-

1Step 1

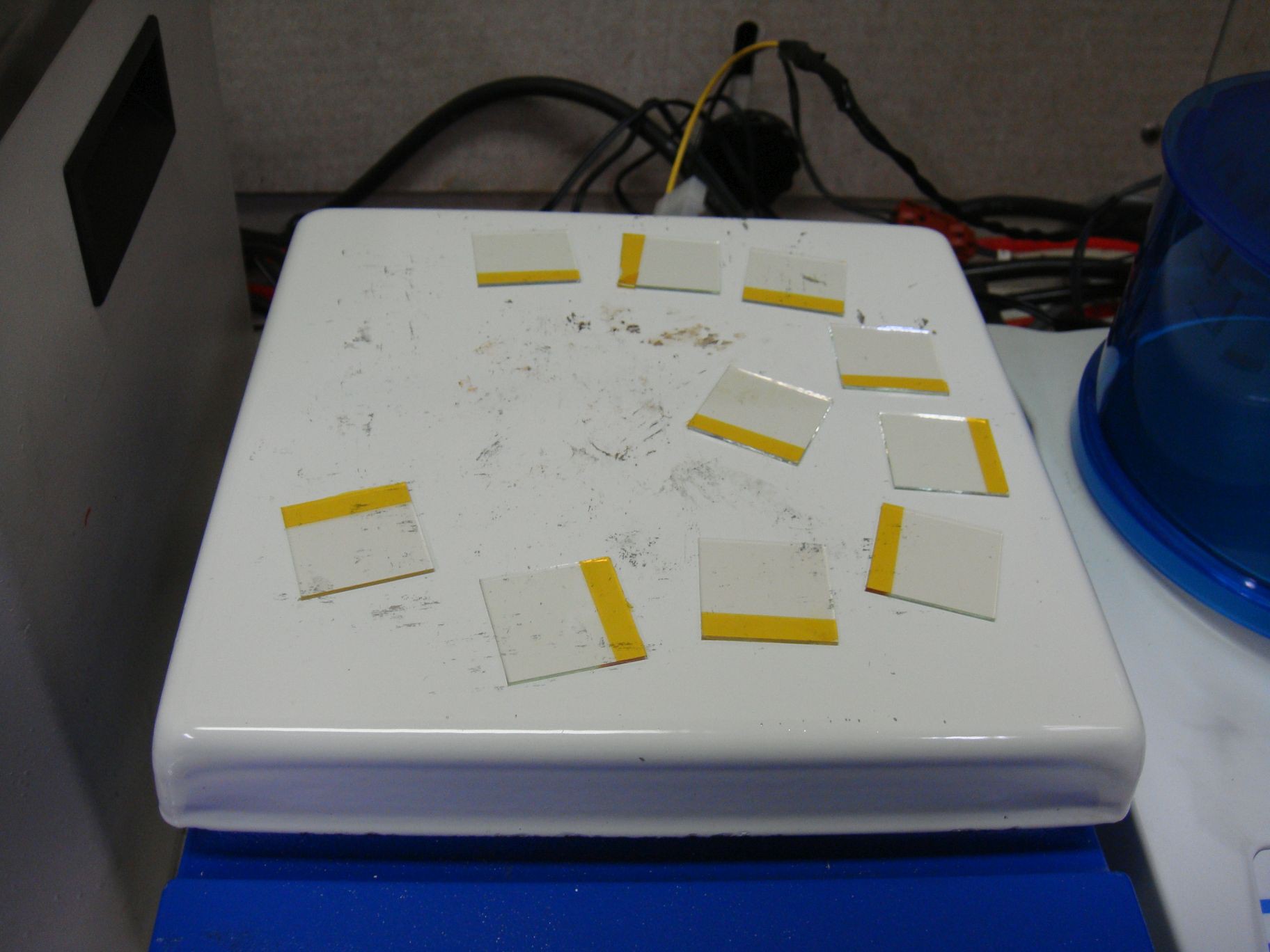

![]() The first thing I do is take pieces of ITO (Indium-Tin Oxide) glass and figure out which side has the conductive coating. Then I apply a small piece of kapton tape to the edge. Each side will make up one cathode and one anode side for a given device. The kapton tape ensures both sides have an uncoated area for attaching an electrode to test the device.

