So I know it has been a while since there has been an update. But I have been busy with a new job. Recently I have gotten a 3d printer and I have been working on the designs for next iteration. Today I printed out usable versions of the mouthpiece and the mouthpiece clamp. There have been a lot of test pieces to get to this point. There are several mouthpieces that didn't quite cut it that are now being used as doorstops.

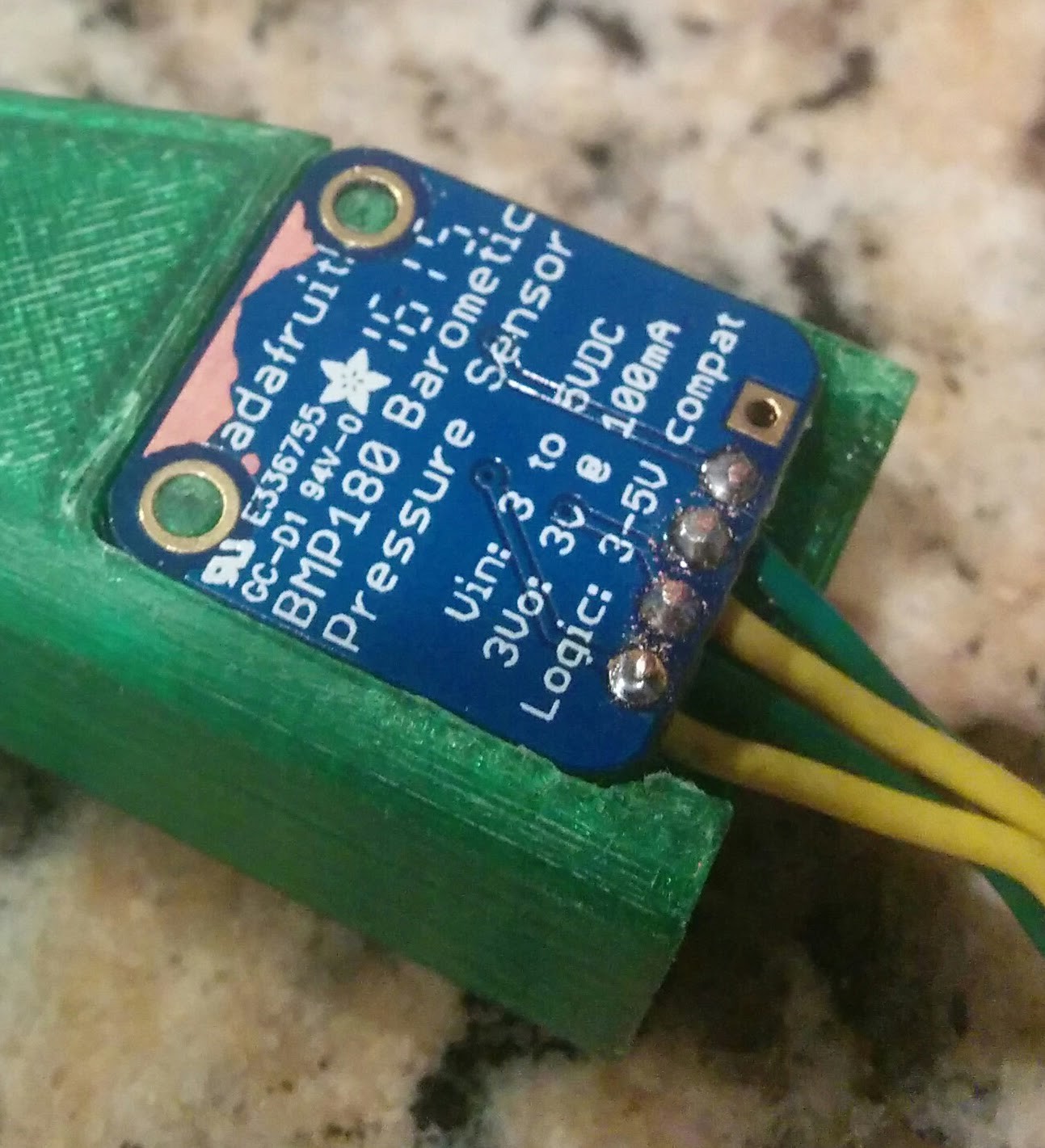

The mouthpiece is printed out of PETG with solid infill. The air passages are part of the print. The only work it needs is some sanding and polishing, and I need to tap the threads for the machine screw used to adjust the air flow. I went with PETG because it is generally considered food safe, and since this part goes in your mouth we need that safety. The solid infill is so that it will be air tight. When I used a non-solid infill, there was substantial leakage. There is also a fitted pocket for the air pressure sensor.

The clamp is printed out of PLA. The rings on top are so that I can use a nut and bolt to tighten it on. The main body will be build with a cylinder on the end to fit inside the clamp.

Gwendolyn Scogin

Gwendolyn Scogin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Looking good :)

It's funny, I'm using a BMP180 as the barometric pressure sensor in my rocket projects...

I need to get back to my instrument and finish off my ideas, I want each key pressure sensitive, build a better body, longer range wireless transceiver etc... But between work, family, and other hobbies it gets challenging.

Are you sure? yes | no

There is always something else that crops up. Im hoping to be able to print off the body soon, but that is going to require several pieces.

Are you sure? yes | no

There is always something else that crops up. Im hoping to be able to print off the body soon, but that is going to require several pieces.

Are you sure? yes | no