-

Alu parts are back!

04/27/2018 at 16:52 • 0 commentsThe CNC milled coolers are back from anodising, and they look... wow

![]()

-

Illustratrion time

04/25/2018 at 21:39 • 0 commentsIn order to enhance the communication of my concept i decided to use the waiting time for the anodised parts for some drawings which should help to explain the concept behind the Blackbox.

![]()

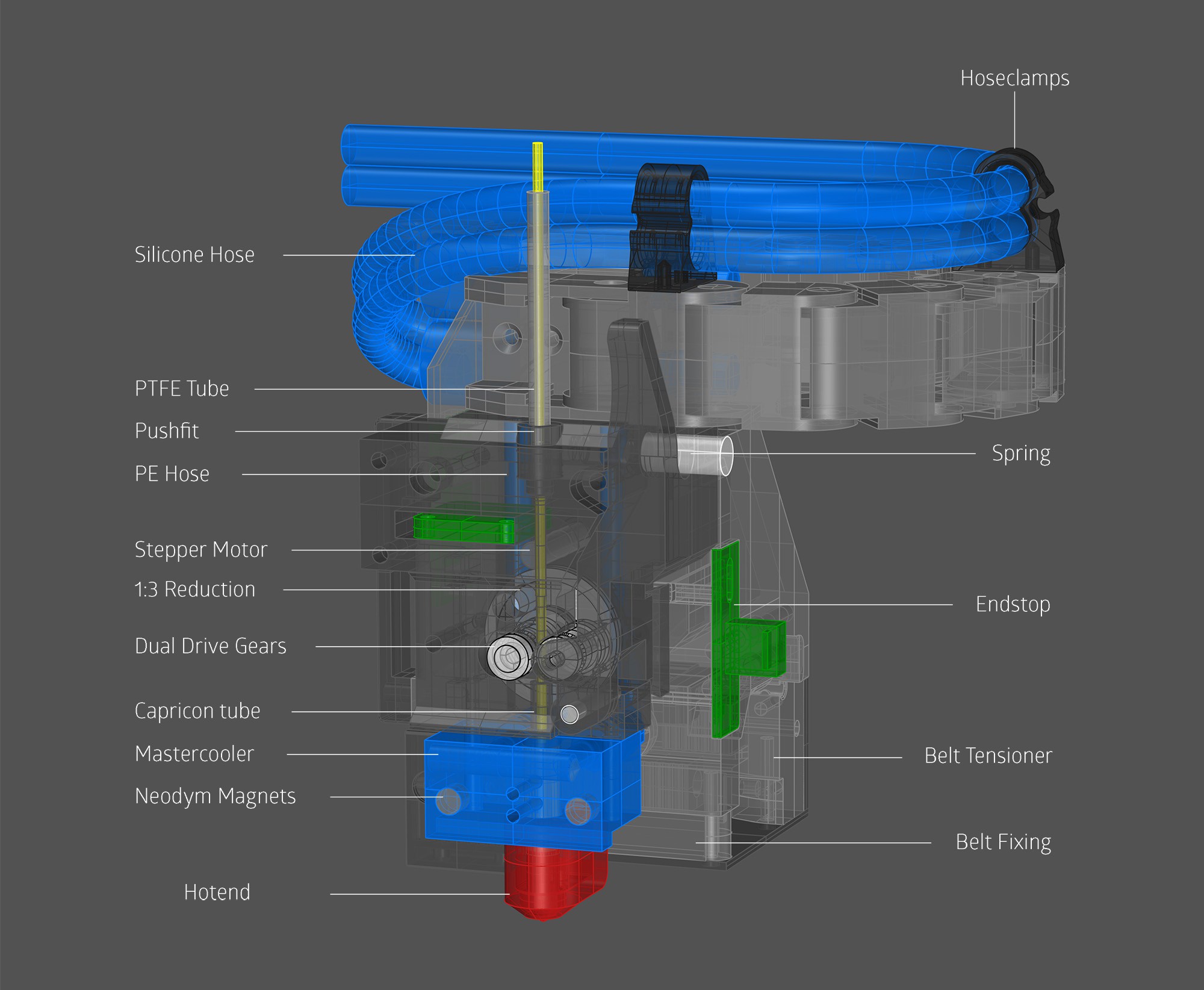

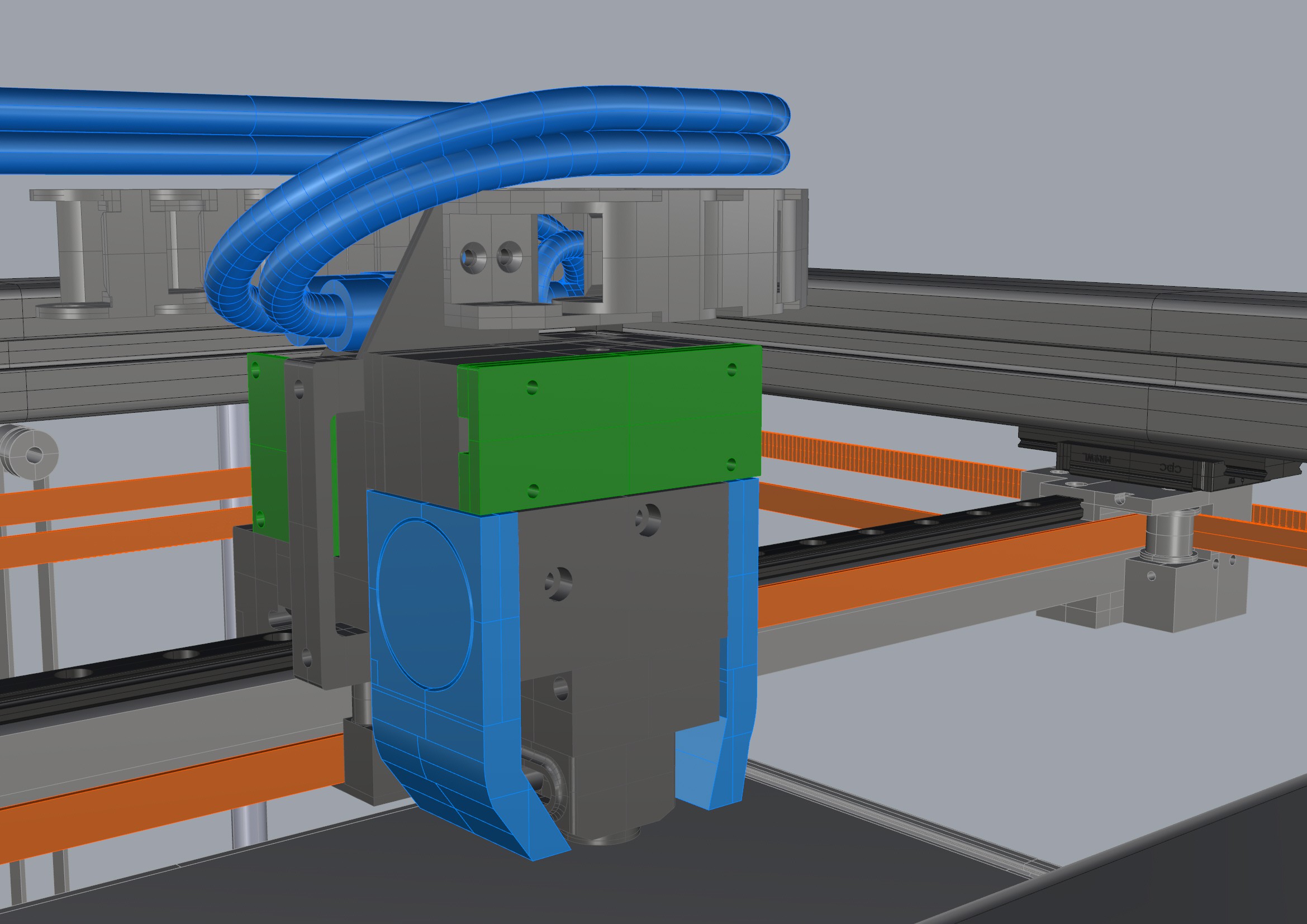

X-Axis, direct drive extruder and toolchanger.

![]()

Toolchange process, the X-Axis has a watercooler as well as the toolbank. So no matter where the tool is hooked to it gets cooled by it.

![]()

