I did not have a detailed plan for this Stickvise, just the aluminium bars as starting blocks. My first idea was to make a simple jaw from flat stock, but I didn't have a suitable piece of brass. I contemplated layering strips of thin brass plate but the plan changed when I was searching through my brass scraps and found the L-profile.

I thought the lowest 'setting' of the jaws (with the bushings on top) would be the most practical, but when I used the vise to solder a PCB (A geiger counter kit) I used the middle setting most. I didn't expect to need the top setting but with headers both on top and bottom on one of the boards being able to rotate the jaws was a very welcome feature. I will write a more detailed log later.

The parts:

- The three aluminium bars are 15 x 15 mm square stock, approximately 7,5 cm long, and drilled with holes for a 6 mm brass rod a bit below the centre line.

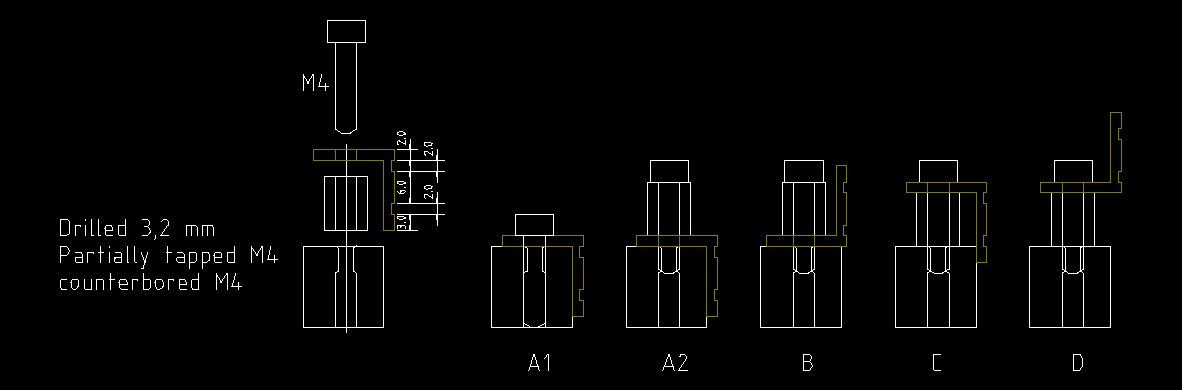

- Both jaw bars have M4 threaded holes for holding the vise jaws.

- The spring loaded and adjuster bars have horizontal holes drilled through. The holes are partially opened up to 6mm. The combined length of the 6mm wide holes can fit the compressed springs

- The spring loaded bar has M4 threads on the jaw side of the horizontal holes. These holes are not threaded and 4mm wide in the adjuster bar

- The stick is long enough to hold a standard sized experimentation board lengthwise, and has a small groove for the set screw in one end.

- The jaws are pieces of 15 x 15 x 2 mm brass, with two 2mm wide milled grooves (0.6 mm deep).

- The bushings are 10 mm in diameter and 10 mm in height, drilled to 4 mm.

- The thumbscrews were made by soldering a knurled and bored bushing to a 22 mm long piece of 4mm rod which was threaded M4 over the rest of its length.

- The spring rods are pieces of 6mm brass rod, turned to 4mm except for the ends. The other ends are tapped M4 and screw into a hole in the spring loaded jaw.

- A brass cylinder, with m8 threading on one end and a 6mm hole drilled perpendicular to it's axis, is inserted in the adjuster bar. The stick/rod passes through this cylinder, and tightening a

- The spring are just some springs I had, 6mm in diameter.

Martijn

Martijn

tonyo

tonyo

Christoph

Christoph

zakqwy

zakqwy

Martijn - @Jan has upped the bar for home builds - check it out: https://hackaday.io/project/9771-low-profile-vise-w-metal-quick-change-jaws