-

21Step 21

![]() Preparing to seal the device - UV cure epoxy. This stuff is great. Apply and use UV light, hard in 6 seconds, intended for displays. Very expensive. My stock of it has unfortunately expired as of December, but it still works great.

Preparing to seal the device - UV cure epoxy. This stuff is great. Apply and use UV light, hard in 6 seconds, intended for displays. Very expensive. My stock of it has unfortunately expired as of December, but it still works great. -

22Step 22

![]() A generous boundary of epoxy is applied to the cathode slide.

A generous boundary of epoxy is applied to the cathode slide.This serves two purposes:

1) To seal off the device from additional moisture (OLEDs hate water)

2) As an insulator (a spacer). We don't want the ITO glass of the cathode side to touch the materials on the anode side directly - indium-tin oxide has a high work function, so we'd effectively short the device out. There is enough gallium-indium-tin eutectic here to fill the vertical gap that the epoxy will create. -

23Step 23

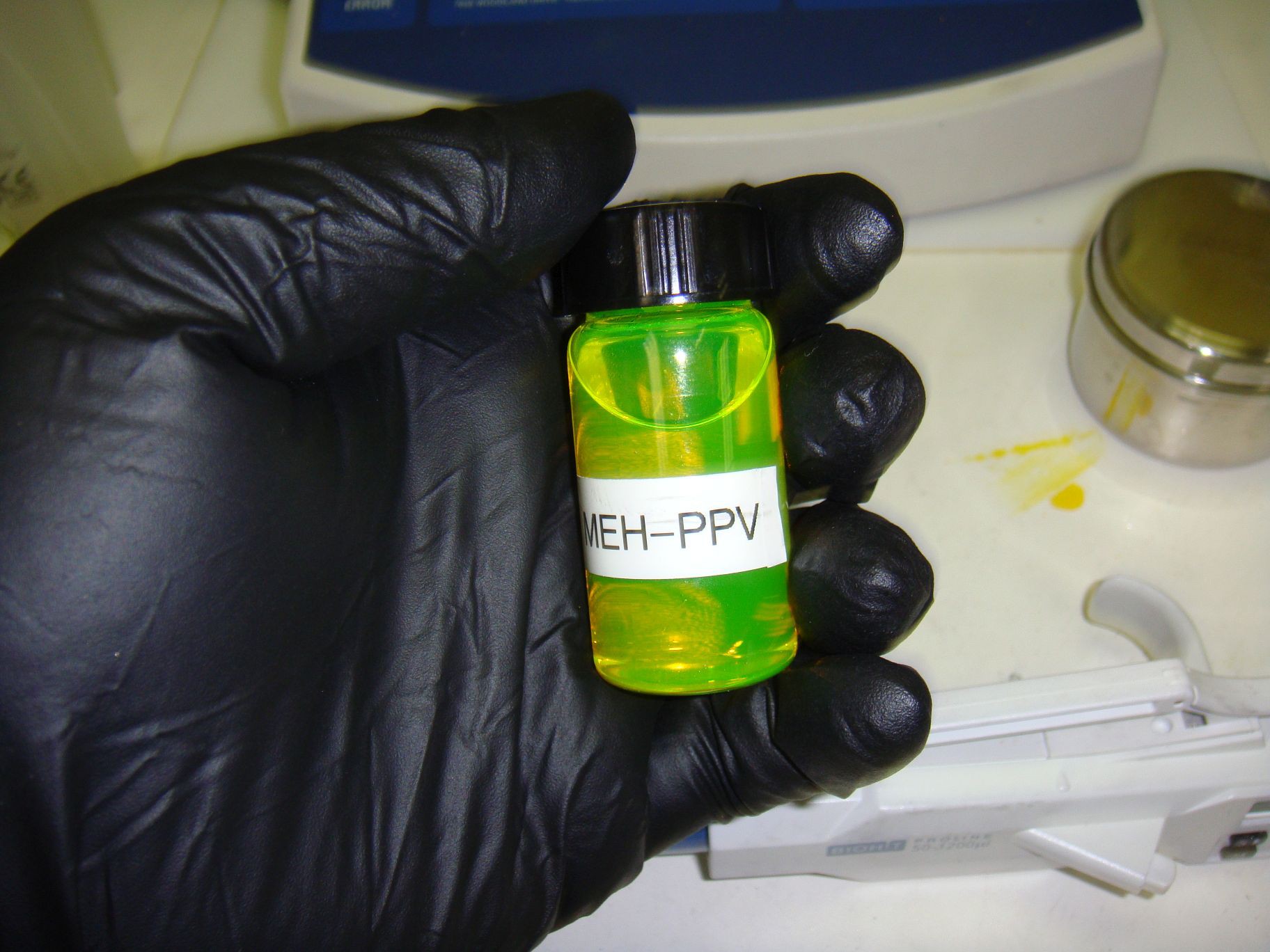

![]() Now that the anode side has heated long enough, the PEDOT:PSS layer is done, any remaining water from the deposition has hopefully evaporated, and we can apply our active layer - the light emitting polymer. This material(MEH-PPV) is suspended in Toluene.

Now that the anode side has heated long enough, the PEDOT:PSS layer is done, any remaining water from the deposition has hopefully evaporated, and we can apply our active layer - the light emitting polymer. This material(MEH-PPV) is suspended in Toluene. -