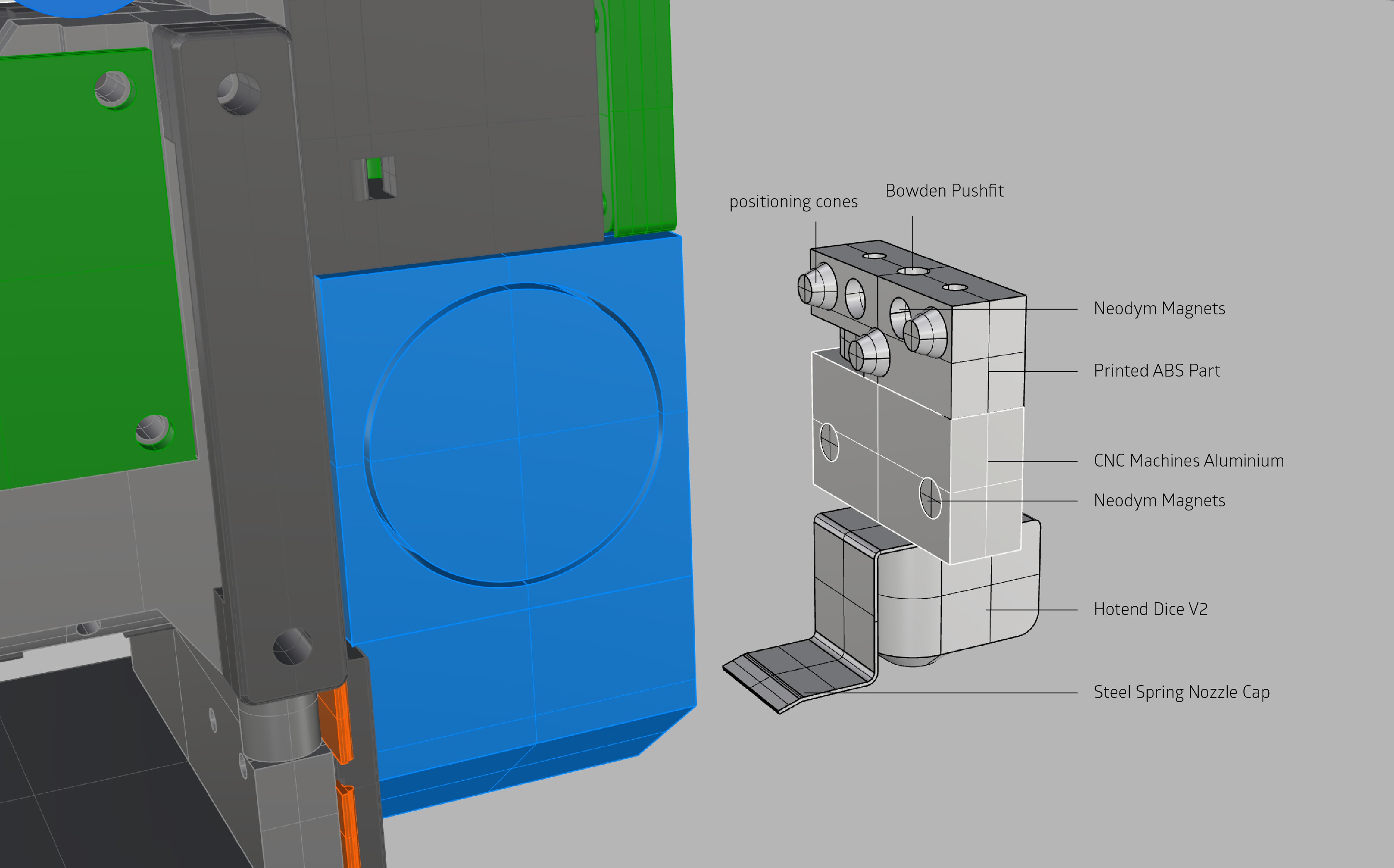

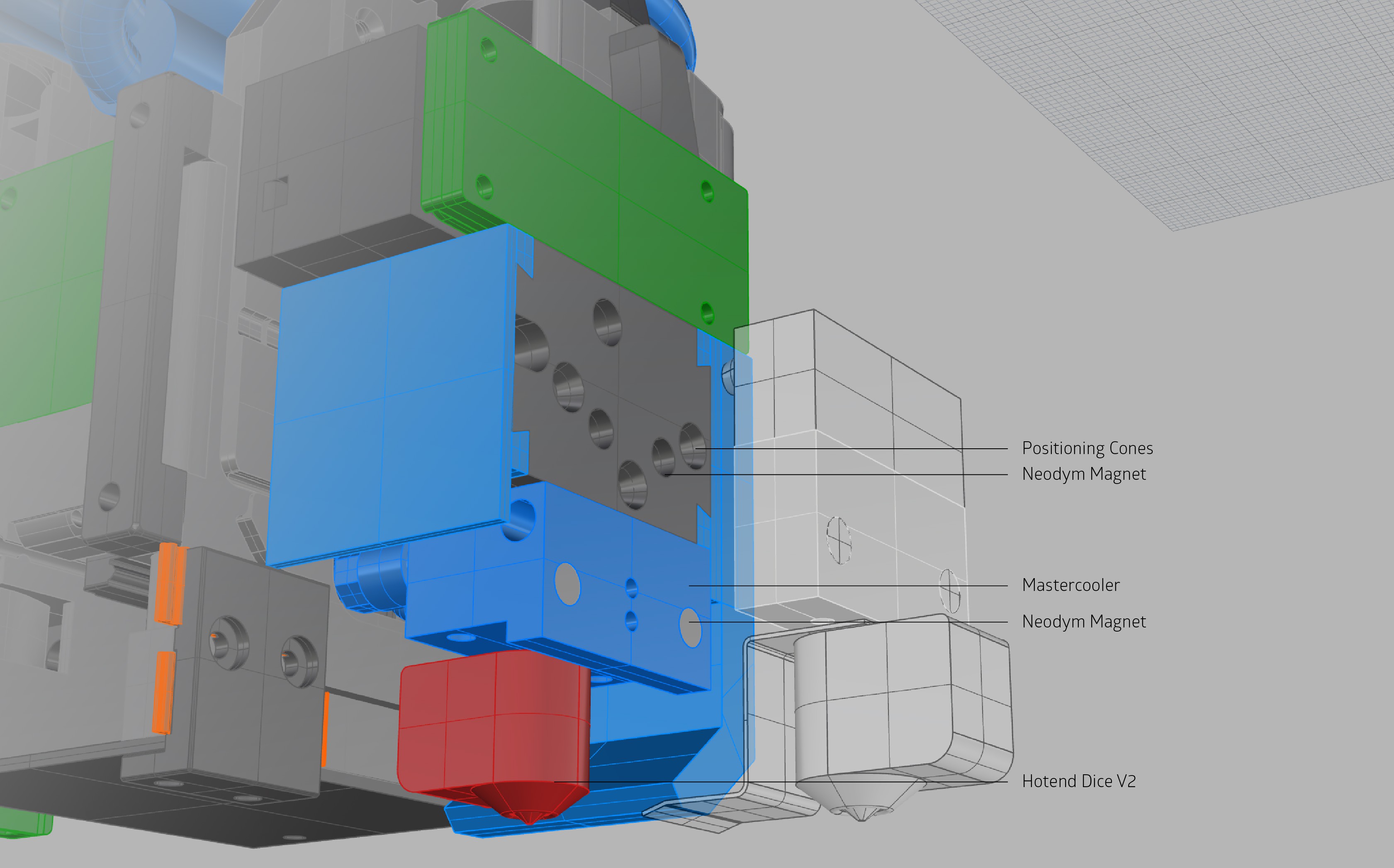

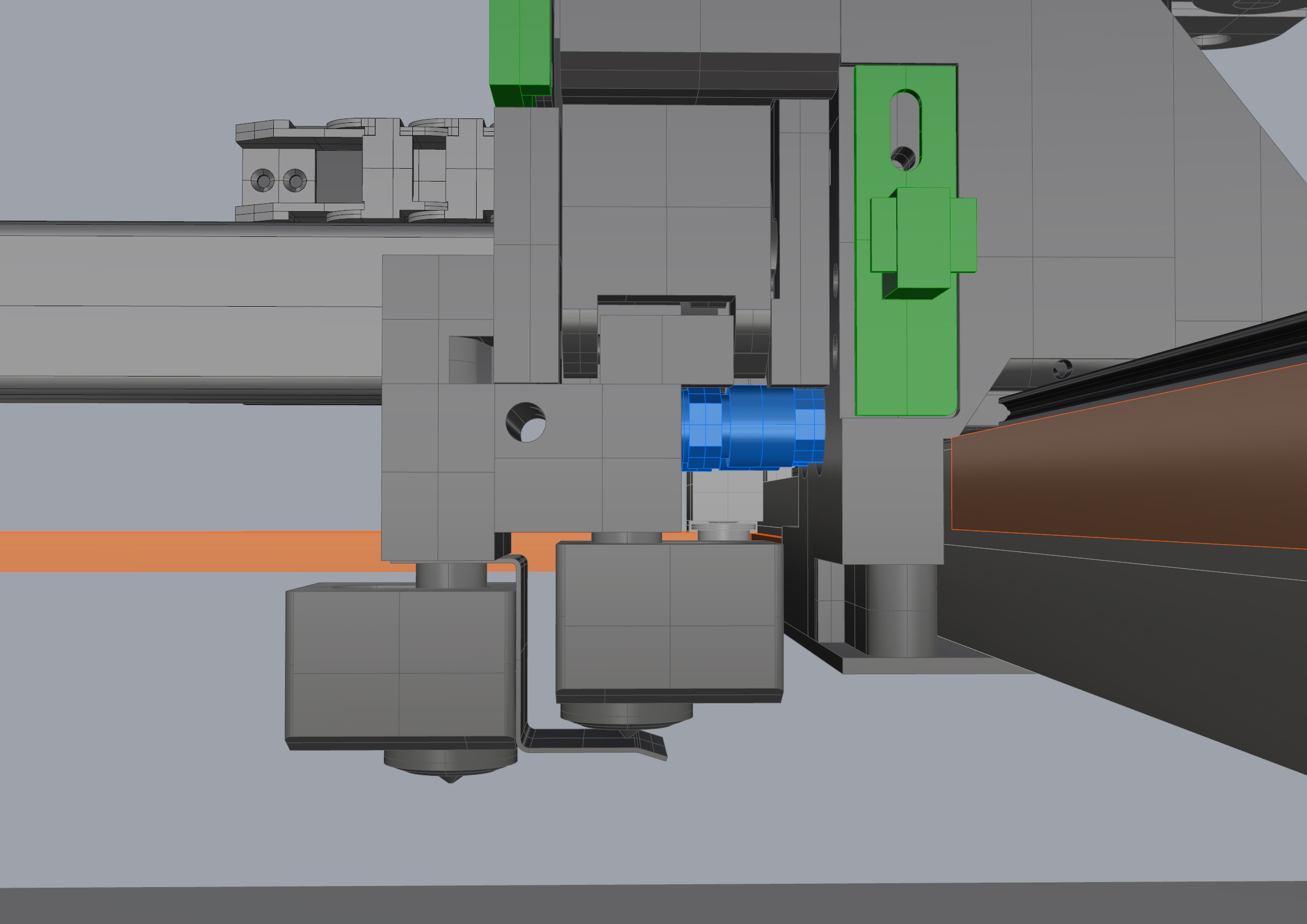

A single tool close to the X-Axis. The CNC machined alumium parts touch the Mastercooler and are constantly pulled by neodym magnets. The tools can be very compact and lightweight that way. Lightweight tools are making the coupling process much easier.

![]()

The X-Axis side of the toolchanger. You can see the blue Mastercooler which features two neodym magnets. Dividing the tools and the coupling into two Parts (Aluminium parts for cooling and printed parts for coupling) makes this solution way more accessible.

![]()

Here you see the belted Z-Axis. The reduction happens next to the stepper motor which transmit the force to a 5mm rotation axis.

-

Watercooling is (almost) ready

04/14/2018 at 13:31 • 0 comments![]()

