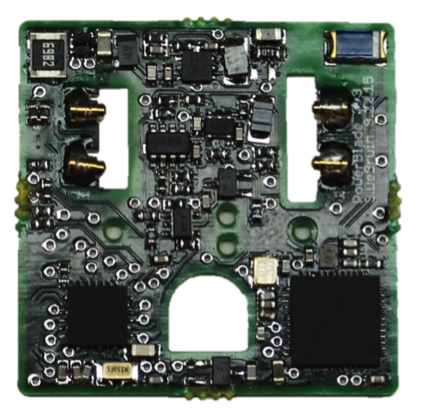

The extremely small form factor in PowerBlade is made possible through two insights. First, other plug load power meters make contact with the AC through prongs, and provide another socket for the device (TV, fridge, etc) to plug into the meter. This creates a lower bound on the size of the meter - the size of the AC socket. Instead, PowerBlade allows the original device prongs to pass directly into the outlet through three cutouts in the PCB face. PowerBlade makes contact with these prongs through flexible tabs built into the PCB itself (visible in the picture).

Second, other meters typically measure current by breaking the path and passing one AC line through a sense resistor. Since PowerBlade does not break the path, this is impossible. Instead, we note that the current in the plug will generate a magnetic field. An inductor placed in that field will generate a signal based on the magnetic field strength, and this signal can be used to measure current (after significant amplification). By thinking about power metering in a different way, these two insights allowed us to move past the fundamental minimum size of a power meter to something significantly smaller.

A third insight in this system is that converting 120V AC to 3.3V DC in this extremely small size results in very little power (on the order of 1 mW), and that impacts our choice of data communication. We wanted something that would be usable even at large scale - checking a LCD screen readout on 50+ units is simply intractable in the long term. Instead, PowerBlade communicates to nearby smartphones using a low power BLE radio. This means the system doesnt require gateways or repeaters, it is usable out-of-the-box.

The device is accurate, with an average of 6.5% error in power measurements for a range of household devices like a fridge, television, and microwave. It works well even in dense deployments, 20 or more BLE devices in a room do not greatly affect BLE packet reception rate. Although we have not yet optimized for cost, the current implementation costs $11 to produce.

Hot-neutral swap makes no difference in this kind of half-wave power supply