The first thing I do is take pieces of ITO (Indium-Tin Oxide) glass and figure out which side has the conductive coating. Then I apply a small piece of kapton tape to the edge. Each side will make up one cathode and one anode side for a given device. The kapton tape ensures both sides have an uncoated area for attaching an electrode to test the device. -

2Step 2

![]() Each slide is then cleaned using solvent and dried off using nitrogen gas.

Each slide is then cleaned using solvent and dried off using nitrogen gas. -

3Step 3

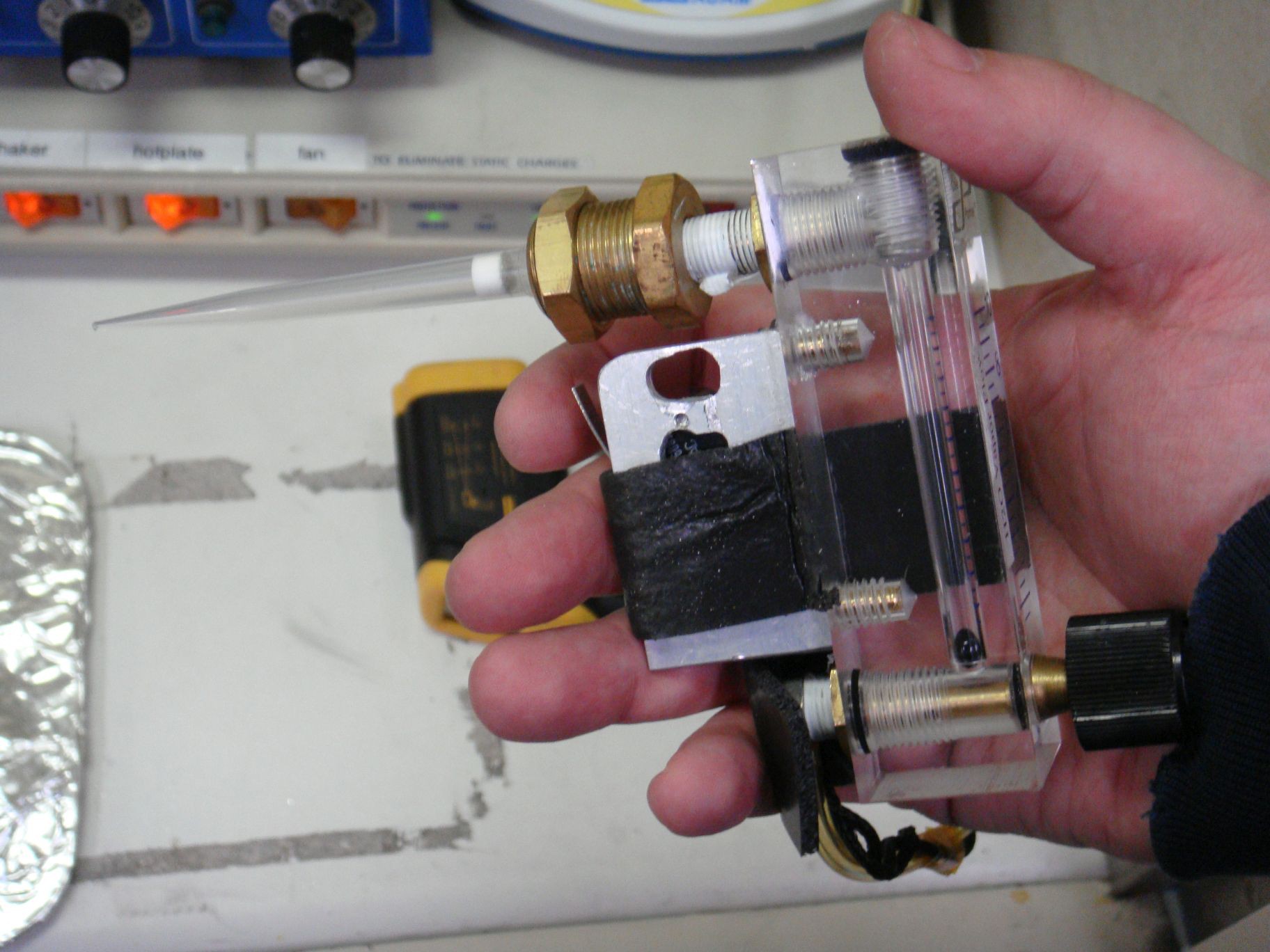

![]() This is my nitrogen gas gun, done on the cheap. It was built using a filtered pipette tip, a gas flow limit/monitor, and a momentary switch attached to a solenoid (not pictured) on the gas line.

