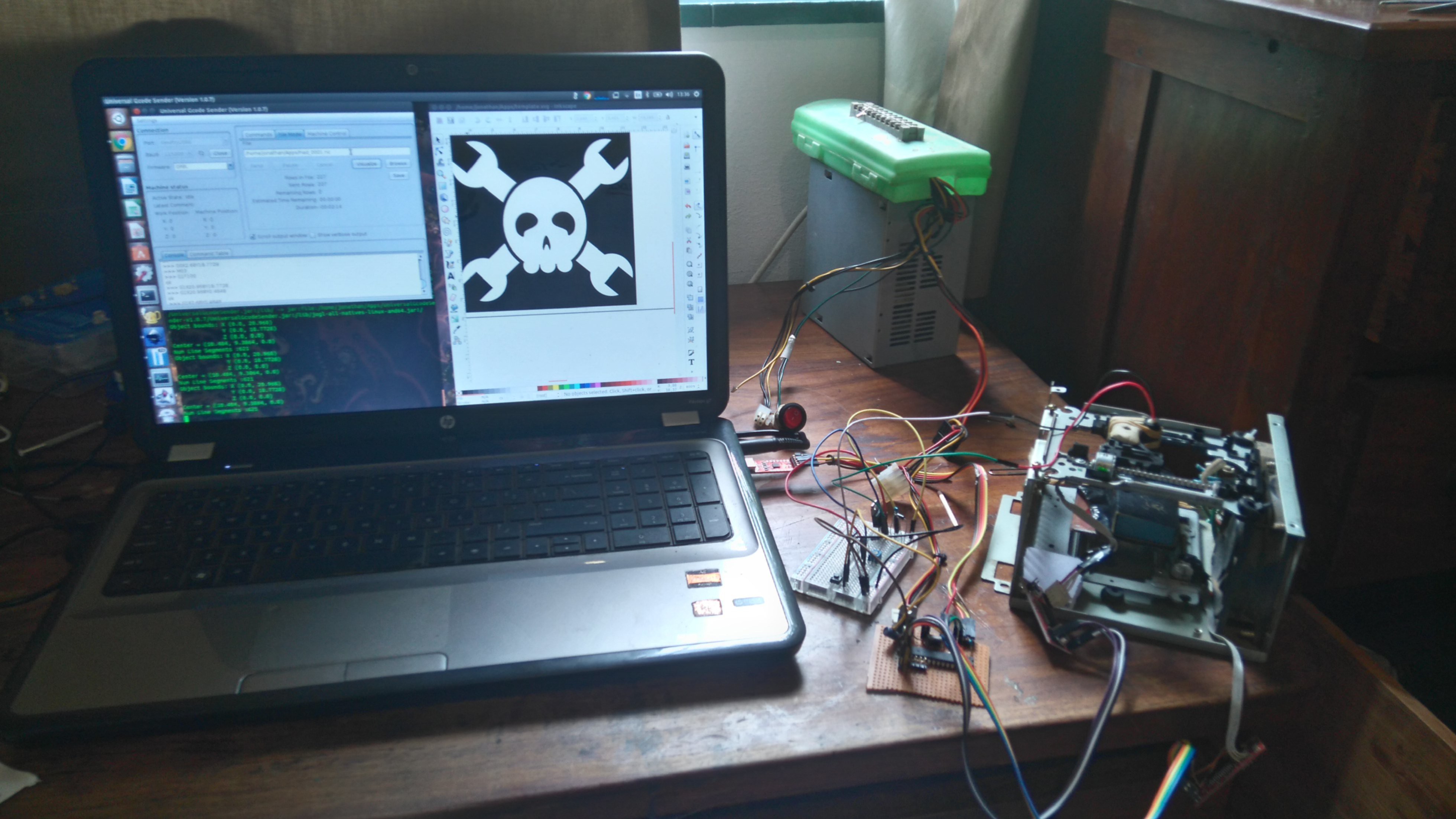

Gave up trying to write the software from scratch, and ended up going with the same sort of setup as groover on instructables. Inkscape is used to make a design, and a modded version of the lasercutter extension turns paths into gcode.