24Step 24

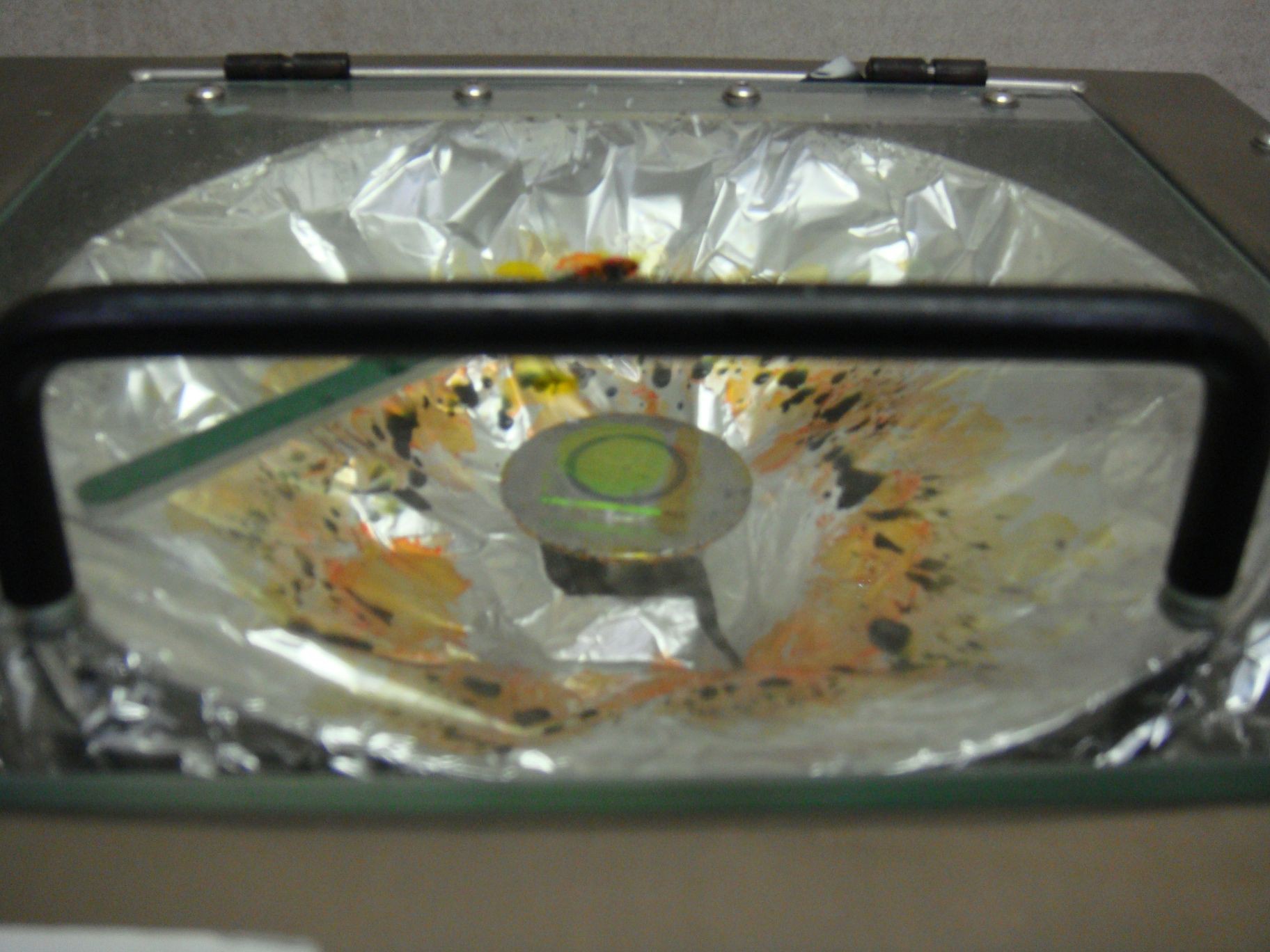

![]() Spin coating the MEH-PPV over the PEDOT:PSS layer on the anode side.

Spin coating the MEH-PPV over the PEDOT:PSS layer on the anode side. -

25Step 25

![]() Heat the anode side again to dissipate any remaining solvent. This step is done carefully - too much heat and the chemical composition of the active layer (the MEH-PPV) can change, ruining the device. This is done at 140C for 2-3 minutes.

Heat the anode side again to dissipate any remaining solvent. This step is done carefully - too much heat and the chemical composition of the active layer (the MEH-PPV) can change, ruining the device. This is done at 140C for 2-3 minutes. -

26Step 26

![]() Cathode and Anode sides, ready to be combined.

