-

1Step 1

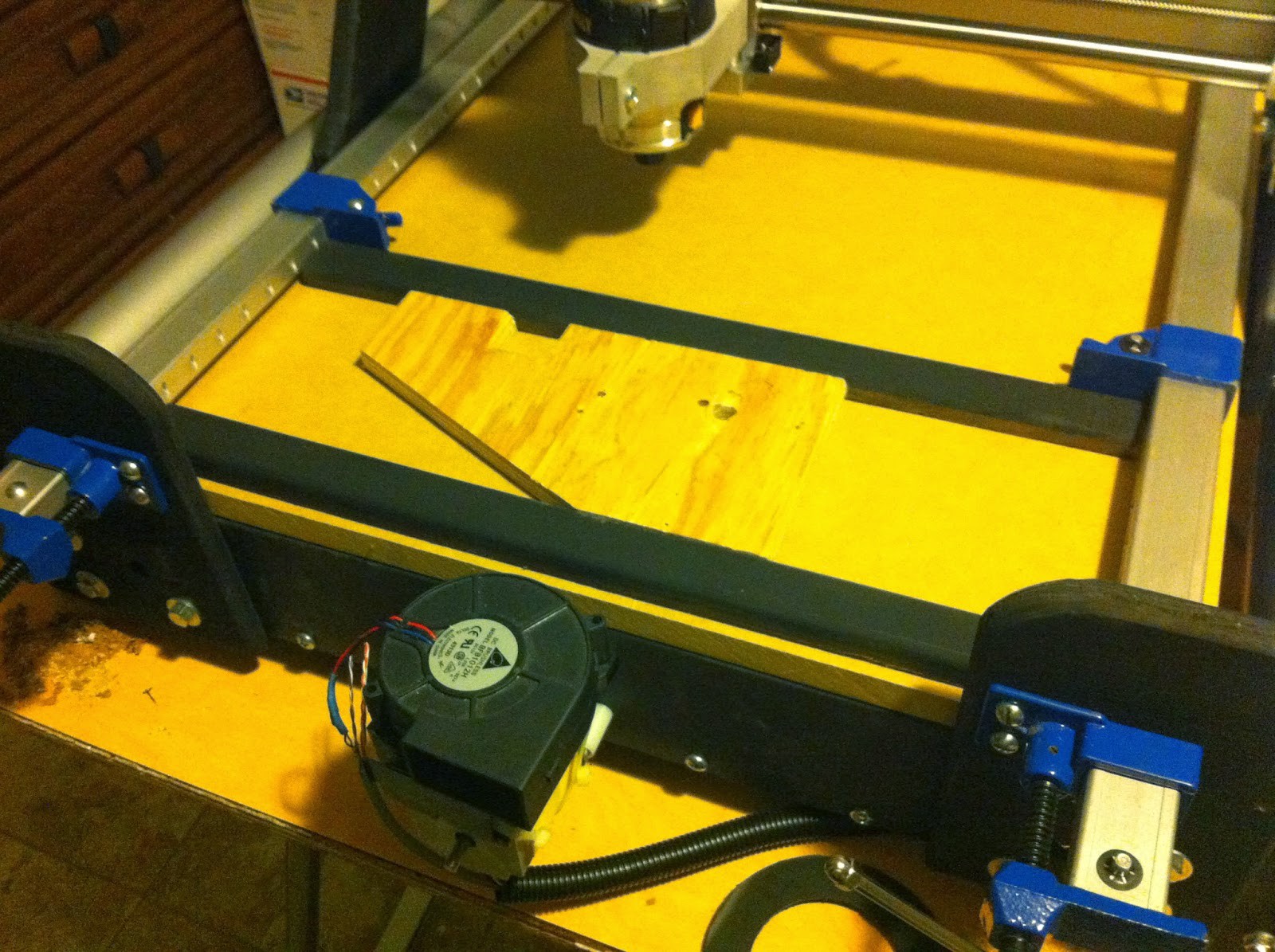

I started by making two sets of plywood braces that would hold the bar clamps as close to the outside edges of the bed as possible. The rectangular holes in each must provide for a snug hold but still allow for easy movement. The braces are held to the Fireball's frame with three bolt-and-washer connections.

-

2Step 2

The vise-action side of the clamp would protrude in the front of the machine attached to the wooden brace in front by two small bolts run through two small holes easily drilled in the aluminum bar clamp base.

-

3Step 3

To gain a small bit of clearance I ground off the lip on the moveable boot for the clamp. About twenty seconds on the grinder and this step was complete.

-

4Step 4

Here you can see the bar clamp installed in the braces. The clamp is simply threaded through the rear brace, not screwed or glued in any way. The only thing permanently affixing the clamp to the brace is the two small bolts mentioned previously. The clamp must be able to slide back and forth through the wooden braces.

-

5Step 5

With the addition of two wooden braces (painted spiffy black) the clamps

can be tightened in seconds holding my material quite firmly for

routing.

Simple CNC Clamp Workholding System

Lacking any work holding attachments I created this easy slide system

mikedouglas

mikedouglas

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.