessel design could be improved to increase the time air is around the condenser coil. The coolant storage tank could also be larger and also have better insulation.

-

16th August - Basic elements of water harvester.

08/16/2015 at 02:52 • 0 commentsThis is a rough prototype, but it basically works. Now to work on the control electronics and software. I'm quite sure there could be many improvements in the condensation side, but it's a prototype that works with a mixture of hacked off-the-shelf parts. Its all about using a 0 to 200W DC supply that is highly variable (solar) and storing coolant to use at a better time of the day. The filter is both for particulates and to drop air pressure suddenly inside the vessel forcing moisture out of the air coming in.

-

August 15th 2015 - Improved liquid cooling

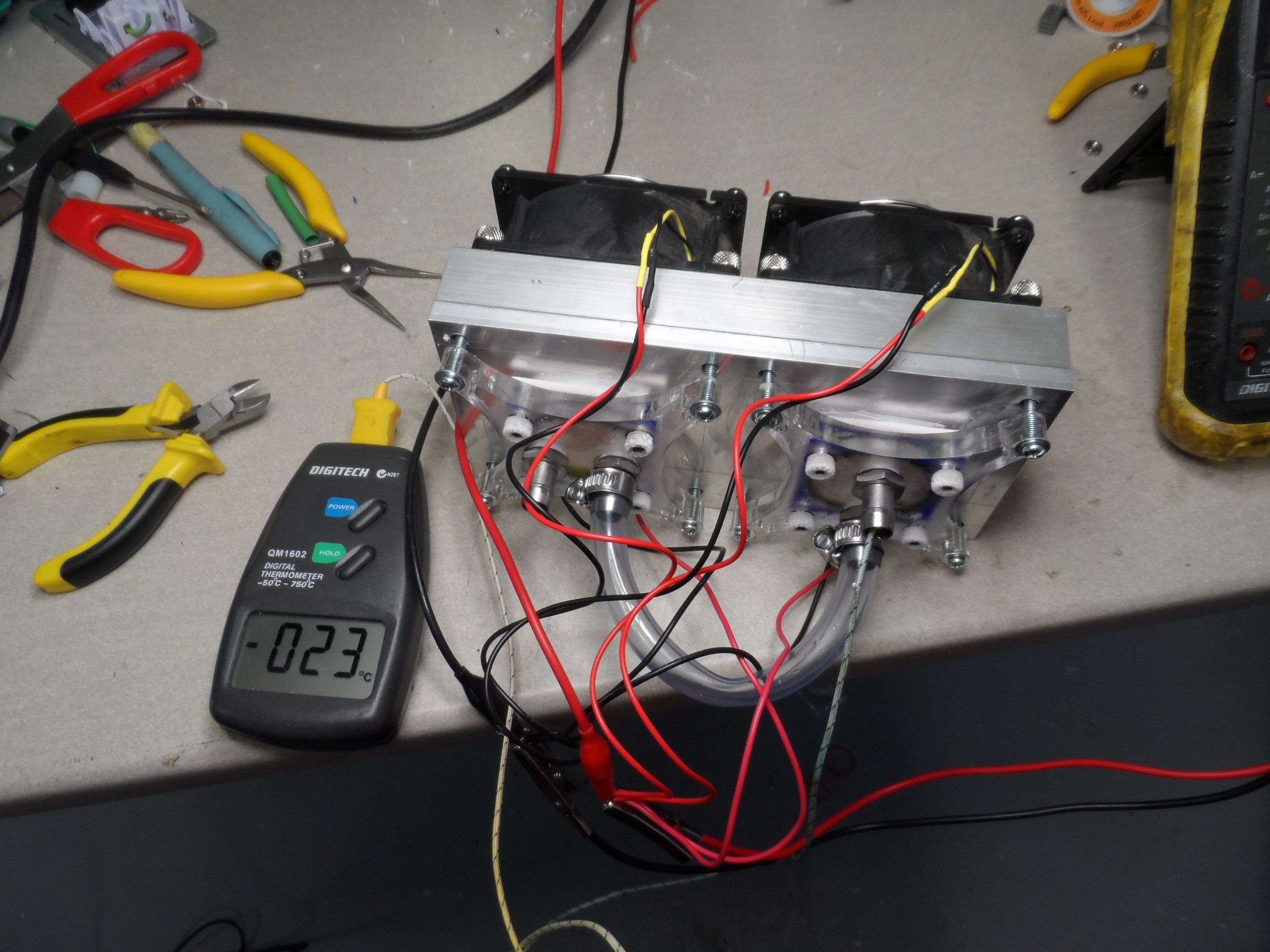

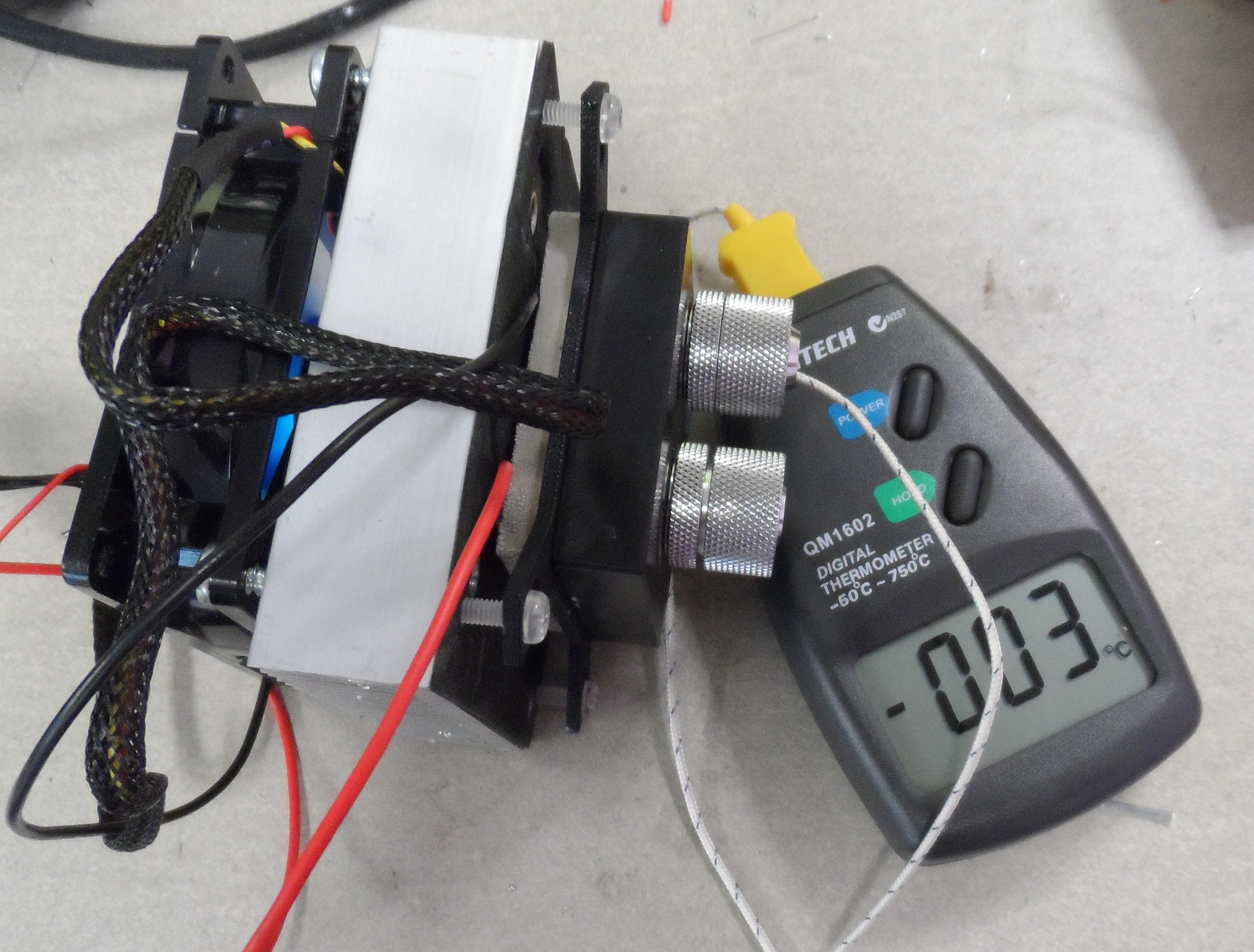

08/14/2015 at 23:00 • 0 commentsIf you're trying to suck heat from a liquid it has to go somewhere and on this planet it's into the air. I've now added server fans and position spacing to ensure maximum airflow through the heat sink. I now have a dry cell temperature of -23C in each peltier.

