-

1Measure the dimensions of the arm.

Measure the circumference of the arm at two points between which the prosthetic arm socket has to be attached.

![]()

-

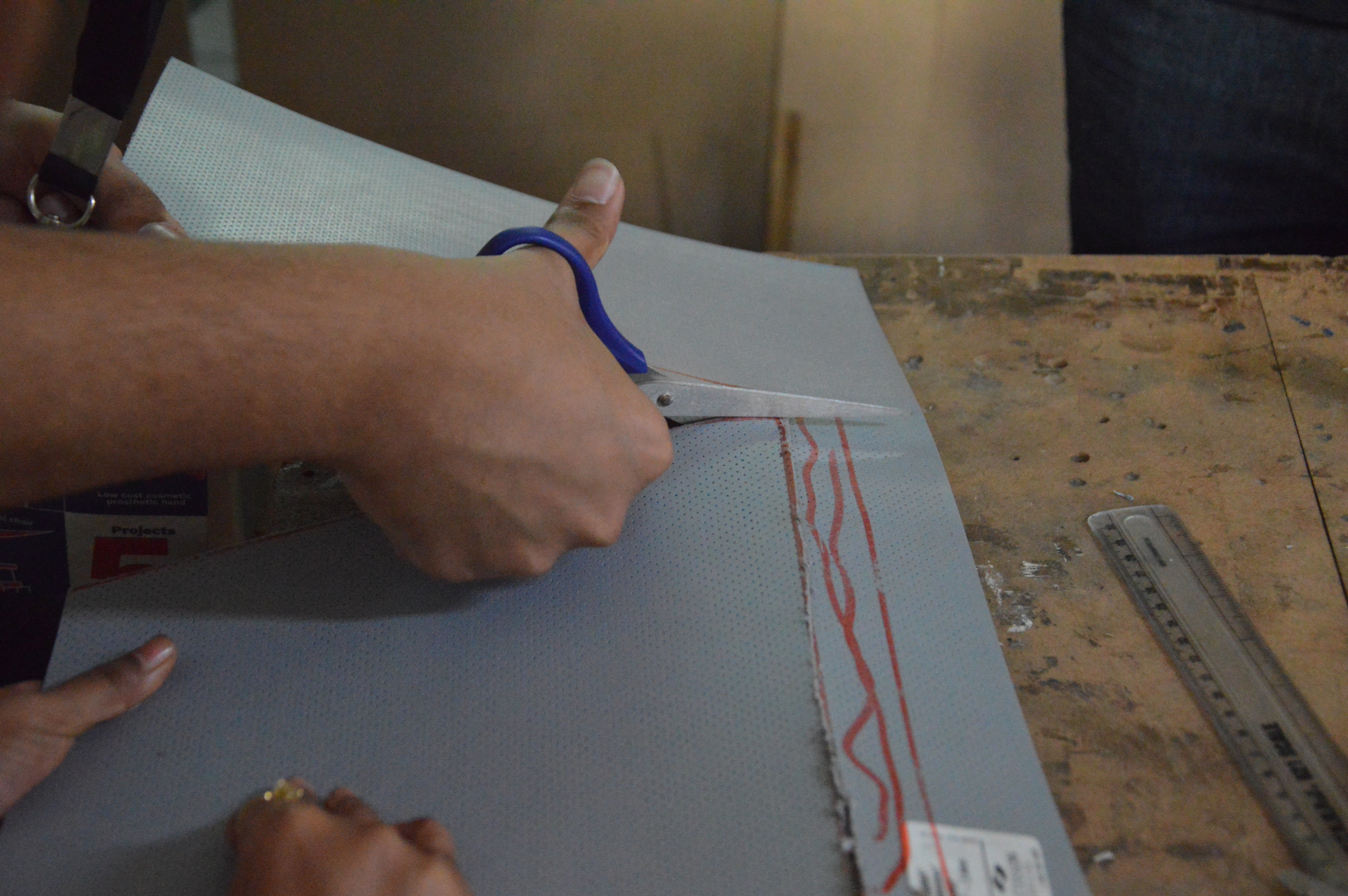

2Cut the Thermoplastic Material.

Mark and then cut the Thermoplastic material as per the earlier measured dimensions.

![]()

-

3Heat the Thermoplastic Material.

Use a heat gun to heat the sized Thermoplastic material until it is malleable enough to apply.

![]()

-

4Moulding the Thermoplastic.

