-

Final Assembly and Working Device!

08/17/2015 at 20:49 • 0 commentsIt works! This project has been a dream in its conception and realization at Stanford. My PCB worked first try, the case did too, so did the BT config, it was magic. The great people of EE47, Professor David Sirkin and the TAs, Akshay Trikha and Joe Aubuchon, best lab lads ever, Room 36 (The Stanford Product Realization Lab makerspace), Adafruit for being awesome, Microchip for making the best BT audio module ever, Bay Area Circuits for the invitation to tour their facility and donating 8 fabulous PCBs from their latest production tech, and all those who's floored jaws in wonder from a little box on the back of their head kept me so passionate about this project, I thank you. Here it is in all its glory (not all of it because the case needs to be printed with shapeways in gloss white, I need a strap for it, and the transducers need mounts, but it works ;) )

![]()

-

PHΛNTOM Case & Electronics Testing

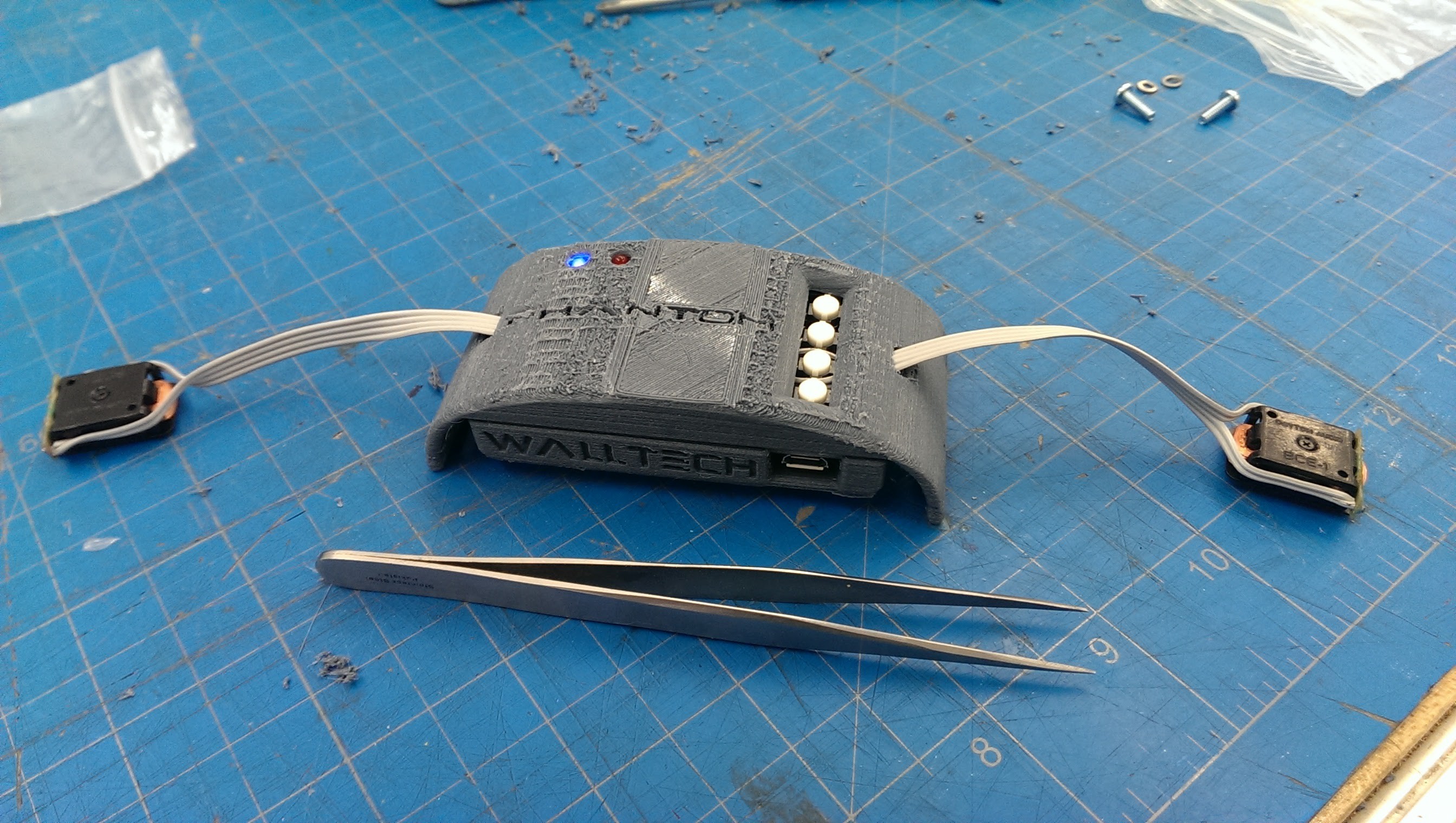

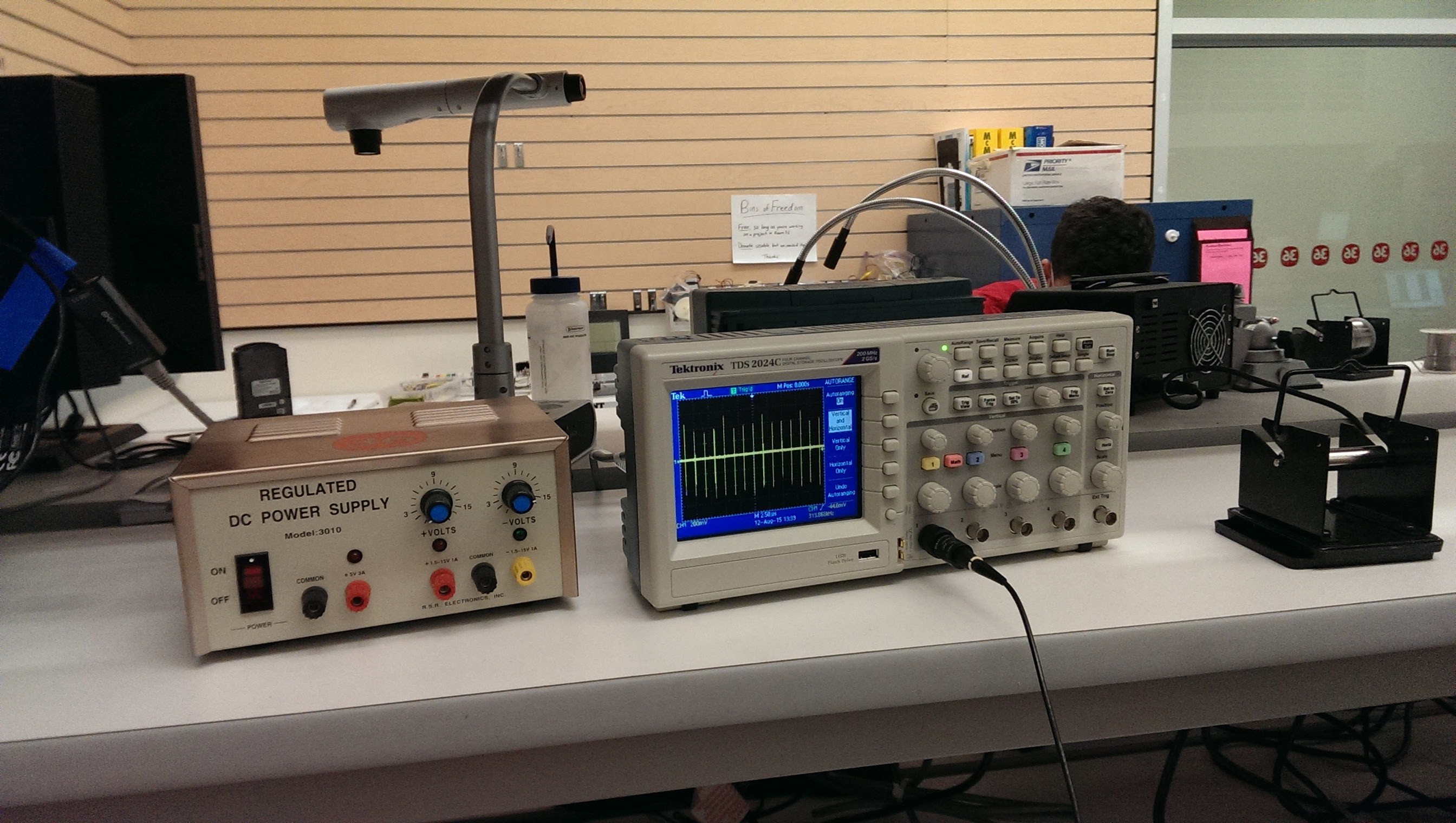

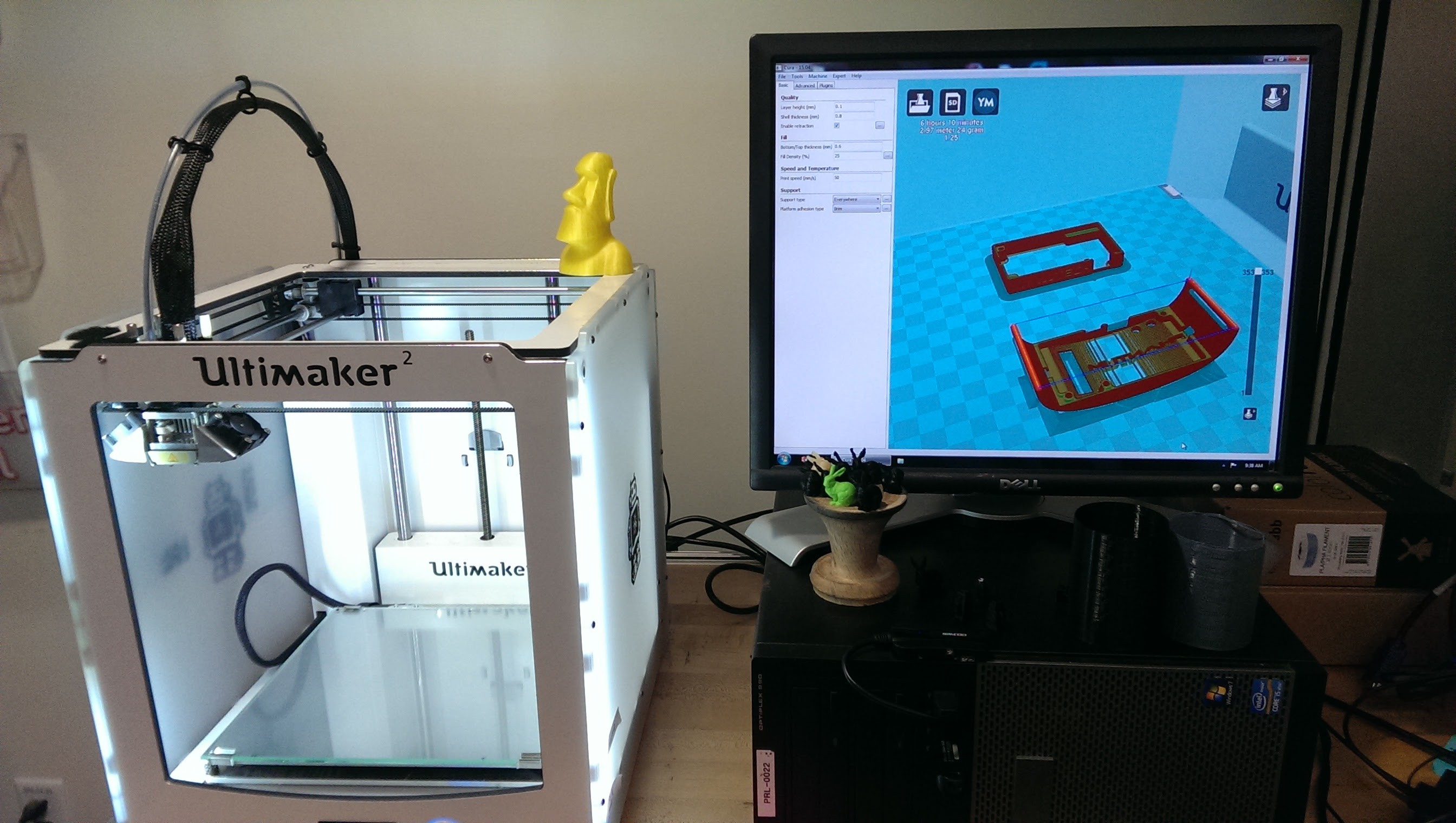

08/17/2015 at 20:14 • 0 commentsAfter the electronics were tested and outputting audio to a Stanford PRL oscilloscope I could start 3D printing the case for the device.

![]()

I printed the case on an Ultimaker 2 in grey PLA to test the inner dimensions and screw holes, and everything aligned and tapped beautifully first time. That's always a good feeling :).