-

Upgrading peltier cooling system

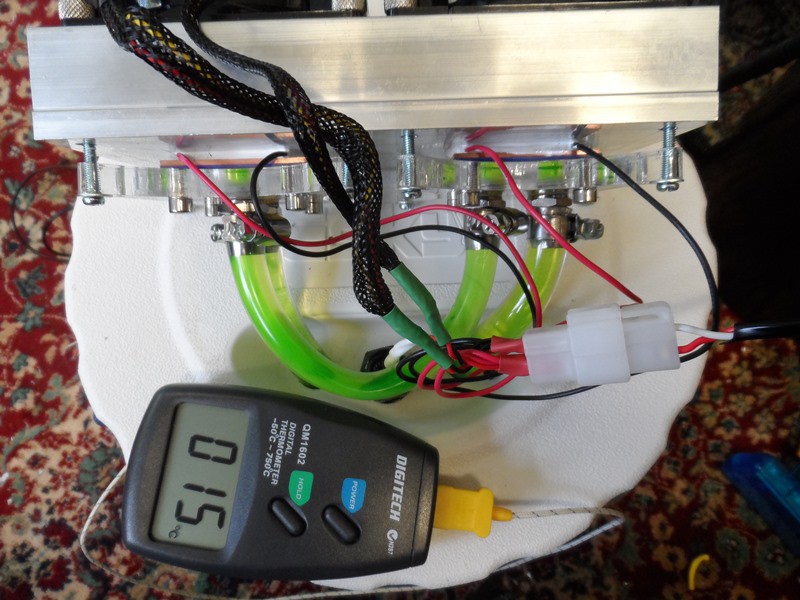

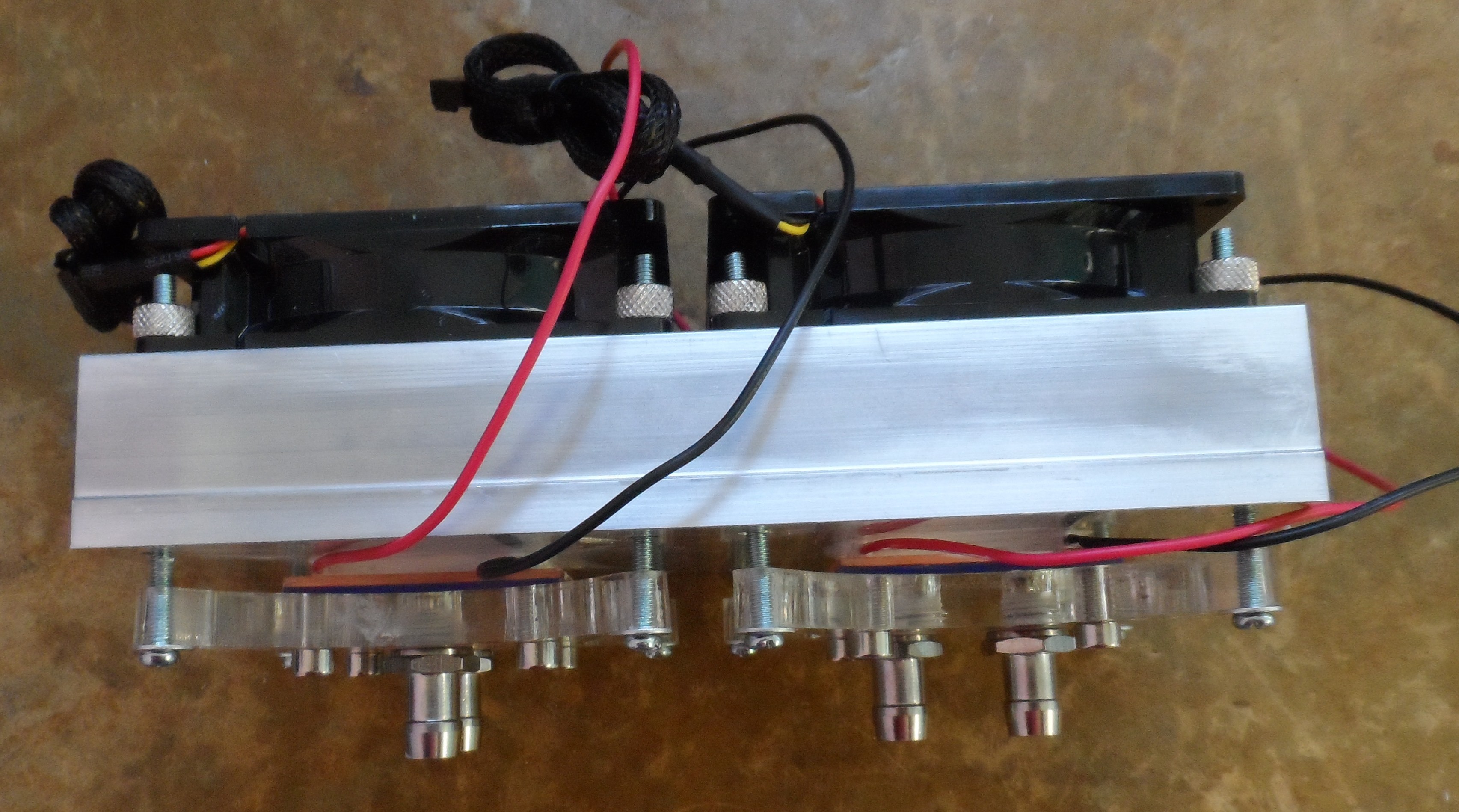

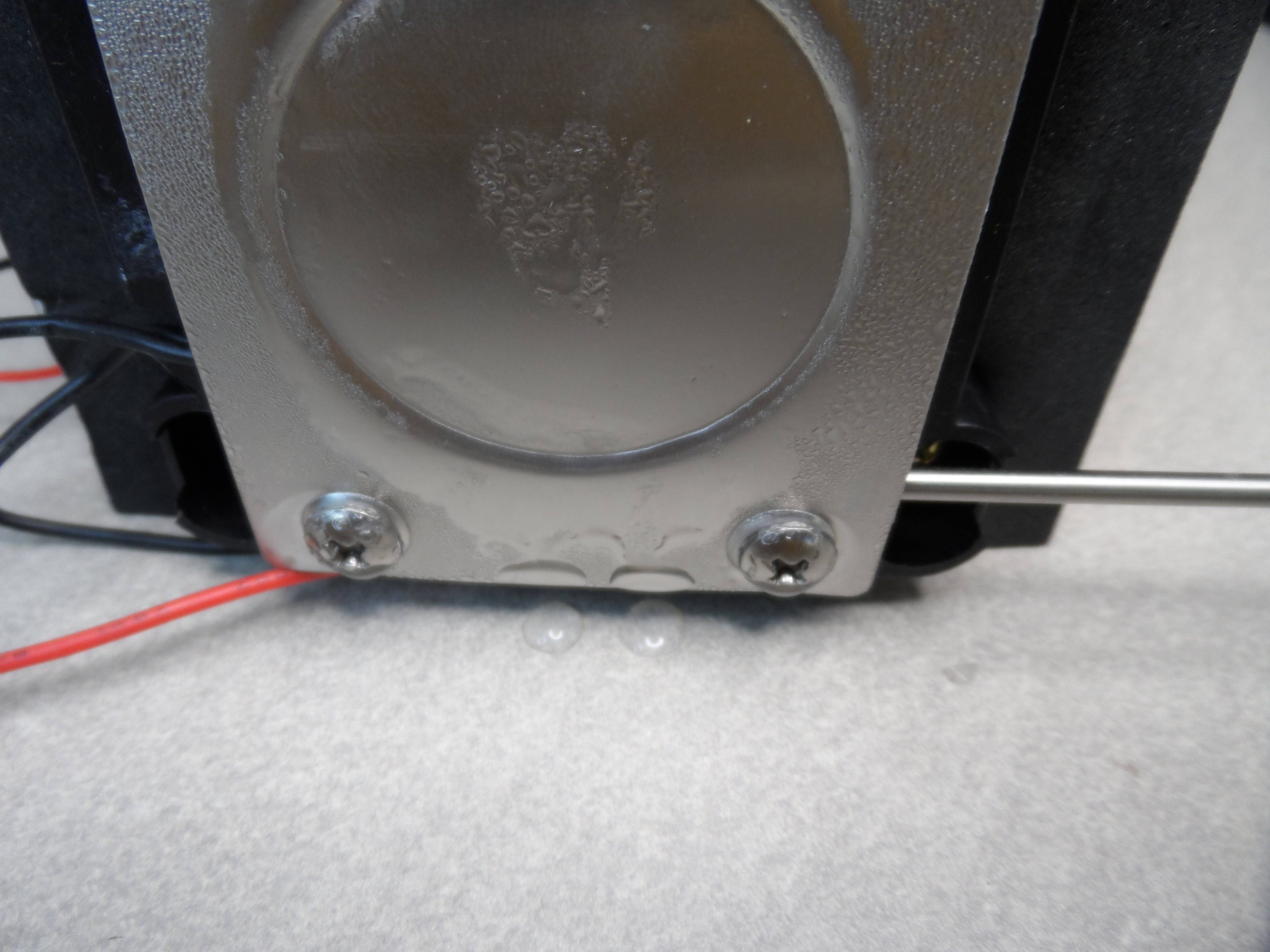

06/13/2015 at 11:13 • 0 commentsJune 20th 2015 New dual peltier cooler liquid cooler.

First run rough power up 12 Volts at 11 amps or 136W

![]()

Screws go straight through the heat sink to hold everything clamped.