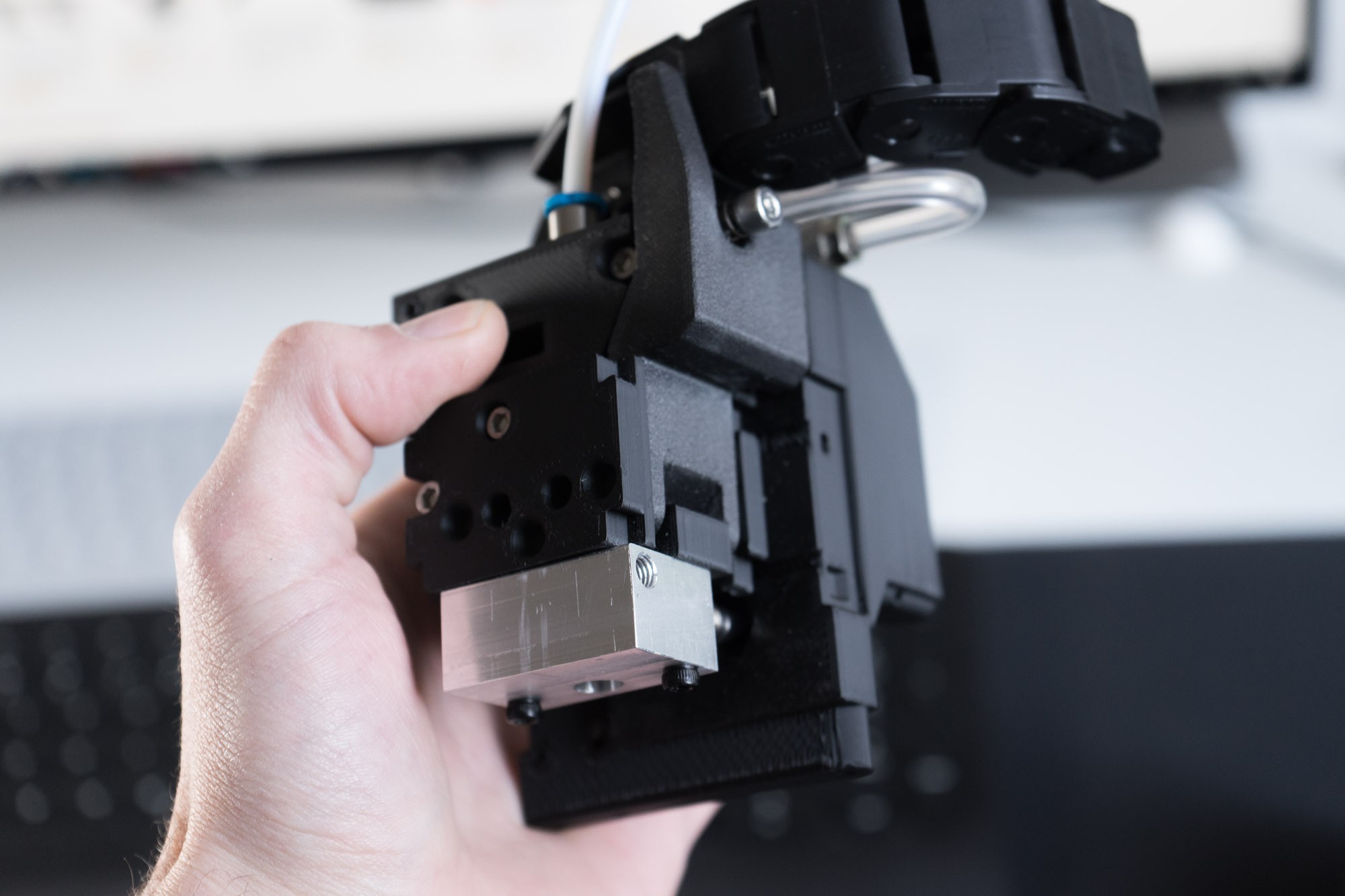

The CNC Parts are back from the shop, and they are awesome!

I had to wait two weeks for them, but it was worth it. Next step will be sanding and anodising the parts. I think this is necessary to prevent corrosion, but also to achieve a harder Surface for the tool changer.![]()

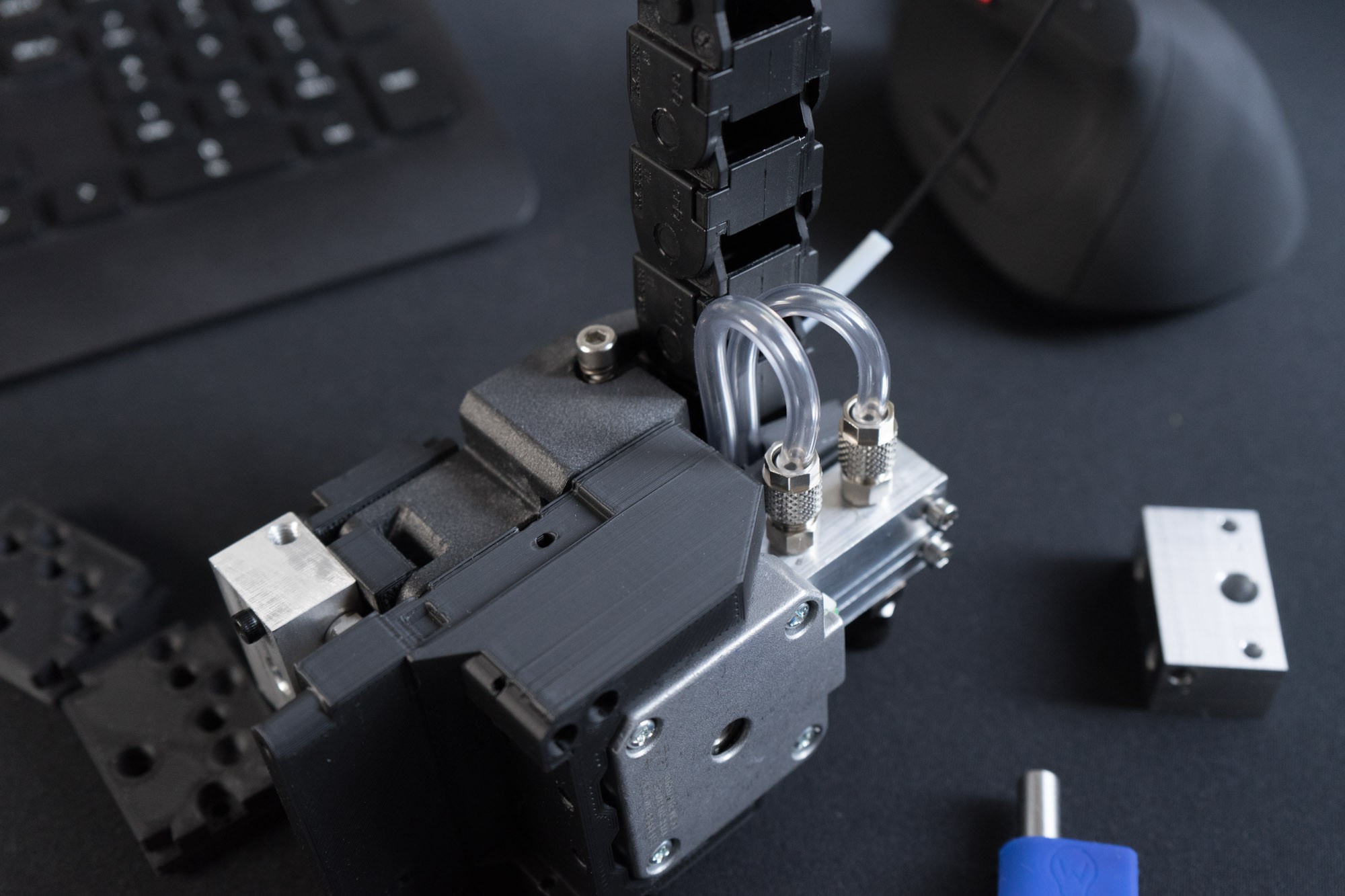

X-Axis/Extruder and the mastercooler which will cool the direct drive extruder directly and the tools indirectly

![]()

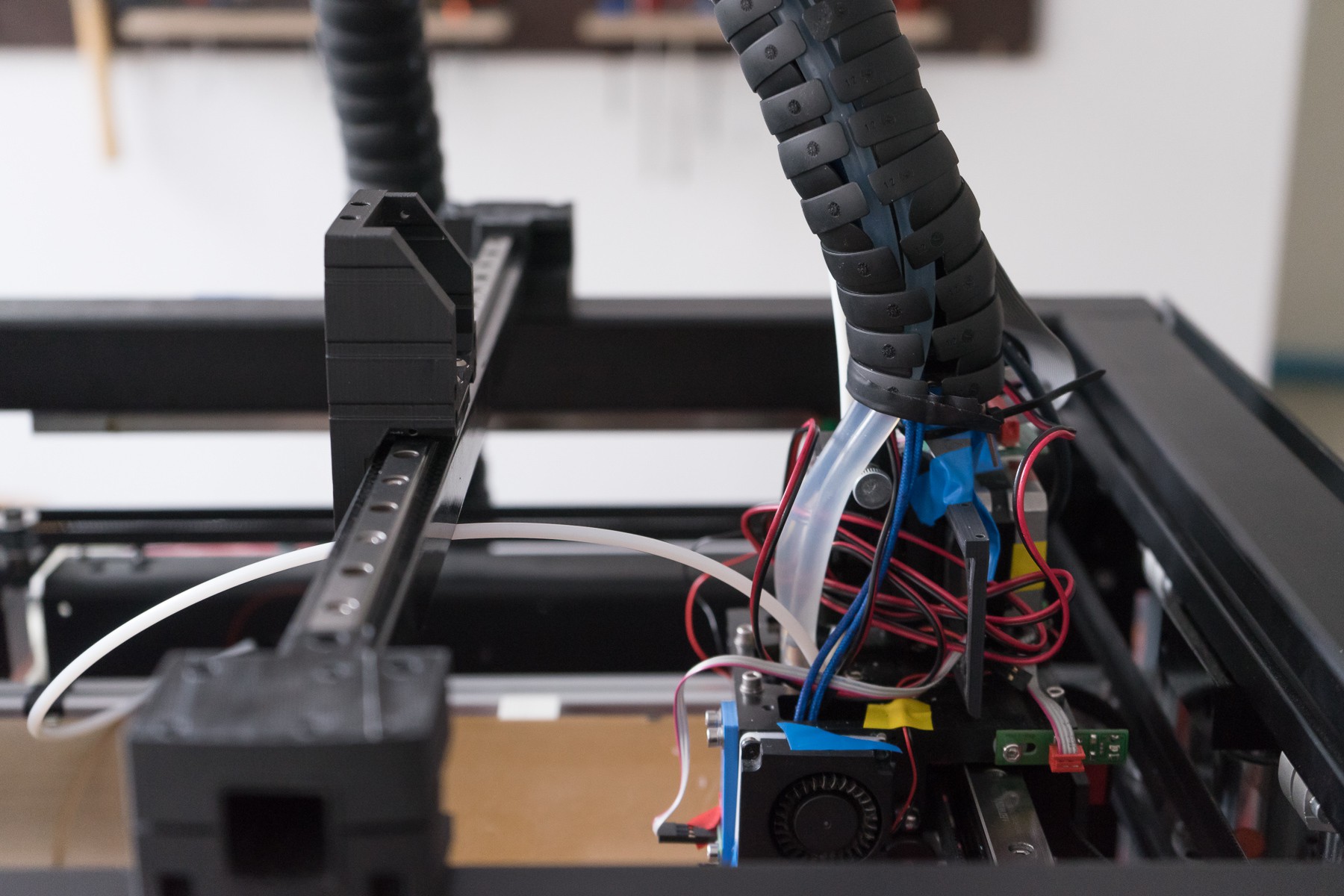

i wanted to use compression fittings known from PC watercool systems. They turned out to be way too heavy so i swapped them with PE fittings used in the chemical industry.

![]()

While i waited for the tools to be machined i worked on how the hoses are guided along the energy chain.

![]()

Z-Axis is also on a good way, the tension mechanism is ready, just a few brackets left to do.

