-

SPACE LETTUCE

08/10/2015 at 07:02 • 0 commentsAstronauts will soon be eating space lettuce.

http://gizmodo.com/astronauts-will-eat-space-lettuce-for-the-first-time-ne-1722798340![]()

More and more research seems like its being conducted into light formulas.![]()

I don't have a huge update this week because I'm transferring jobs from Tampa to Denver within the next two weeks and its been a time sink. This comes the week of the entries so things are hectic.

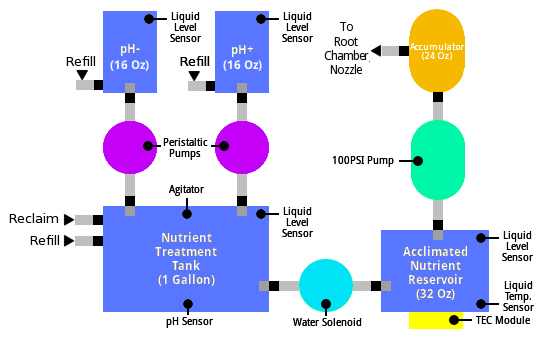

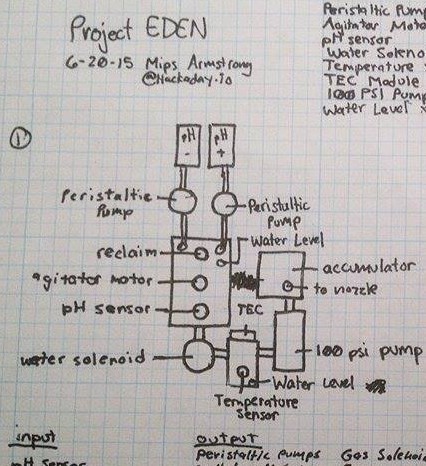

I have managed to create some better diagrams than I was using before.

![]()

![]()

![]()

-

Designs

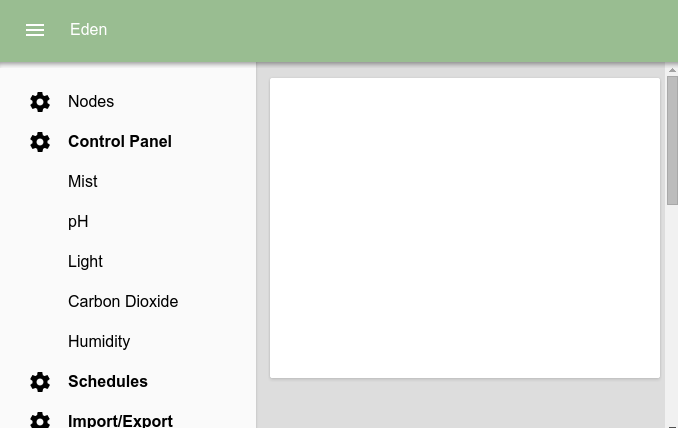

08/02/2015 at 21:23 • 0 commentsThis weekend I've been working more with google polymer to get the web-interface going. It's going to take a little more work with node.js to get it functional. I'm theorizing more ways to make this run efficiently in memory with all of the dependencies.

![]()

Still looking kind of empty but I wanted to post some progress. I've also made more progress on the CAD schematics and should be ready to have the enclosure machined soon. Here is the most complex part, the bottom of the LED array enclosure.

![]()

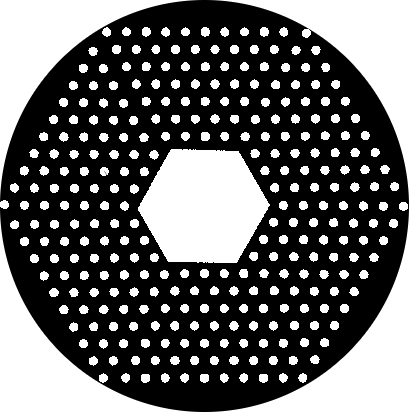

The opposite piece for the bottom enclosure is a circle with a hexagon in the center and two rectangles which will remove to allow access to the CO2 tank and nutrient systems. The other parts will just be big circle discs and the siding.

I plotted the LEDs as well.