![]()

![]()

![]()

![]()

-

PCBs and PHΛNTOM Assembly

08/17/2015 at 16:34 • 0 commentsTo pick up my PCBs that were perfectly crafted by Bay Area Circuits in Fremont, CA, about an hour away from Stanford, I toured the facility (cheers Brian) and got to see the whole production process as well as the incredible machines that make it happen. It was an amazing tour, and I'll release photos as they are approved by PR for the public.

![]()

Finished PCBs: (JUST DO IT!)

![]()

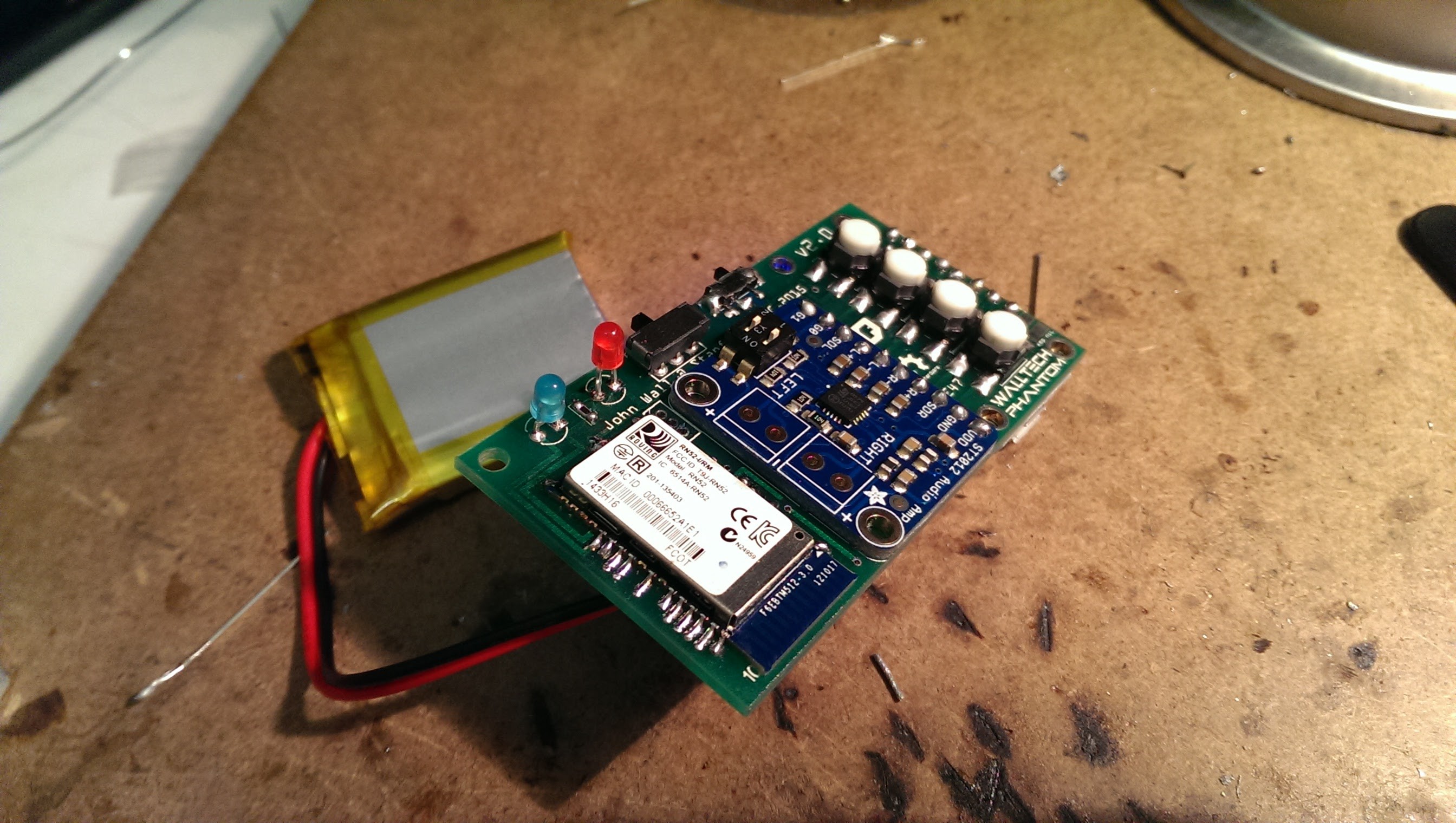

I assembled the first prototype in the Stanford Product Realization Lab (the campus makerspace) and every function of the device worked first time! Here it is! On to the case and final testing!