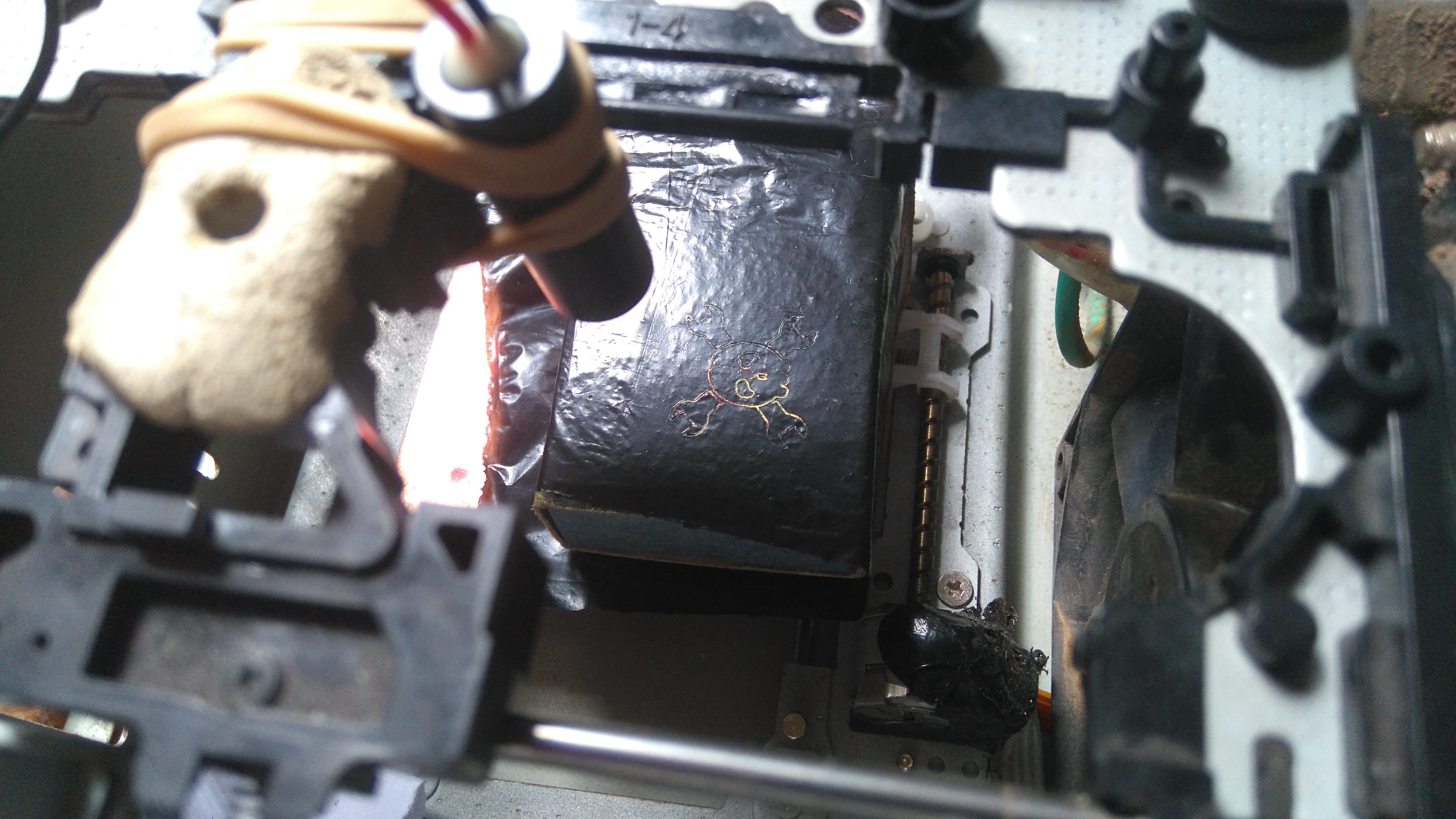

Universal gcode sender then passes the commands to my ATMega328 over serial, where the gbrl firmware decides what to do with it all. The whole shebang is mounted in an old PC power supply box, so the fan can keep everything cool. Still messy, but dialing it all in and slowly getting rid of the hacky bits of tape, jumper wires and cable ties.

