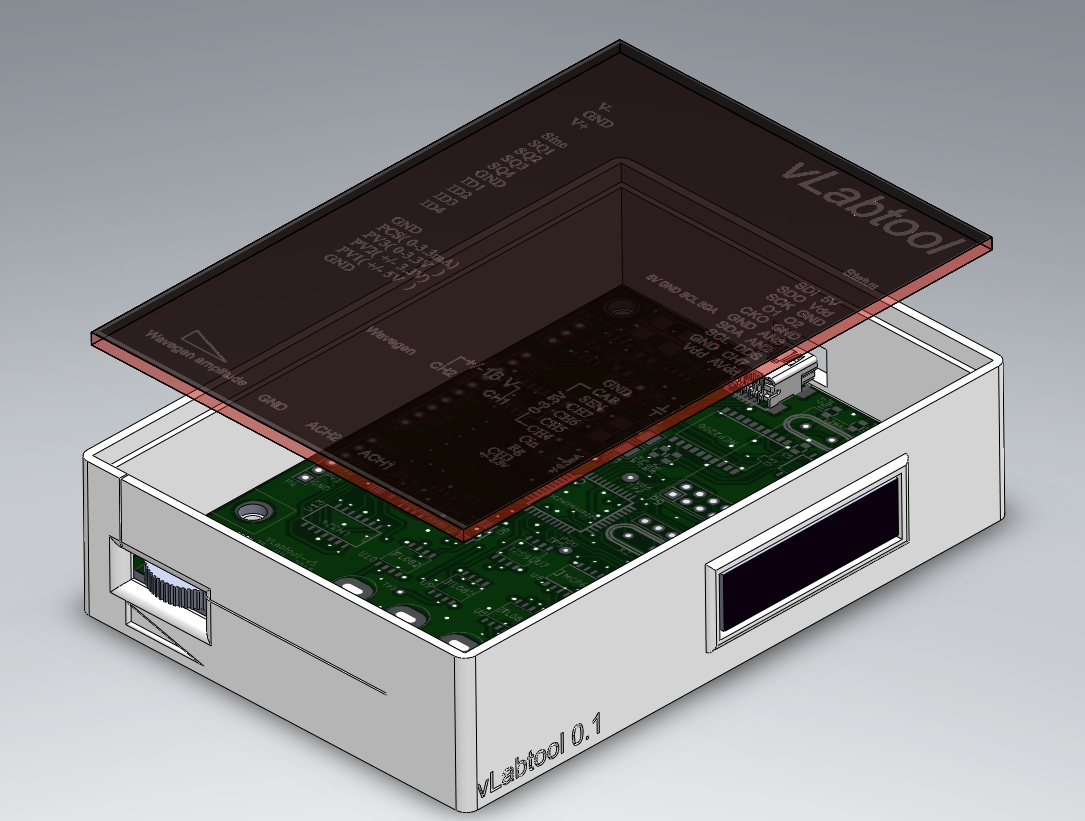

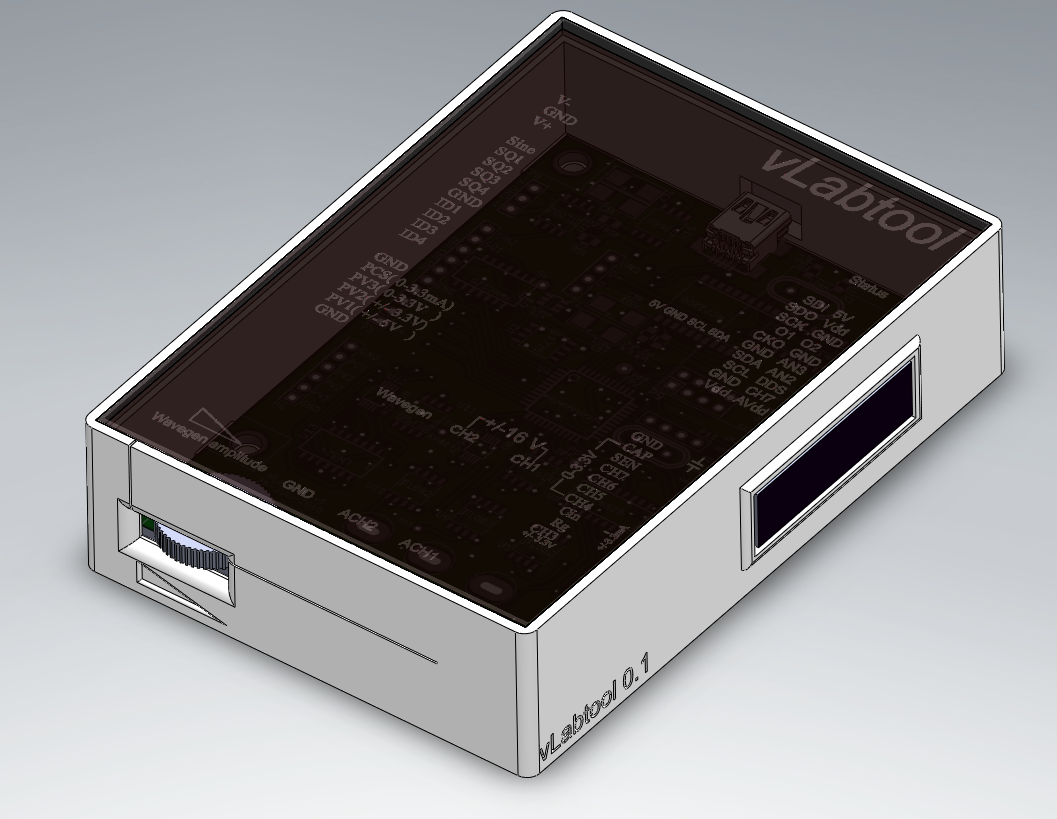

So far I've designed a 3D enclosure using SolidWorks. The bottom will be 3D printed for now, and any errors can be rectified before going for an injection mould. The top plate will be laser cut and engraved in translucent acrylic, and added .

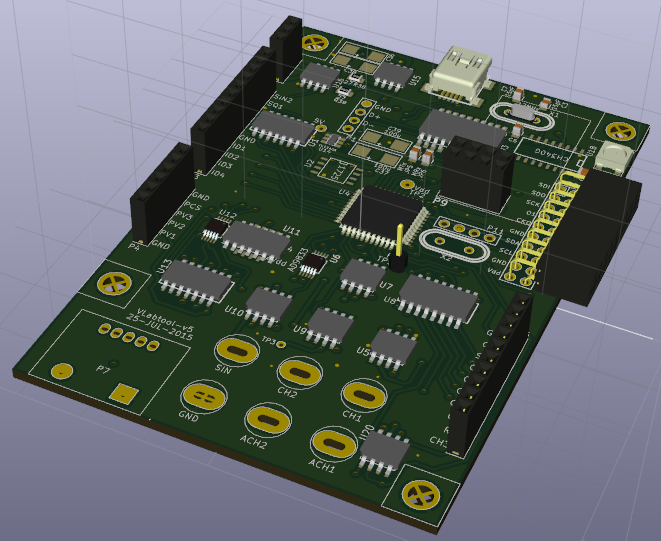

Figure:3D rendering of the PCB designed with KiCAD.

A SolidWorks render will have to do as an 'artist's' impression

Here is an exploded view of the designed

case. It would've been great to be able to use the 3D generated objects

from KiCAD, but it seemed impossible to use them in a SolidWORKS

assembly. Instead, I took a screenshot of the PCB, and overlaid it on a

65x95 part with similar thickness. The overlay allows me to roughly

determine the position of objects without referring to KiCAD, or

measuring manually. AUX jack shown was a quick sketch-extrude-cut job.

I really wish the kicad 3D output had played nice with SolidWorks. Now you'll have to picture the fully populated circuit board yourself. And you've already seen the 3D printed box on the main page anyway.

Here's the Splash screen for the App framework. The PNG is transparent.

Was created with GIMP.

Jithin

Jithin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hi again!

I just uploaded the new version of kicad StepUp, with

some minor improvements, and with a new tool to align the 3d model to

footprint in just few clicks! :)

keep in touch, Maurice

PS thanks for the skull :)

here a small tutorial about this new tool:

Are you sure? yes | no

Hi,

from now on it is possible to export KiCad board and component assemblies to 3D MCAD environment...

you may consider to have a look here:

https://hackaday.com/2015/11/08/kicad-script-hack-for-better-mechanical-cad-export/

and here:

https://hackaday.io/project/7926-kicad-stepup-script-hacks-mcad-world

feel free to ask if you need any assistance... (feedback is welcome)

Maurice :)

Are you sure? yes | no

Hi,

Thanks for the great project!

I spent some time with your instructions the day Anool blogged about it. I've gotten the basics set

up, but haven't found the time to build a fully functional render. instead, I've made do with manually building the essential extrusions like sockets and through holes in SolidWorks so I don't get the injection mould wrong.

Thanks again. I hope to use it properly soon, and I'll certainly take you up on your offer to help out :)

Are you sure? yes | no