-

Cold-Start Realtime Demo

10/04/2015 at 19:42 • 0 commentswith a shoutout to #Hacker Channel for the support!

-

Artist Renditions and Semifinals Video

09/21/2015 at 20:11 • 0 comments![]()

-

The Keystone of the Design

09/20/2015 at 14:59 • 0 commentsBefore we get to that live demo video (the worldwide debut?) of the FireVolt. I'd like to present the "Opposing T" core bypass system. This focuses, not on the plumbing or pumps up at the top, (nor the core array below), but the space in the middle. As you may notice, the silver "mini T" connects to the large black T (originally where the straight smokestack was). This is a keystone design element which allows the system to harness the true power of the InStove's awesome combustion characteristics. The pathways that the combustion gasses flow through are each controllable (adjustable) by dampers, allowing a fine-tuning of the burn and power generation profile.These are off-the-shelf DuraVent chimney flue components. As a side note - The very top of the silver T features a "clean-out cap"which currently has a Rutland Burn indicator (temperature gauge) sitting on it to provide a rough core temperature reference. Ready to fire it up?

![]()

-

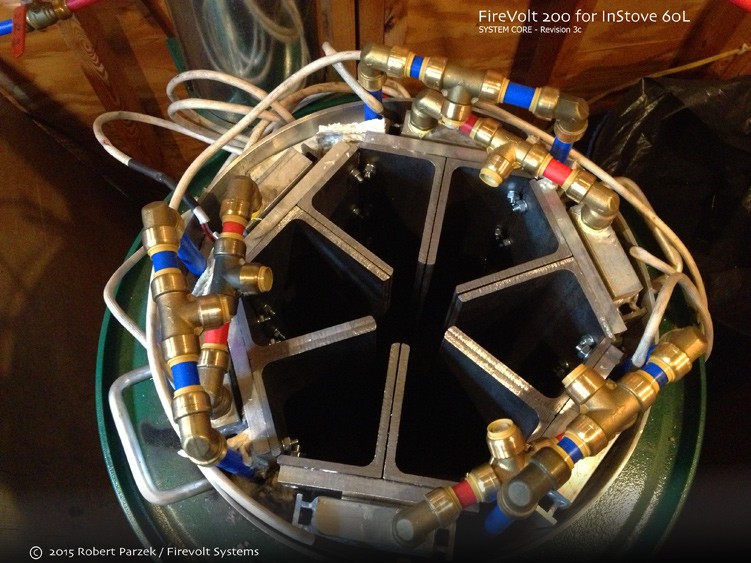

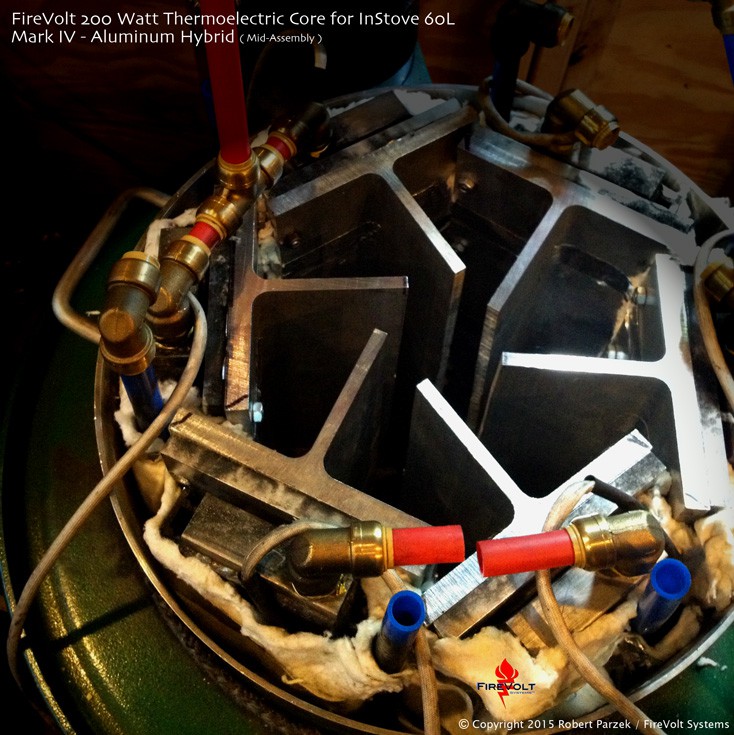

FireVolt 200W Hackaday Edition (Mark IV)

