The general theory behind this project is that modular design can lead to very low production & logistics costs.

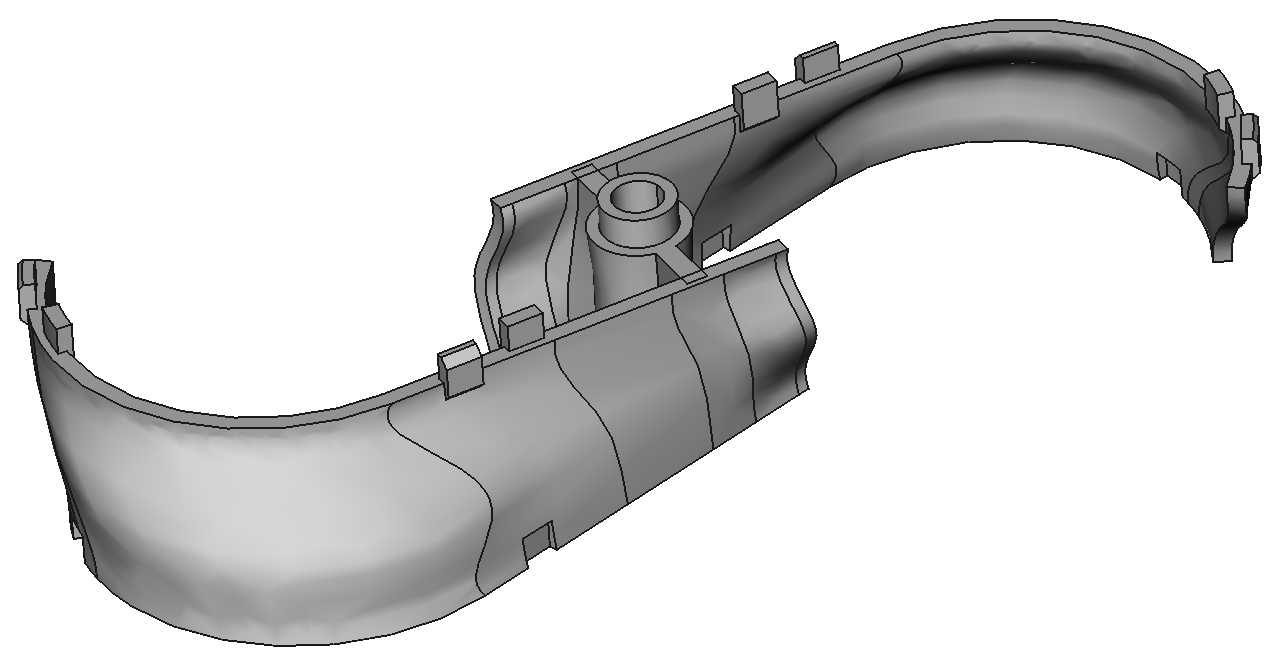

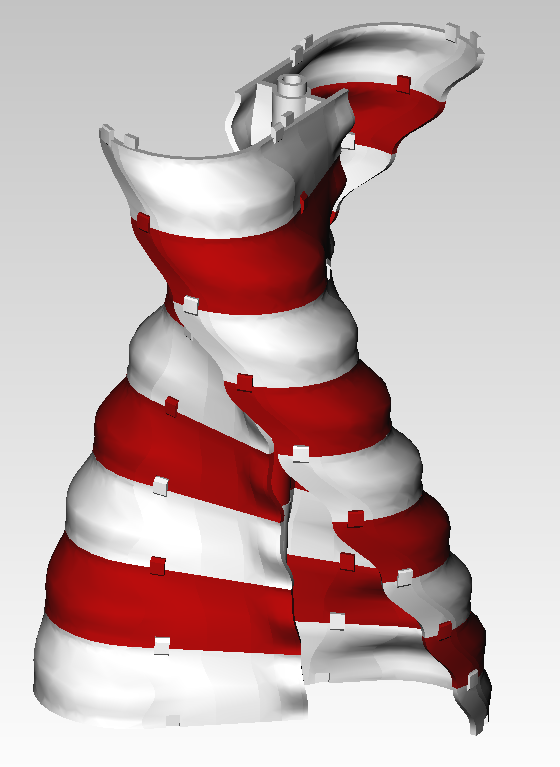

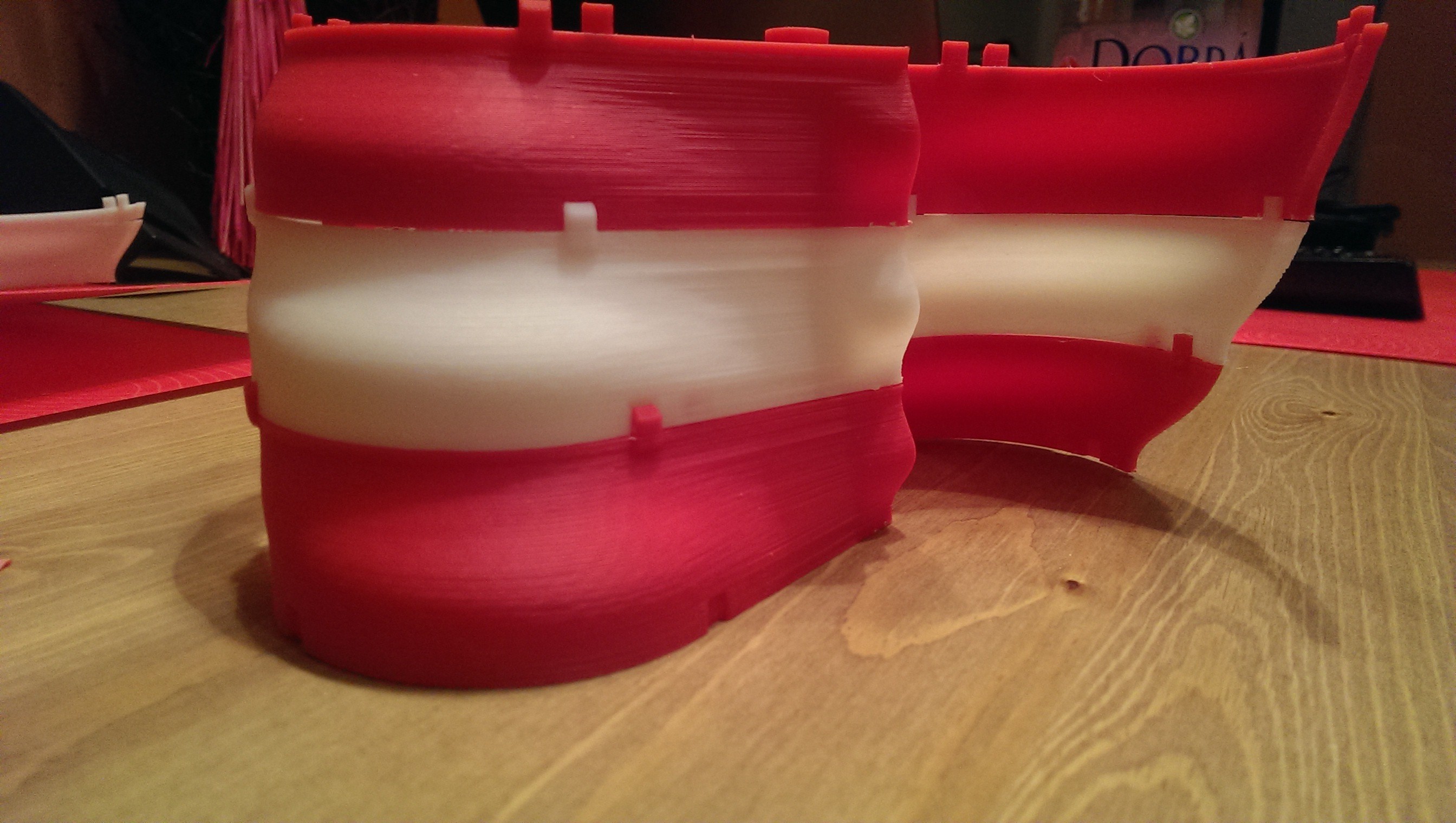

The turbine will consist of a number of smaller identical pieces designed to lock together. Each individual DNA piece will be 210mm high & 1260mm wide. Stack 10 together & the total height of the turbine will be 2.1 meters. Making multiple smaller identical pieces is cheaper & more efficient than making one huge piece.

