-

Water Circulation Test!

09/13/2015 at 20:26 • 0 commentsBefore getting too excited and moving all my cramped plants into the new grow system I decided to conduct a test of the pump circulation system. I wanted to make sure the pump I am using can handle pumping from the reservoir into the input manifold. Setting up the NFT system with water for the first time is sort of a process, first I'll talk about the setup/function and what I found out about my chosen design.

The setup as left after the silicone sealing of the end caps. It was good it was still mostly dismantled, installing the reservoir in place beneath the until requires lifting the frame, its a lot easier with everything removed.

Flow rate sensor removed from pump tubing assembly and installed to the input manifold. The fitting on the end of the flow rate sensor adapts from 1/2" threads to a 1/2" barbed end for attaching to the tubing on the submersible pump.

To get things started I began with setting up the reservoir internally, an airstone in each corner almost and the pump centered in the middle, secured to the bottom with suction cup feat. The tubing for the airstones, pump power cord, and pump tube all fit through the same hole in the top.

Next I filled the reservoir with 5 gallons of water, everything inside got swished around.Later a better method for securing the pump and airstones will have to be worked out, possible using silicone as a glue to secure the tubing in place on the bottom. The reservoir has to be filled before hand at the moment since there isn't an input pipe yet, later I plan to add another 1 1/4 " pipe for adding more water/nutrients/boosters to the reservoir.

Next I slid the reservoir beneath the frame. Since the drain manifold is built into the frame the frame needs to be lifted up to slide the reservoir underneath.

Reservoir installed into place, with the drain manifold exit protruding directly through the hole cut for it on the top of the reservoir.

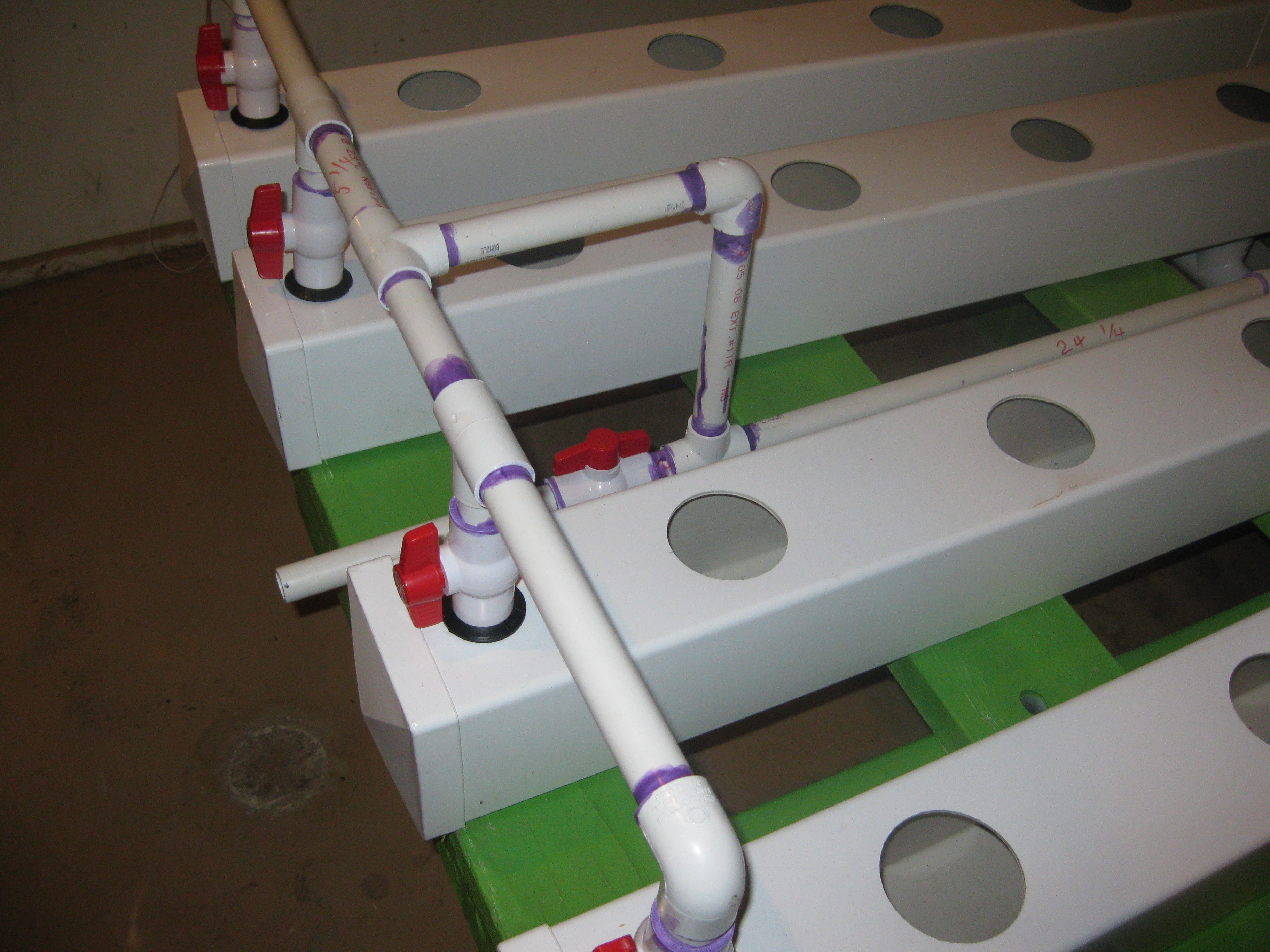

All four fence post grow rows installed into place after installing the reservoir. The next step was installing the input manifold and connecting it to the pump. After the input manifold was in place, valves on 3 of the four rows were closed before starting the pump, each row disabled at the start were enabled one at a time starting after the first row was filled and running into the drain manifold.

Water inside the first two rows

Close up of the water draining into the drain manifold on one of the rows.

After attempting to get all four rows filled with water, I discovered a problem. It seemed the pump was too weak to pump the water into the manifold. After some investigation and testing different rows by opening and closing the valves, I determined that the pump only has enough power to run half the system. A larger pump will be needed to get the system up and running but its not the end of the world.

Additionally I wanted to test the reservoir pump out valve. This vale in the middle of the system is for using the reservoir's internal submersible pump as sort of a sump pump to drain out the reservoir into a bucket. The reason for this feature is for changing out water in the system if it get too dirty, the unit needs cleaning, etc for whatever reason you'd want to remove the water really. The whole idea is to make it easy and semi automated by using the same pump inside the reservoir and turning some valves. In order to use it the pump must be turned off, next the valves on each row need to be completely closed, finally the drain valve can be opened. The pump gets turned back on and pumps until the reservoir is empty.

Back to the topic of the pump being undersized. The mistake made with the pump choice comes down to a few things. Submersible pumps are rated in a height they can pump this is called the total dynamic head, this rating pertains to the vertical height the pump must move the fluid. The total dynamic head is also influenced by the design of the pipe fixture it is pumping into, in the case of the input manifold, also most total dynamic head ratings assume there is not fixture added. The trick is to design the pipe fixture or manifold in this case to fit within the range of the dynamic head of the pump. So basiclly I need to go back and take into account all the parameters of the manifold and make some calculations before getting a new pump. I plan on making a dedicated log explaining this a bit more clearly. Thats all for now, thanks for the continued support and stay tuned!

-

Manifold Gluing

09/13/2015 at 08:40 • 0 commentsThis week I glued the manifolds for pumping and draining water through the NFT system.