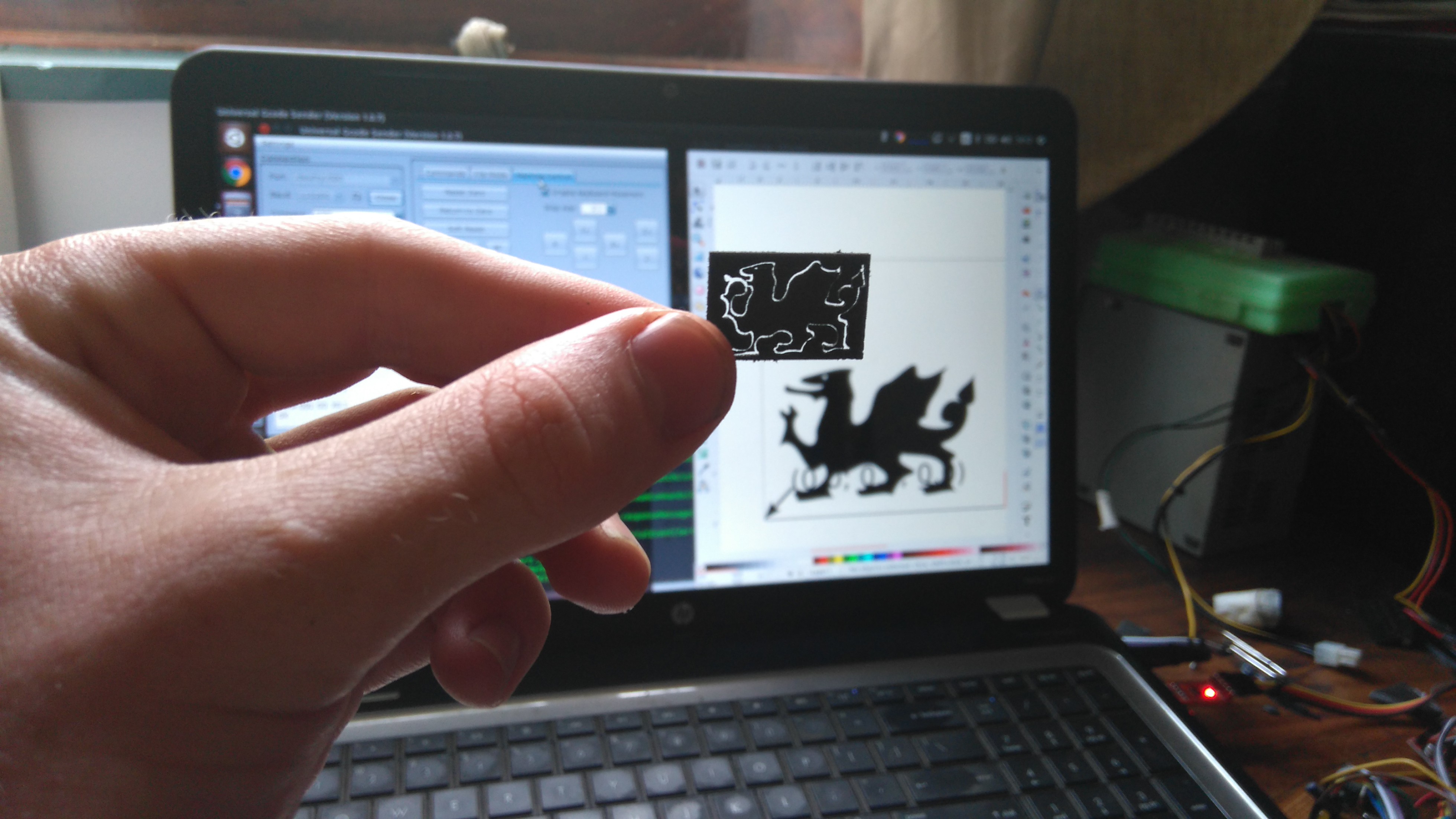

Had to share the first proper cut (after a triangle for calibration):

___EDIT____

What can it cut?