-

Quick Update

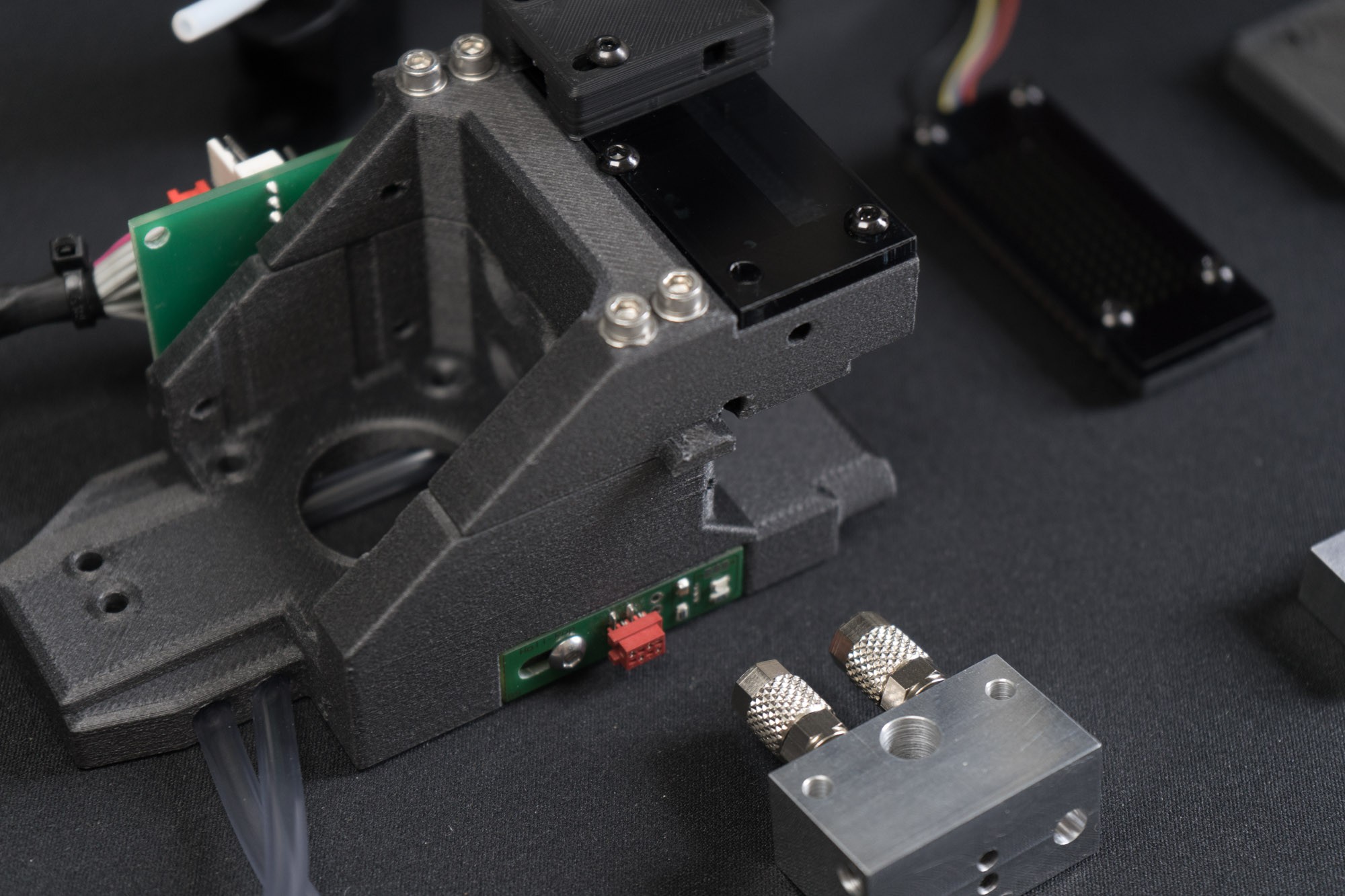

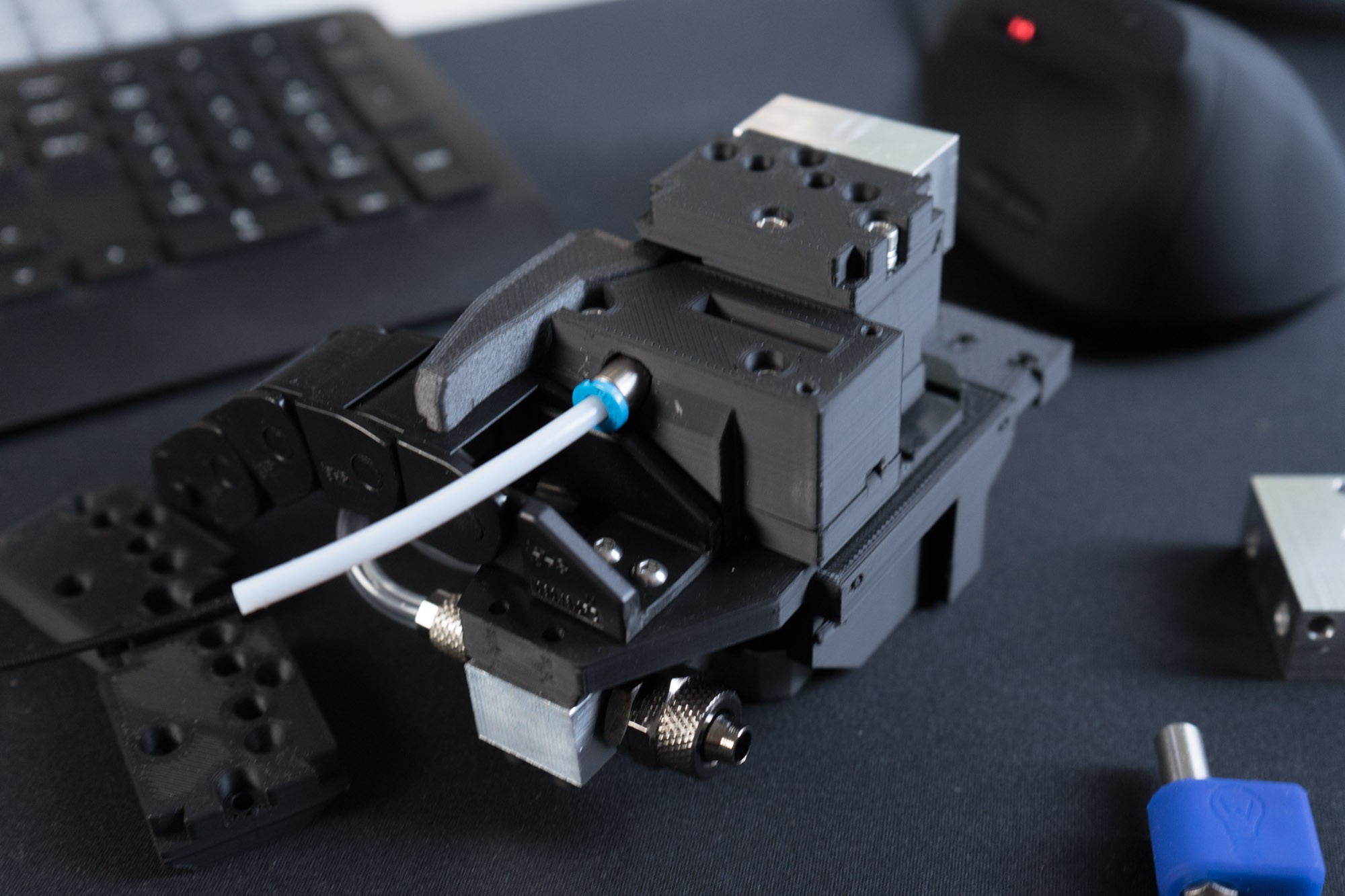

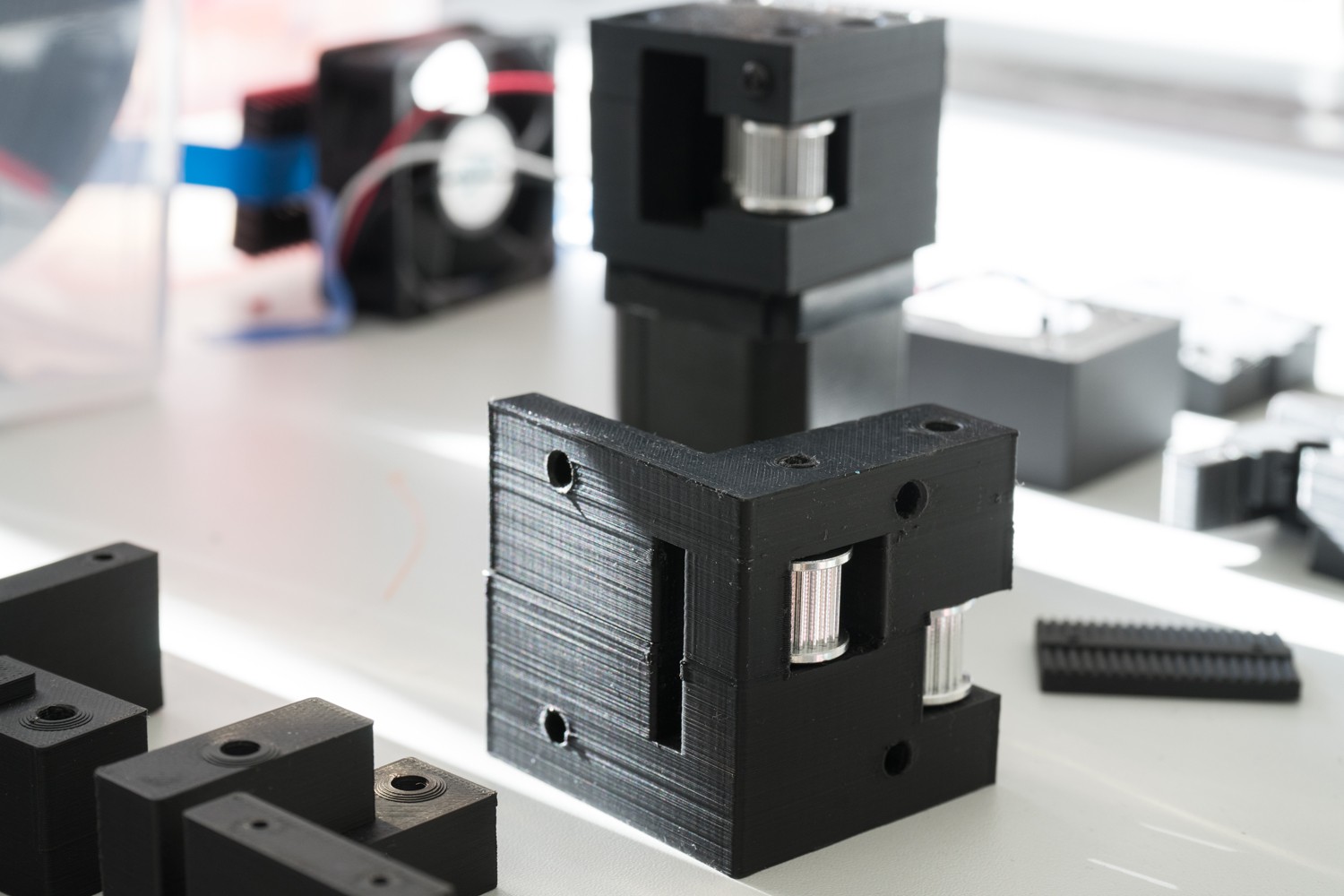

03/24/2018 at 16:50 • 0 commentsJust a quick update: Im currently way behind my time shedule, i was a bit distracted setting up my new workstation and the Extruder turned out to be really tricky in detail. Anyway im close to finish with the 4. Iteration and will upload the new source files soon. What you see here is a modificated Bondtech BMG with a custom Waterblock/Tool changer and Belt fixtures (basically 90% of the X-Axis)

![]()

![]()

![]()

![]()

![]()