Cathode and Anode sides, ready to be combined. -

27Step 27

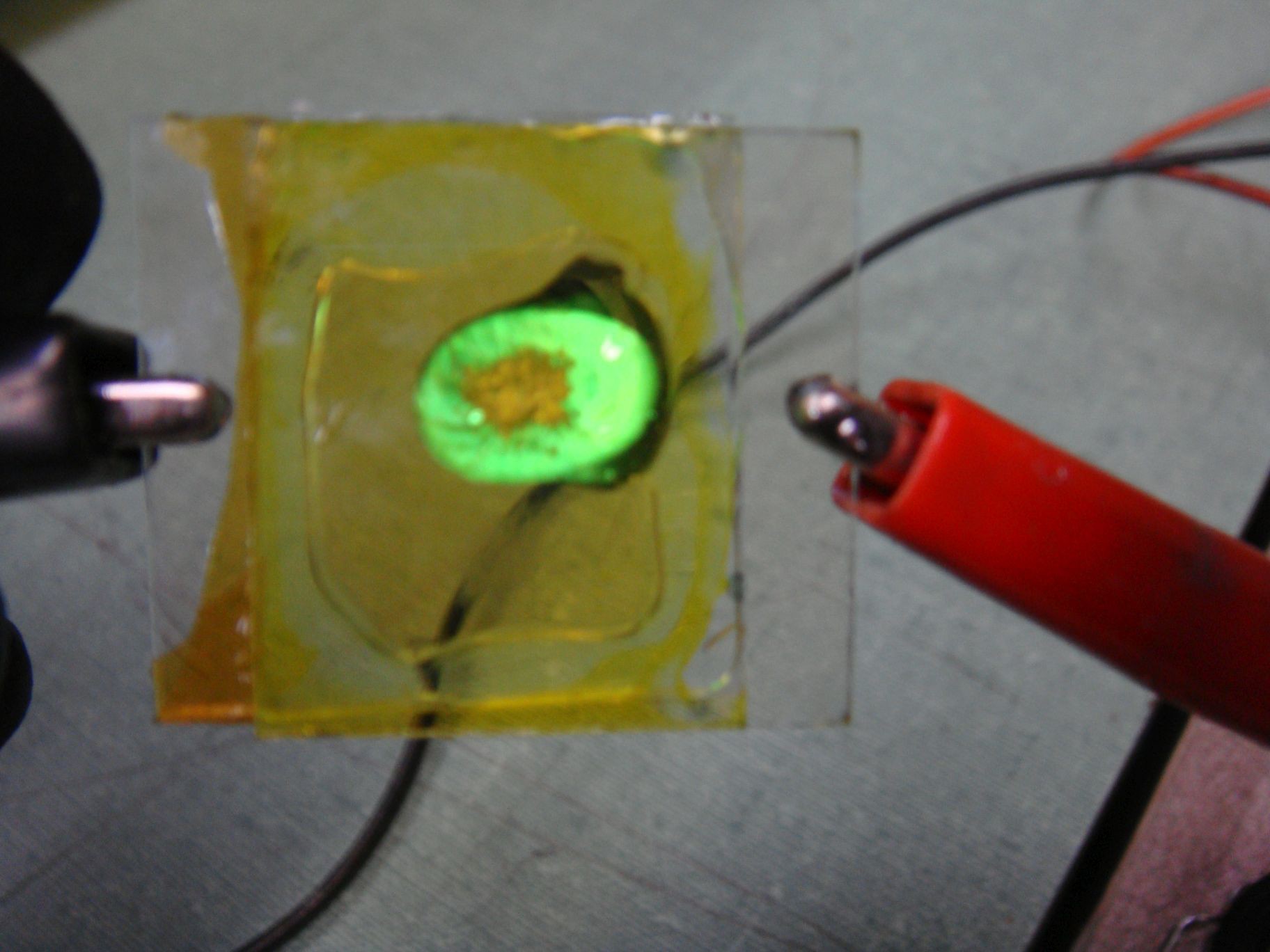

![]() Applying UV. I use a violet laser instead of a fluorescent UV light. I had been using an EPROM eraser from China, but it didn't work well with the glue. Using the laser I can trace the epoxy boundary a few times and it's completely dry. The active layer is fluorescing green in response to the laser in this photo.

Applying UV. I use a violet laser instead of a fluorescent UV light. I had been using an EPROM eraser from China, but it didn't work well with the glue. Using the laser I can trace the epoxy boundary a few times and it's completely dry. The active layer is fluorescing green in response to the laser in this photo. -