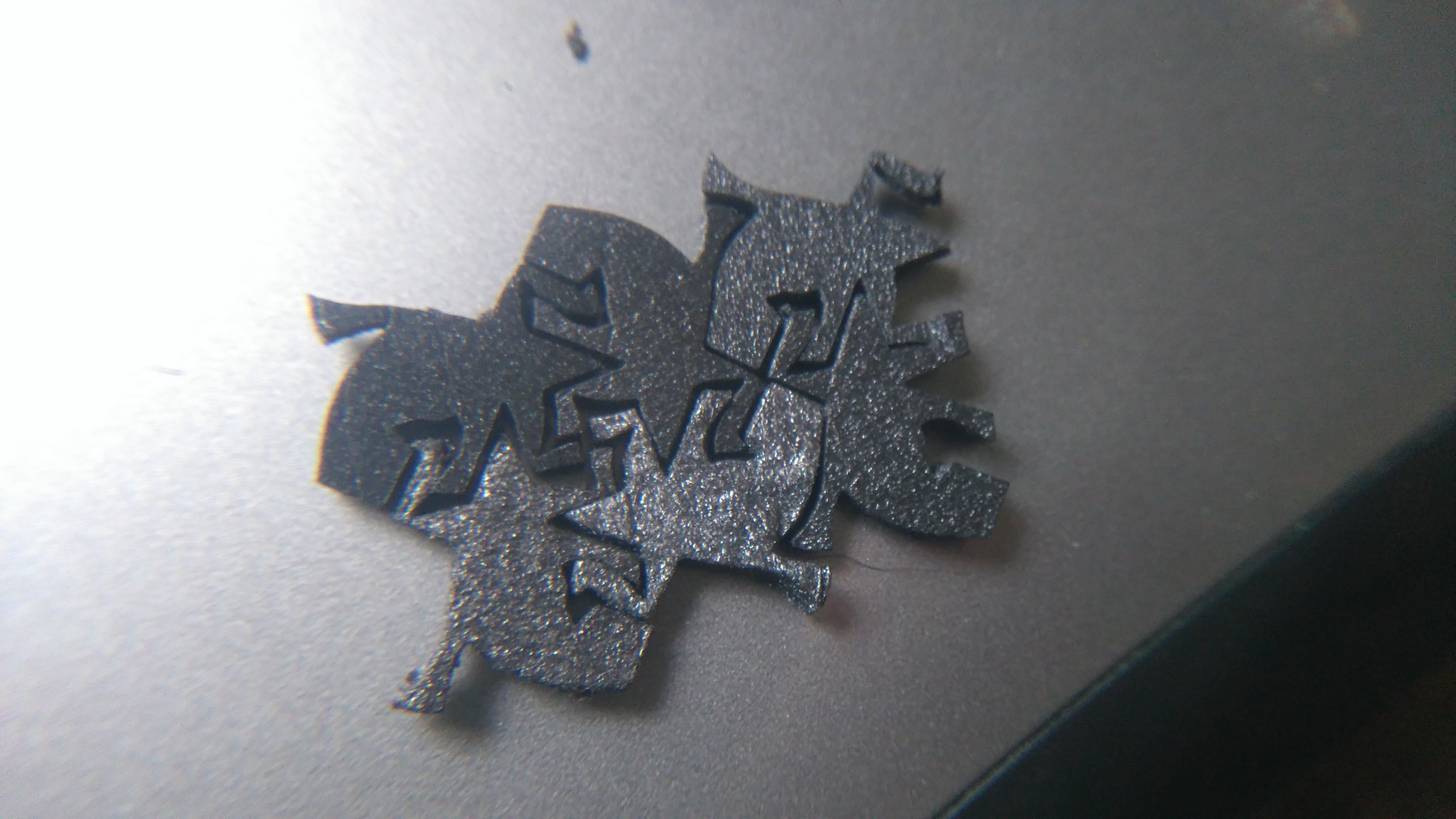

It struggles with white paper, or anything very light coloured. It cuts through bin liners easily, engraves black plastic (eg my phone cover) like a charm, can cut black electrical tape at slower speeds, makes short work of 1mm black polystyrene (from which i have cut the obligatory tesselating escher lizards) and gets 2mm into thicker polystyrene.

johnowhitaker

johnowhitaker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Sure! Its pretty simple - based around an LM317 mounted to a heatsink (also from the dead PSU).

I kind of followed this schematic:

The cap I used is 100nF, the diode isn't really important, the total resistance I dialed in with a variable resistor and then replaced with three 2.2ohm resistors as that gave me a ~200mA current flow through the laser, which had a ~2.4V drop, so ~480mW (spot on for my 500mW laser). I didn't bother with a fuse, and instead of the switch you can drive it from the arduino with a transistor.