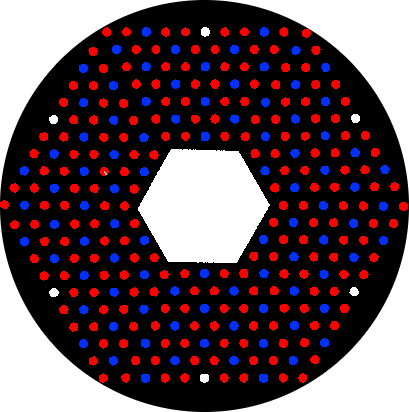

![]()

It only shows red, white, and blue even though there are deep red and royal blue. I've found the easiest way to distribute the LEDs would be in rows. For the reds you see, one horizontal row will be red, the next deep red, then red, etc. Blue and Royal Blue will be similar except on the opposite axis.

If you've seen the front page, you'll know the project deadlines are coming. I plan on releasing a video soon.

-

Design Revisions

07/19/2015 at 09:49 • 0 commentsSo last week my buddy Dakota and I talked more about the project. Dakota brought to my attention some issues going into drafting the project that needed further work. In this case it was mostly the root chamber and mounting it to the rest of the enclosure. Its now past 5am and mostly figured out, have a look?

![]()

I wanted the root chamber to be modular and to support the weight of the LED array in addition to several pounds of vegetation. What I am left with is about 5 feet of root chamber with 15 growing pods (the circles - to be coupled with an elbow and rockwool growing base). There is a capability for much more than this, but I don't want any canopies.

![]()

The windows between the pods will have removable magnetic PET plastic sheets to access the roots for harvesting, or to take a quick look at the root structure. The end result will be wrapped in a reflective barrier to prevent light from damaging the roots. I'm pretty satisfied with this root chamber because it can be easily be modified for more or less plants depending on their size.

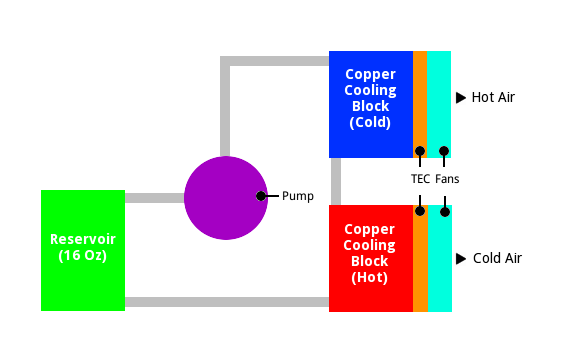

More work must go into the structure of the enclosure. I must also address the heat the LED array is bound to produce, and there's a lot of power distribution stuff to think about.

I'll conclude this log with an updated partslist!

https://docs.google.com/spreadsheets/d/1lPFTdldgs6HVyugyByvTj9iVUbvBaWwO2ivABECh8HU/edit?usp=sharingIt's just about finished, it has the correct pipe fittings and most of the equipment short of the temp/humidity stuff. I will add parts to the official components list as I build EDEN.

This week I am putting more thought into the programming as components will be coming in soon.

-

LEDs

07/11/2015 at 00:48 • 1 commentThe LEDs are ordered. Its looking like $140 for a 900w ~20,000 lumen array. That price includes:

- 100x 650-660nm Deep Red LEDs with pcb

- 100x 610-630nm Red LEDs with pcb

- 50x 460-465nm Blue LEDs with pcb

- 50x 445-455nm Royal Blue LEDs with PCB

- 6x 250w power regulators

I'm also ordering 300 45 degree angle reflector lenses and some relays to control the amount of powered LEDs. I'm looking around for some very powerful white LEDs - these won't be 3 watts like the rest, I want something brighter. The white LEDs are mostly intended for monitoring plants with the human visible spectrum, but I'd like for them to be able to be utilized for their spectrum signature as well. I'll be prototyping with some old PC power supplies I've found laying around at work until I can sink more into a fancy ~1500w PSU.

In other news, it looks like GE and Phillips are onto the right idea!