28Step 28

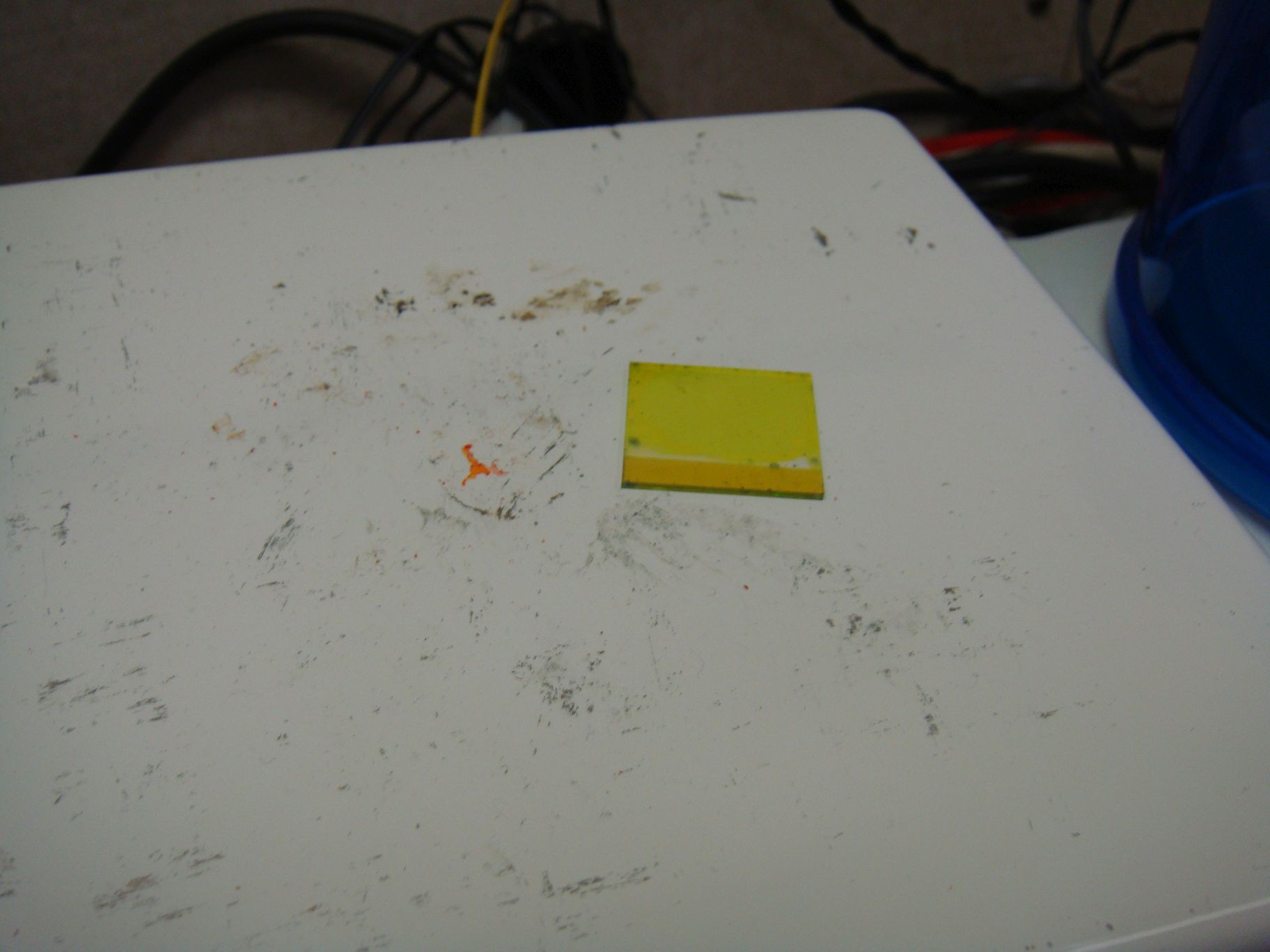

![]() Completed device, ready to be tested.