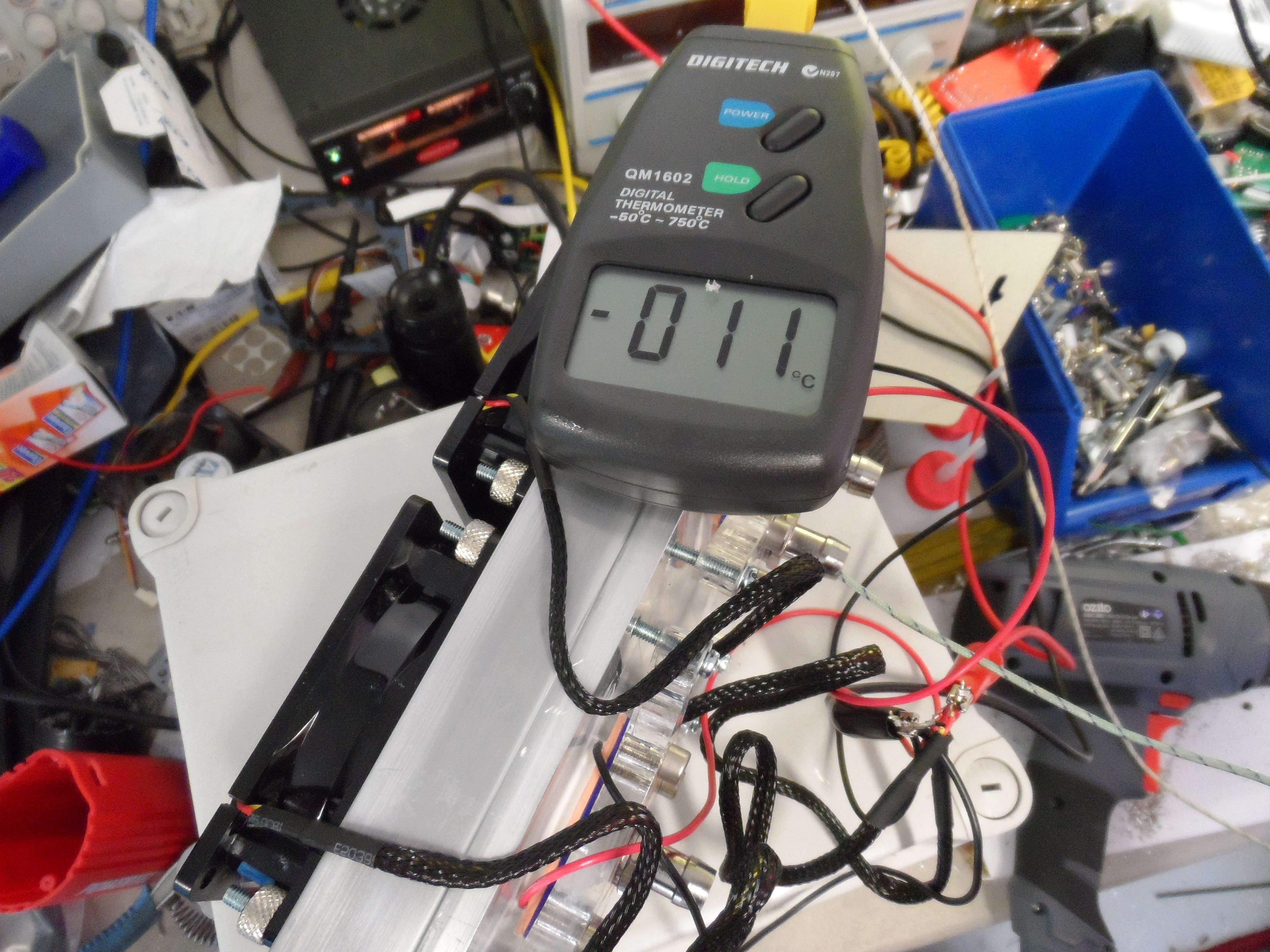

![]() Achieve -11C per peltier without coolant, the previous design was only -3C

Achieve -11C per peltier without coolant, the previous design was only -3CJune 19th 2015 more parts arrive, weekend assembly.

![]()