![]() http://www.slashgear.com/philips-is-developing-led-light-growth-recipes-for-indoor-farms-08392246/

http://www.slashgear.com/philips-is-developing-led-light-growth-recipes-for-indoor-farms-08392246/The researcher center is 234m2 — one of the biggest ever, says Philips — and it is located in Eindhoven, the Netherlands. The company will be concentrating its efforts on developing light recipes for growing strawberries, herbs, and leafy vegetables , as well as increasing the production of carb-rich food like potatoes that are grown indoors.

If you've been following the project, you may recognize this as one of the main goals, except EDEN also emphasizes on the entire habitats 'recipe' for success. We've recently passed a thousand views and have a pretty good ratio of followers to show for it. On top of that EDEN won some sponsorship prizes for the top 50 atmel and TI parts projects . I'm super excited to see the open source hardware communities response to this once the prototype is ready!

I have my old engineering classmate coming over this weekend for some work on the enclosure and I can't wait to keep you guys updated!

-

Components

07/05/2015 at 23:24 • 0 commentsThe pipe fittings are finally mapped to their respective regions. In the below diagram you can see numbers which indicate a particular bulkhead union or fitting. I have also calculated the hose diameters and its looking like I'm I'll be making a large part order in the near future. Prior to ordering all of my components I will be updating the components list and attaching a spreadsheet with numbered parts and an assembly diagram.

![]()

The LED array is at the height of my priorities because the deadlines and shipping ETA is becoming ever closer.

I have decided that I will use 288 LEDs consisting of about 198 red (about half deep red) and 90 blue (about 40 royal blue). I will also use 6 high power white LEDs for observation. I will arrange these in a hexagonal matrix of about 7 rows. At approximately 3w each that provides around 900w of lighting at full brightness.

I ran into a problem with the original plan of using an 8 inch diameter pipe for the root chamber. 8 inch pipe runs about $40 per foot. I decided a more effective solution would be to make a hexagonal root chamber. Flat surfaces are easier to mount pipe entries onto for the plant base. I'm excited to implement this new strategy because formerly a circular pipe would have been a hastle for potatos, turnips, and carrots - as it would have left the roots mostly inaccessable. With a hexagonal root chamber they can be removed as panels allowing for easier harvesting. If possible Id like to use a transparent material so root growth can be examined by removing the reflective sheilding around it.

Apart from that it is mainly the temperature/humidity system that needs to be drafted. I have ideas but considering that I have about 6 weeks remaining I may put this aside until I have a beta unit completed.

-

CO2 Enrichment System & LED arrays.

06/26/2015 at 21:20 • 0 commentsIt's been a crazy week since my last update. I've started with the HTML5 webpage, I haven't gotten as far as I'd have liked to due to a busy schedule. I have been working out a lot of the design challenges, particularly with the CO2 / LED systems. The nutrient delivery system is mostly complete in terms of the design however I have been struggling to make sure all the fittings are uniform to avoid unnecessary pressure fluctuation in the lines.

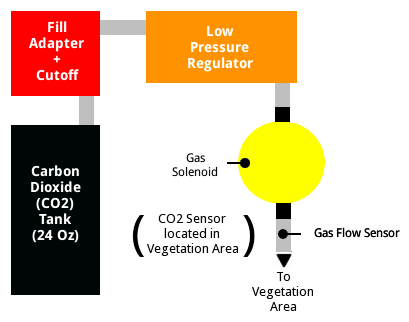

- CO2 SYSTEM

The Carbon-Dioxide enrichment system not only keeps the plants inside of EDEN alive, it bulks them up allowing more growth to occur. Without a fresh supply of CO2 the plants will eventually wither away like my girlfriend's failed attempt to grow flowers in her window. The most basic way of supplying CO2 is by having good ventilation so outdoor air can circulate and replenish the CO2 concentration. This is easy to implement - however is less effective. Atmospheric carbon-dioxide levels are not ideal for plant growth, even with all the fuss about climate change. There is also the challenge of keeping the air temperature just right, the humidity right, the pressure right, and the nasty pollutants out. Because of that, relying on ventilation varies too much to achieve controlled results like other alternatives offer.