![]()

-

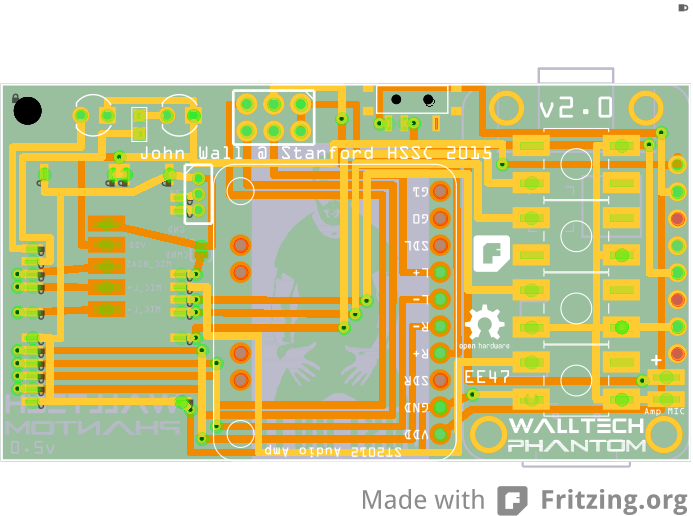

PHΛNTOM 2.0 Design

08/10/2015 at 07:27 • 0 commentsI've finally found a way to work on the latest prototype of my bluetooth bone-conduction headset/hearing aid: by submitting the project as my EE47 final project at Stanford! My professor loves the project and as the class is an open engineering/design course, it satisfies the course's requirements. I'm free work on it in my EE lab and the Stanford makerspace, the Product Realization Lab, and parts should come in tomorrow for me to assemble the first prototype. I designed the PCB with Fritzing even though I wanted to upgrade my software this summer as it's quick, easy, familiar, and more than capable for this project. This new version of the bluetooth bone-conduction headset concept adds higher-quality components, better aesthetic design, a bigger battery, and more features. v2.0 has stereo microphones to receive bluetooth phone calls and add adaptive-volume hearing-aid functionality to the device. The four push buttons control volume up, play/pause, skip, and volume down functions in order from top to bottom. An internal amplifier boosts the volume to the transducers, an issue with the last prototype. The internal bluetooth audio module is a Microchip RN52, a VERY nice improvement over the $5 generic module from china in v1.0. Range should be increased as well as audio quality and the addition of microphone capability and status led feedback. Several people have asked for a 3.5mm audio jack to be included as an optional input, and at the scale of the internals of this device and the nature of its mounting, a wired connection would be impractical and against its intended use. If people really want one, I'll think about adding it into a future revision.

(yes, that's Shia Labeouf motivating on the back of the pcb, he's the Stanford EE47/ dorm mascot :) )