This is my nitrogen gas gun, done on the cheap. It was built using a filtered pipette tip, a gas flow limit/monitor, and a momentary switch attached to a solenoid (not pictured) on the gas line. -

4Step 4

![]() This N2 tank supplies both the gas gun and the spin coater.

This N2 tank supplies both the gas gun and the spin coater. -

5Step 5

![]() The slides are then heated at 140C for about 10 minutes.

The slides are then heated at 140C for about 10 minutes. -

6Step 6

![]() During some of these steps I wear an organic respirator, as well as chemical safety goggles. All of the work is done inside a fume hood with the fan on during all spin coating and some drying steps.

During some of these steps I wear an organic respirator, as well as chemical safety goggles. All of the work is done inside a fume hood with the fan on during all spin coating and some drying steps. -

7Step 7

![]()

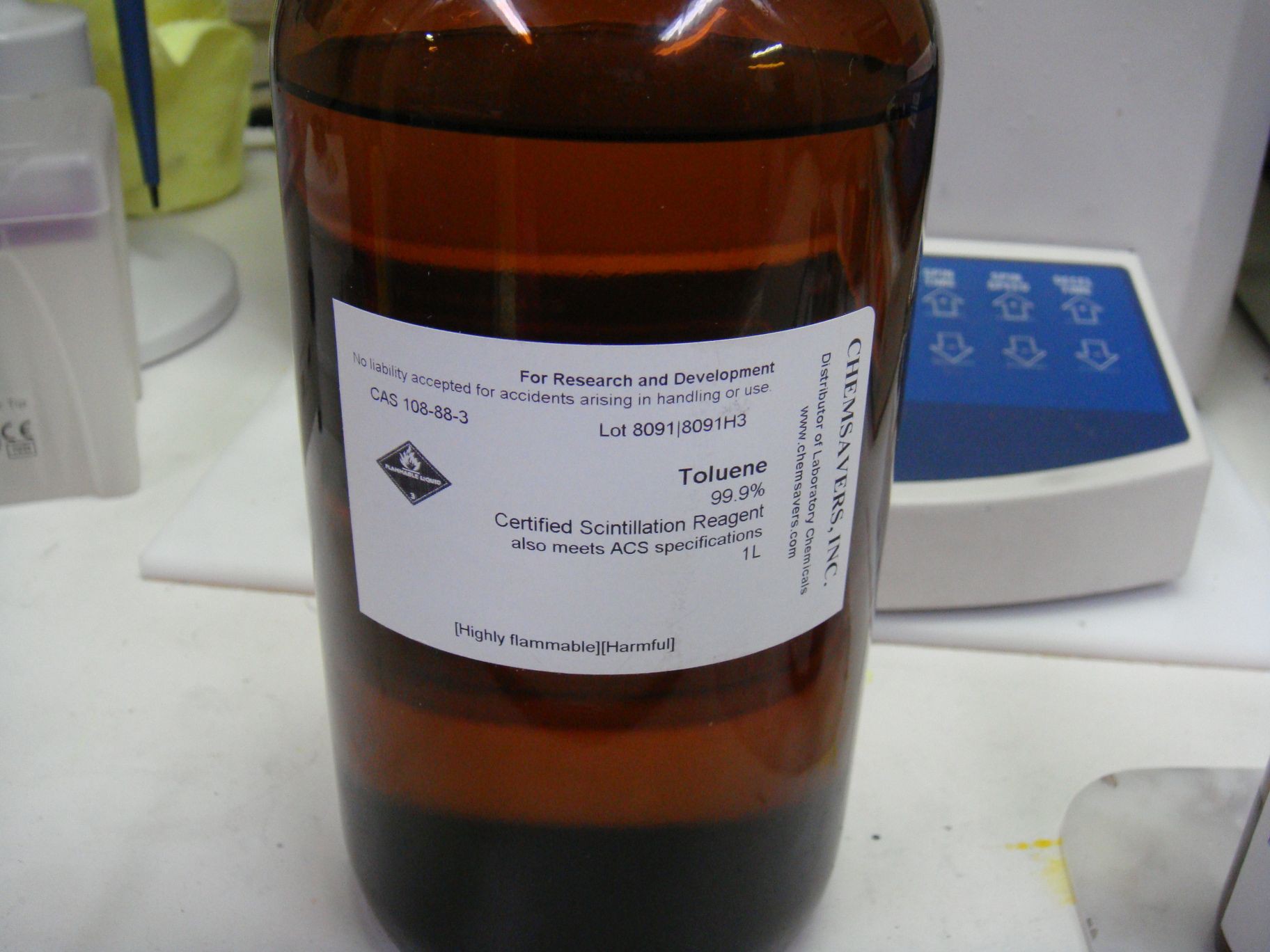

The process I use to lay down most of the materials I use to make OLEDs is called spin coating. It is roughly what it sounds like - the substrate (the ITO glass) is spun at a high speed, in an atmosphere of nitrogen gas. The material to be deposited is dissolved in a solvent, and either dropped onto the glass before the spinning starts, or while spinning for a different coating effect. Most of the solvent evaporates during this process, and combines with the (inert) nitrogen gas to leave the fume hood.

I use Toluene. It's scary stuff, hence the fume hood and organic respirator. It's a trade off between being the safest solvent I could find, as well as being a solvent that leaves very little material behind after evaporation during spin coating. This is an important part of creating a successful device.