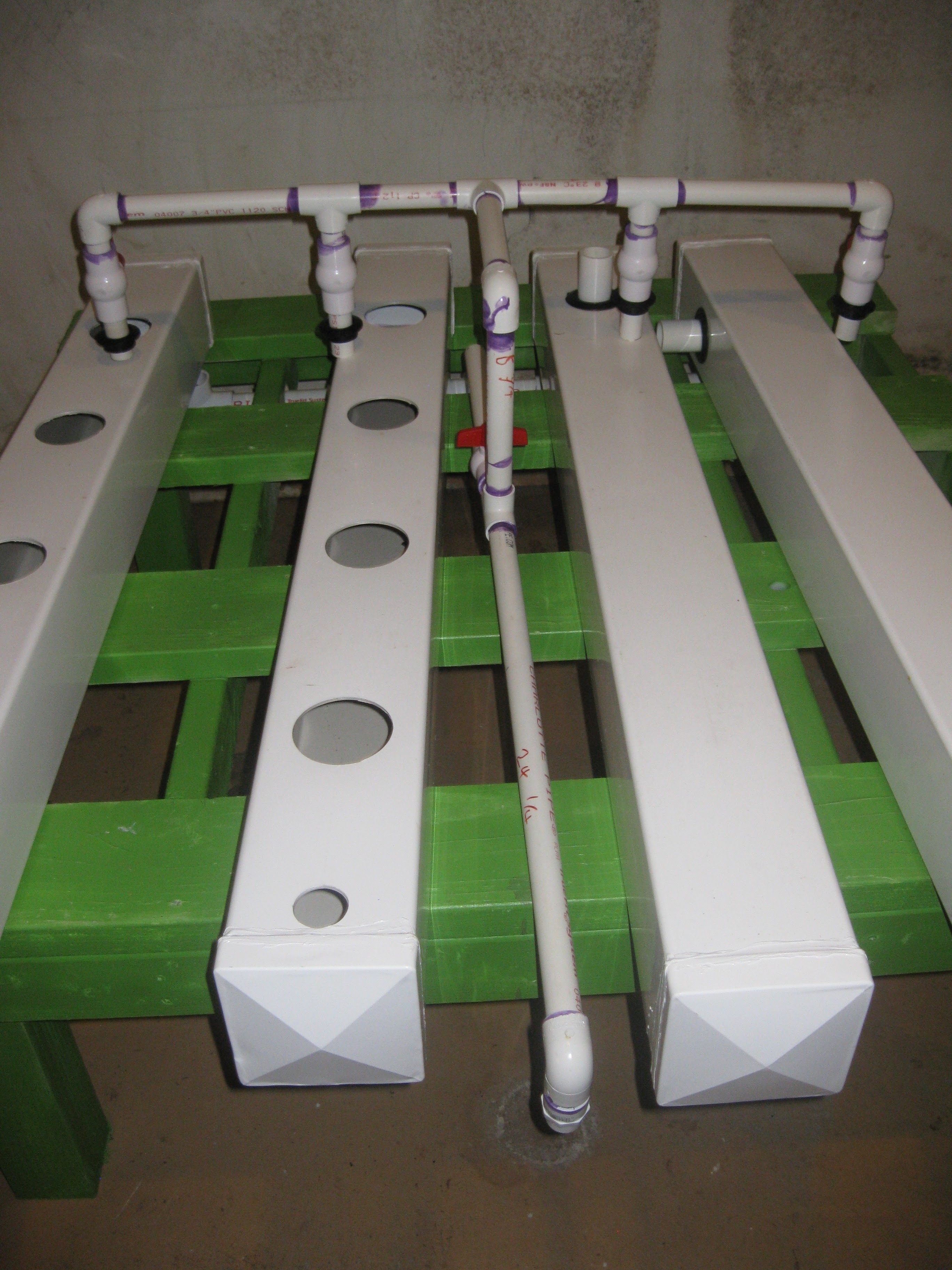

Dry press fit the drain manifold in place, Input manifold in pieces.

Input manifold dry fit together.

Drain manifold gluing process, the manifold is assembled within the frame, it gets permanently installed this way but it adds rigidity to the system and serves to lock the fence post grow rows in place.

One side assembled

Midway assembling second side of drain manifold.

Another view

Second half of manifold completely assembled.

Another view of the completed manifold

View from beneath, all four drains from the fence post rows converge to this output, it protrudes about an inch into the reservoir.

Another view from below

A view from the side below.

Fence Post Grow Rows installed, they just press fit in place

The gluing of the input manifold was a longer more careful process. The input manifold has PVC ball valves for setting the water depth in each row, I decided to assemble the manifold in stages to prevent PVC cement vapor from damaging the valves. As I assembled the manifold I made sure to take down all the lengths of the different pieces of pipe, I will be updating the other project page with this information so anyone out there can build one like mine. Moving on with the photos:

Assembling the t-joining piece

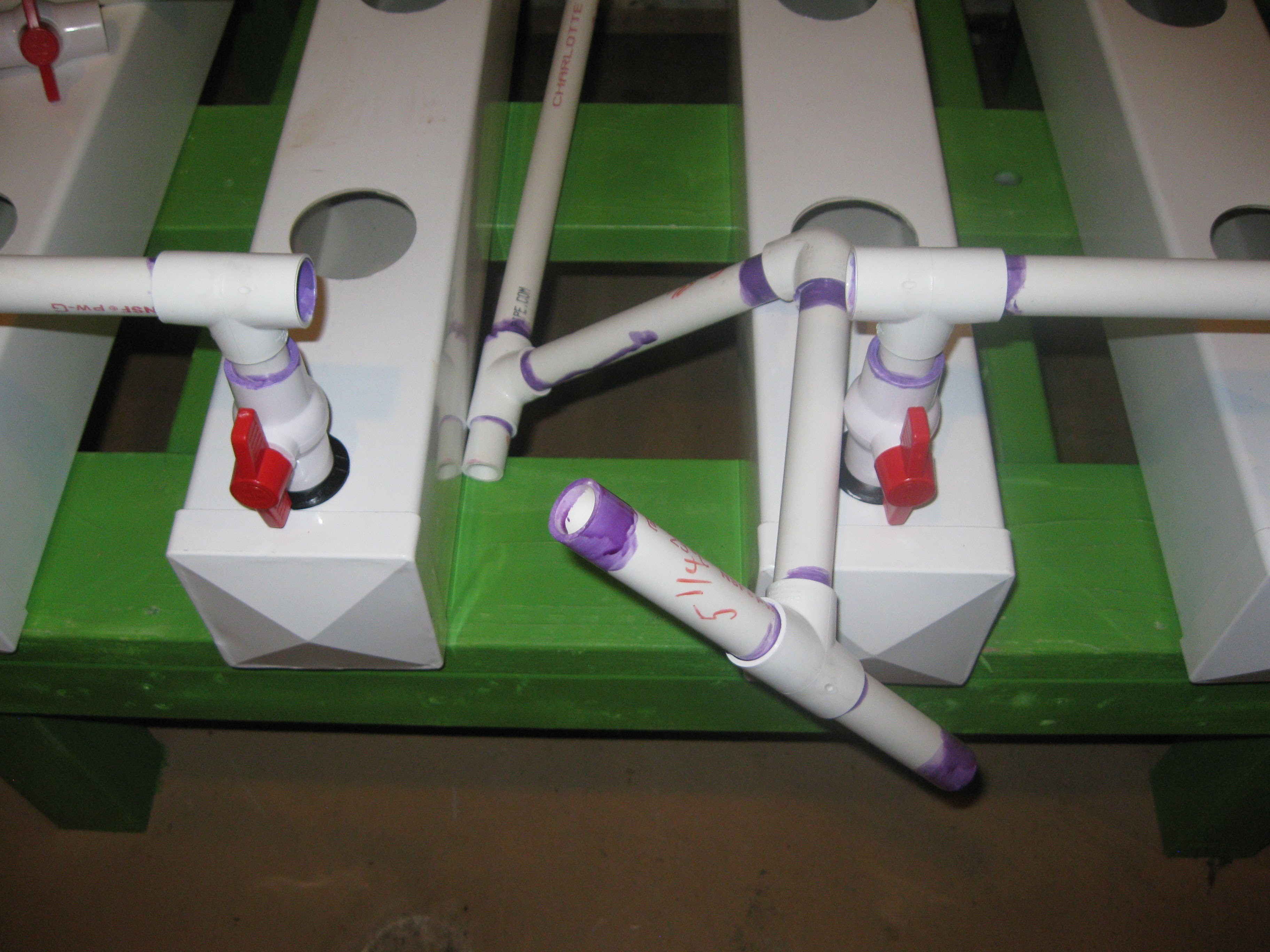

Assembling valve sections of the manifolds. For assembly the manifold was assembled in half essentially, pairing two fence post rows together. Each side of the manifold was assembled separately, with the idea of being installed into place and joined together with the T shaped piece above. This piece is dry assembled here and not yet glued.

Part of section without valves assembled first. The valves and the pipe for connecting them to the fenceposts were assembled separately.

This piece connects the pump and flow rate sensor to the manifold.

Fitting assembly for connecting flow meter to pump and input pipe glued together.

Gluing one of the manifold halves.

Small sections of pipe glued to valves and set to dry, these were attached before gluing the valves into the manifold sections so they would dry a bit before hand to prevent excess vapor of the cement from melting the internals of the valve. Also picture are the two sides of the manifold that the valves glue onto and the fitting assembly for atting the pump and flow meter to the input pipe.

Beginning the input pipe gluing. the input pipe connects the pump inside the reservoir to the T-shape piece designed to join the two halves of the manifold containing the water level set valves.

Input pipe assembly components primed for gluing.

Input pipe assembly in the process of being glued.

Input pipe and T-shape (joins both sides of manifold) glued and drying for next step.

T-shape piece and input pipe glued together.

Manifold pieces glued in sections, set up to dry briefly before valve gluing.

Pump/flow meter fitting assembly added to input manifold pipe.

Getting ready to glue the valves onto the two sides of the manifold.

Adding water level set valves to each side of the input manifold.

Two sides of the manifold assembled with valves.

Both completed sections of the manifold placed on either side with the middle T-piece primed and ready for gluing.