A. Firstly prepare the arm on which the prosthetic by putting insulating material on the hand.

B. Then slowly apply the heated plastic on to the arm.

![]()

-

5Attach the 3D printed wrist part.

A. 3D print the downloadable file available in the files section this project.

B. Mould the Thermoplastic over the slitted part of the wrist.

![]()

-

6Cooldown.

Let the Prosthetic Arm cool down to Harden up and keep its shape.

![]()

-

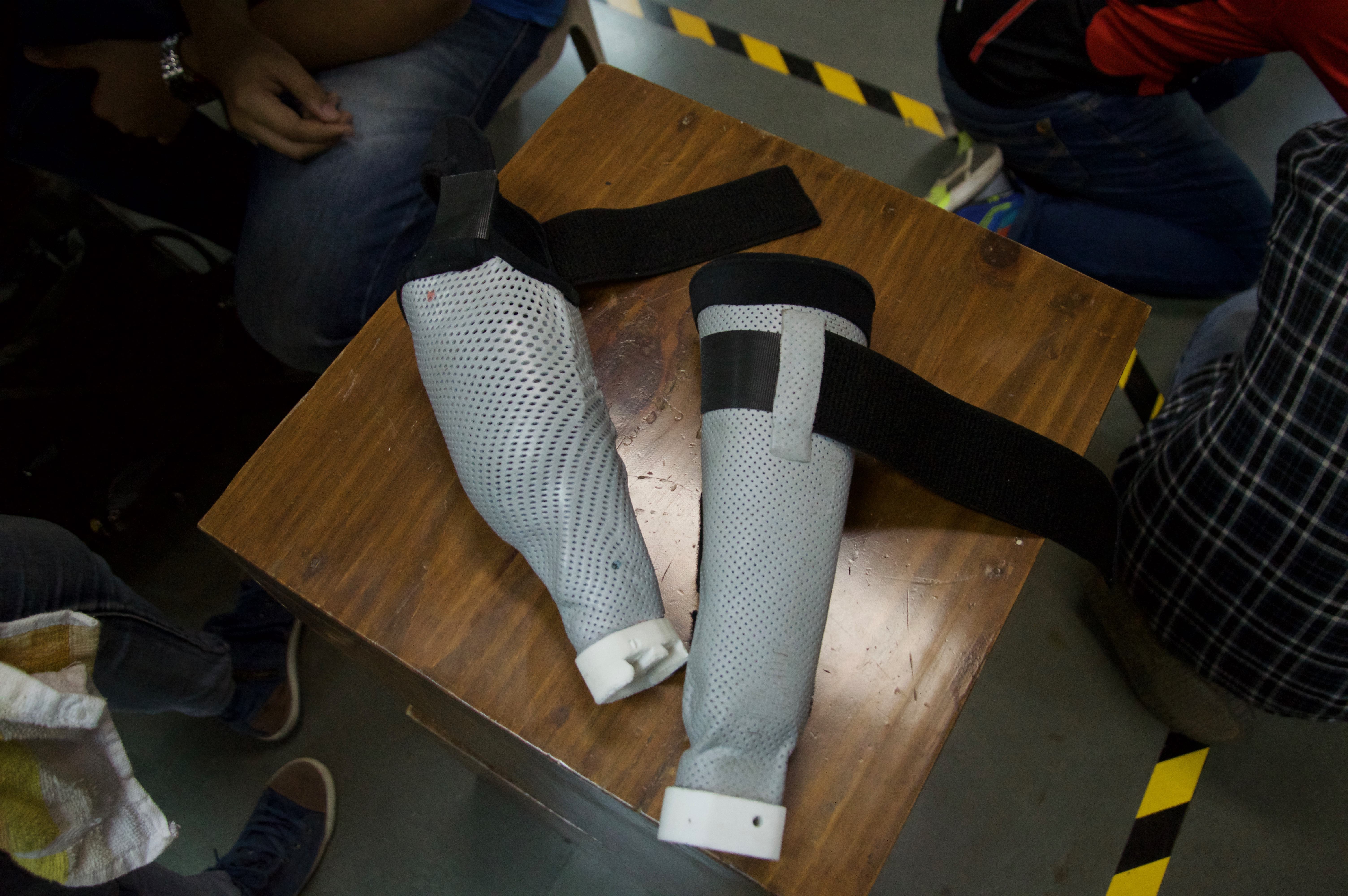

7Form-fitting.

Not everyone's arm is the same and so for that very reason we may need to adjust the form of the prosthetic to fit it perfectly.