-

8Step 8

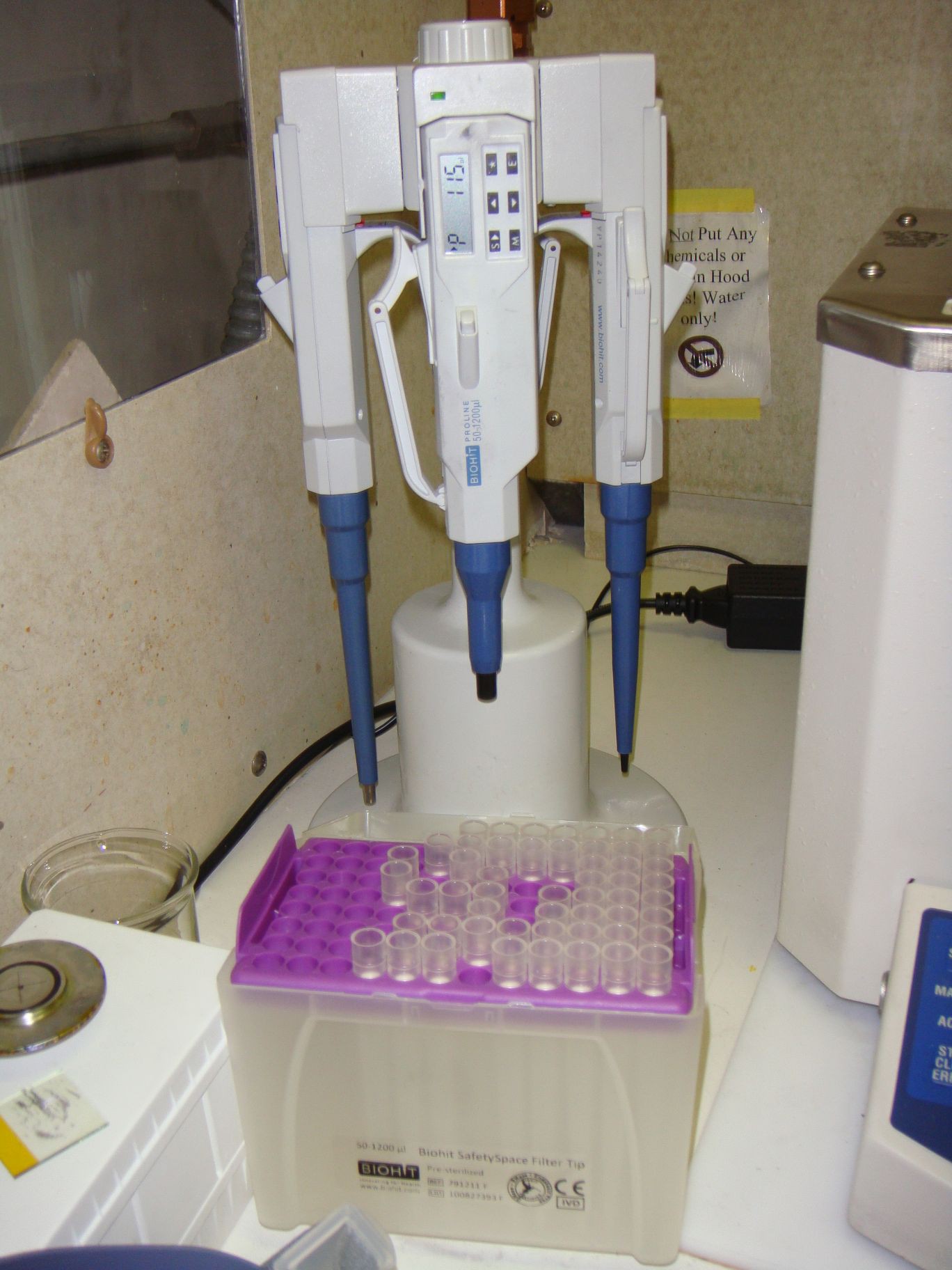

![]() When working with materials to be spin coated, and creating spin-coatable solutions, I use an auto-pipetter with a filtered pipette tip. It's real handy for getting the right amount, and I got these on ebay for cheap!

When working with materials to be spin coated, and creating spin-coatable solutions, I use an auto-pipetter with a filtered pipette tip. It's real handy for getting the right amount, and I got these on ebay for cheap! -

