Based on what I learned with my first cnc I knew that I wanted something better. It had to be more rigid and more accurate. The size was not as big of deal as I once thought. My first cnc was 24"x24"x4", The x and y bed was bigger than I needed, but the Z was too small. It could only cut wood and plastic. I tried aluminum once and it was horrible. I also was not happy with using a palm router for the spindle. I didn't have control over the speed and it could only hold 1/4" bits.

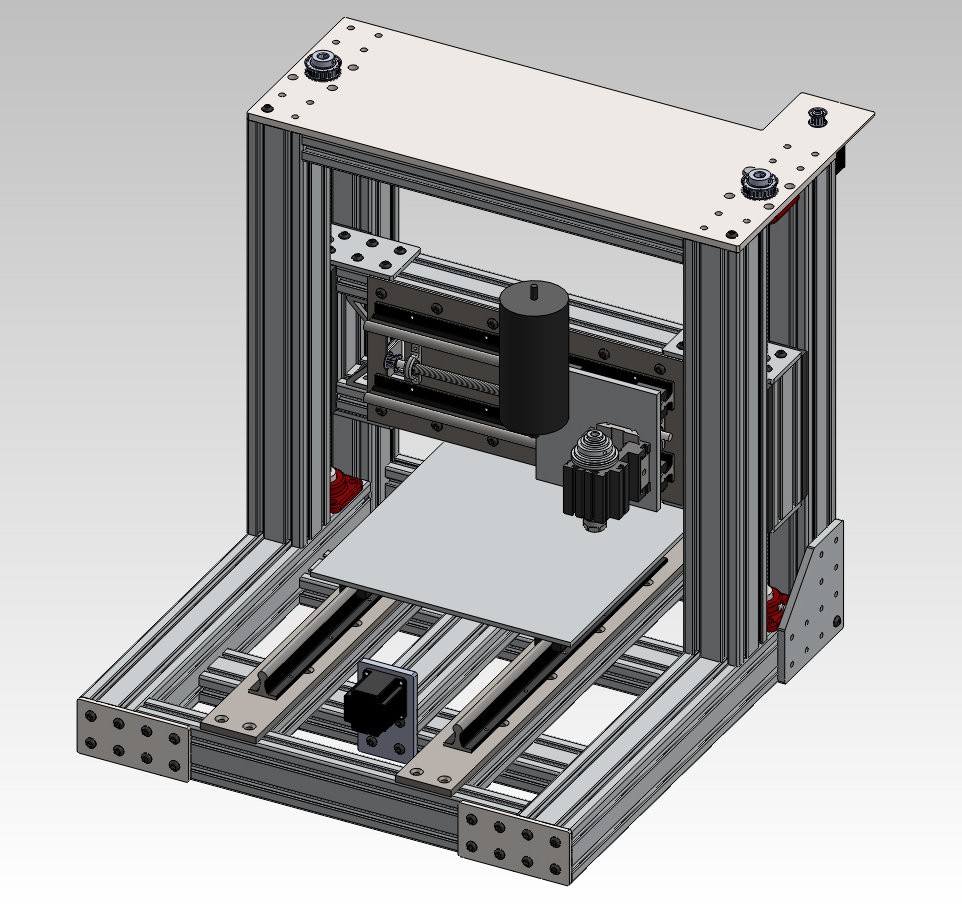

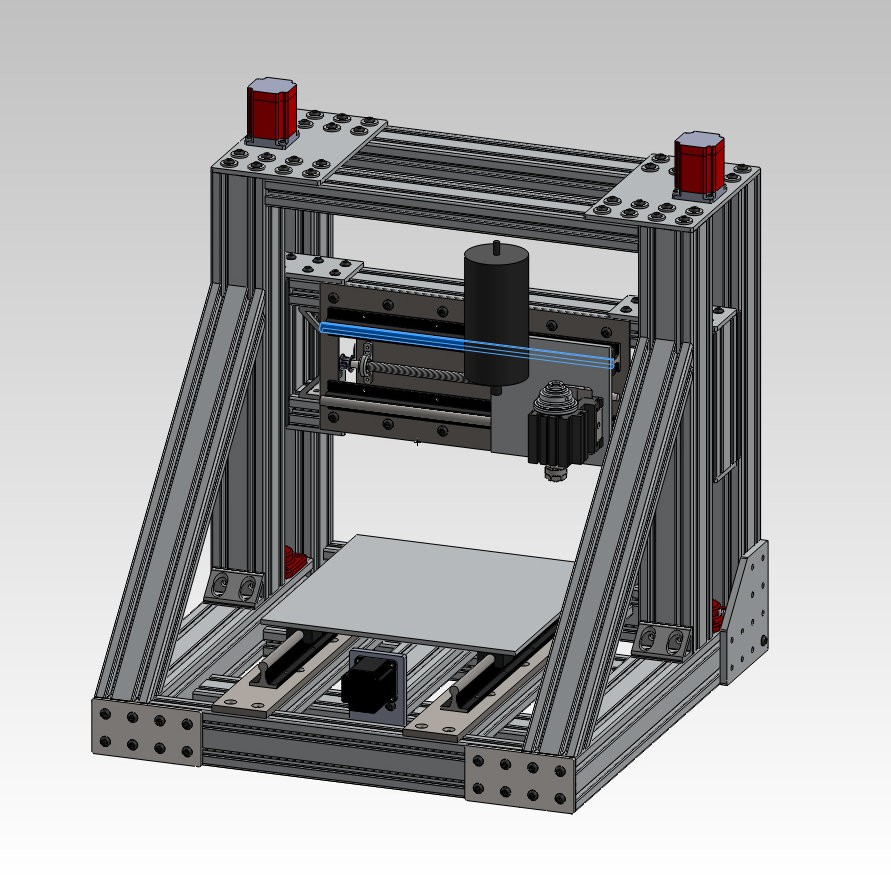

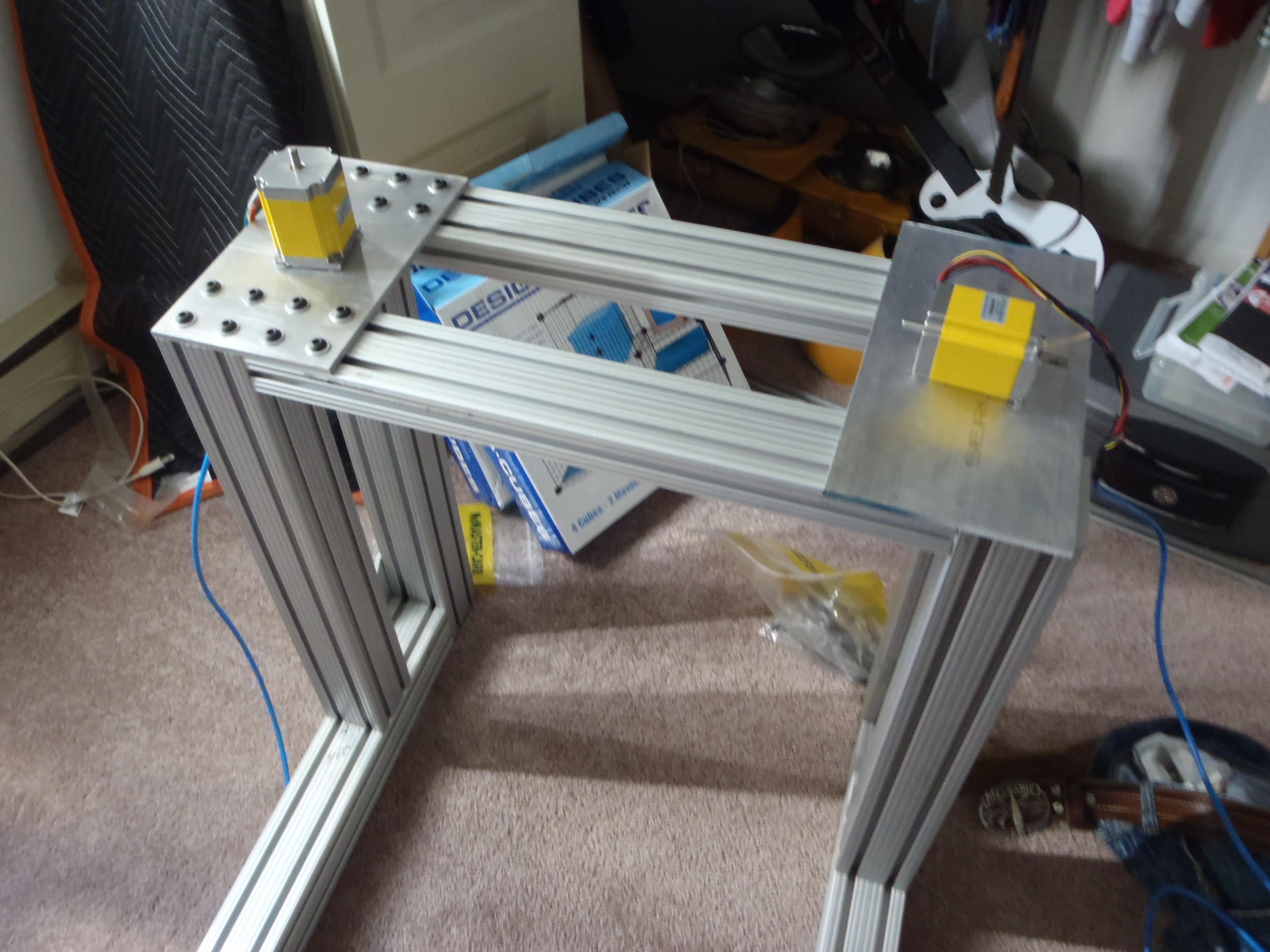

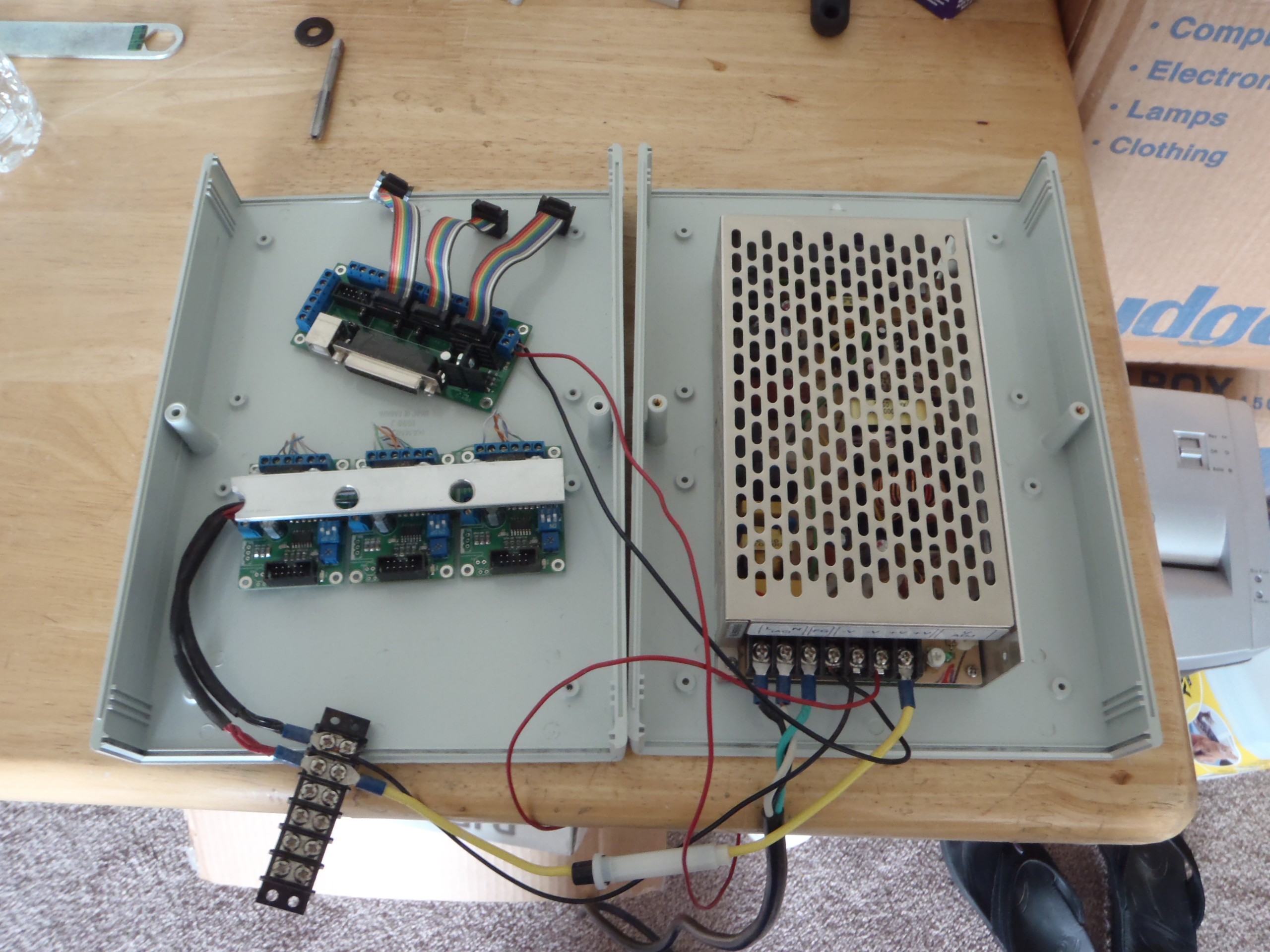

I did a lot of reading and redesigning. I started collecting parts for the new machine. I was lucky and salvaged some linear rails and some 3"x3" aluminum extrusion. I designed a machine around the parts I had. This was the first version of my design.

Then I change the z axis design. I decided to have two motors and use the software to sync them.