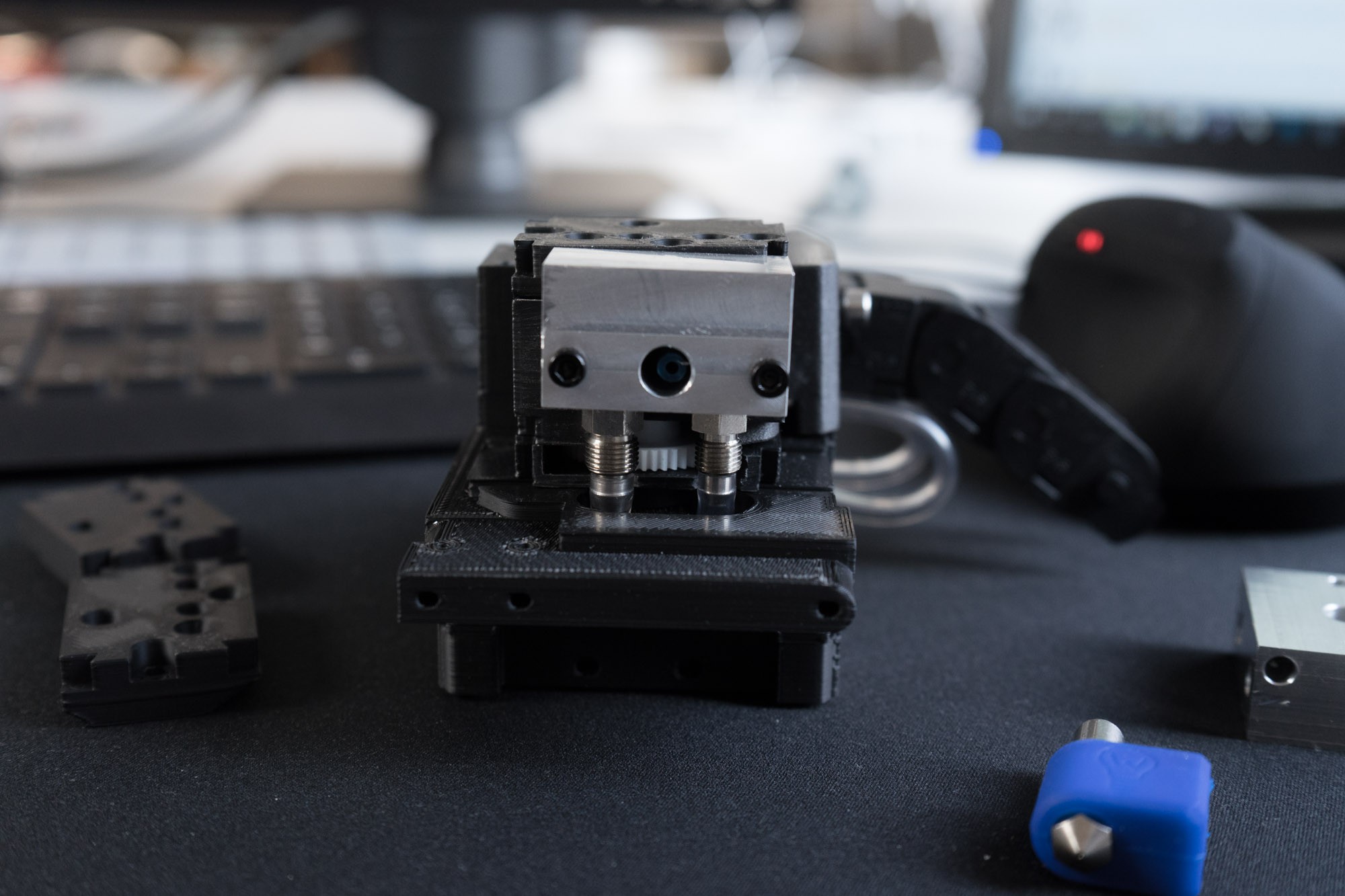

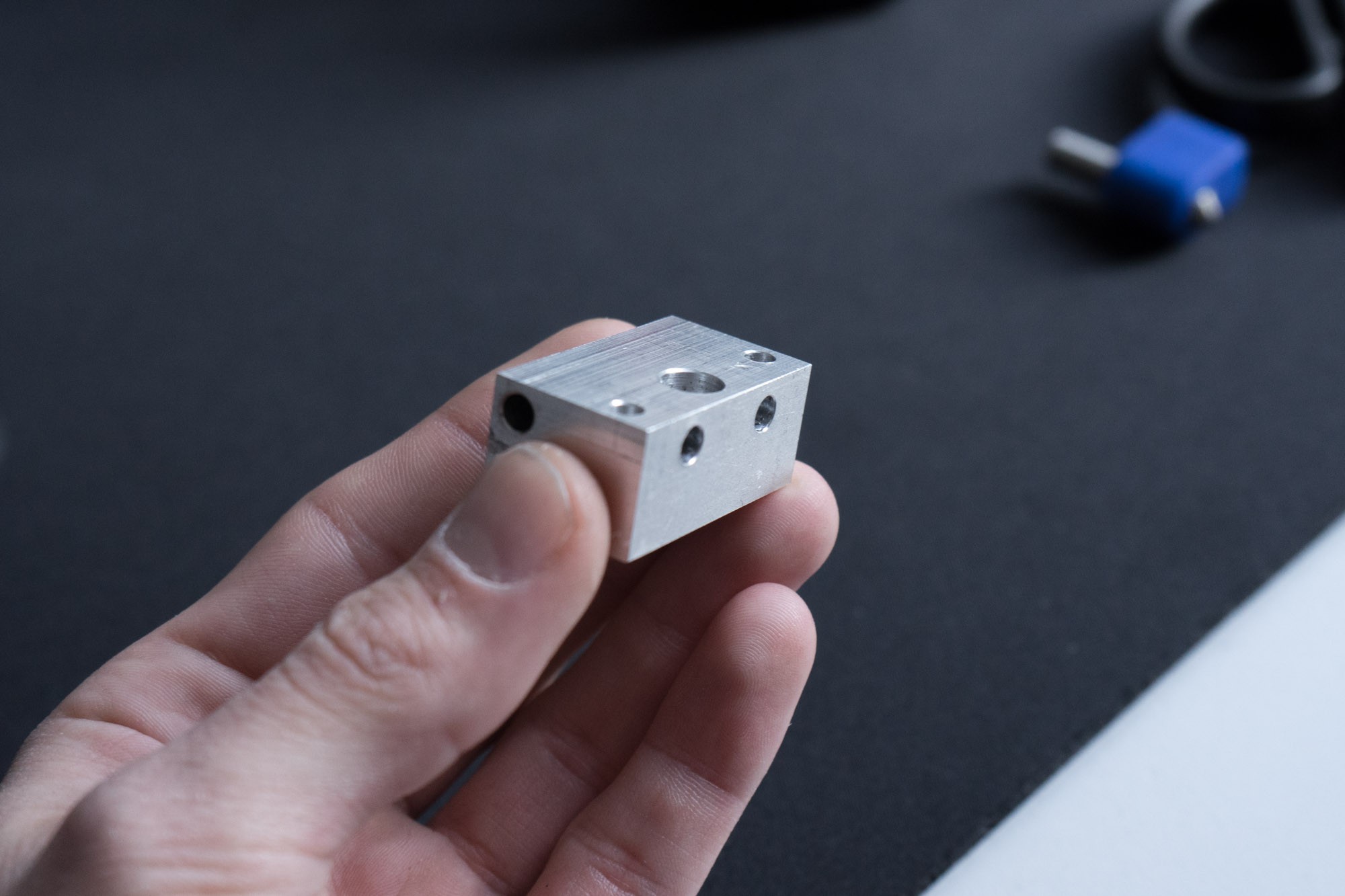

Custom Waterblock, its a very waterblock with two fron holes and one cross hole which get sealed with two grubscrews.

![]()

The magnet side of the Waterblock, tools will be attached to the block and hopefully cooled enough just by contact. Magnets are inset .1 so they are permanently pulling.

![]()

Hose adapter and water block for the Extruder in one Part.

-

Introducing the BOM

02/26/2018 at 21:41 • 0 commentsI started the Blackbox BOM, i don´t know whats the best way to keep track of all the Items but until now im using a google docs excel sheet:

https://docs.google.com/spreadsheets/d/1L5v7SuMWrlGfRz0OFCthQMxkcMX9GIYf3i2thz9PU30/edit?usp=sharing

The Price (Without Acryl Housing, Screws Nuts and Watercooling) should be around 1400€.

Yes, this is not a cheap Printer but it could be dropped way down with cheaper retailers. If you want to collaborate on this BOM just contact me.

-

Blackbox V0.3 - STEP Files

02/25/2018 at 18:59 • 0 commentsThese are the current CAD Files for the Blackbox Printer. I don´t recommend replicating it yet!!! I didn´t planed to release the files so early but due to request i decided to change my plans. Most Parts are untested. The Frame howeever is final and will not be changed.

It would be really nice if you would share Feedback, Ideas and toughts!