09/04/2015 at 12:52 • 0 comments![]()

-

70 Watt TEG Sub-Assembly

08/17/2015 at 19:08 • 0 commentsModular design principles throughout, this picture shows the water block cooling side of a 70 Watt pair

![]()

-

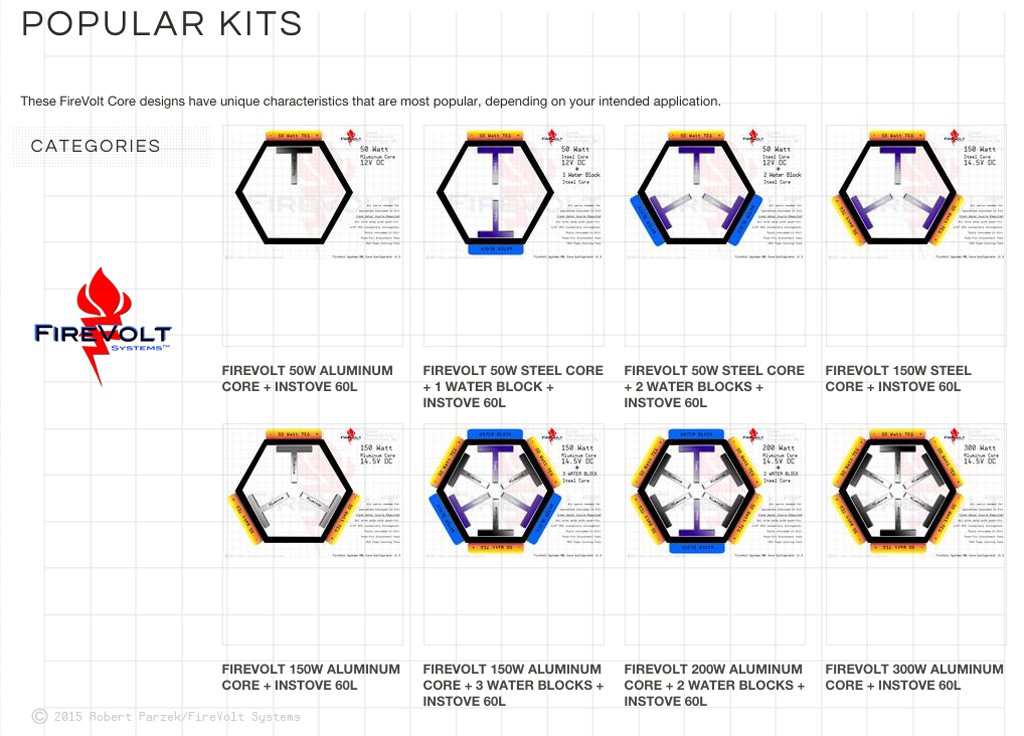

The Many Flavors of FireVolt

06/28/2015 at 13:48 • 0 commentsScalability and Modularity are a big part of the design goals. Here are some variations on the theme.