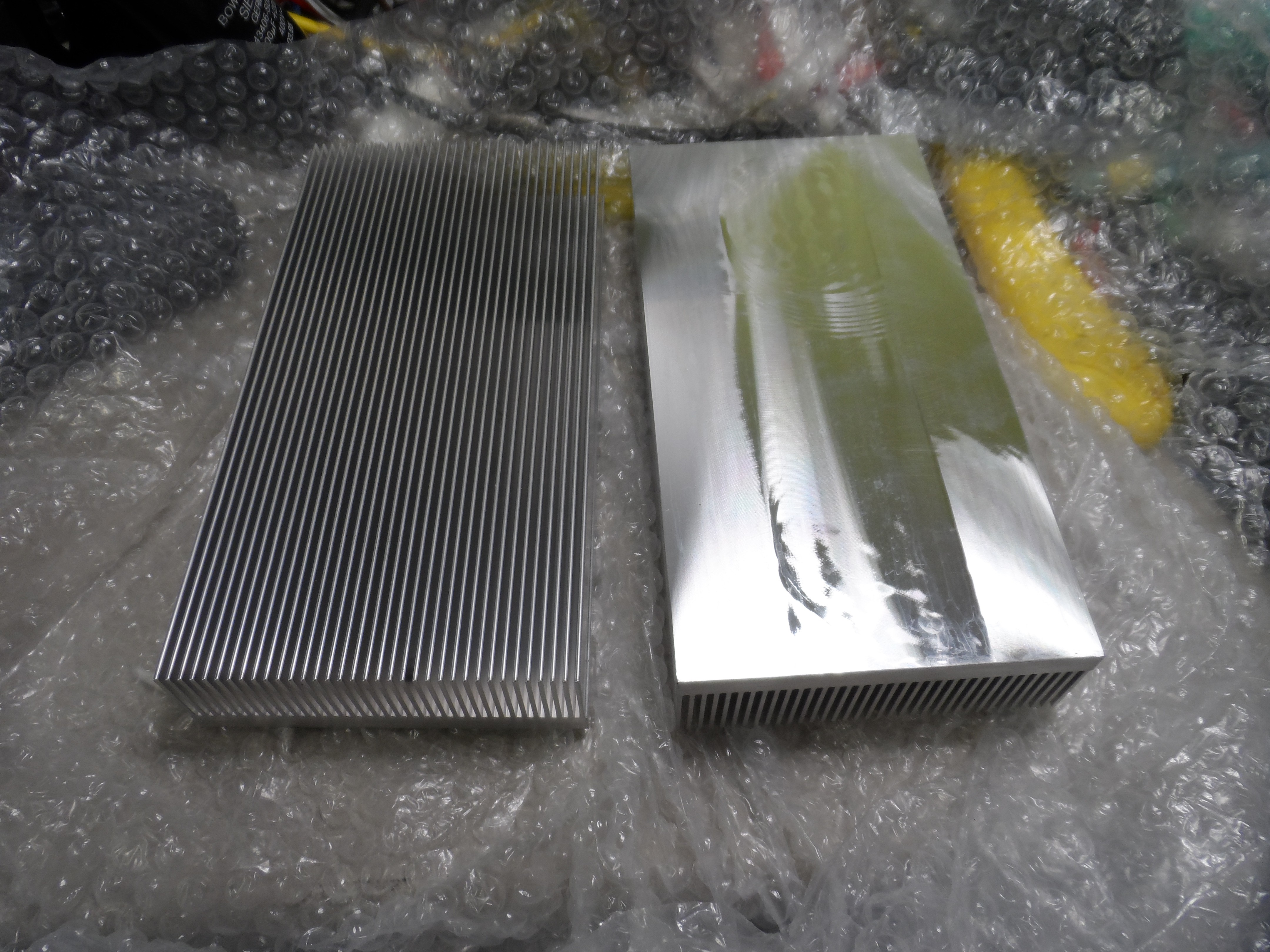

June 13 2015 I'm waiting on parts for a new dual peltier cooler system. This design will use different liquid cooling block and 65W peltier coolers. Mounted on a better fan heat sink combination. Bought two of these as they were on special.

-

4th June Update - Cooling keeping cool

06/04/2015 at 06:23 • 0 commentsA single 65W peltier cooler is not sufficient to bring 10 litres of liquid coolant down to a good operating range ~0 to 6C within a reasonable time <6 hours for reliable dew-point harvesting in one day of sunlight, currently this process takes over 12 hours. Further the insulated tank currently being used can not keep the coolant at that temperature for more that 48 hours.

Another issue is due to the size of the the condenser coil (no design here, just what I found I could buy off the shelf) the coolant is rapidly absorbs heat quickly and transfers it to the coolant. This is great for sucking moisture out o the air! But it also means a considerably more coolant needs to be cooled and stored. Meaning a bigger tank, better insulation and greater cooling capacity.

-

Basic operating parts assembled

05/31/2015 at 10:27 • 0 comments31st May 2015 - Basic operating parts assembled.

Completed the basic assembly, air-filter, air flow, liquid pumps, coolant, peltier liquid cooler and condenser all connected up. Need some more work on the filter but good enough to start testing basic functions under controlled conditions.

![]()

![]()

![]()

![]()

-

Coming together

05/23/2015 at 06:48 • 0 commentsMay 23 2015 - Polyethylene Insulators for condenser coils

