My first cuts at the crazy clock calibrator were using TCXOs with two different firmware loads. One load would test the clocks, the other load would accept a GPS PPS signal and would display the oscillator's drift relative to GPS. I could then subtract that drift out of the measurements of the clocks.

I tried to think of ways to allow the controller to do both at once. After all, a PPS signal (in principle) shouldn't distract the controller too terribly much. The problem is that the ATMega328P controller I like to use has only one input capture pin. Recall that the input capture pin allows you to use a non-prescaled timer (running at the system clock speed) to time things at maximum resolution, while the clock's value will be "frozen" by a rising edge on the ICP pin.

Since you can't watch two events at once with a single ATMega, it briefly occurred to me in a humorous way to simply use two. But in a "ha ha only serious" moment, it immediately occurred to me to simply separate the two problems - resulting in a frequency counter with a separate clock source, and a hyper-accurate disciplined clock generator.

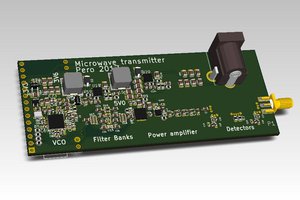

The basic design of the project centers around either a VCTCXO - a Voltage Controlled Temperature Compensated Crystal Oscillator or a VCOCXO - a Voltage Controlled Oven Controlled Crystal Oscillator. At first, that nomenclature seems contradictory. Which is controlling the oscillator? A voltage or the temperature compensation? In fact, what a VCTCXO is is a normal TCXO (a crystal oscillator which is "steered" by a temperature compensation circuit) with a voltage input that allows the output frequency to be trimmed over a relatively narrow range. The specification of the oscillator says that a voltage ranging from 0.3 to 3.0 volts will push or pull the TCXO ±10 ppm or the OCXO ±400 ppb. A VCOCXO is like a VCTCXO, except that the crystal is housed in an oven that tightly controls the temperature of the crystal. OCXOs are much more stable than TCXOs, but the oven requires a great deal of current.

The microcontroller is going to need to be able to manage the control voltage to trim the frequency from the GPS feedback. I briefly considered using the traditional Arduino method of PWM duty cycle manipulation to effect a D/A converter, but quickly rejected that. The TCXO has a basic short-term stability of 1 ppb. If we want to try and keep it in trim, we need to be able to have at least that level of granularity of control, preferably much less. We're already using the 16 bit timer for measuring the frequency. If you do the math, a one volt change in the reference is 7 ppm (or so), meaning that dividing our 2.7 volt tuning range into 256 levels results in a granularity of ~70 ppb per step. That's not nearly good enough. Using a 16 bit D/A converter, by contrast, gives us a granularity of just under 0.4 ppb. We can do better than that, however, because the outer 0.3v of the DAC range is "dead space" to the oscillator. Also, the long term accuracy specification of the oscillator lists < 5 ppm of total, lifetime drift. That means we can throw away half of the DAC tuning range (the outer 25% on the top and bottom) and still be able to steer the oscillator more than its lifetime expected error range. That doubles our granularity to around 0.2 ppb.

Connor Winfield has an application note that actually includes a schematic for a D/A trimmed oscillator. We started with that design, but a lot of the things they recommend have gone by the wayside. Their design included a buffer OP amp. Along the way, we turned that into a compression amp, but the design now is simply a voltage divider consisting of just 3 resistors. The aim of the voltage divider is to reduce the range of the DAC to the useful portion of the oscillator's control voltage input. For the TCXO, we reduce the swing to 50% of the 3.3v DAC output range, and for the OCXO, we reduce the swing by around 25%. But in both cases, we want the center of the range to remain...

Read more » Nick Sayer

Nick Sayer

Pero

Pero

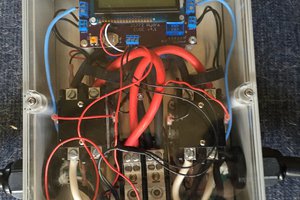

Interesting project. Many years ago, I tinkered with an oven controlled oscillator from a commercial television sync generator. They built their own oven, using a machined block of aluminum with a cavity to fit the crystal, another for a thermistor, a milled flat for a power transistor as heat source, and an op-amp to control the current source transistor.

One thing I noticed was that the oven, when not enclosed in its insulated metal case, was extremely sensitive. Monitoring the current to the heater, and blowing gently at the oscillator from about three feet away, the response was impressive.

If I were to tackle such a project, I would probably build the oven in a similar way, rather than buy a commercial package. More work, but the inevitable trade-offs would be mine to make.