![]()

-

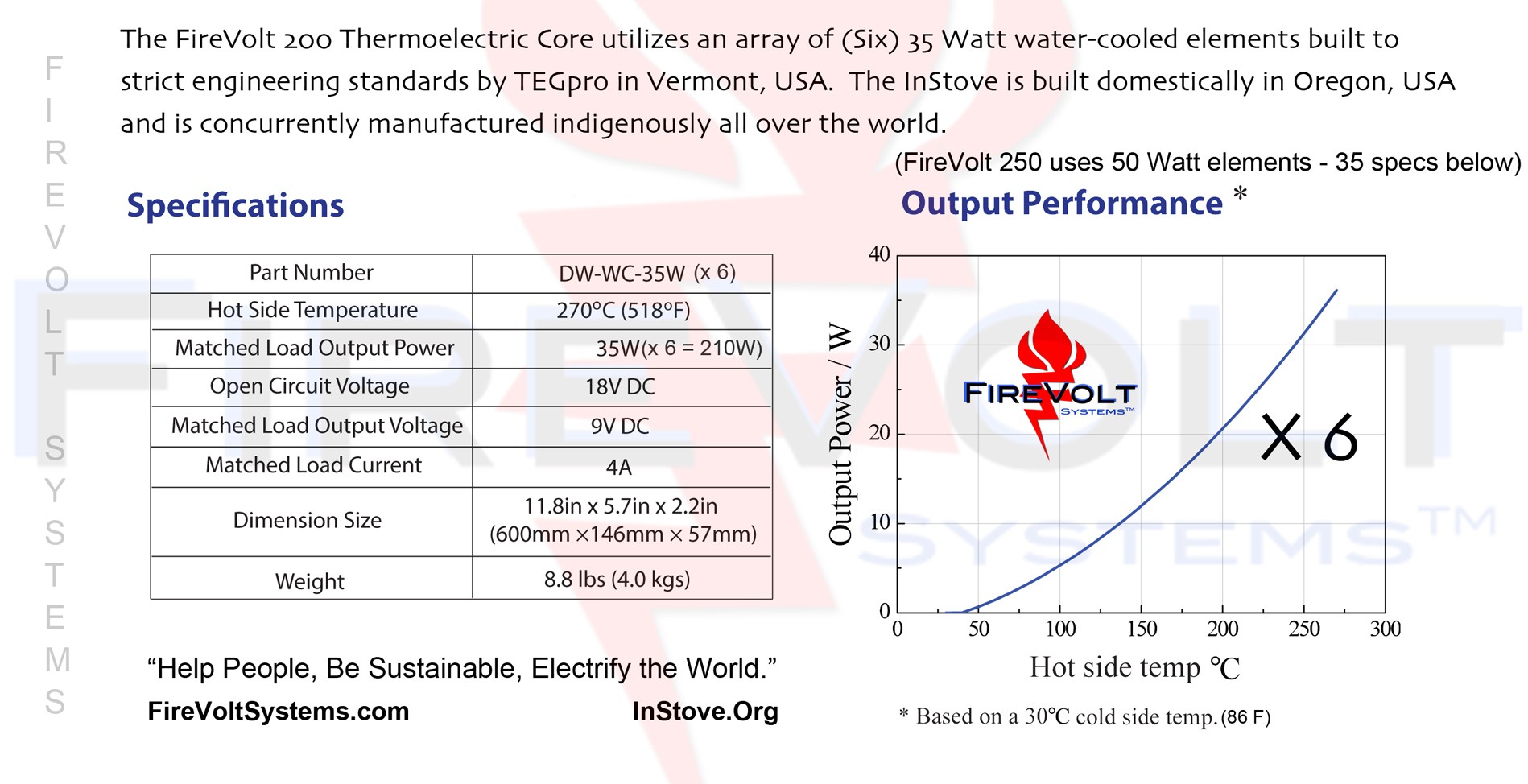

FireVolt Electro/Thermal Specs

06/15/2015 at 15:05 • 0 commentsFor those of you interested in the Electrical Engineering specs on the FireVolt 200 Watt Thermoelectric Generator for InStove 60L.

