The principle behind the longboard brake is similar to a bicycle brake. When I put my foot on the braking lever the inner part of the braking cable gets pulled which pulls the lever with the braking pad attached to it so it makes contact with the wheel. I used some rubber bands as a spring to pull the braking pad back after I lift my foot of the braking lever.

The first reason I choose the Onda Board was because of it's big 180mm wheels that give me plenty of room the add the brake parts and they make enough contact with the brake pad. The second reason is the rectangular trucks that make mounting things to it extremely easy. Also there is conveniently placed hole on the back of the boards deck.

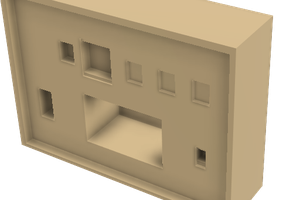

The printed parts are designed in 3ds Max and printed in PLA with 100% infill on the Printrbot Metal Simple. To save material and increase strength I used M5 screws wherever I could and only 3d printed connectors for them.

I may add a brake on the other back-wheel for faster braking. Also I think I will 3d print an rectangular attachment for the braking lever screw so I can more easily hit it with my foot and also offers more surface area to transmit the force I put into it.

Here is a video of the brake in action in my living room.

Alain d'Espaignet

Alain d'Espaignet

Brian Brocken

Brian Brocken

Dusty

Dusty

Braking is all about heat dissipation--have you tried the brake under high load, such as slowing a rider down on a long hill?

Great project!