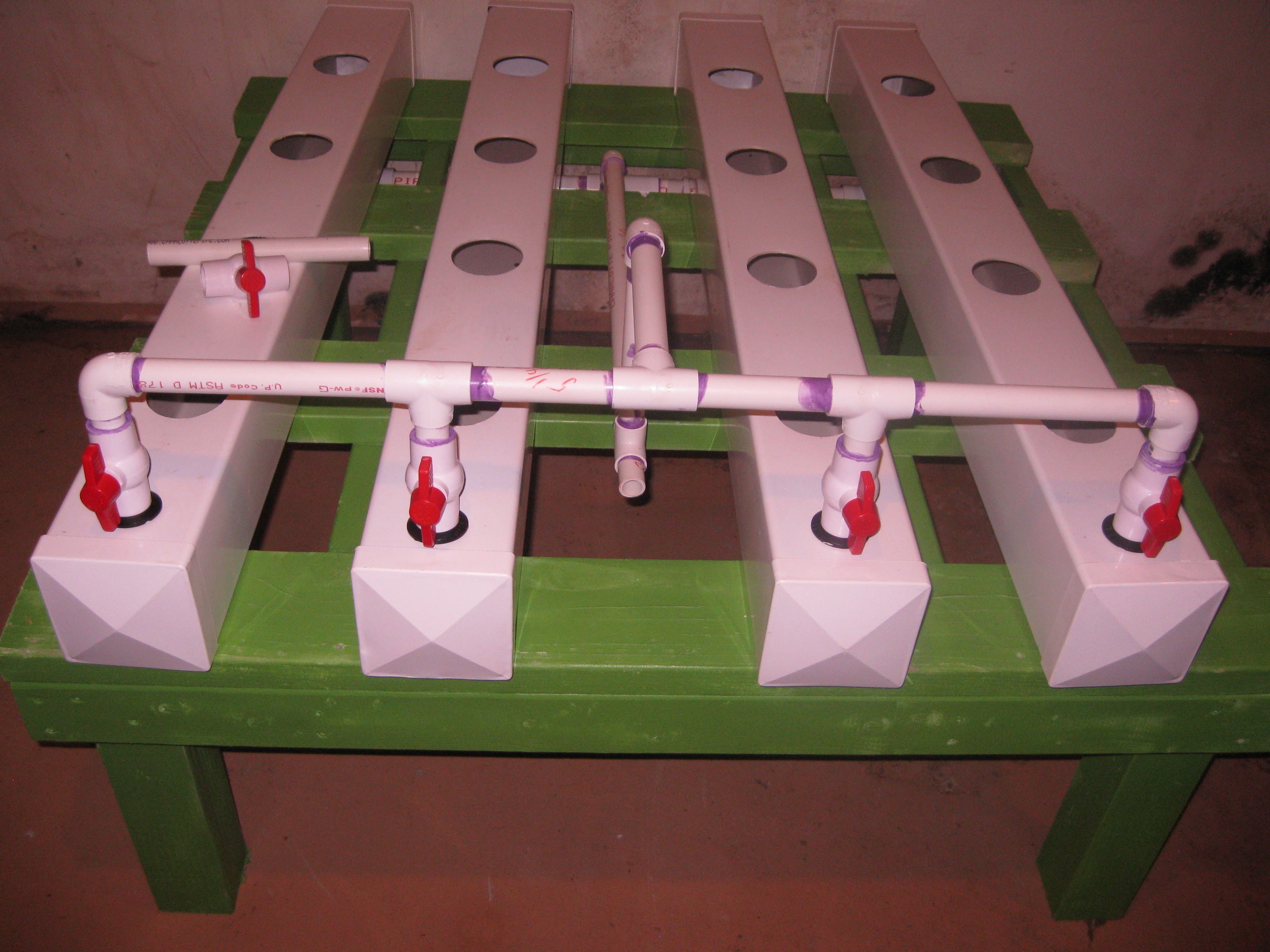

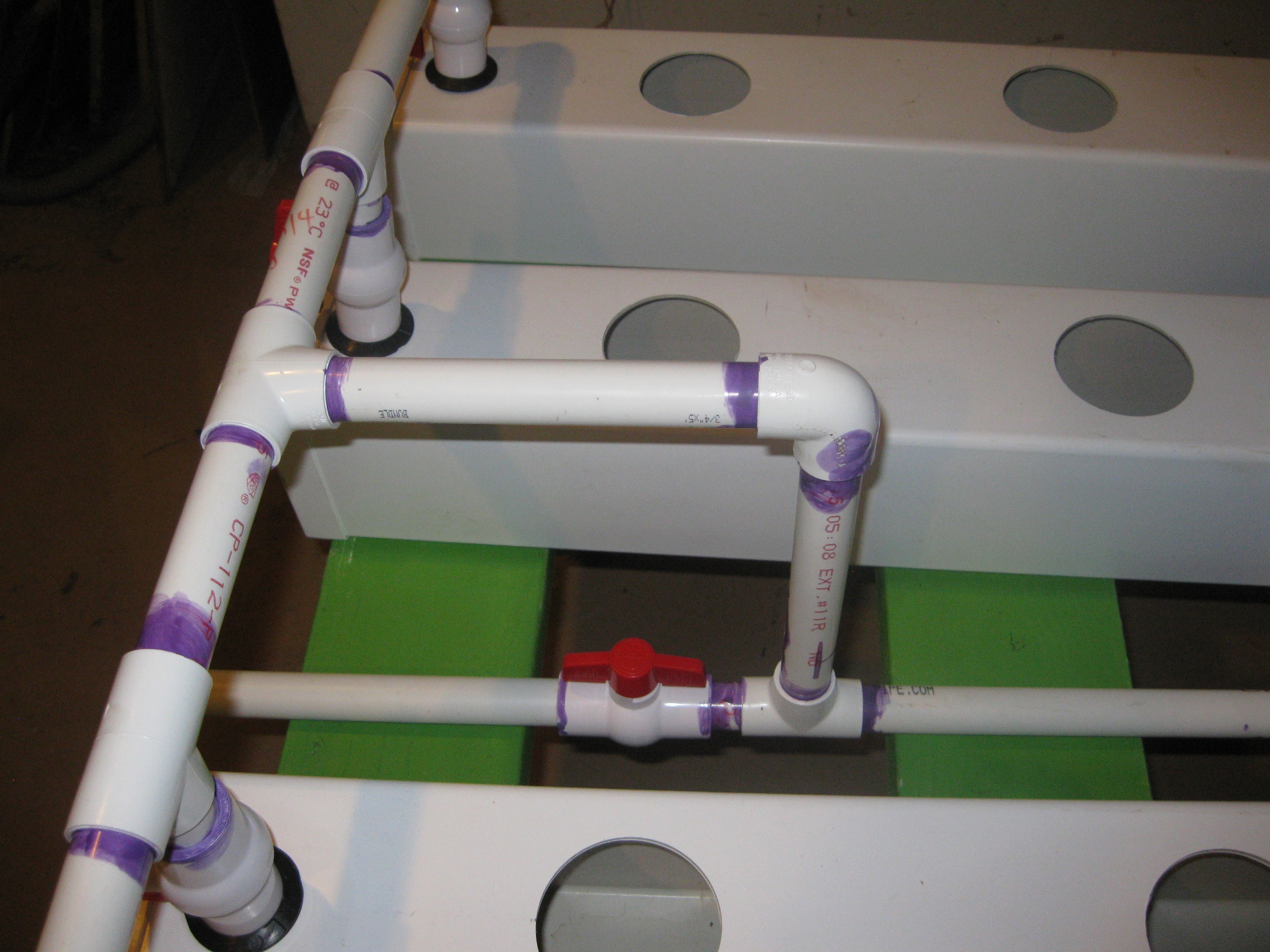

Manifold glued and installed, with the waste water draing valve to be glued in place next.

Gluing the waste water drain valve and pipe

Manifold completely Assembled and installed.

Both manifolds in place, directly above where the reservoir will be placed, perfect.

View from below after both manifolds and fence posts rows installed

Everything in place after moving the rest of the junk out of the space.

Netted pots in place

-

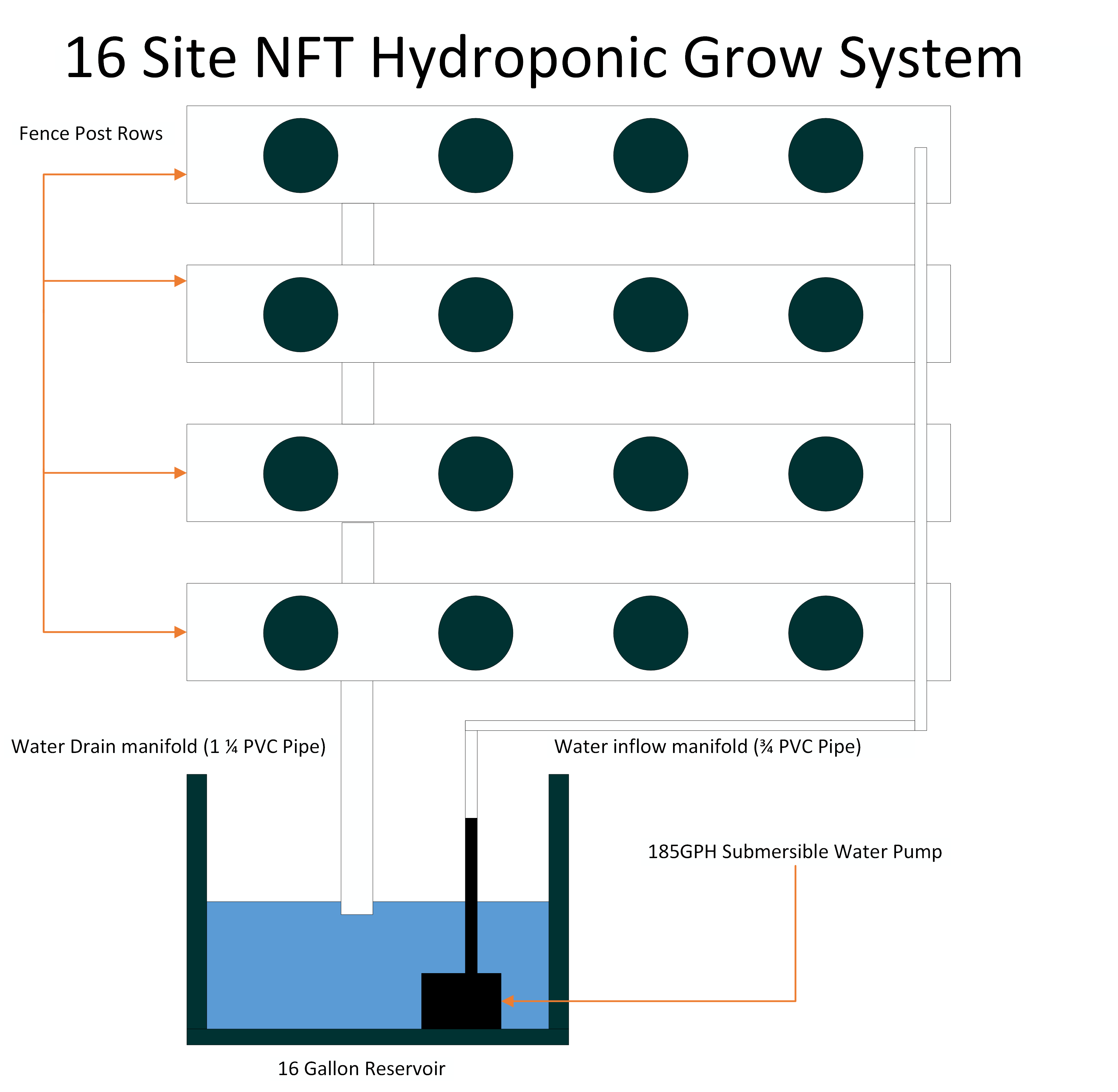

Water Circulation and Manifolds

09/13/2015 at 07:55 • 0 commentsThe NFT grow system is constructed from PVC fneceposts and PVC pipe. The fence posts hold the netted pots where the plants grow, the PVC pipe is used for piping the water in and out. For this system I build an input manifold from 3/4 inch PVC pipe and PVC ball valves. The purpose of the ball valves is to so the water level inside the fenceposts can be adjusted, when the plants are first starting out the water level has to be high, when their roots grow big enough the water level can be lowered. Eventually I intend to motorize these valves and add sensors to enable closed loop water level tuning. The next piece I worked on was the drainage manifold, it consists of 1 1/4 pipe and a few 1 1/4 inch fittings. The drain manifold is made from larger sized PVC so that the water drains fast enough relative to the circulation pump. In the picture below I show how the drain manifold will go together:

Pipes, fittings, valves, etc

As for attatching the manifolds to the fenceposts I originally was planing on drilling holes in the endcaps and using PVC glue and epoxy to hack it all together. I decieded that would be a rather terrible way to put it together so I did some research on what other folks are doing with similar builds and someone recommended uniseal gaskets. They work really well and they are very simple to install, basically you buy a seal based on the size of pipe and they have a hole-saw chart explaining what size hole is required for the seal, just drill the hole pop in the seal and push in the pipe, water proof and you can take it apart for cleaning. Here is where I got them BTW http://www.aussieglobe.com/uniseal1.htm

The input manifold pictured not yet finished, next pipe needs to be cut to join the two sides with a t fitting in the middle that connects to the circulation pump in the reservoir. Also in the picture the two halves are different sized, I was still deciding on the exact spacing I wanted. I should also note that I primed and painted the wood frame to that nice planty looking green color, I think it turned out great and gives the rig a nice look, the plan is to build another rig but paint it a different color. Its really just for fun.In addtion to the manifolds I finally found a reservoir for the system. I was planning on a 55 gallon water barrel originally but that would be too much water and require a bigger more expensive pump, I also decided to build the green two by four stand shorter in case plants get way too tall. The next idea for a reservoir was a storage container, at first I was going to go with a 10 gallon container but ultimately decided to get a 16 Gallon container because the dimensions allowed for a better fit underneath the grow system itself. Inside the reservoir is s submersible pump used for circulating the water through the NFT system, connected directly to the input manifold. Also in the reservoir are aquarium airstones connected to an aquarium air pump , this serves to aerate the water/nutrient-solution and agitate it to prevent stagnation/algea growth.

Submersible Pump, airstones, tubing, fittings, and leftover air valves.

16 Gallon storage container, AKA the reservoir!

Rervoir internal setup, 185GPH submersible pump and airstone setup.

How all this works:

The diagram above should explain the general idea behind everything discussed in this log update. The pump sits in the reservoir and pumps water into the fenceposts via the input manifold, the water drains after flowing from the fenceposts into the drain manifold and back into the reservoir. Stay tuned for more!![]()

-

Materials and Construction

09/10/2015 at 02:23 • 0 commentsMaterials: 2X4s, 4X4s, and 5X5 PVC fence post

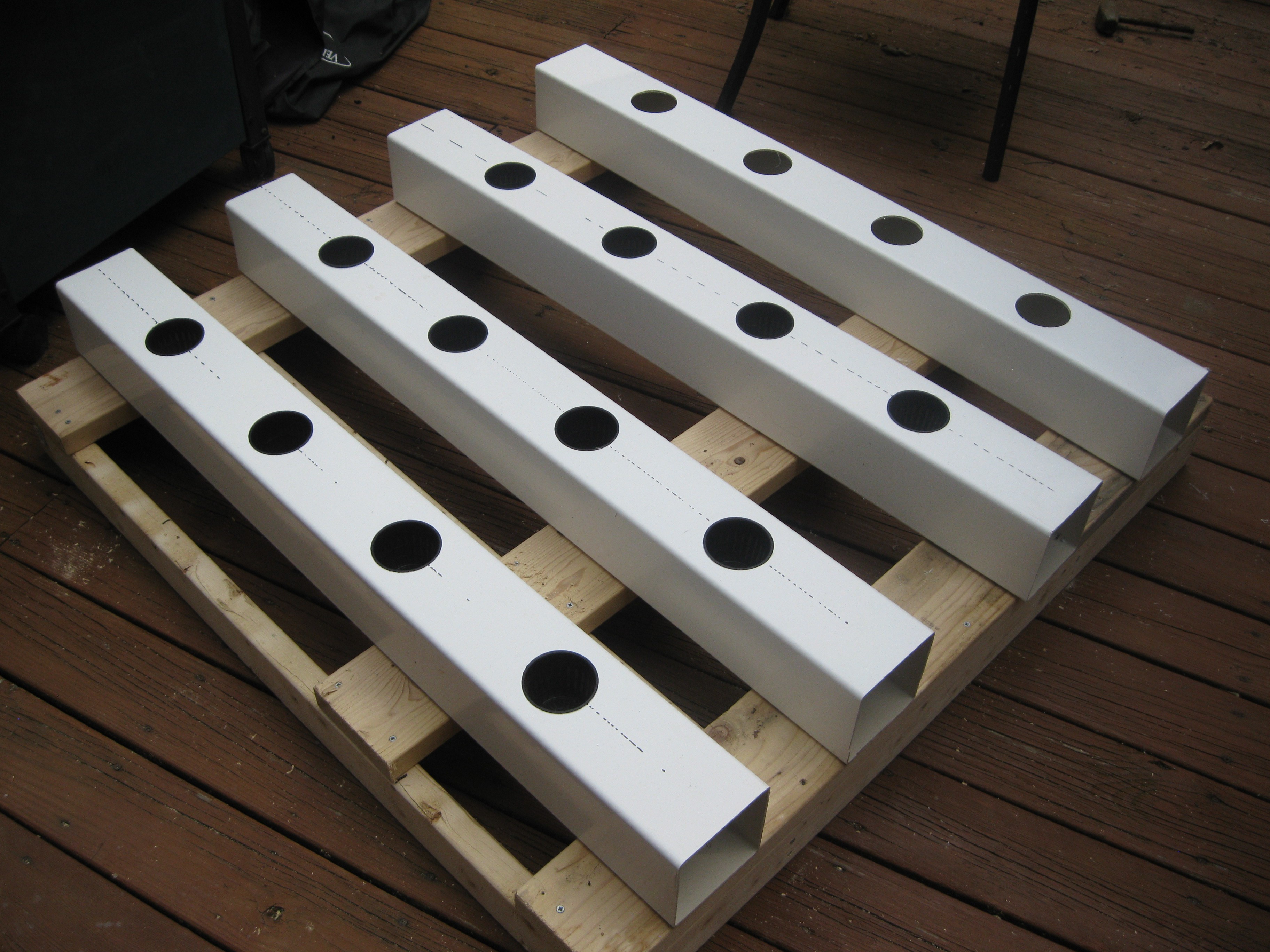

Cutting Fence posts, I bought two 8 foot lengths and cut them in half for four 4 foot units. Each unit will hold 4 plants in 3" diameter hydroponic plastic grow baskets, filled with hydroton grow media.All Cut, the chop saw wasn't big enough to fit the whole width of the post so I had to rotate it 3 times to cut them, I don't recommend this but if you do wear safety glasses and be very careful.

Measuring spacing of the plant pots and drilling pilot holes for the hole saw. I was planning on using my 3 inch hole saw to cut holes for the pots but the drill (on the table) I have won't fit the hole saw. I need to borrow a friends drill to finish. Next off for building the unit will be the frame, I haven't decided what the frame is going to look like. Simple requirements for it will be to mount the 4 rows and be tall enough to fit a 55 gallon water barrel underneath to act as the reservoir for the system. I plan on using the 4X4s to make legs and to build the rest of the frame with the 2X4s.

So thats what I got done on the unit so far, I'm hoping to do some more work Friday if its nice outside to use the saw, stay tuned for more updates later!