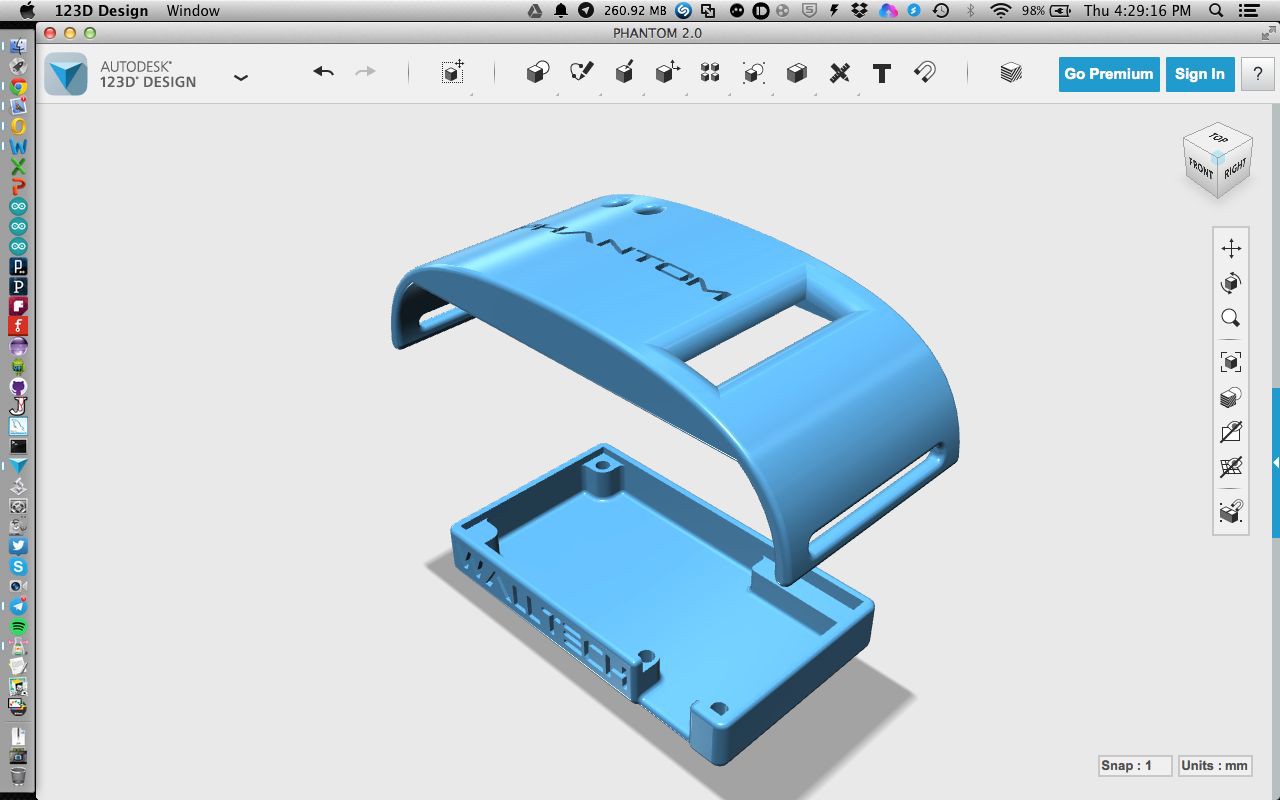

![]()