![]()

-

TEGpro Announces 22 watt, 7 volt TEGs

06/09/2015 at 15:28 • 0 commentsExciting news for the FireVolt output specs! TEGpro has just released their next generation TEG elements. Output ratings of 7 volts and 22 watts (per TEG tile) will allow the InStove 60L Core to reach 300 watts max, 250 watts nominal. The same form factors allow a whopping 500 - 600 watts possible on the InStove 100L (though build cost is also proportional) it is exciting to consider a solid state, non-radiant, wood-fired rig with those numbers.

Want to help the FireVolt project and get your hands on some of the very best TEG components?

I'm offering TEGpro hardware for sale and will price match or better, depending on your needs and quantity. Message me directly, or browse the online shop. More to come.

-

The Balance of Thermal Mass & Thermal Conductivity

06/05/2015 at 02:23 • 0 commentsA brief rant on the properties of base metals and heat transfer. From a practical angle, the FireVolt prototype design revision 3c incorporates a great deal of thermal isolation and a range of ferrous and non ferrous metals, jacketed by the InStove's insulation and a steel shell. To say it another way; "This thing doesn't radiate heat very much" and you can run it, indoors, full-tilt on a hot day, with nothing but a vent fan on in the room to maintain ambient temp. The rest of the buildings temps are virtually unaffected because the InStove itself is highly concentric and insulated, as is the FireVolt Core. (You can also choose to run it outside, but a small weather shelter is highly suggested for outdoor installations).

![Un-modified InStove cross-section]() (the above cross-section is of an un-modified InStove)

(the above cross-section is of an un-modified InStove)Where you actually put the harvested heat (harvested via water riding the 1/2" PEX plumbing) is up to you. For these warmer months I'm operating a water holding tank, a mini cooling tower in essence, outdoors as a thermal diverter. Once the buildings' domestic hot water tank is brought up to 110 Fahrenheit, and the building itself has no further heating requirements (signaled via thermostats) - the excess heated water is cycled into a large open-top tank which radiates to the open air outside. There are better (more conservative) ways to do this, but it works for now as a robust thermal dumping ground while I've been pushing into high temperature test cycles.

In the warmer sunny months the system gets run at night usually, as it delivers a steady charge to the buildings' 12v LiFePo4 battery array at a time when Solar is useless.

But - back to the Thermal Mass vs. Thermal Conductivity topic;![]()

The current core material, Carbon Steel "Angle Iron" - has a rather nice thermal mass but a poor thermal conductivity compared to, say, Aluminum. However, core firebox temperatures can hit 1000c and the slow but steady creep of that heat - through the steel, eventually hits the TEGs hot side Aluminum plate, and things really start to get interesting about 45 min after startup, full power is usually hit around 1.5 hours.

Another interesting thing related to the Steel core. After the firebox flame goes out (due to fuel starvation) the system continues to produce highly useable power for 2 hours on cool-down., again because steel conducts heat poorly, but there is so much of it, you get this nice long discharge profile on cool down. Now, when the next re-pack of the core takes place I may swap the Carbon Steel for Aluminum and all of you Thermodynamics gurus can imagine what that'll yield for a temperature Delta between my hot and cold sides : D - thats why theres a cooling tub outside! eventually I think it may end up as a pool. Year round. We'll see.

-

FireVolt Project To-Date

06/03/2015 at 14:09 • 0 commentsGreetings and thanks for checking out my project. The FireVolt 200 Prototype has been in operation for about 5 months as of this entry. The consistency of the system performance has yielded a breadth of data about further system optimization, which is the framework for the next steps of the project. There is much more to follow relating to micro-controller based system / load management, automated pellet feed and unattended long-runtime configuration. Ultimately the system will self-feed, self regulate and provide remote monitoring and control.

The FireVolt Project

A 200w Wood & Pellet fired Thermoelectric Generator for the InStove 60L Rocket Stove; "Help People, Be Sustainable, Electrify the World."

Rob Parzek

Rob Parzek

(the above cross-section is of an un-modified InStove)

(the above cross-section is of an un-modified InStove)