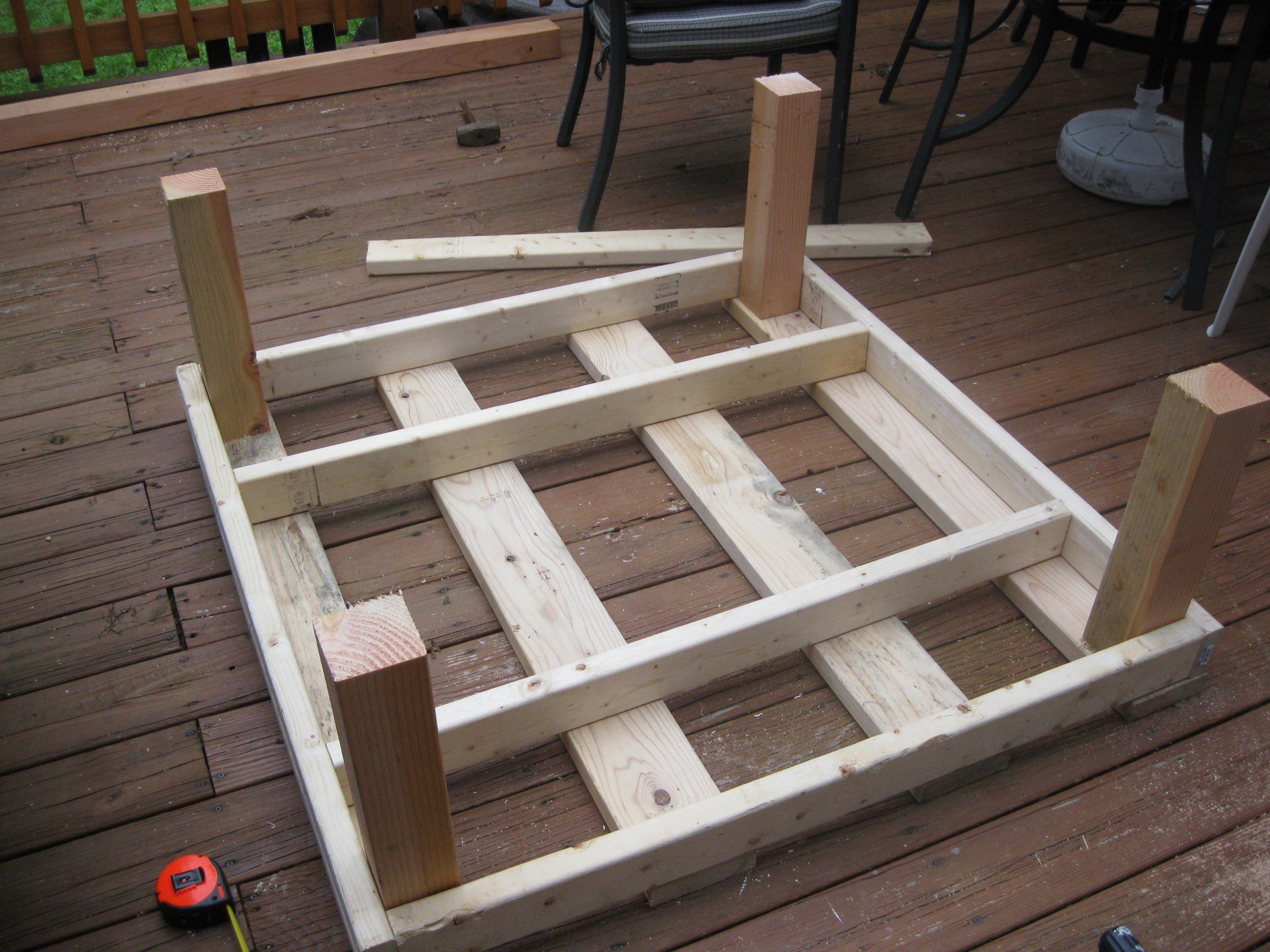

Last week I did a lot more work on the NFT grow unit the HydroPWNics control system will be deployed on. I finally decided on a simple design to hold up the 4 cut piece of fence posts holding the plants. I choose to cut the two by fours into two pieces one larger than they other. I used all these piece to make a simple box frame and added boards on top to strengthen and support it further. Its hard to describe with words so I have included a bunch of pictures of what I have done so far:

Materials laid out being measured and cut

Wood all cut to length, time to drill pilot holes and screw it all together:

Just placing it together to see how it fits and see how well the cuts came out. The cuts were spot on, and everything slid together without any real big gaps between wood. You can see how the pieces were cut purposely uneven (like how I mentioned before) so that they fit together neatly at each corner.

Closer look at the at the construction

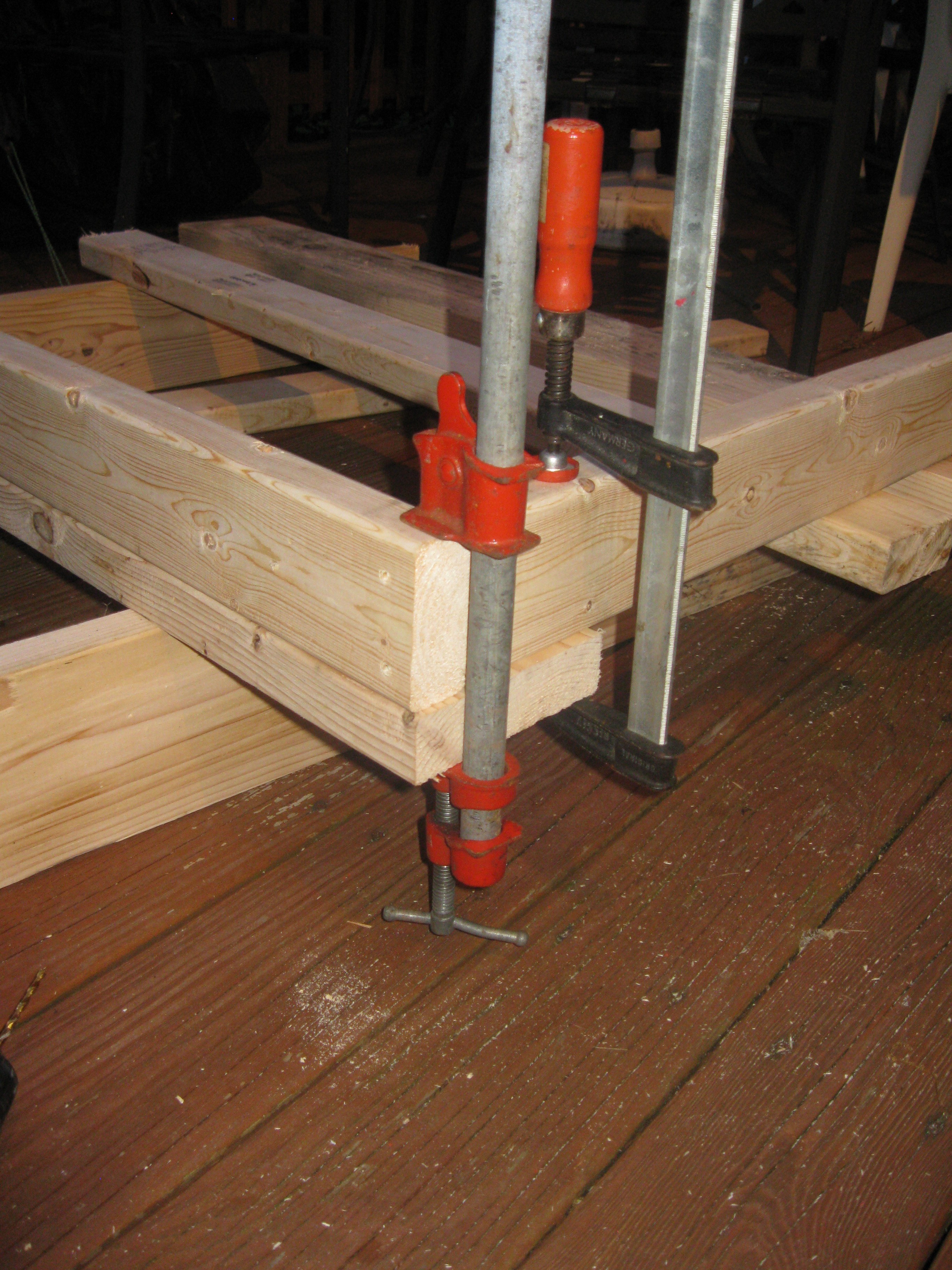

Its much darker out because it took me a while to find some clamps around the house. I clamped each joint together, when I drilled the pilot holes and left them clamped when I added the screws. It took much longer to clamp and drill pilot holes but in the end I didn't get any cracks in the wood and everything went together rather smoothly.