Completed device, ready to be tested. -

29Step 29

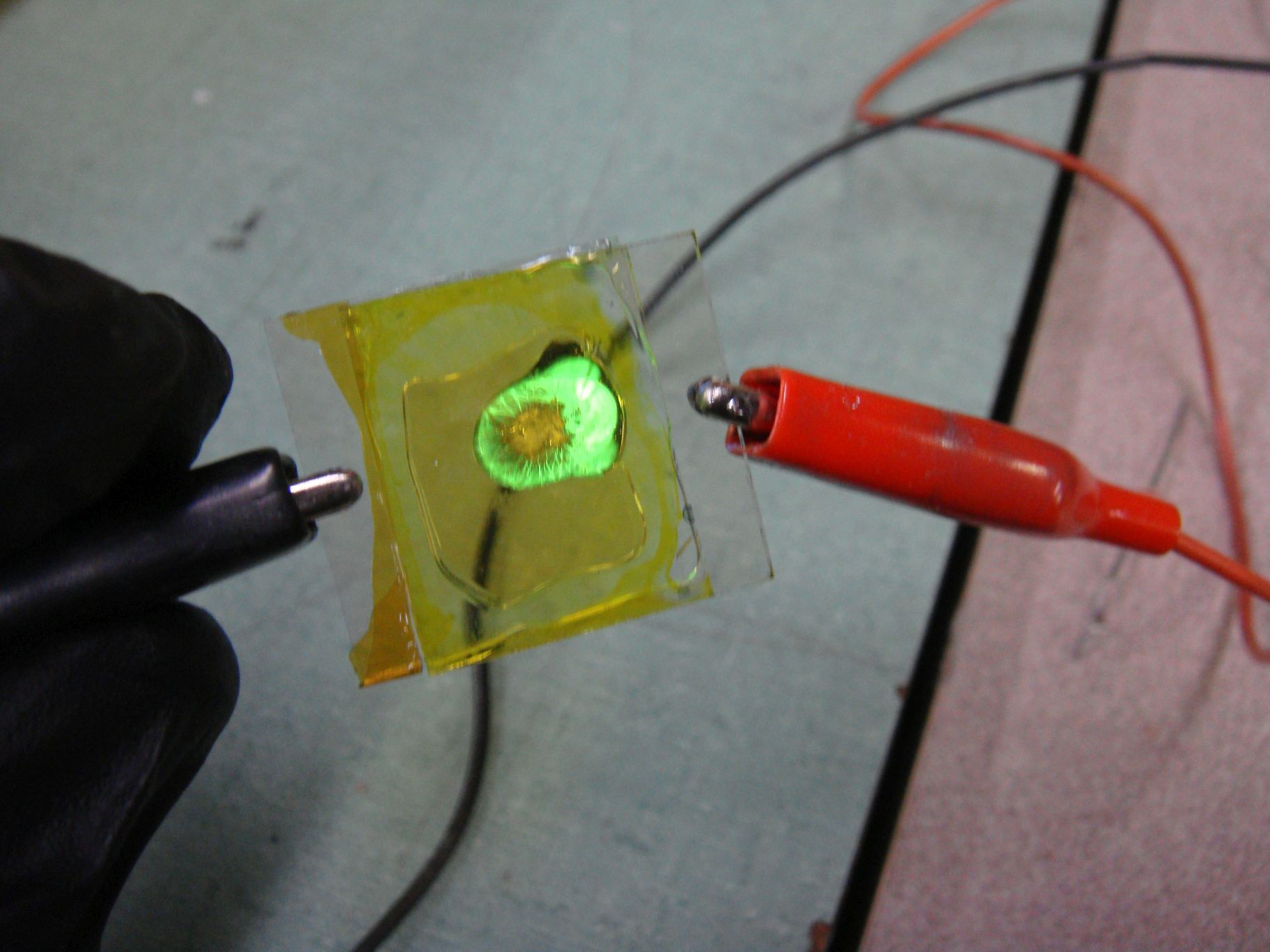

![]() When I was joining the two sides, I accidentally slid the slides together a bit, causing a scratch on the anode side - you can see the liquid metal completely touches the other side. Thankfully its work function is low and the rest of the device works.

When I was joining the two sides, I accidentally slid the slides together a bit, causing a scratch on the anode side - you can see the liquid metal completely touches the other side. Thankfully its work function is low and the rest of the device works. -

30Step 30

![]() Closeup photo.

Closeup photo.

Ian Hanschen

Ian Hanschen Preparing to seal the device - UV cure epoxy. This stuff is great. Apply and use UV light, hard in 6 seconds, intended for displays. Very expensive. My stock of it has unfortunately expired as of December, but it still works great.

Preparing to seal the device - UV cure epoxy. This stuff is great. Apply and use UV light, hard in 6 seconds, intended for displays. Very expensive. My stock of it has unfortunately expired as of December, but it still works great. A generous boundary of epoxy is applied to the cathode slide.

A generous boundary of epoxy is applied to the cathode slide. Now that the anode side has heated long enough, the PEDOT:PSS layer is done, any remaining water from the deposition has hopefully evaporated, and we can apply our active layer - the light emitting polymer. This material(MEH-PPV) is suspended in Toluene.

Now that the anode side has heated long enough, the PEDOT:PSS layer is done, any remaining water from the deposition has hopefully evaporated, and we can apply our active layer - the light emitting polymer. This material(MEH-PPV) is suspended in Toluene. Spin coating the MEH-PPV over the PEDOT:PSS layer on the anode side.

Spin coating the MEH-PPV over the PEDOT:PSS layer on the anode side. Heat the anode side again to dissipate any remaining solvent. This step is done carefully - too much heat and the chemical composition of the active layer (the MEH-PPV) can change, ruining the device. This is done at 140C for 2-3 minutes.