9Step 9

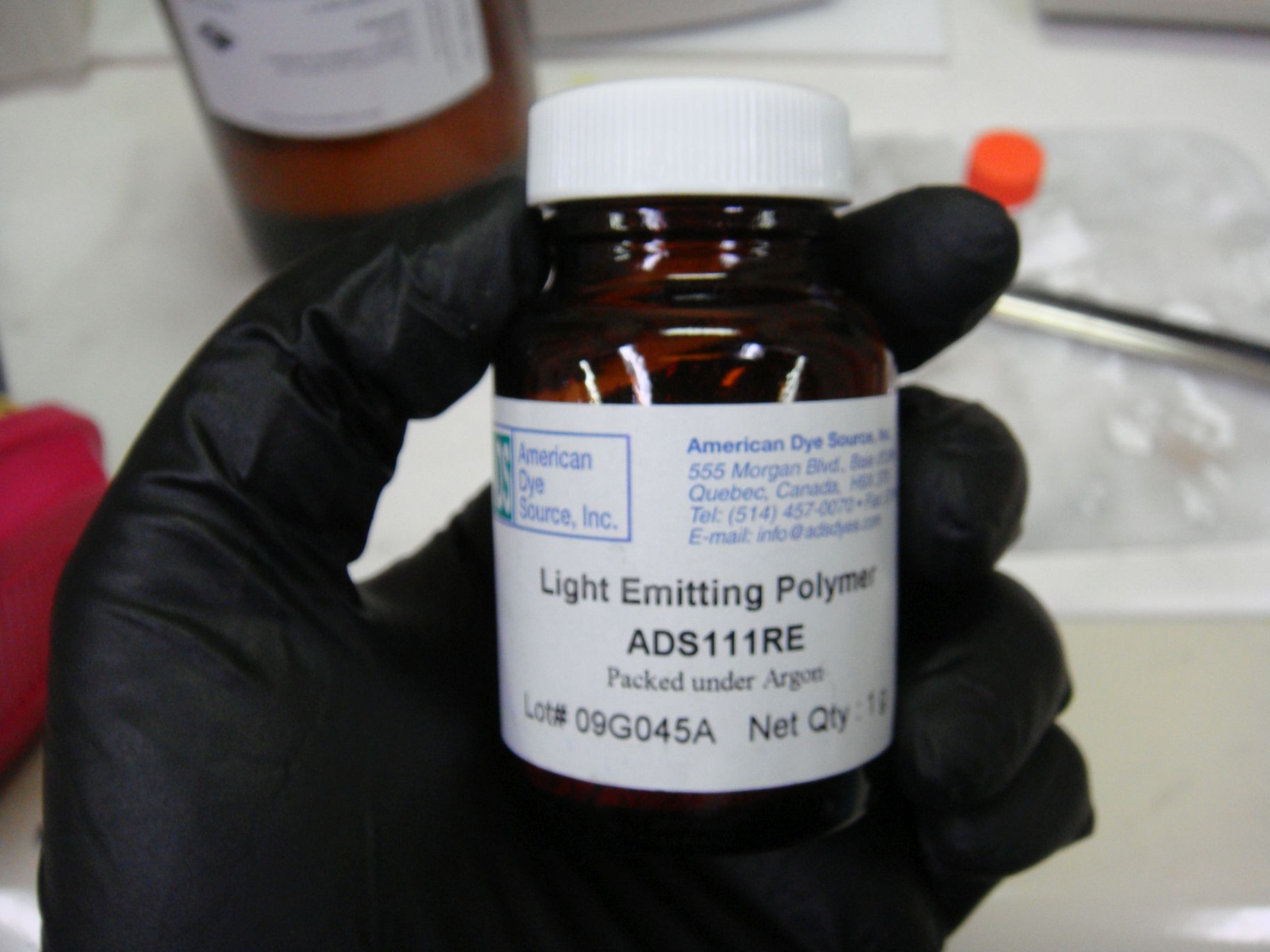

![]() This is the material I'm going to dissolve in Toluene - it is a red emitting polymer, Poly[{9,9-dihexyl-2,7-bis(1-cyanovinylene)fluorenylene}-alt-co-{2,5-bis(N,N'-diphenylamino)-1,4-phenylene}]. Unfortunately I don't know of a short name for it. Let's call it PFO-RED for short.

This is the material I'm going to dissolve in Toluene - it is a red emitting polymer, Poly[{9,9-dihexyl-2,7-bis(1-cyanovinylene)fluorenylene}-alt-co-{2,5-bis(N,N'-diphenylamino)-1,4-phenylene}]. Unfortunately I don't know of a short name for it. Let's call it PFO-RED for short. -

10Step 10

![]() Just an empty vial.

Just an empty vial.

Ian Hanschen

Ian Hanschen The first thing I do is take pieces of ITO (Indium-Tin Oxide) glass and figure out which side has the conductive coating. Then I apply a small piece of kapton tape to the edge. Each side will make up one cathode and one anode side for a given device. The kapton tape ensures both sides have an uncoated area for attaching an electrode to test the device.

The first thing I do is take pieces of ITO (Indium-Tin Oxide) glass and figure out which side has the conductive coating. Then I apply a small piece of kapton tape to the edge. Each side will make up one cathode and one anode side for a given device. The kapton tape ensures both sides have an uncoated area for attaching an electrode to test the device. Each slide is then cleaned using solvent and dried off using nitrogen gas.

Each slide is then cleaned using solvent and dried off using nitrogen gas. This is my nitrogen gas gun, done on the cheap. It was built using a filtered pipette tip, a gas flow limit/monitor, and a momentary switch attached to a solenoid (not pictured) on the gas line.

This is my nitrogen gas gun, done on the cheap. It was built using a filtered pipette tip, a gas flow limit/monitor, and a momentary switch attached to a solenoid (not pictured) on the gas line. This N2 tank supplies both the gas gun and the spin coater.