Closer look at the clamp placement and placement of the wood. I forgot to take pictures earlier but what I did firs was take the longer lengths of two by four for the frame and bolted them to the top planks at the end, which are also the same length. I did that first to make it easier to clamp, drill, and screw each corner of the frame.

The frame after the first day of work. The middle two by fours are screwed in from the top and side, so they are held in place rather well. One got attached crooked and it makes things look weird but I plan to fix it later before I paint the frame.

Stay tuned for another update on the frame as well as the rest of the project either later tonight or tomorrow. This post is for last week's work and I just forgot to make a post. I hope to have some more to show from this past week, so stay tuned!!!

Posts all drilled with pots in all but 4 positions, see that the frame isn't finished, more on that next!

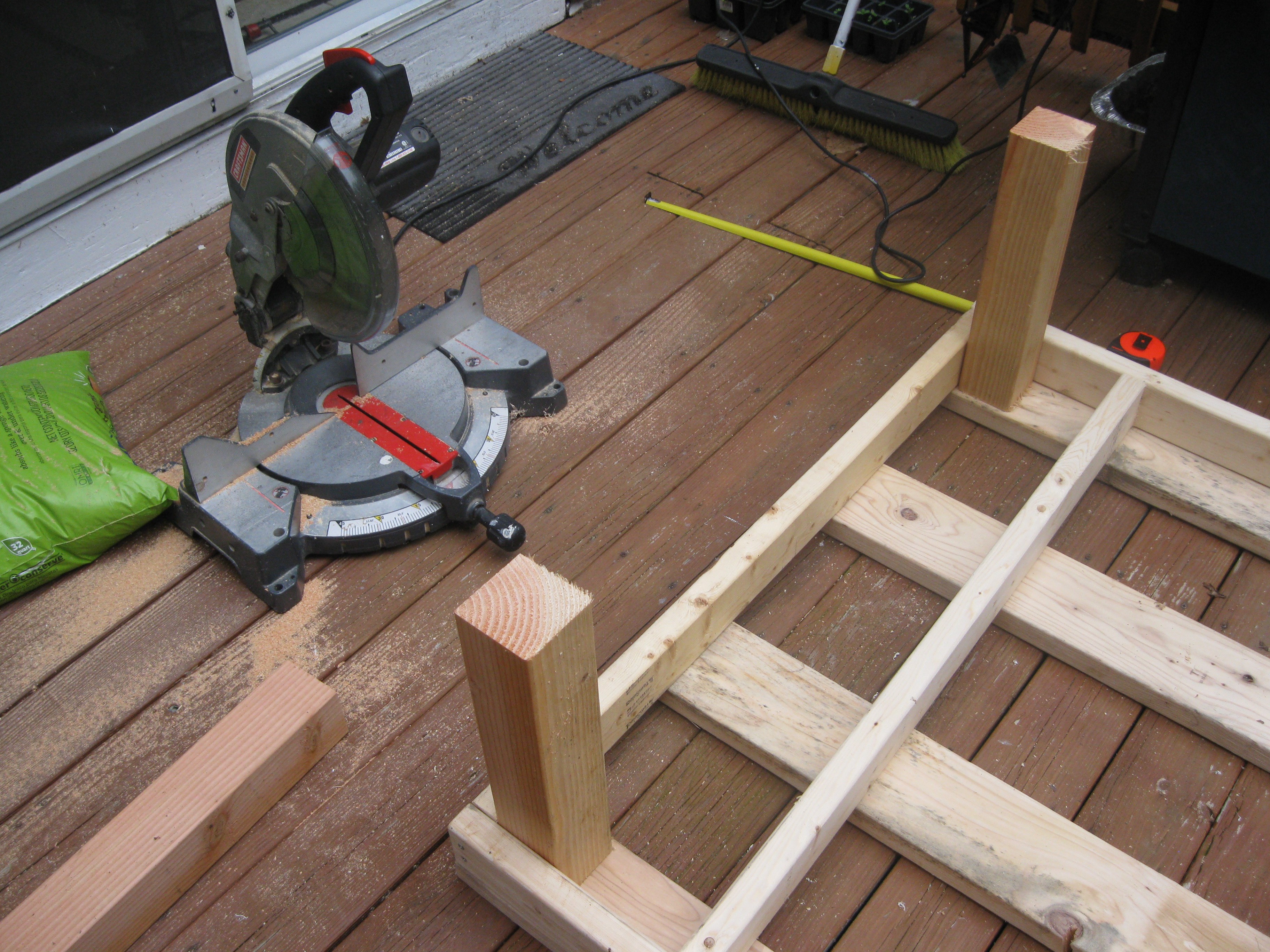

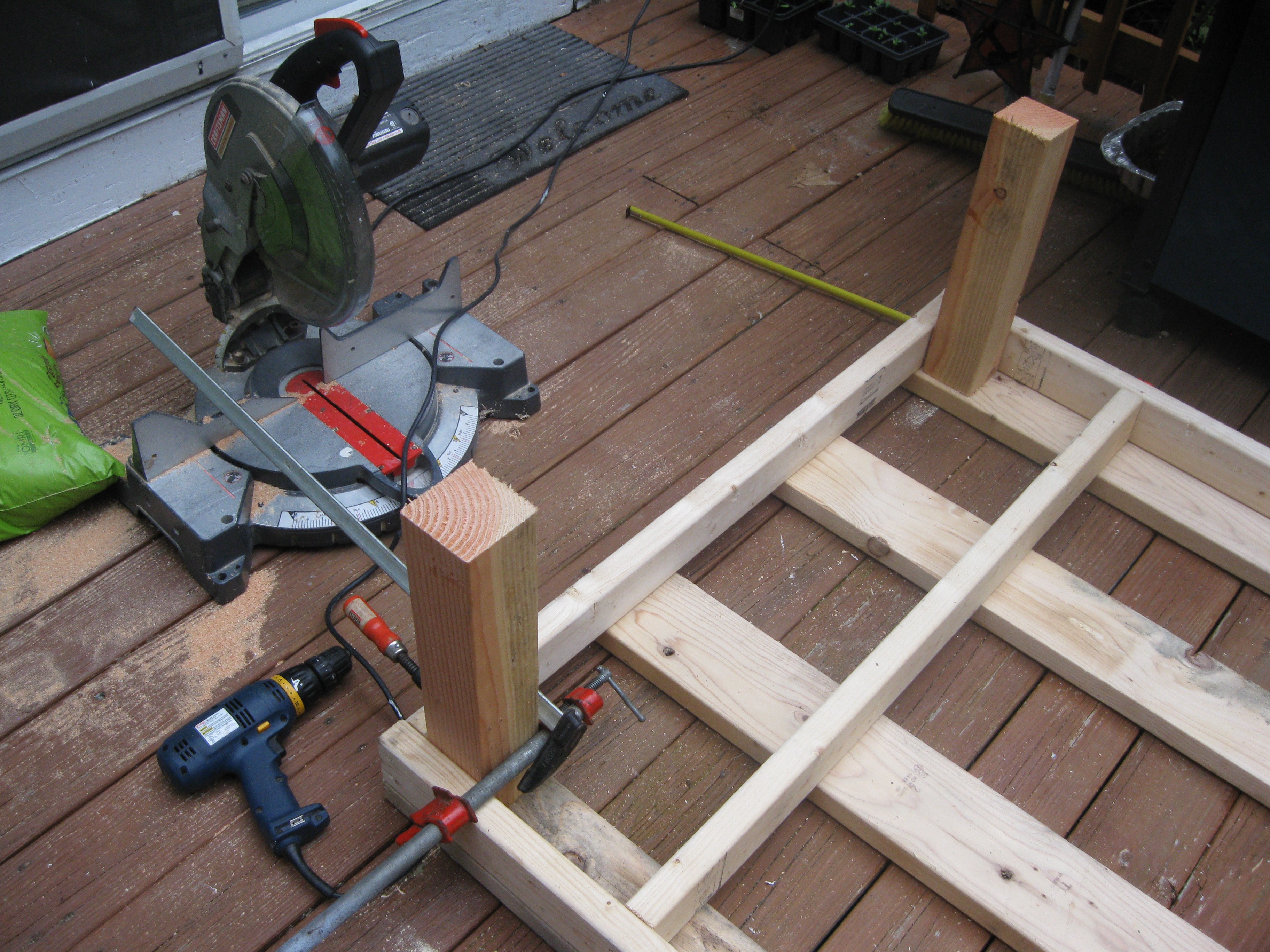

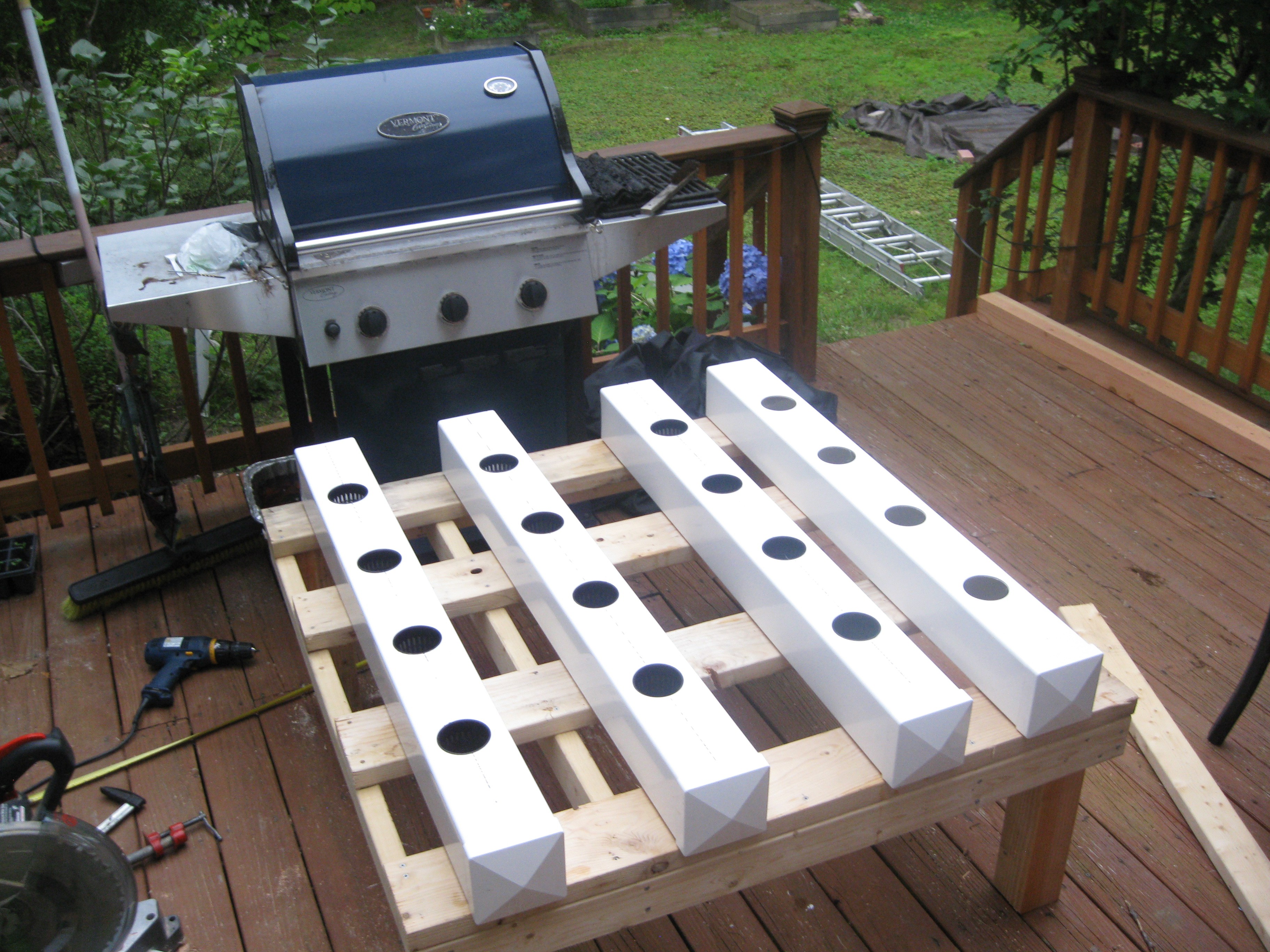

Today I finished the wooden frame of the whole unit. I added the crossboards and legs, take a look at the pictures to see what I mean:

Dry fitting the legs after the cross boards added to the top of the frame.