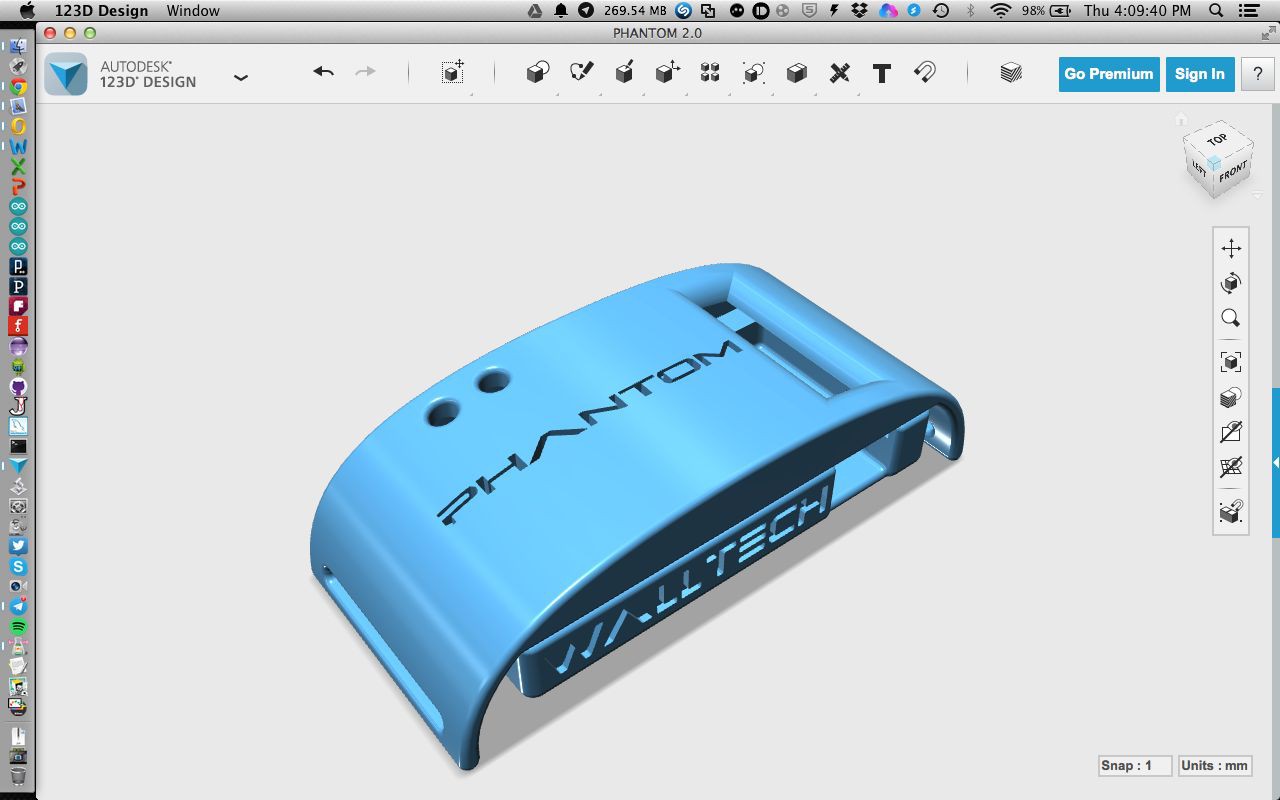

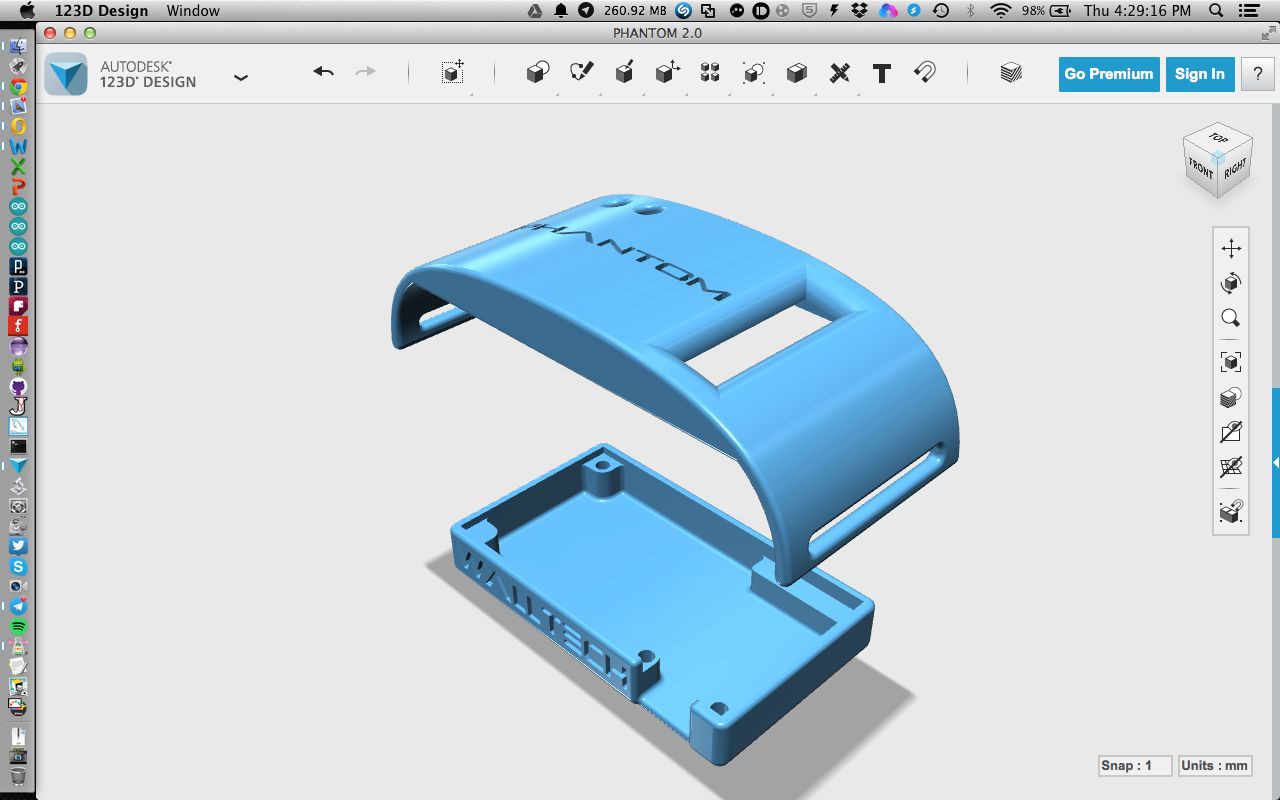

Once the PCB was complete, I used Autodesk 123D Design to 3D model a case to enclose the circuit board and components. The case will slide onto an adjustable or elastic band that will secure the device and transducers to the back of the user's head. The new shape is much more appealing than the last design, and the mounting style is simpler, more adjustable, and more user-friendly. I will eventually have this case printed in high-quality glossy white from Shapeways, but I might try the industrial 3D printers in the Stanford makerspace if they turn out to be cost effective. The main body of the case is 40x70x20mm.

