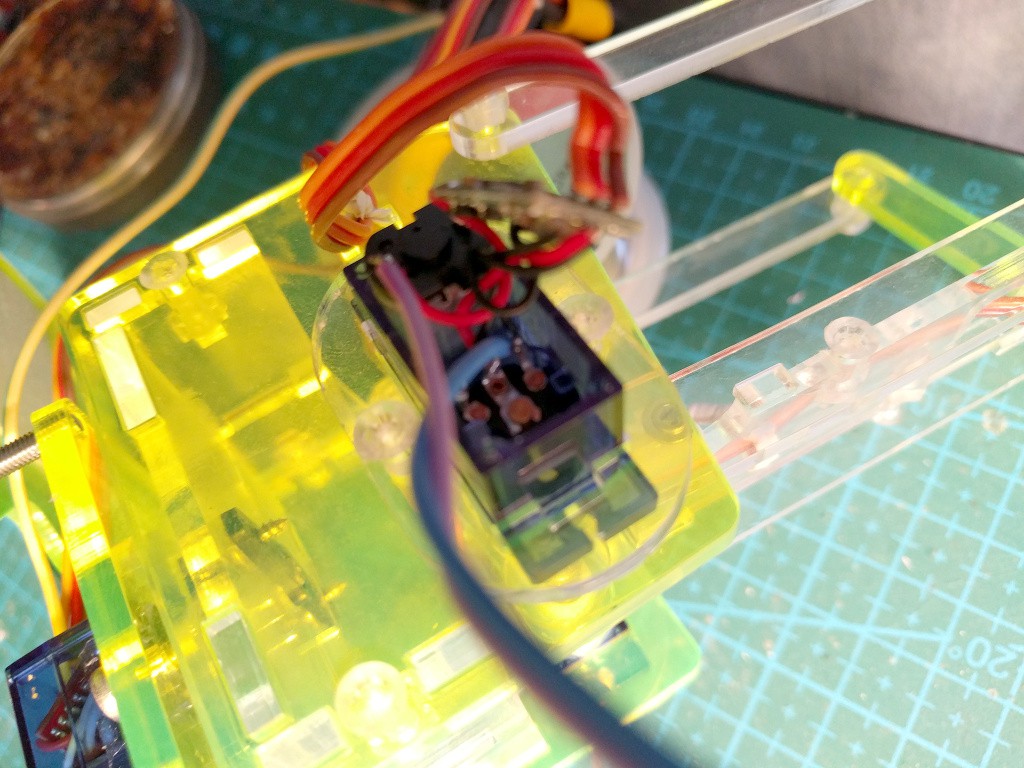

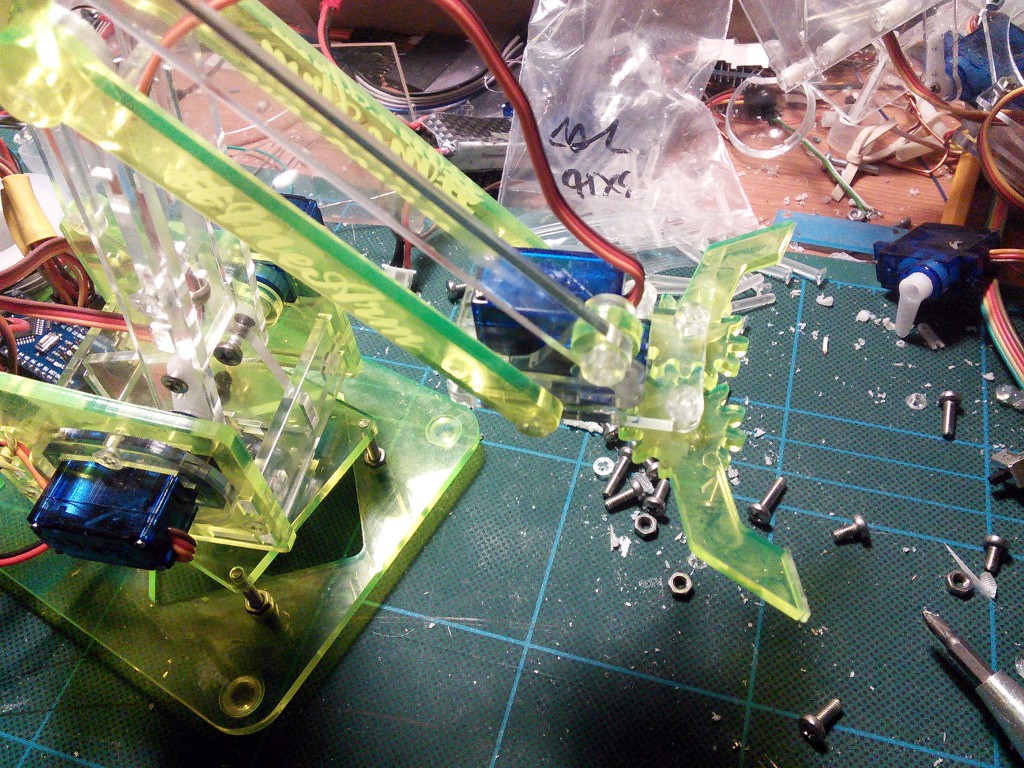

Basically I got a #MeArm, and I'm going to do stuff with it. That may involve modifying it a little, adding position and force feedback to the servos, and programming it to do cool stuff.

Hacking the MeArm

I've got a MeArm and I'm going to do science to it.

deʃhipu

deʃhipu

The plastic bolts look good too! Tapping could be laborious but I'm going to check this out!