-

The Keystone

02/16/2018 at 19:27 • 0 commentsI have another idea to go beyond the idea of a flat "board" of plastic to swap in.

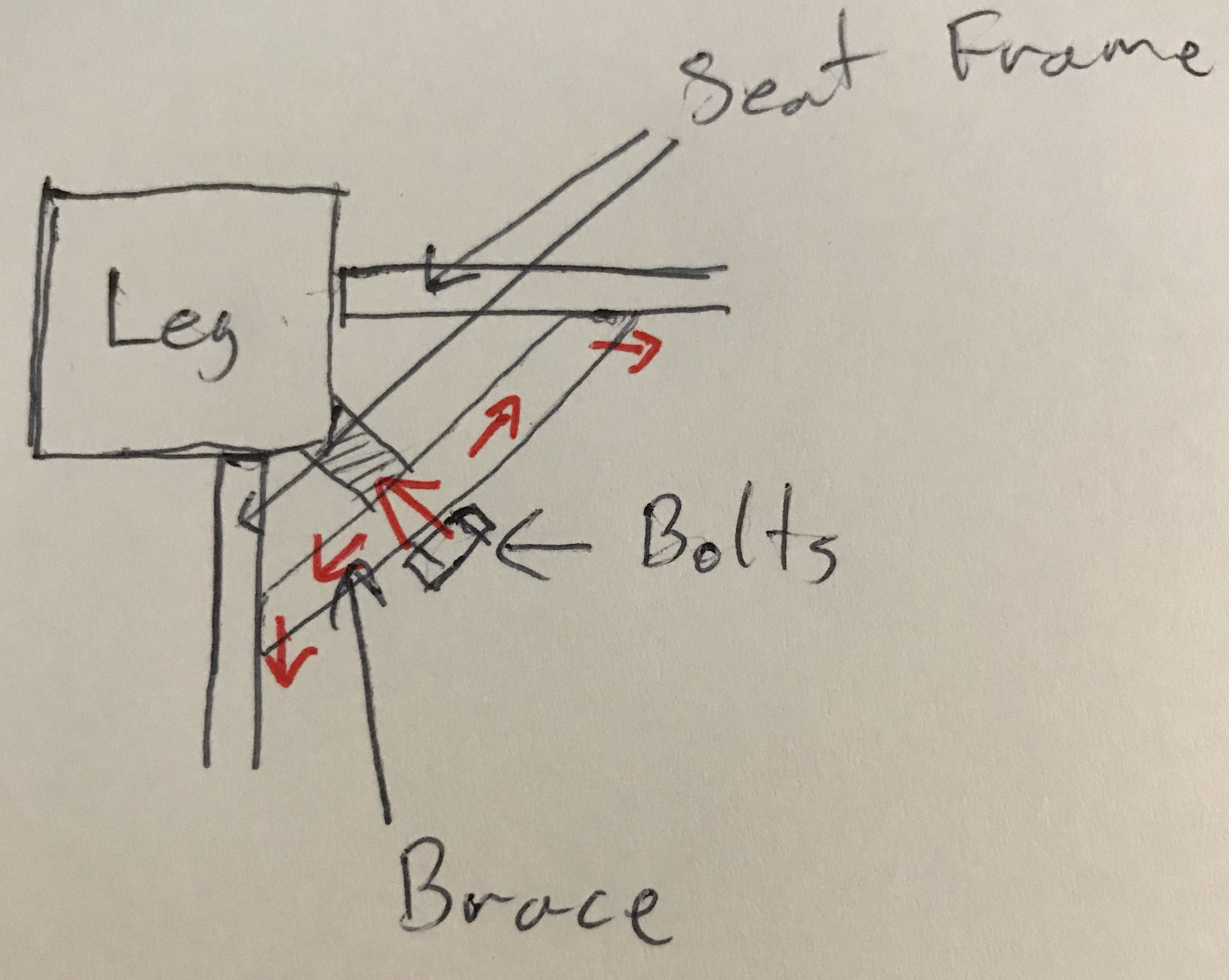

The chair leg itself is pulled into the frame of the seat as the bolts are tightened. It seems to me that this creates forces directly in the center of the brace where the bolt heads rest and the edges of the brace where they contact. Not unlike the span of a bridge.

![Brace Force Sketch Brace Force Sketch]()

Existing Brace Sketch with suspected Forces in Red

This line of thinking led me to a structure that is often used to support spans at length. The Arch. So my replacement brace would be an arch. The problems I begin to see here are the span length, filament / printing direction, and any complex geometries that may not be easy to print as a single piece.This also led me to on consider one of the architectural elements of the arch. The Keystone. The keystone effectively being a wedge at the apex of the arch's span. Using my own wedge or keystone would allow the design to naturally be broken up into pieces. I could use a central wedge and print separate "arms" for the span.

This distributes the forces differently. The span arms are pushing on the wedge of the keystone and frame of the chair.