![]()

![]()

![]()

-

Arduino, Raspberry Pi or beagleboard ?

05/21/2015 at 07:28 • 0 commentsNow trying to decide on an appropriate controller platform which would need to be low powered so naturally I thought a Arduino. However I will want to test it in the field remotely over a G4 connection so the setting can be tweaked. The unit would monitor and log temperature and barometric pressure. Where a sustained drop in temperature and/or barometric pumps, fan etc. can be controlled for the best results.

-

Notes as I begin assembly and testing.

05/02/2015 at 11:01 • 0 comments19 May 2015 - Trip to the hardware store caused a rethink of my air-flow system as I couldn't find what I wanted. But adaptation lead me to a better design. I've changed the schema drawing to reflect the change.

![]()

18 May 2015 - Slowly taking shape

17 May 2015 - Built a new Peltier Liquid Cooler Model. Fan - Heatsink - Peltier Cell - CPU liquid block. -3C from Ambient temperature in workshop 22C.

16 May 2015 - Coolant storage Tank and submersible pumps

10th May 2015 - Peltier Cell Liquid Cooling Experiment

Cooled 15 litres of common tap water in a Esky 15L Blue Keg in 12 hours I cooled to 6C from 17C now waiting to see how long it will stay below 10C.

April 4th 2015 - Rough Peltier Cell Cooling Experiment

A very rough and ready bench test in Adelaide April 4 at 05:00pm temp 21.2C Rel Hum 44% Barometric pressure is 1014.9 hPa Dew Point is 8.7C . I'm running a 12V 36W peltier cooler and fan on heat sink. At only 5V 1.3A it sustains a temperature of 3C and droplets of water form after 10 minutes.

Robert Hart

Robert Hart