This N2 tank supplies both the gas gun and the spin coater. The slides are then heated at 140C for about 10 minutes.

The slides are then heated at 140C for about 10 minutes. During some of these steps I wear an organic respirator, as well as chemical safety goggles. All of the work is done inside a fume hood with the fan on during all spin coating and some drying steps.

During some of these steps I wear an organic respirator, as well as chemical safety goggles. All of the work is done inside a fume hood with the fan on during all spin coating and some drying steps.

When working with materials to be spin coated, and creating spin-coatable solutions, I use an auto-pipetter with a filtered pipette tip. It's real handy for getting the right amount, and I got these on ebay for cheap!

When working with materials to be spin coated, and creating spin-coatable solutions, I use an auto-pipetter with a filtered pipette tip. It's real handy for getting the right amount, and I got these on ebay for cheap! This is the material I'm going to dissolve in Toluene - it is a red emitting polymer, Poly[{9,9-dihexyl-2,7-bis(1-cyanovinylene)fluorenylene}-alt-co-{2,5-bis(N,N'-diphenylamino)-1,4-phenylene}]. Unfortunately I don't know of a short name for it. Let's call it PFO-RED for short.

This is the material I'm going to dissolve in Toluene - it is a red emitting polymer, Poly[{9,9-dihexyl-2,7-bis(1-cyanovinylene)fluorenylene}-alt-co-{2,5-bis(N,N'-diphenylamino)-1,4-phenylene}]. Unfortunately I don't know of a short name for it. Let's call it PFO-RED for short. Just an empty vial.

Just an empty vial.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I came across this wondering how OLEDs are made for brake lights. This is a pretty awesome write up. Thanks man.

Are you sure? yes | no

Hello and thanks . Did you measure the light intensity, driving voltage and the lifetime?

Are you sure? yes | no