Heat the anode side again to dissipate any remaining solvent. This step is done carefully - too much heat and the chemical composition of the active layer (the MEH-PPV) can change, ruining the device. This is done at 140C for 2-3 minutes. Cathode and Anode sides, ready to be combined.

Cathode and Anode sides, ready to be combined. Applying UV. I use a violet laser instead of a fluorescent UV light. I had been using an EPROM eraser from China, but it didn't work well with the glue. Using the laser I can trace the epoxy boundary a few times and it's completely dry. The active layer is fluorescing green in response to the laser in this photo.

Applying UV. I use a violet laser instead of a fluorescent UV light. I had been using an EPROM eraser from China, but it didn't work well with the glue. Using the laser I can trace the epoxy boundary a few times and it's completely dry. The active layer is fluorescing green in response to the laser in this photo. Completed device, ready to be tested.

Completed device, ready to be tested. When I was joining the two sides, I accidentally slid the slides together a bit, causing a scratch on the anode side - you can see the liquid metal completely touches the other side. Thankfully its work function is low and the rest of the device works.

When I was joining the two sides, I accidentally slid the slides together a bit, causing a scratch on the anode side - you can see the liquid metal completely touches the other side. Thankfully its work function is low and the rest of the device works. Closeup photo.

Closeup photo.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I came across this wondering how OLEDs are made for brake lights. This is a pretty awesome write up. Thanks man.

Are you sure? yes | no

Hello and thanks . Did you measure the light intensity, driving voltage and the lifetime?

Are you sure? yes | no