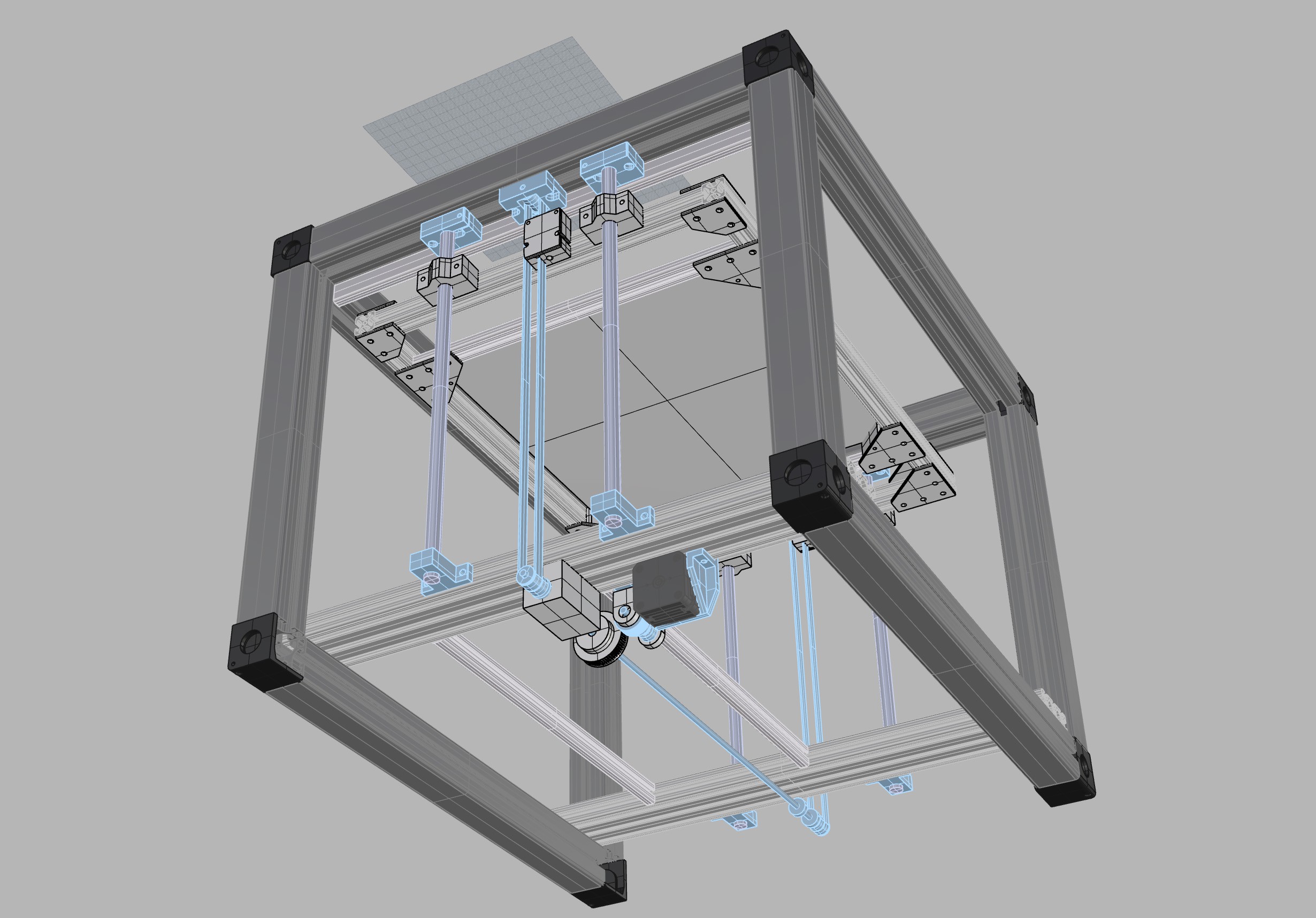

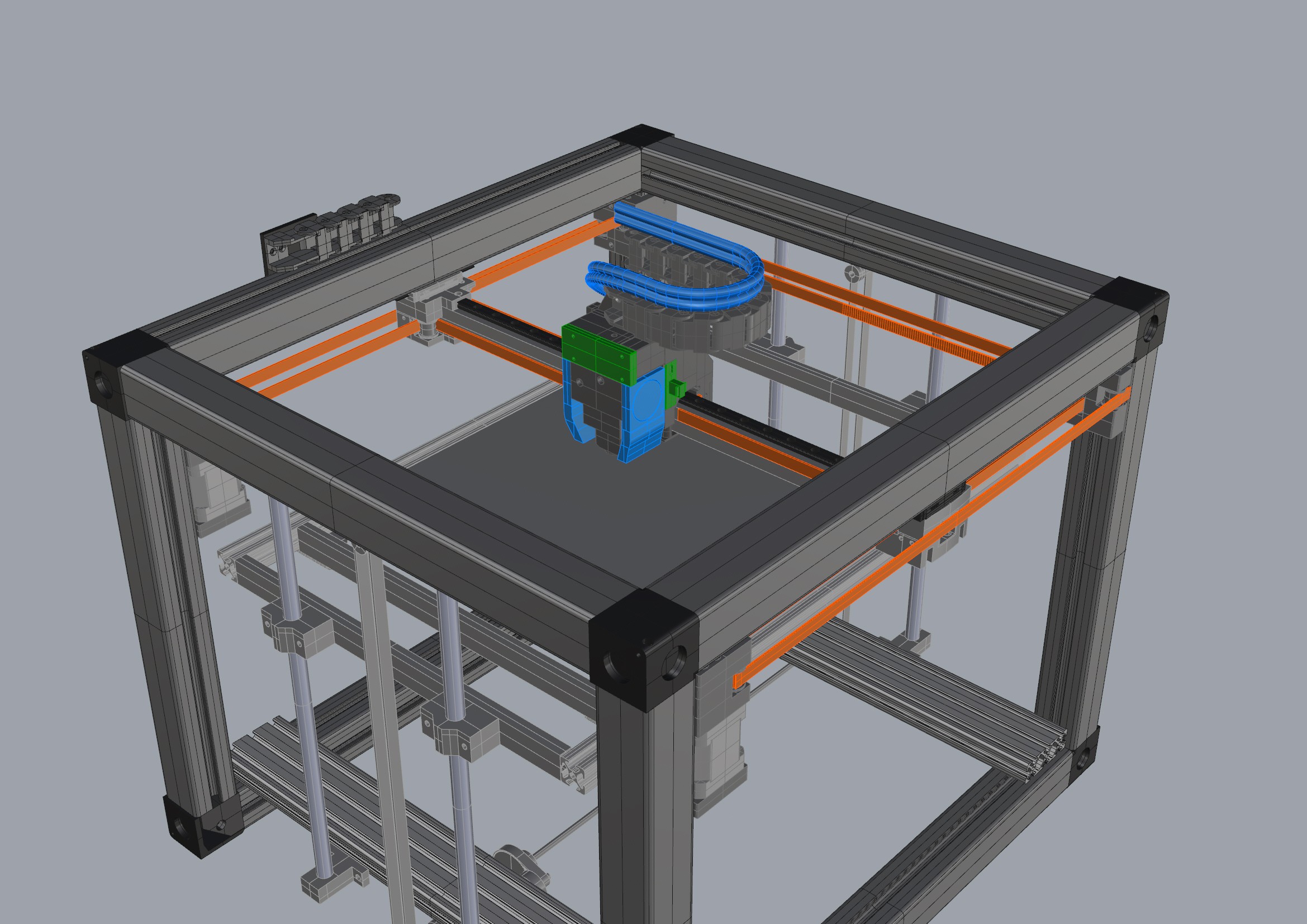

![]()

T-Slot Frame

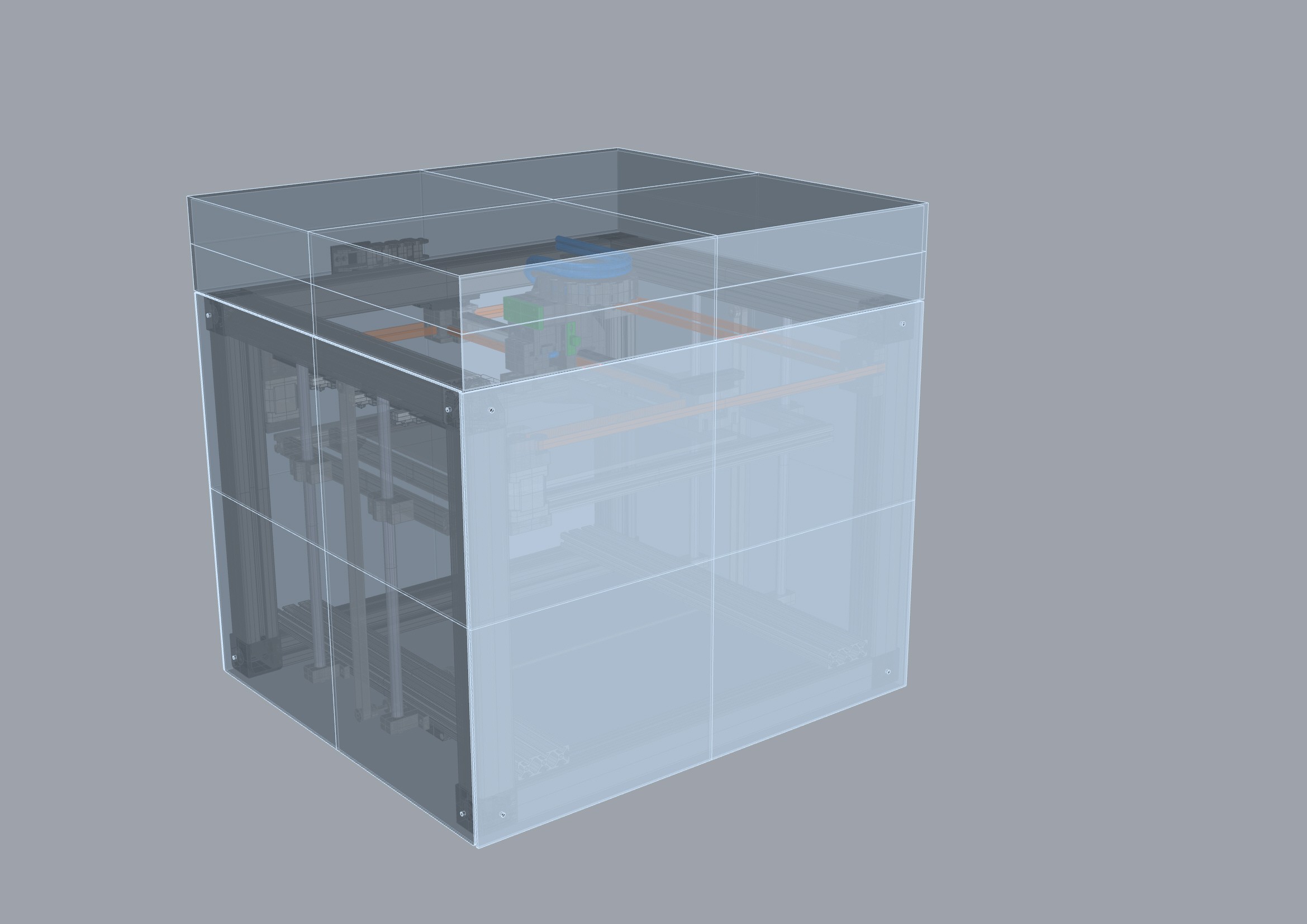

![]()

Blackbox with Acryl Housing

![]()

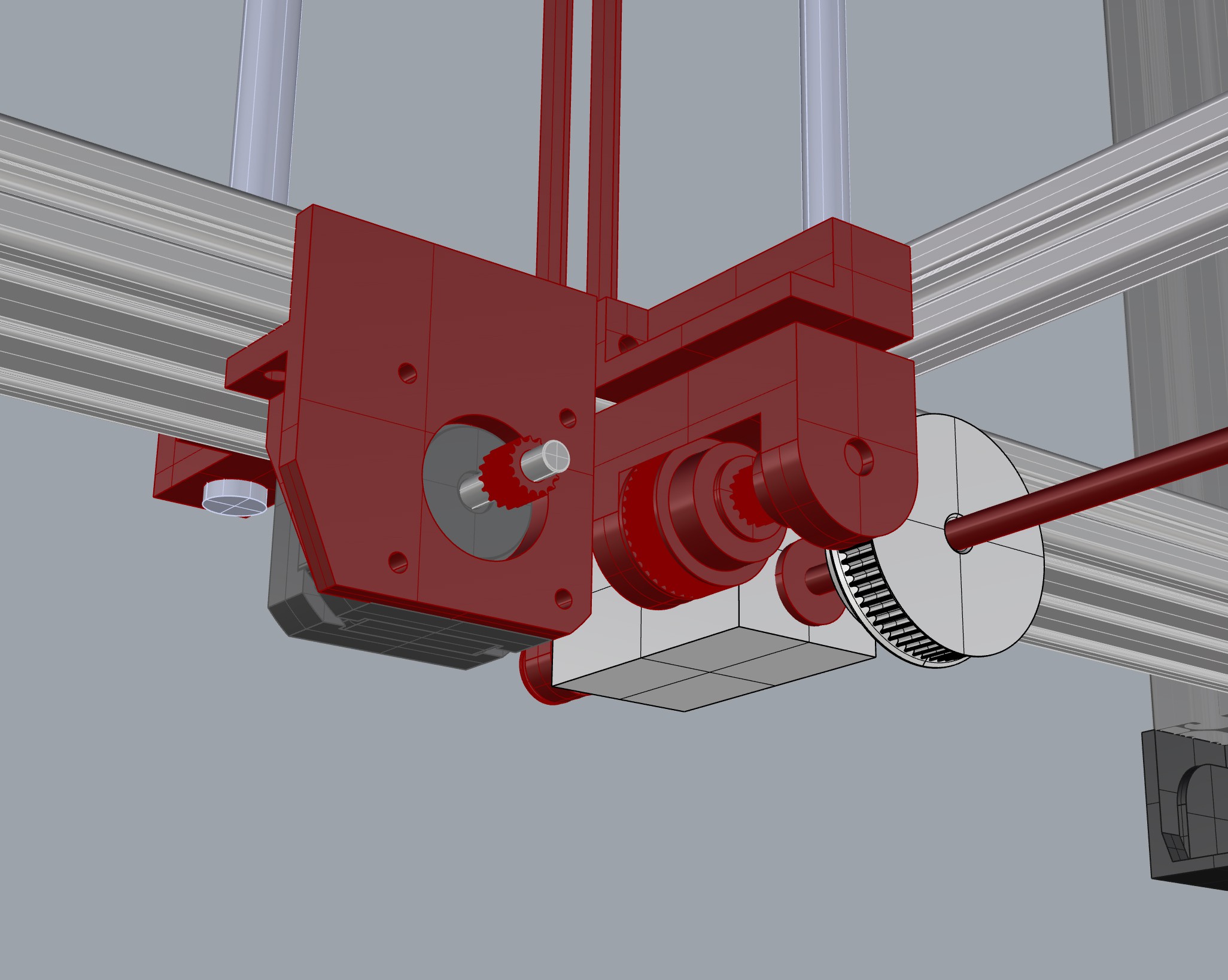

Direct drive Extruder / Custom Bondtech

![]()