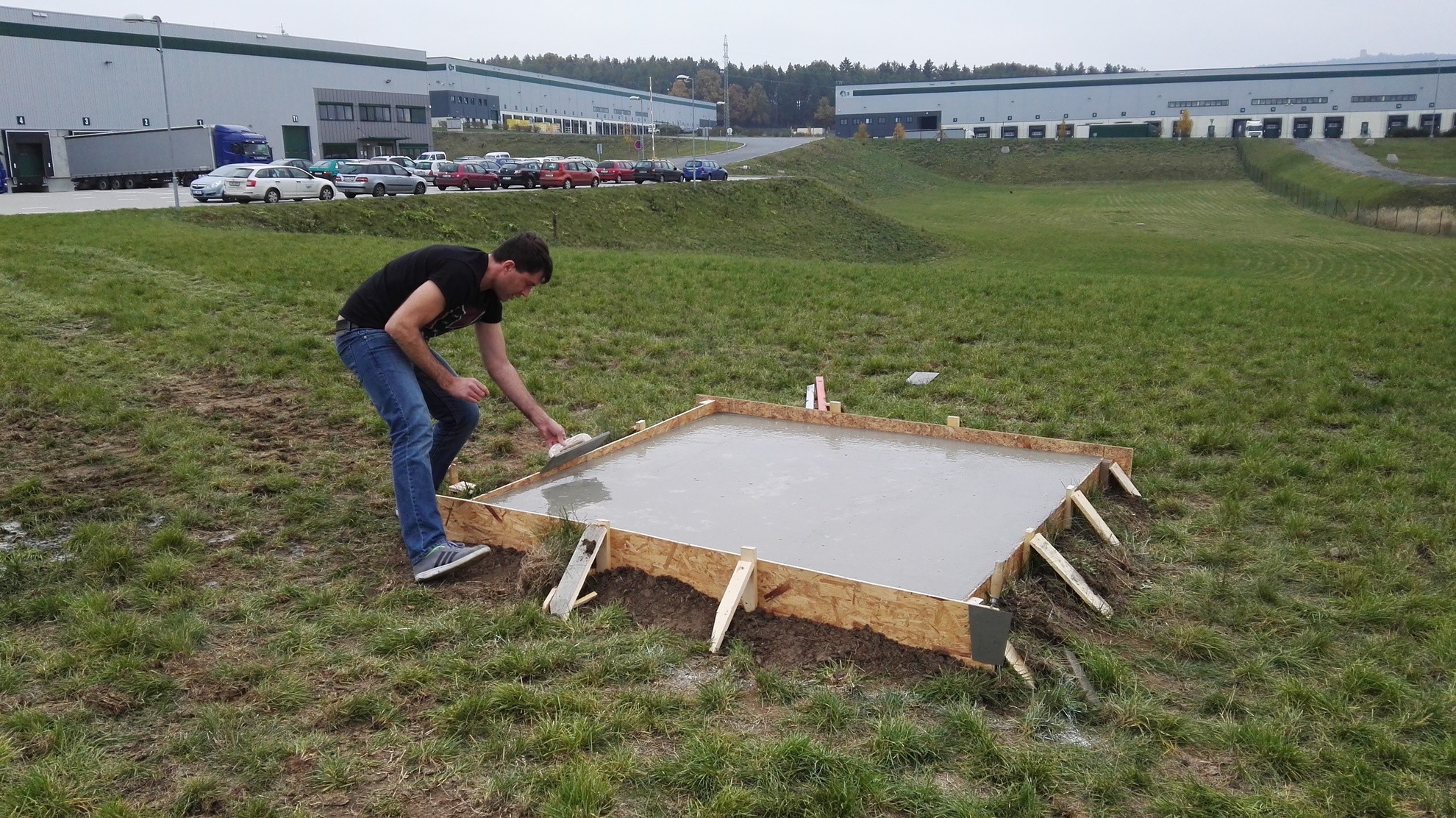

We started this project years ago so the project updates will reflect things that happened in the past, not in real time. At this time, we have all the parts fabricated we just need assemble the final product in a windy location. Unfortunately, we do not have a windy location so we have decided to built it in a non windy location. On the occasional days when we get decent wind, we can get good performance data. Additionally, we do occasionally get huge storms so structural integrity can be tested even in the poor location we have chosen. Once we know more, we might consider moving the device to an official test site somewhere (but that costs a lot of money).

We spent a lot of time on the design of the individual pieces. Getting the perfect shape & finding an effective way to lock the pieces together was challenging.

Because each piece is 210mm x 1260mm, we have the ability to flat pack a big windmill onto a fairly small pallet. Similar to an IKEA piece of furniture, the device is designed so anyone can assemble it using simple instructions & simple tools. Each DNA piece is very light so easy to maneuver.

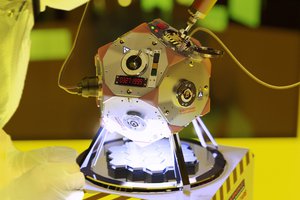

We are fortunate to have a 3D printer. After each design modification, we were able to print scale models of the DNA piece & stack them together..

The complete DNA turbine is mounted on a pole & spins a generator. The generator size depends on the height of the turbine & the wind conditions in the location it is built.

The windmill should be useful for off grid folks. It will be rather beautiful, completely silent & it will not kill any birds. It could also possibly be used by companies as a form of green energy & advertising. That is, mount it at the entrance to a facility where flag poles usually go, put the company name on it & it will demonstrate that the company at least pays lip service to saving the environment.

The turbine will produce energy at very low wind speeds but output is a function of the cube of the wind speed so good wind really helps!. The turbine can also be roof mounted..

The device is supposed to be cheap. Actual price is somewhat irrelevant. The price has to be judged relative to the amount of energy the windmill makes. We have a degree of confidence that it will pay for itself in 5 years (with no subsidies) if mounted in a windy spot in a country with high(ish) electricity costs. If we achieve that, it will be seriously ''efficient''. When I say ''price'' I mean the total installed cost. Even with a mini turbine like this designed for on site assy, installation will cost some money & time.

MW Motors

MW Motors

Zingo Andersen

Zingo Andersen

Dewet

Dewet

Ben Brooks

Ben Brooks

Greg Stephens

Greg Stephens

Thanks. I will add drawings & other info later. I am miles behind on everything now. Once we have shown the wind turbine actually functions & have shows how well it does at various wind speeds, I will post 3D drawings & all other info.....