![]()

![]()

My parts from Mouser and Adafruit should arrive tomorrow, then I can assemble and test all the cool features of this latest PHΛNTOM design! I can't wait to experience the eerie phenomenon of bone-conduction audio and show my friends and EE professor at Stanford!

-

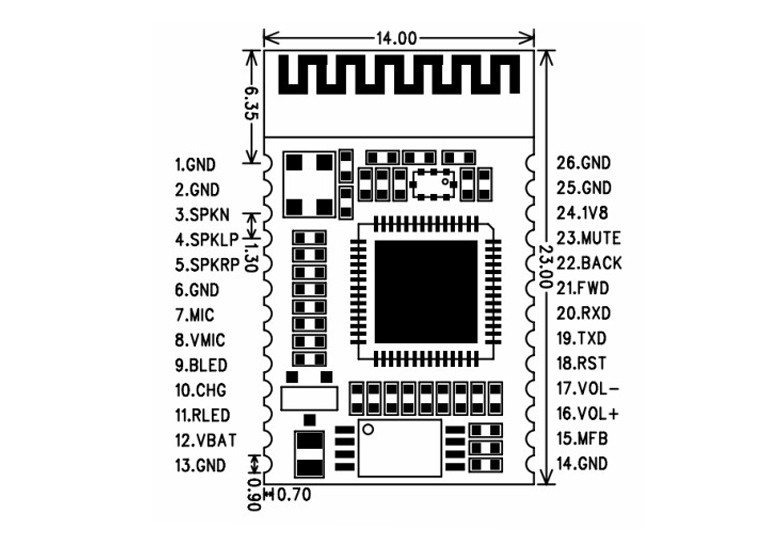

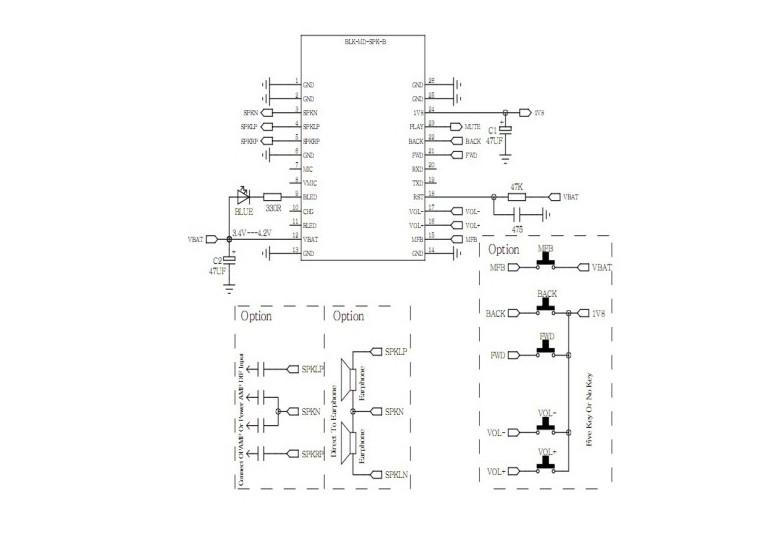

BLK-MD-SPK-B Reference

08/01/2015 at 20:45 • 0 commentsIf you would like to create a simple bluetooth audio project of your own, the BLK-MD-SPK-B is a good place to start! It's ~$6 and easy to find, but pinouts and example circuits are tough to find. Here is what I used to help me design the first prototype of the PHΛNTOM:

![]()

![]()

WΛLLTΞCH PHΛNTOM: Bone-Conduction BT Audio

A BT/NFC bone-conduction audio device that transmits sound directly to the auditory nerve through the skull. Music for the deaf & disabled.

WΛLLTΞCH

WΛLLTΞCH