I had to follow some guide to disable variable spindle speed in gbrl 0.9, which lets you use the spindle enable pin as a laser on pin. You can also just use a switch and manually do it (good for testing).

I am also running it from 12V since getting 9V out of the PSU I'm using was a pain. This isn't a big deal since the LM317 is mounted to a heatsink, but when it wasn't it got sizzling hot within 20 seconds due to the excess power it's having to dump.

Are you sure? yes | no

Thanks! I figured the driver would be based on a LM317 but there seem to be some variations out there so I was interested in your take on it since it seems to work reliably. Those additional tips are very helpful as well!

Also thanks for the update on what materials can be cut, good stuff! Do you think the laser is up to etching spray paint as done here?

Are you sure? yes | no

Couldn't find spray paint to test, but I had thought of that! What does work is sticking down some think black plastic/tape and burning out the design, but it's fiddly to get the bits that are left in off without peeling back the rest. I am definitely going to try a few more things, and see what I can fit in a 2.5cm by 3.5cm PCB :P

I also tried burning off permanent marker in place of paint, but no joy.

Thanks for the idea though!

Are you sure? yes | no

Ah hah, a simple between-step... use the burnable tape as a stencil for spraypaint... hmm...

Are you sure? yes | no

@esot.eric Hmm, yes. But like @johnowhitaker said, plucking 32 tiny pieces of tape from a board to reveal the pads of a QFN32 footprint sounds like a pain. Though as last resort if the laser is to weak to etch the paint this would be a great alternative. Too bad the tape won't work as solder mask...

Are you sure? yes | no

or burn the entire area rather'n a line?

Are you sure? yes | no

Cool, I'm looking forward to see your experiments!

Regarding the work area, if you run out of ideas there's of course the #The Square Inch Project. Which sounds like a perfect match ;)

Are you sure? yes | no

Woot woot!

Are you sure? yes | no

oh my gosh... did I do some bad math trying to figure out my laser-driver...? Maybe that's why I burnt so many diodes! So lemme get this straight: P=VI=Vf(diode) * I... sheesh. I need to check my logs, somehow I think I was *equating* power to current, or something equally stupid.

Are you sure? yes | no

oh nooooooes ! poor diodes :-(

Are you sure? yes | no

I have tried again with cutting tape as a mask for a PCB. The new problem is that even very thin materials that would otherwise cut easily are now presenting difficulty due to being mounted right on to a lovely copper heat-sink.

I have one more idea that I want to try, but I will be travelling the next few weeks so maybe @esot.eric you can try this with your remaining working laser? Laser toner (i took apart a lasr printer yesterday so I'm rolling in the stuff) is designed to melt on. So If I can deposit the powder in an even layer I should be able to heat just the area of interest, then clean off the rest.

Are you sure? yes | no

whoa, now there's a concept! I haven't got any toner to try it with, but I'll definitely keep it in the ol' concept-banks... Maybe powder of different sorts. Definitely want to hear if you/anyone else tries! Hey, if that works, then maybe the next step is *cough* 3D-powder-printers ;)

Are you sure? yes | no

@Stefan Lochbrunner, did you see this? It's been achieved!

Of course, toner's meant to be melted, so it wouldn't make for a good solder-mask, but then... spraypaint atop, and heat to melt the toner off, and you've got your soldermask :)

Are you sure? yes | no

Oh yes, I didn't think about the copper sinking the heat but maybe it works on an actual PCB where small pads can't sink the heat.

@esot.eric You mean like a lift-off process?

Are you sure? yes | no

that's encouraging !

Are you sure? yes | no

Thanks :)

Are you sure? yes | no

Very cool! I love the way the axis are mounted in the PSU case and can take advantage of the fan. Could you please share some info on your laser diode driver?

Are you sure? yes | no

Meant to reply to your comment :P

Also, thanks for pointing me to stepstick on another log - I have a friend wanting to mess around trying this and those are insanely cheap! Lowers the barrier to entry even further.

Are you sure? yes | no

Yeah, it's crazy how cheap those are. The ones I bought (for 5$ each at that time XD) have all the components on one side but there there are also ones that have the IC and the passives on opposite sides which would make mounting a heatsink easier, just a thought.

Are you sure? yes | no