-

Project Shutting Down... For Now.

07/21/2015 at 16:10 • 0 commentsHello,

I want to apologize for being away so long. I'm writing this to let you know that I am suspending this project for now. Again, I apologize to everyone that has been interested, but I have way to many irons in the fire, and I have taken on new responsibilities that I had not previously accounted for. I will be withdrawing the project from the Hackaday 2015 contest. I will be wrapping up a few other projects shortly and will be posting them on here. Sorry again for the inconvenience, but I feel that with my limited time, I need to finish the projects that completed sooner first. I plan to come back to this project in the future.

Thank You For Your Support And Understanding,

Chali Baicunn

-

Sorry For The Delay

06/08/2015 at 17:16 • 0 commentsHello Everyone,

I want to apologize for the delay in posts, but I have been putting in a lot of work on my website https://www.baicunnpress.com . I'm wrapping up the rest of the backend work on my site in preparation for convention season. When I'm done with the work there, I'll be back here and posting updates. If you get a chance to swing by the site and share, please do. Thanks for the patience.

Thanks,

Chali Baicunn

-

Catalysts & PEMs: Brainstorming Alternative Solutions Part 1

05/13/2015 at 21:52 • 0 commentsAt the heart of the project is finding an alternative for the PEM. One of the biggest issues that I have run into is that there very little information out there about exactly how PEMs are contructed. There is a lot of information available regarding some of the materials used and the chemistry of the process, but I have yet to find a good cut away image of a commercially manufactured cell or PEM.

FYI.... If you contact hydrogen fuel cell manufactures asking for more information... They don't respond.. Or they do, but it's a blanket statement that it's a trade secret, and ask you not to contact them again... :/

So what to do.... what to do.... Well as Dr. Whitehall so eloquently put it "Discovery requires experimentation.... Hail Hydra!" Sorry had to get the mad scientist bit out of the way.

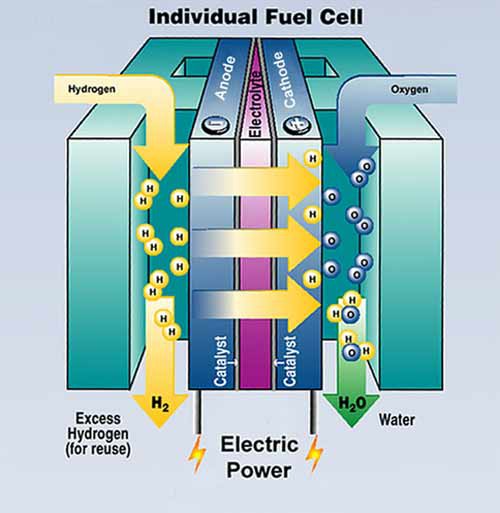

Through my research, I have found that a PEM cell seems to be comprised of an anode and a cathode with an electrolytic membrane sandwich between the two along with a catalytic layer on both the anode and cathode sides.

Here's a few generalized diagram of what the PEM cell should look like:

---------- PEM Fuel Cell----------

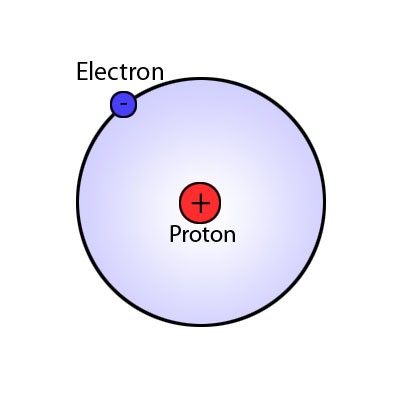

The reaction needed for a PEM fuel cell to function is a redox reaction. This means that we need to take the single electron from the hydrogen atom through an oxidation state and deliver that electron to the other side of the cell where hydrogen will meet up with oxygen and the spare electron to create water in a reduction state.

Here's a link to the Wikipedia page explaining redox reactions

---------- Hydrogen Atom---------

---------- Bonding of Hydrogen To Water----------

---------- Diagram of Reaction In Fuel Cell----------

Catalysts:

With that last bit out of the way, it's time we discuss catalysts. There are three major metal that are unique in their ability to catalyze reactions between hydrogen and oxygen. Those are platinum (Pt), palladium (Pd), and rhodium (Rd). Unfortunately these metals are both rare and hard to work with. But fortunately there are several possible sources where these metals exist in a form that is more or less easier to work with. The most common sources that I could find these metals are in catalytic converters and hard drives.

- I have thought about using slightly roughed hard drive platters stacked as both a catalyst and for the anode and cathode. I do not know if this will work as I have a rudimentary understanding of chemistry, and I am unaware of Pt, Pd, and Rd compounds present on hard drive platters. As I am unsure of this, I am also unsure of whether it will actually work as a catalyst, but I'll be sure to test.

- I have also thought about cutting sections out of a catalytic converter from an internal combustion engine, as they are specifically manufactured to catalyze hydrogen and oxygen compounds. However, I has been told that the support material in some catalytic converters may contain asbestos. Further research is needed, bc I don't like cancer, and would feel pretty terrible about encouraging others to potentially contaminate themselves.