-

9Video of the whole process to make the upper limb socket

Video made by Erwan Calvier (professionnal orthotist) for My Human Kit

-

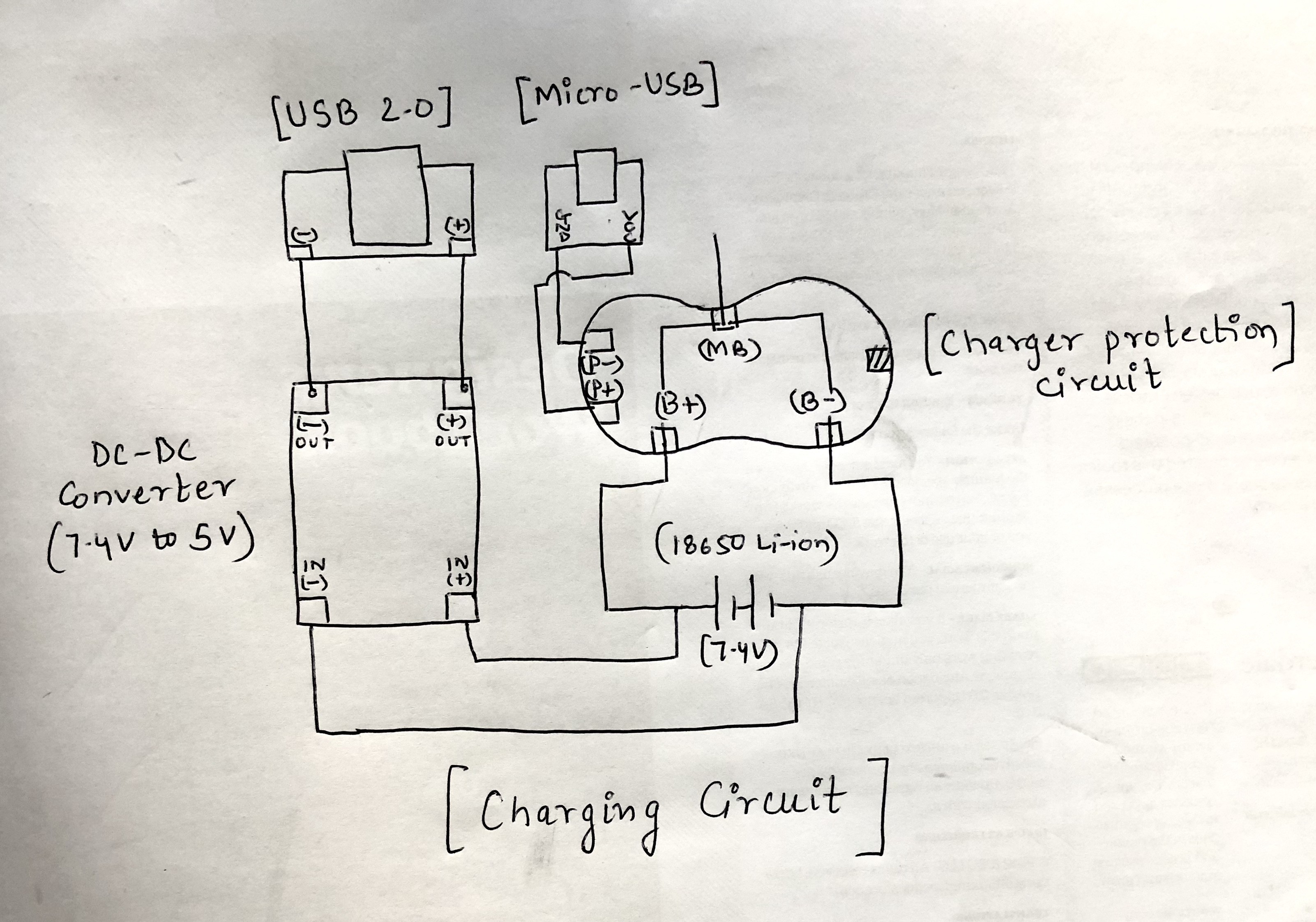

10The Circuitry

Layout all the components and follow the circuit diagram to connect the components to the PCB board.

![]()

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

The exact reference is: Aquaplast Watercolors 3/32X18X

24 silver ultra perf 13%

Link to one provider: https://www.performancehealth.com/rolyan-aquaplast-t-watercolors-perforated#sin=43660.

Are you sure? yes | no

The thermoplastic molding process looks a little tricky but the end results appears to be quite good. Do you have any more information on what specific material is being used here?

Are you sure? yes | no