This is an international collaboration of three friends located about 9400km apart, so a device for transporting across vast distances seems perfect. Unfortunately, I cannot yet generate wormholes at will, so we will have to settle for transporting information via the internet.

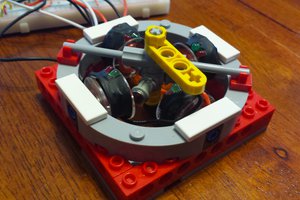

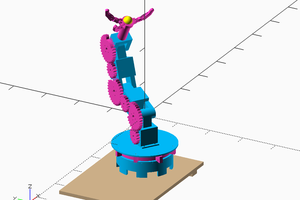

The project consists of a small(19cm diameter), SG-1 variety stargate with dialing computer. It will move and light up just like the version in SG-1. A wormhole... I mean internet connection between two computers/gates will transfer information, and the two ends will react(rotate or play animations and sounds) simultaneously.

One team member, myself, will design and build the physical device. Another member, dkopta, will create the software. Another member, Brando, who does not have an account here so he isn't on the list to the left, will be in charge of the audio portion of the project.

shlonkin

shlonkin

Of course I will post the code here when it is finalized. The next steps include setting up the IR communication with the remote dialer, putting it in a proper stand that conceals all the stuff on the bottom, and getting some software made for the internetting side side of the project. Team member dkopta is working on the software, but it is not ready yet.

Of course I will post the code here when it is finalized. The next steps include setting up the IR communication with the remote dialer, putting it in a proper stand that conceals all the stuff on the bottom, and getting some software made for the internetting side side of the project. Team member dkopta is working on the software, but it is not ready yet. Yes, those teeth were cut by hand with a utility knife. There are hundreds of teeth. It was a painful and maddening process. There are a couple places where the teeth were just slightly too big and the motor does not mesh well, but tests have shown that it still still rotates without much skipping.

Yes, those teeth were cut by hand with a utility knife. There are hundreds of teeth. It was a painful and maddening process. There are a couple places where the teeth were just slightly too big and the motor does not mesh well, but tests have shown that it still still rotates without much skipping. I then wanted to improve the bearing surface against which the rotating ring will press. I tossed the inner spacer and made a new one in a very different way. First I used scissors cut thin strips(3mm and 7.5mm) of 1.2mm polypropylene. I then wrapped them into circle placing the ends together like so.

I then wanted to improve the bearing surface against which the rotating ring will press. I tossed the inner spacer and made a new one in a very different way. First I used scissors cut thin strips(3mm and 7.5mm) of 1.2mm polypropylene. I then wrapped them into circle placing the ends together like so. Then I used my handy homemade foam cutter to melt the ends together, welding them. This produced a very smooth, round ring for the rotating ring to press against.

Then I used my handy homemade foam cutter to melt the ends together, welding them. This produced a very smooth, round ring for the rotating ring to press against. Oh, and here's the foam cutter if you wanted to see it. I had to go beyond the foam cutting settings to get hot enough for this plastic.

Oh, and here's the foam cutter if you wanted to see it. I had to go beyond the foam cutting settings to get hot enough for this plastic. Once I had the pieces all made, I stuck them together and fought with it for a few days to get it moving. Here it is without the front layers attached. Notice that the rotating ring is painted.

Once I had the pieces all made, I stuck them together and fought with it for a few days to get it moving. Here it is without the front layers attached. Notice that the rotating ring is painted.

To keep the gears meshed nicely, a spring pulls the motor up and one of the mounting screws rides in a slot.

To keep the gears meshed nicely, a spring pulls the motor up and one of the mounting screws rides in a slot.

And here are some pictures of the layers just sitting on each other, not attached. Trust me, it will look a lot better when it is cleaned up, painted and illuminated. But before I do that, I will work out the ring moving mechanism. I'll update again after I get things moving.

And here are some pictures of the layers just sitting on each other, not attached. Trust me, it will look a lot better when it is cleaned up, painted and illuminated. But before I do that, I will work out the ring moving mechanism. I'll update again after I get things moving.

Adam Smallcomb

Adam Smallcomb

Eric Wiiliam

Eric Wiiliam

Les Hall

Les Hall

Guys, maybe you could hold this - sync sound and lights effect thing. And start the wormhol thing first ? :)