- Another approach would be to harvest the catalyst metals and convert them into a metallic salt as suggested in the comments by Jehu:

" ...The way I'd get the Pt out is to snap the platters, submerse in NaOH to react the Al, wash and roast the Pt foil and then react with Aqua Reiga to make a chloro platinate salt."

Membrane:

Now we have come to what I believe will be the most challenging part of the build; The PEM. The reason I feel like this is the most changeling part is that finding a material that will only allow a single proton (.1 µm) to pass through and/or acidic enough to assist with knocking the electron off of the hydrogen atom, while allowing the hydrogen proton to pass through the membrane to the cathode side of the fuel cell. This also means that the both the anode and cathode would need to separated via a barrier from the acid.

- One of the primary materials used as a PEM is a chemical cousin to Teflon (PTFE), known as Nafion. It's a pretty amazing material that conducts protons but not electrons. (Check out the Wikipedia page for Nafion) For the sake of this project Nafion is a dead end in the project due to it's extremely high cost. The same applies for any commercially available that i can find. (Link to a pricing list of PEMs at Sigma-Alrich

- I've also been kicking around the idea of doping Tyvek (Official website here) with catalyst and ceramic and then stacking layers tightly together, and then sandwiching a common mild acid (preferably a solid) between the layers

- I have read bits and pieces about using silica as a PEM, but have been unable to find any substantial information.

Thanks for stopping by! If you have any suggestions or questions, please feel free to comment and share. If you have a chemistry background and see anything that I have screwed up, please feel free to correct me.

-

Safety First: Integrating A Microcontroller

05/05/2015 at 15:46 • 0 commentsSo after a wonderfully terrifying dream last night, I have come to the realization that I have been a bit too cavalier with safety.

Hydrogen is an extremely flammable gas that is tasteless, odorless, and colorless!

So I have decided that I will be setting up a monitoring and emergency shutdown system. I plan on integrating several hydrogen gas sensors that I found on Sparkfun (HERE) along with microcontroller.

Microcontroller integration also allows for added functionality from monitoring gas levels, power output, and temperature. It will also allow for great gas flow control, by giving the user access to electronically controlled gas solenoid valves.

But the primary dilemma in using a microcontroller, is access to a computer. Since this project is being designed to use in places without access to power let alone computers.

So..... What to do?....

I could get the coding packaged up and ready then the controller could be flashed, but this may not work depending on environmental factors, plus what if there is a fault, and no one can repair the code.....

I could integrate a microcontroller with a simple LCD screen and a keyboard, but the tech may not be easily sources, plus it's just adding to the cost.

After trolling around for a few hours, looking at several different options, and thinking about several work arounds. I decided to see what the Hackaday users have done to get a low power small package solutions. Then there it was in front of my face...... LightBlue Bean. It meets all or the requirements; small, low power, easy to program, plenty of room for sensors, economical, plus phone integration over Bluetooth.

This might strike you as odd, but Africa has more cellphone users than North America or Europe. Asia is the fastest growing cellular market by some accounts. Many parts of Asia and Africa are home to some of the world's most underdeveloped regions.

So looks like LightBlue Bean it will be.

If someone has one of these just floating around they want to throw my way, it'd be appreciated... Not saying any names, but heard these are being handed out.......

-

The Science

05/04/2015 at 17:48 • 0 commentsBefore I dive in on the build, I want to take a few minutes to explain the basic science of how a hydrogen fuel cell works for those of you who don't know.

The Process:

1) Hydrogen gas flows into the anode side of the of the fuel cell

2) The hydrogen gas is exposed to an electrolytic material that allows for hydrogen protons to pass through. However, the free electrons are forced pass over it's surface through the anode where the electrons can be used as electricity.

3) Once the hydrogen reaches the cathode side of the electrolyte the hydrogen is then combined with oxygen atoms to create waste water.

So long short, if i end up with water and electricity, then I have a working fuel cell.

For more details checkout:

http://americanhistory.si.edu/fuelcells/basics.htm

http://en.wikipedia.org/wiki/Fuel_cell

http://auto.howstuffworks.com/fuel-efficiency/alternative-fuels/fuel-cell.htm

-

The Idea

04/30/2015 at 18:52 • 0 commentsThis idea has actually been a bit of a thought experiment floating around in my head for quite sometime. So I figured what better time then now to get it built.

Project Goal: To create a small proof on concept hydrogen electric fuel cell, that is safe, low cost, and easy to build and maintain using materials that are readily available.

Project Needs: Hydrogen gas, cheap P.E.M. (Proton Exchange Membrane), Electrical storage device

Challenges: Finding a cheap and readily available P.E.M. material, finding readily available source of hydrogen (preferably renewable), handling hydrogen safely, avoiding excess heat and electrical spark (I like my flesh and limbs intact), and using materials that do not react with hydrogen, oxygen, or water violently.

How does this make an impact?: A working hydrogen fuel cell built from common and/or recycled materials makes the technology much more accessible for everyone. And Increased accessibility has historically fueled innovation and economic growth. The hope in successfully achieving the project goal, would be that electrical power could be delivered to people in remote or impoverished locations, that would otherwise not have access to electricity.

Junkyard Hydrogen Fuel Cell *Currently Suspended*

Making Hydrogen Fuel Cell Technology More Accessible And Recycling In The Process

Chali Baicunn

Chali Baicunn