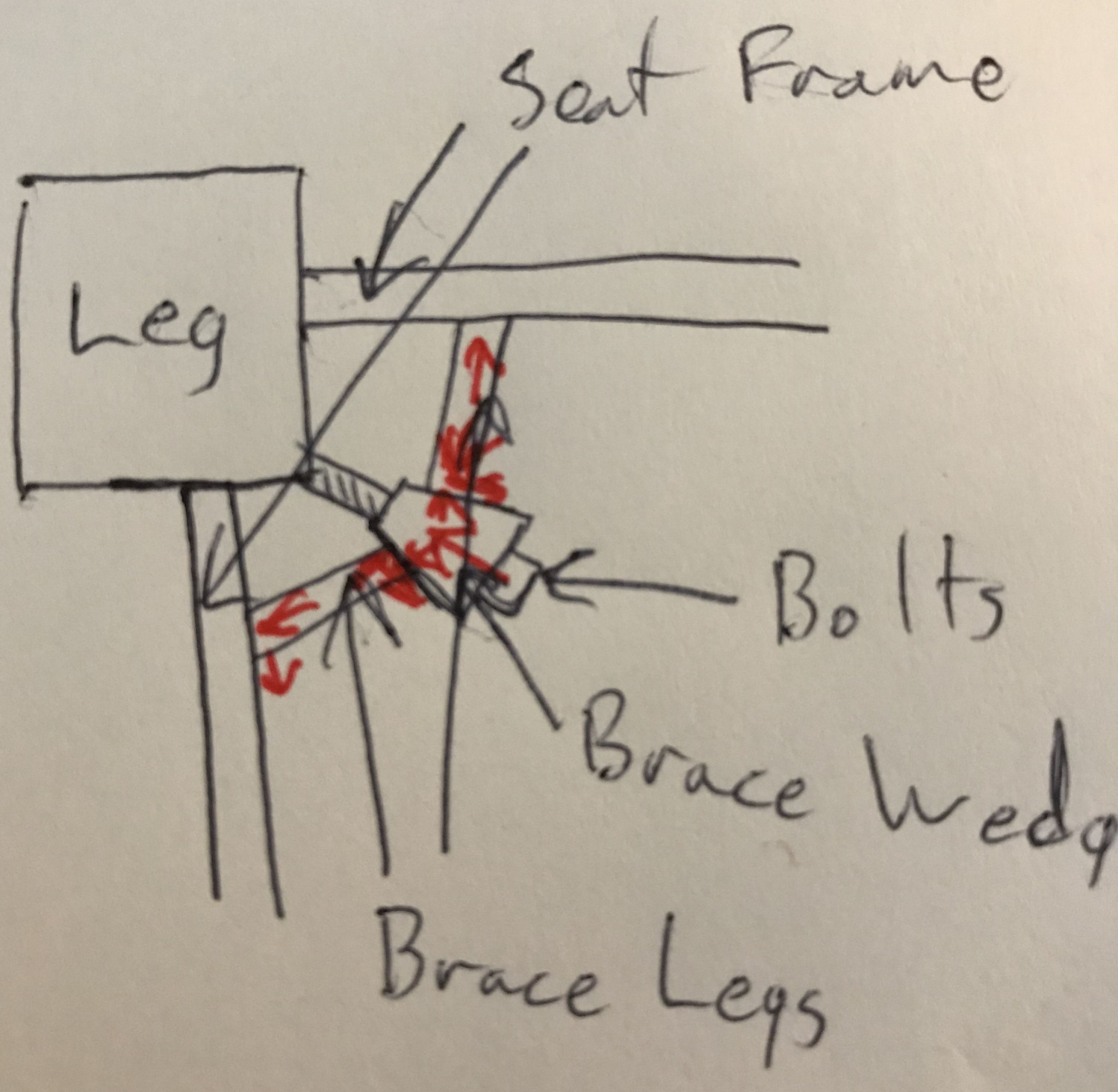

![Arch Brace Arch Brace]()

Arch Brace with Keystone (Forces in Red) My thinking here is that as the bolts tighten, the wedge moves closer to the chair leg. But this is met with the opposing force of the span "arms". It also allows me to print the design in three pieces instead of a single monolithic piece. This should accelerate the design process as any problems will not necessarily need an entire reprint. It should also allow easier scaling and access to more printers as the individual parts will be smaller.

-

First Thoughts

02/16/2018 at 18:42 • 0 commentsMy starting point for this project is to consider how best to structure the part to be a suitable repair. I think if it is a simple replication of the wooden brace it fail. I don't think the print would be strong enough. Even keeping in mind, or exploiting, the "grain" implied by the print layers. Essentially a flat, board like piece of plastic would put too much pressure at the bolt holes.

OR it could necessitate making the part very bulky and/or dense. But increasing the size and infill would makes it take longer to print, iterate the design as needed, AND burn up more filament.