EDEN will use 24 oz CO2 tanks. The tanks I have selected for this project are actually paintball tanks in order to allow ease of refills. Theoretically I expect the tanks to last the duration of the grow, if they run out - they can be refilled during the sleep cycles since plants use light to absorb CO2. I have invested a good amount of confidence in these tanks after seeing them used in aquaponics projects, with some users actually complaining that their aquarium plants are getting too big.

CO2 tanks for paintball guns typically are around 800-1000 psi, overpowering most of the electronically controlled gas solenoids I've found for the project. I've found a low pressure regulator which will drop the pressure down to around 100 psi, however I must do extensive testing to make sure it's not going to vent CO2 outside of the gas lines. It has been a challenge to ensure all fittings match up perfectly, but progress is being made.

I'm going with a cheaper CO2 sensor like the MG-811 and coupling it with a pressure sensor to determine the right flow intervals. Something to note is that a full tank releasing gas for 5 seconds is going to be quite different from a low tank releasing gas for 5 seconds because of a pressure drop. The pressure sensor will detect drops which helps to calculate how long to keep the solenoid open and when the tank is low. The role of the CO2 sensor is to determine the overall demand.

- LED Array

The LEDs are closely tied to the CO2 System. From my research I have come to the conclusion that the CO2 absorption rates increase as the amount of light increases. Initially when I learned of CO2 enrichment I became skeptical of greenhouse gases because plants thrive at higher levels, until I realized that the amount of light would not increase to accommodate those absorptions. The LED array must be powerful enough to provoke higher CO2 consumption.

Many hydroponics projects use crazy expensive lights, with claims of 'full spectrum' and gigantic power consumption being used as marketing standards. LEDs are not only more power efficient, they allow for targeting the spectrum of light that chlorophyll captures and uses for photosynthesis. Our optical sense tells us these huge HID arrays are bright, but plants have a different sense of optics.

This week I found an LED supplier in China that is selling 3W LEDs with pcbs for around $35 per hundred. I'm anxiously trying to order these ASAP so they arrive before THP deadlines. They are 440-470nm (Blue/Royal Blue) and 610-660nm (Red/Deep Red), and emit about 70 lumens of brightness each. I expect to use around 300-400 LEDs. 900-1200 watts of light is quite a bit, but my logic behind that amount is due to the idea that not all of those LEDs will be active at once. They can be, but I intend to separate the LEDs into stands of 12. These strands will be regulated by a converter with a switch that can customize the spectrum the plants receive. The light that is optimal for early stages of growth differs from the light that is optimal in later phases. I want to allow custom LED profiles, but I intend to do a few presets - like power saver, phase based, maximum growth, maximum brightness.

- Power

Driving all of those LEDs, sensors, solenoids, and other electronics is going to take a pretty decent power supply. I calculate a demand for around 1500 watts maximum, and for now I've decided to go with a decent desktop PC power supply.

I will use my TI MSP430 for the LED controller, and an Arduino Due for just about everything else. I am going to spend most of this next week bouncing between web design and double checking that the fittings for everything are compatible. Next weekend I will be doing more work in the realm of circuit design. Here's a glimpse at the nutrient system.

![]()

-

Web Interface

06/16/2015 at 04:49 • 0 commentsThis week I will be working on some of the web interface for EDEN. I have begun to order the components which are coming from China. I want to work on as much code as possible in the meantime, so over the coming days I will be working on most of the front end. I will likely host a web server on EDEN which is connected to locally, but I'm toying with the idea of remote access. I'm also considering that protected WiFi networks will require passwords, so more thought must go into that whole situation. For now I just want the webpage built.

The interface will include features such as:

- Misting Interval / Amount + schedules

- LED balance + schedules

- pH balance + schedules

- CO2 level + schedules

- Relative Humidity + schedules

- Temperature + schedules

- Import / Export configuration

That is the basic functionality I'd like to accomplish. Adafruit has some neat IR cameras that monitor plant growth which would be fun to implement into the web UI for comparing results, but that's for later. Later there will also be a need for a community webpage in which configurations could be exchanged, and of course a main website.

Aside from that, I've freed up more time and resources to see this project through to the end. I'd estimate by this time next month I should have all of the components short of the enclosure.

Project EDEN

Project EDEN is an open initiative to grow crops quickly, under near-optimal conditions with automated aeroponics habitats.

sadhana

sadhana