Watercooled toolchanger

![]()

Watercooled tool Rack

![]()

1/2 of the Extruder Bracket

![]()

Belted Z-Axis and Belt gear 1:10 (Draft)

-

Blackbox V0.3

02/25/2018 at 18:39 • 0 commentsThis will be the new (and huge) Update for the Blackbox.

Major Changes:

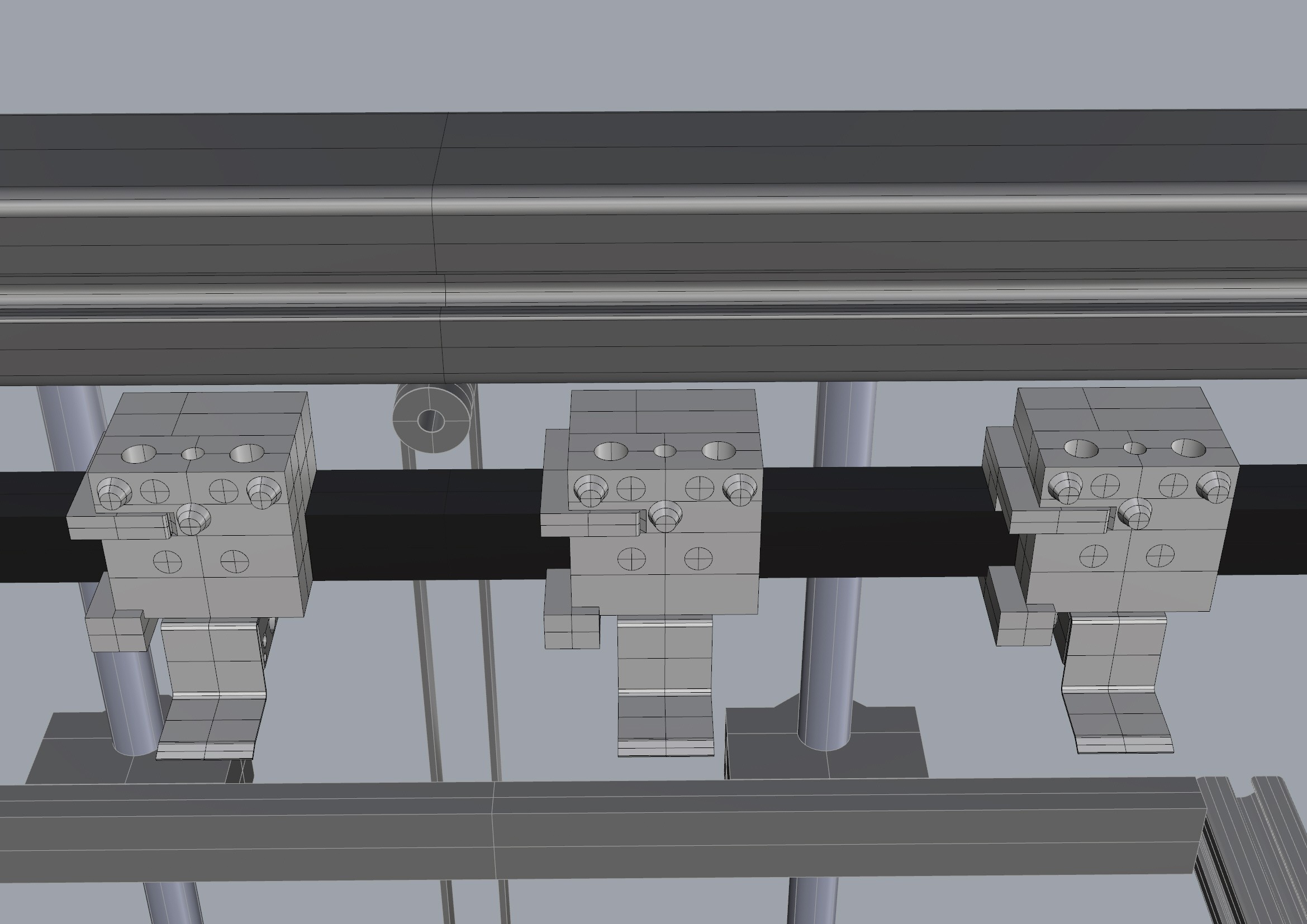

- Carbon supported X-Axis

- Extruder carriage (Draft)

- Custom Bondech Extruder (Draft)

- Motor Brackets

- Pulley Brackets

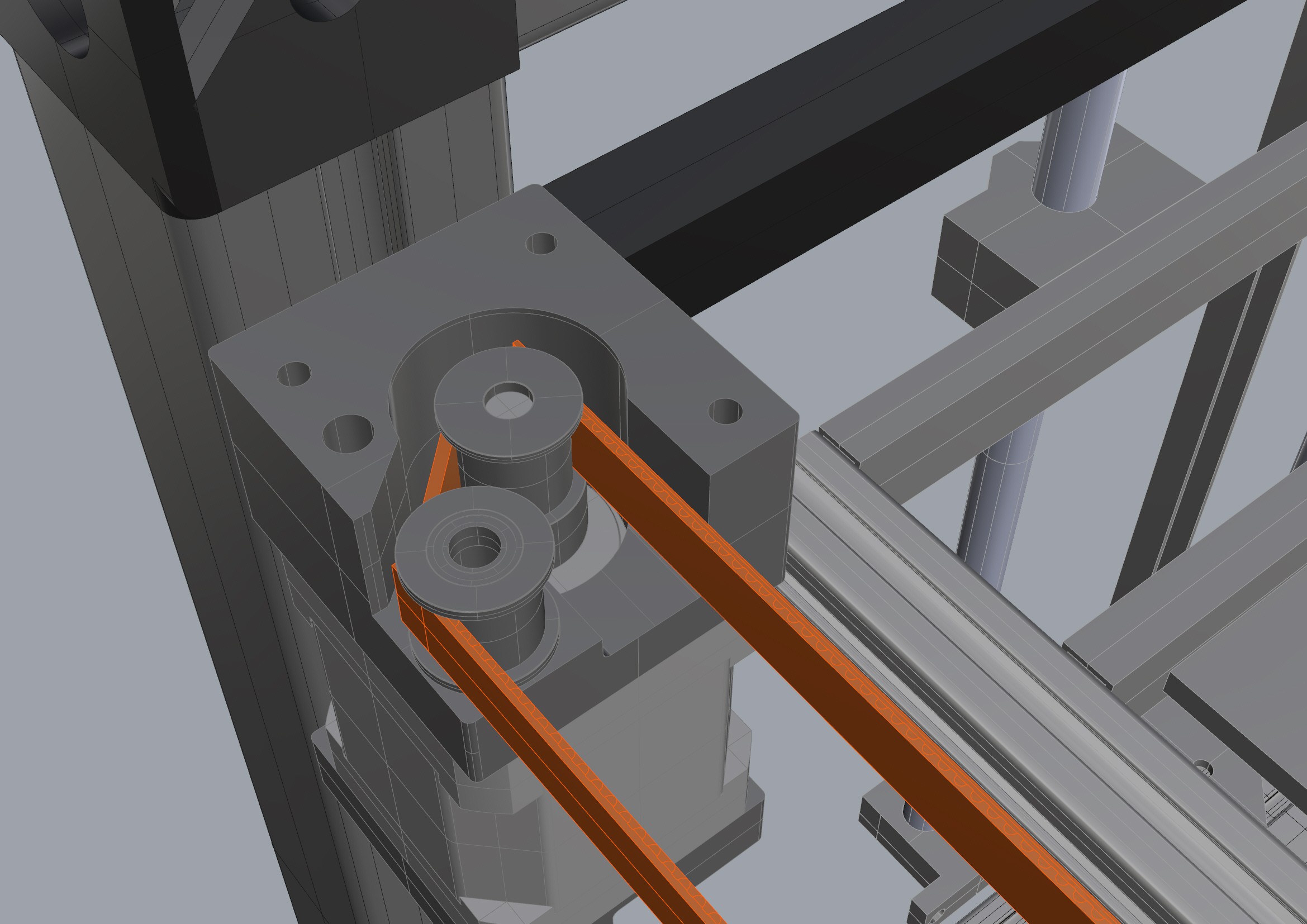

- Belt driven Z-Axis (Draft)

- Watercooled Toolchanger (Draft)

- New User Interface (7x15px LED Matrix) (Draft)

As you can see it´s quite a List, im currently focusing on the XY Axis. Motor Brackets, Pulley Brackets and the X-Axis are ready to test. As soon as im done with the Extruder Carriage and Custom Bondtech i will order them from Shapeways and test them. I want to be done with XY update by 11.03.18.