To attach the legs securely and straight, I clamped them tightly into each corner with the same two clamps I used the other day. I used a spare piece of the 4X4 wood to hammer each leg after being clamped to make sure its flat up against the board on the top of the frame. I used 4 screws on each leg. I'm trying to decide if I want to have crossmembers between the legs or have a skirt for the frame at the bottom, or both. I think a skirt at the bottom is definitely going to happen, mainly so I can build a giant drawer underneath the unit to store the water reservoirs.

Another view:

Done for now, there will be a two by four skirt added to the bottom (as I stated previously), next trip to the hardware store I will be getting the remaining wood to build the skirt and bright green paint!

What it looks like with the rows of fence on top:

Overall I like how the frame came out, its almost a perfect 4X4 foot square and a little less than two feet of the ground. Orignally I was going to make it 5 tall off the ground, but I wanted more height for the plants to grow. I am also going to be using rubbermaide tubs for a reservoir instead of a 55 gallon water barrel which was also another reason to make it shorter.

-

Comprehensive BOM

08/07/2015 at 04:23 • 0 commentsHey folks, this project log is just to show what the BOM looks like currentlt. This project isn't intented to be worked on to too much, it is essentially a sub-project to HydroPWNics anyways here is where the BOM stands at around $217 USD

Low Cost NFT Hydroponic Garden (under $250)

A low cost NFT hydroponic garden design cheaper than most online kit solutions. Developed as a test bed for HydroPWNics

AVR

AVR