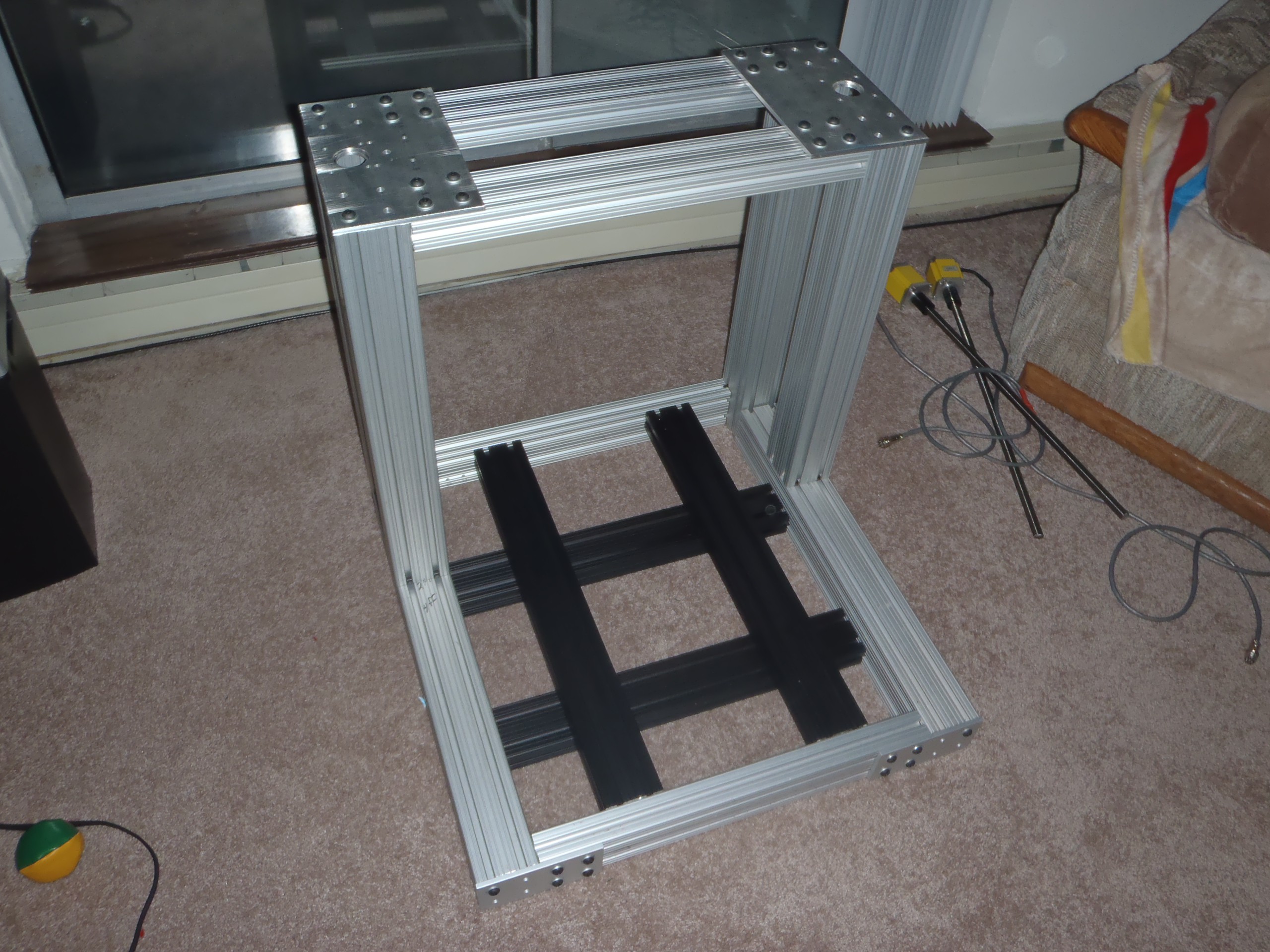

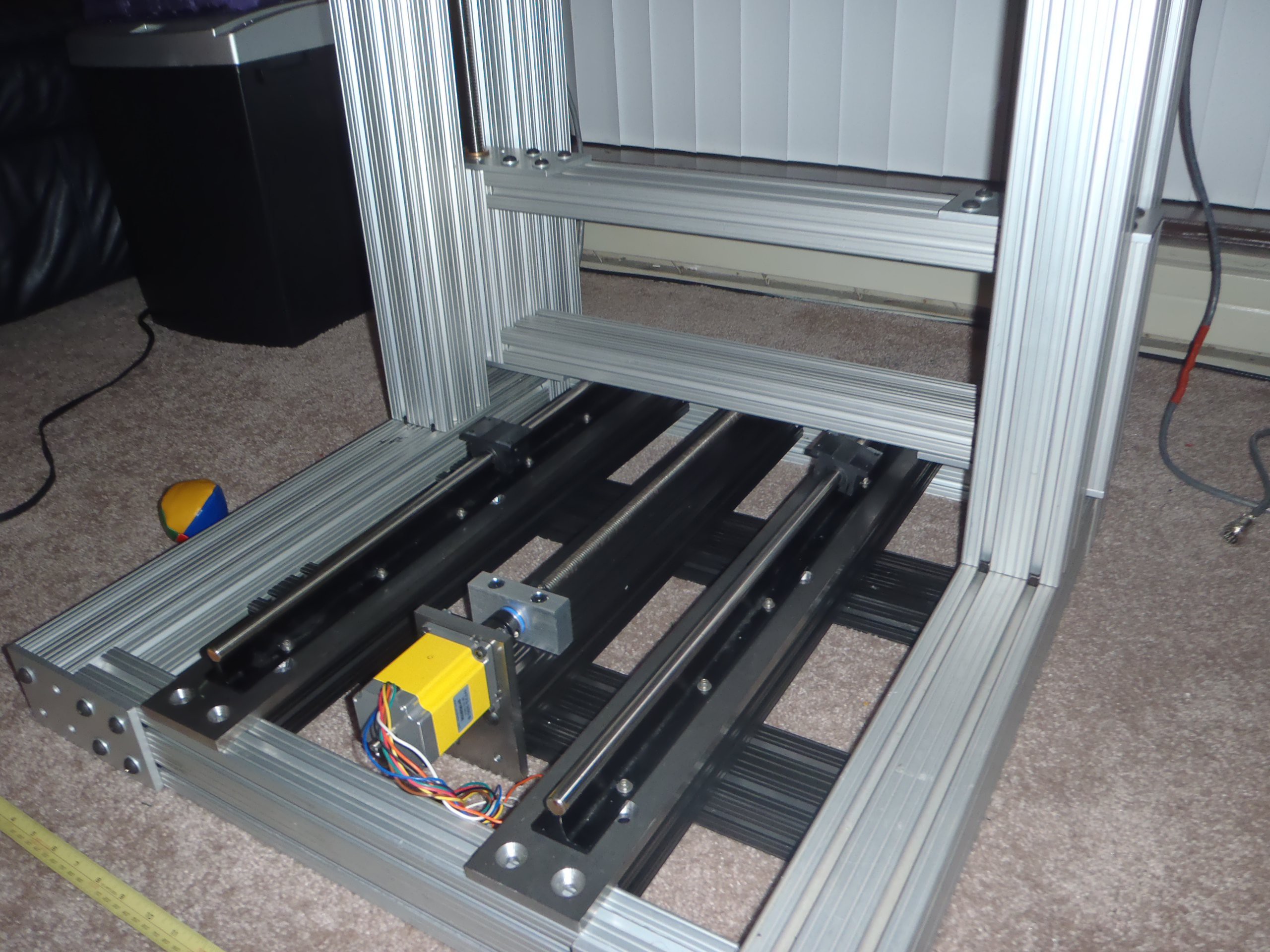

Then I started building it. WOW. I did not realize just how much work there was in this design.

jupdyke

jupdyke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.