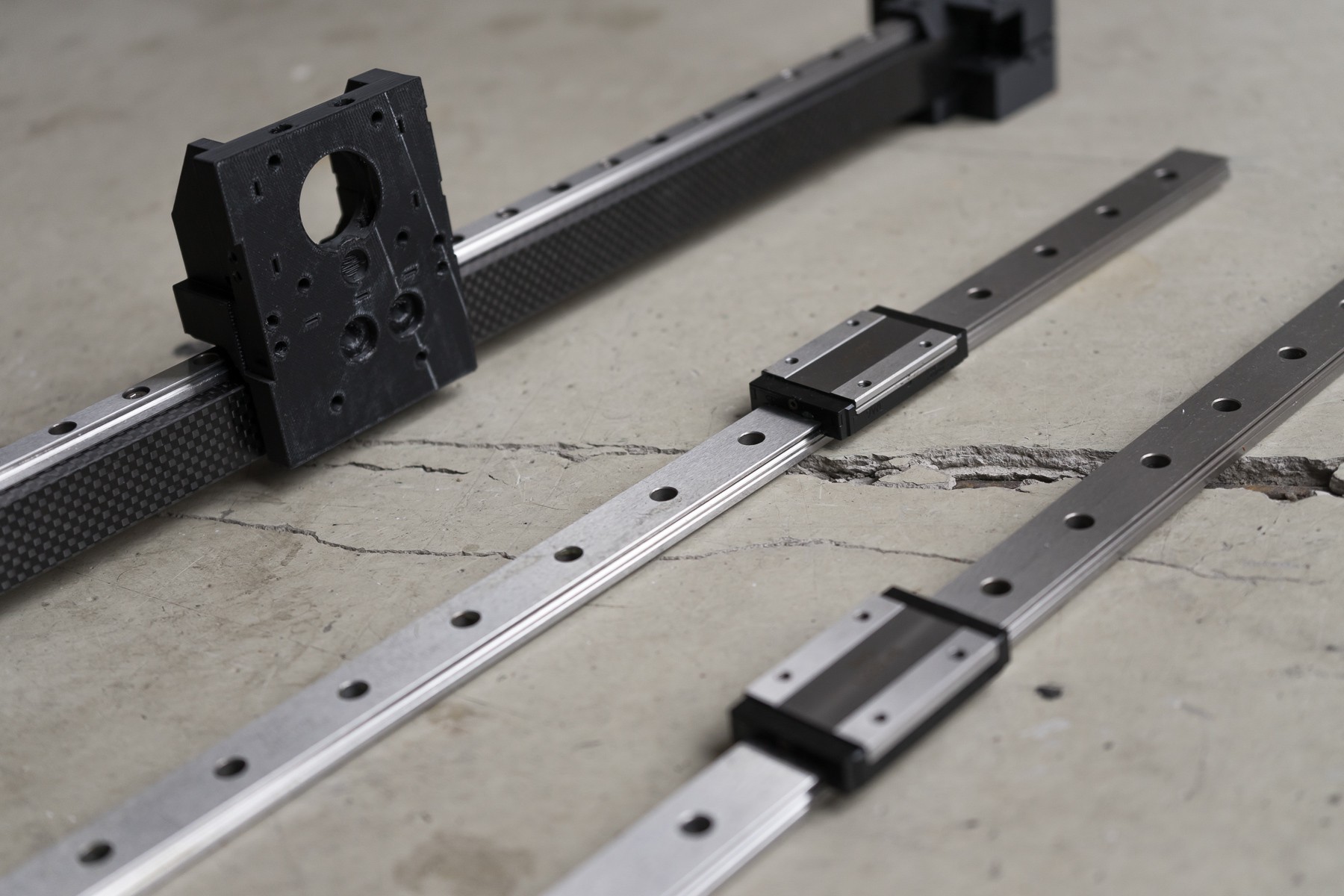

![X and Y linear Rails X and Y linear Rails]()

These are the new Linear Rails and bearings i got from Smalltec: MR-9 M for X and 2x MR-9 W

![]()

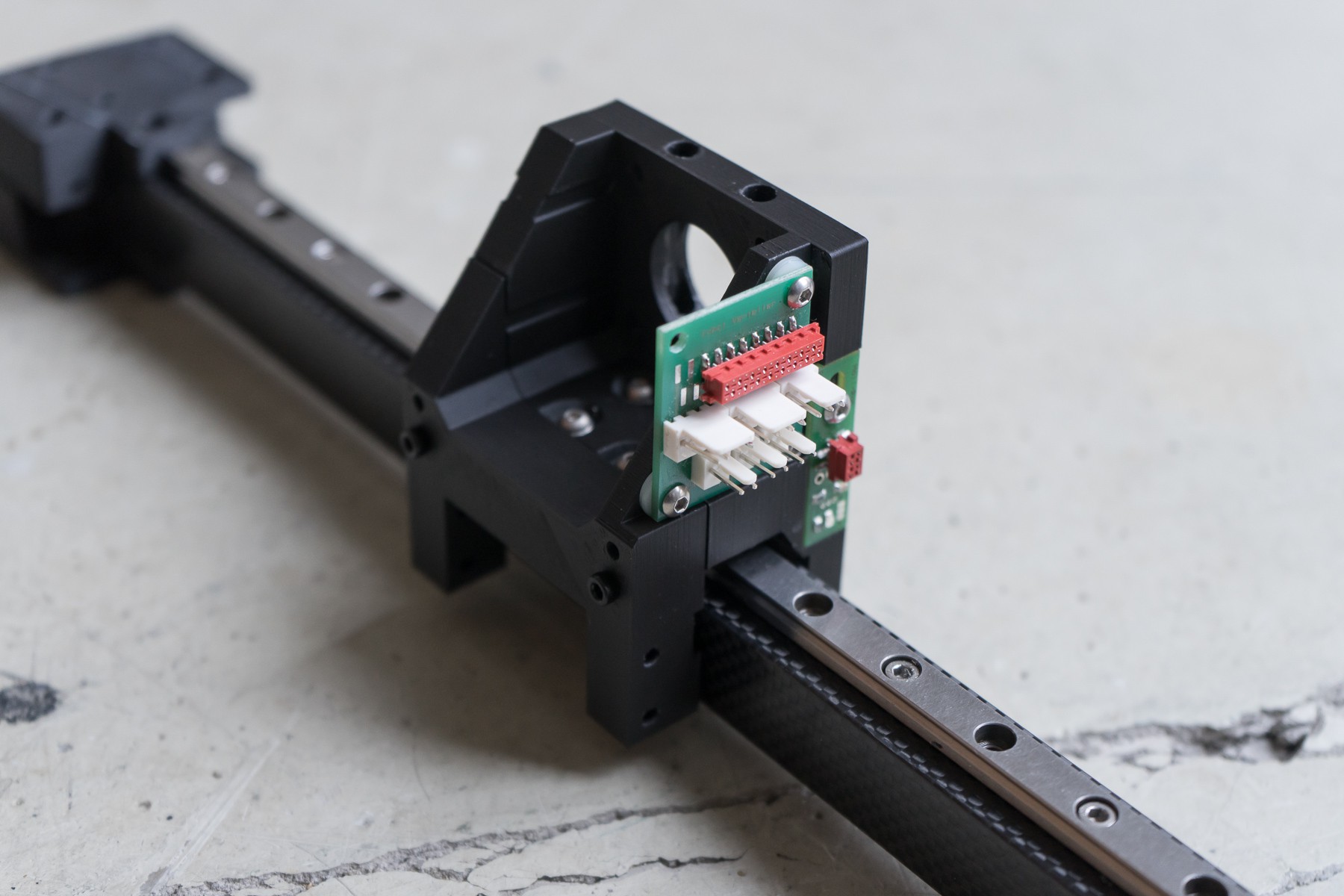

New X-Carriage with custom PCB adapter boards with Micromatch flatcable. The carriage consists of basically two printed parts.

![]()

The small gaps you see are for Carbon strips which i want to glue on there in order to enhance strengh in Z-direction.

![]()

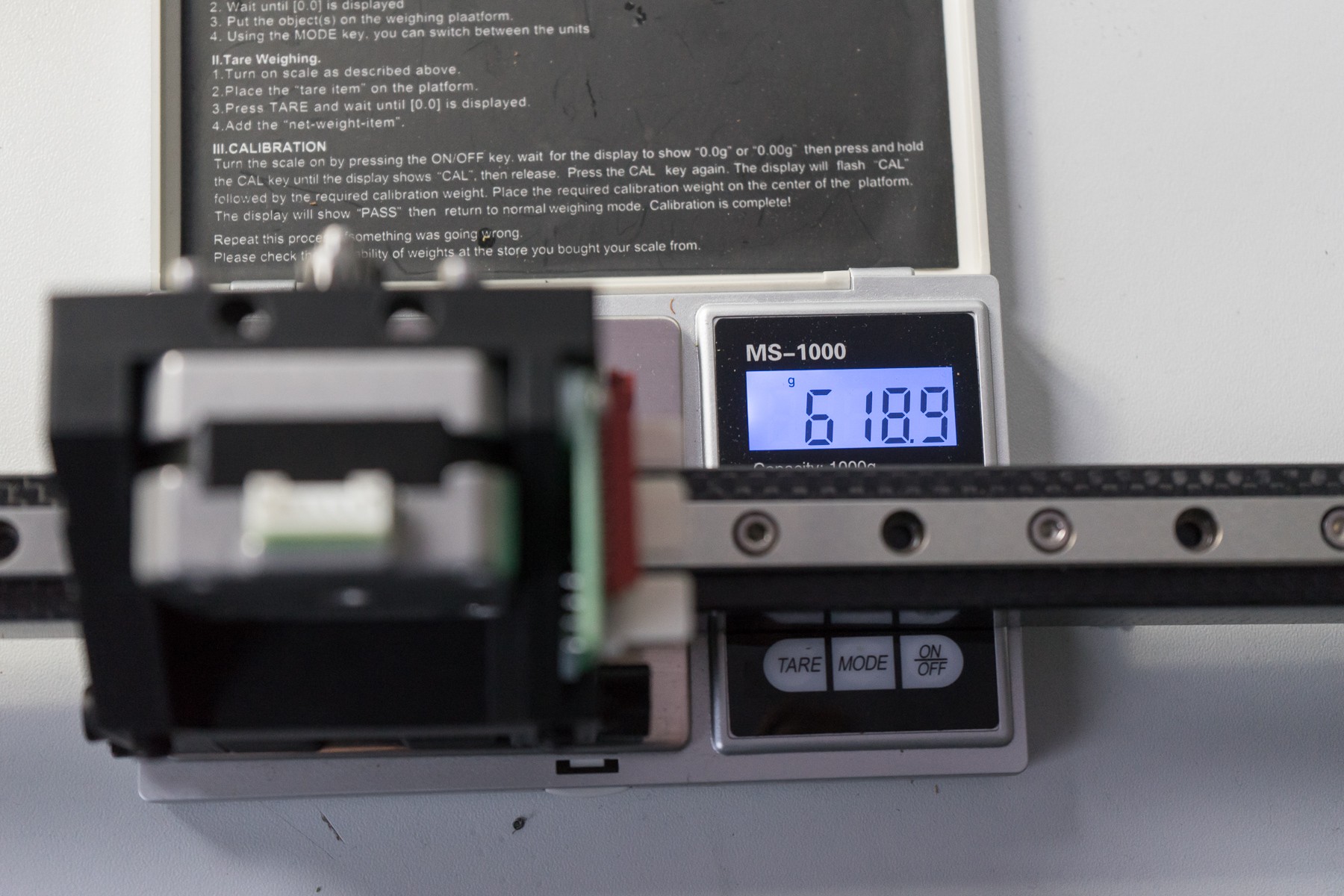

Carriage weights around 620g with everything but the Cablechain, printed Extruder Parts and Hotend/cooler. I think it will end up with around 700-750g in the end. In comparison, my current X-Axis with Openbeam (Alu t-slot) weights more than 1.5kg.

![]()

New and old carriage in comparison.

![]()

The new Pulley Bracket, two parts with cones to ensure that the outer ring of the bearings doesn´t touch the Bracketsurface. New Motor bracket in the Background.

Blackbox - Tool Changing 3D Printer

high-end open-source printer with a water-cooled tool changer.

Marc Schömann

Marc Schömann