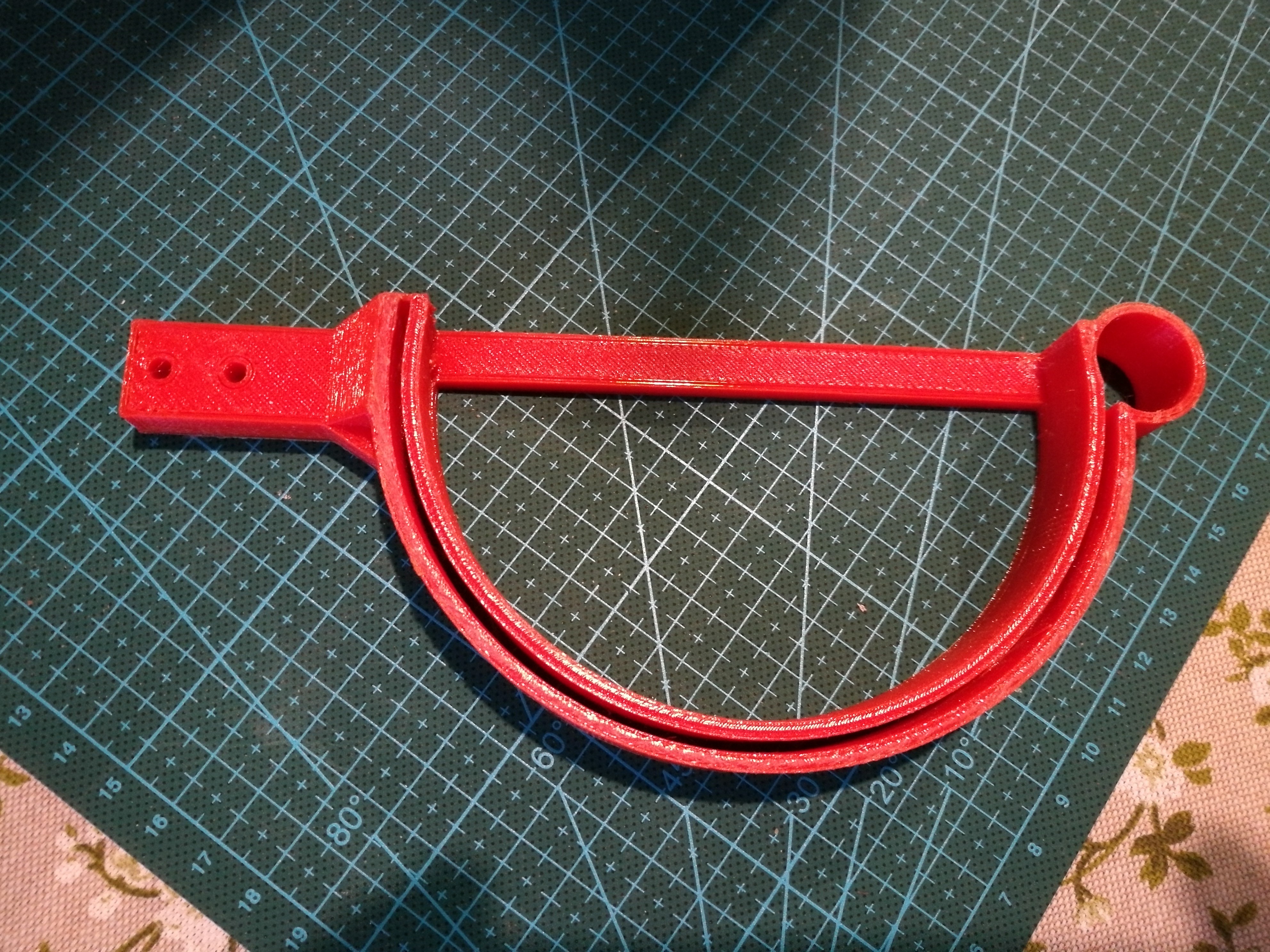

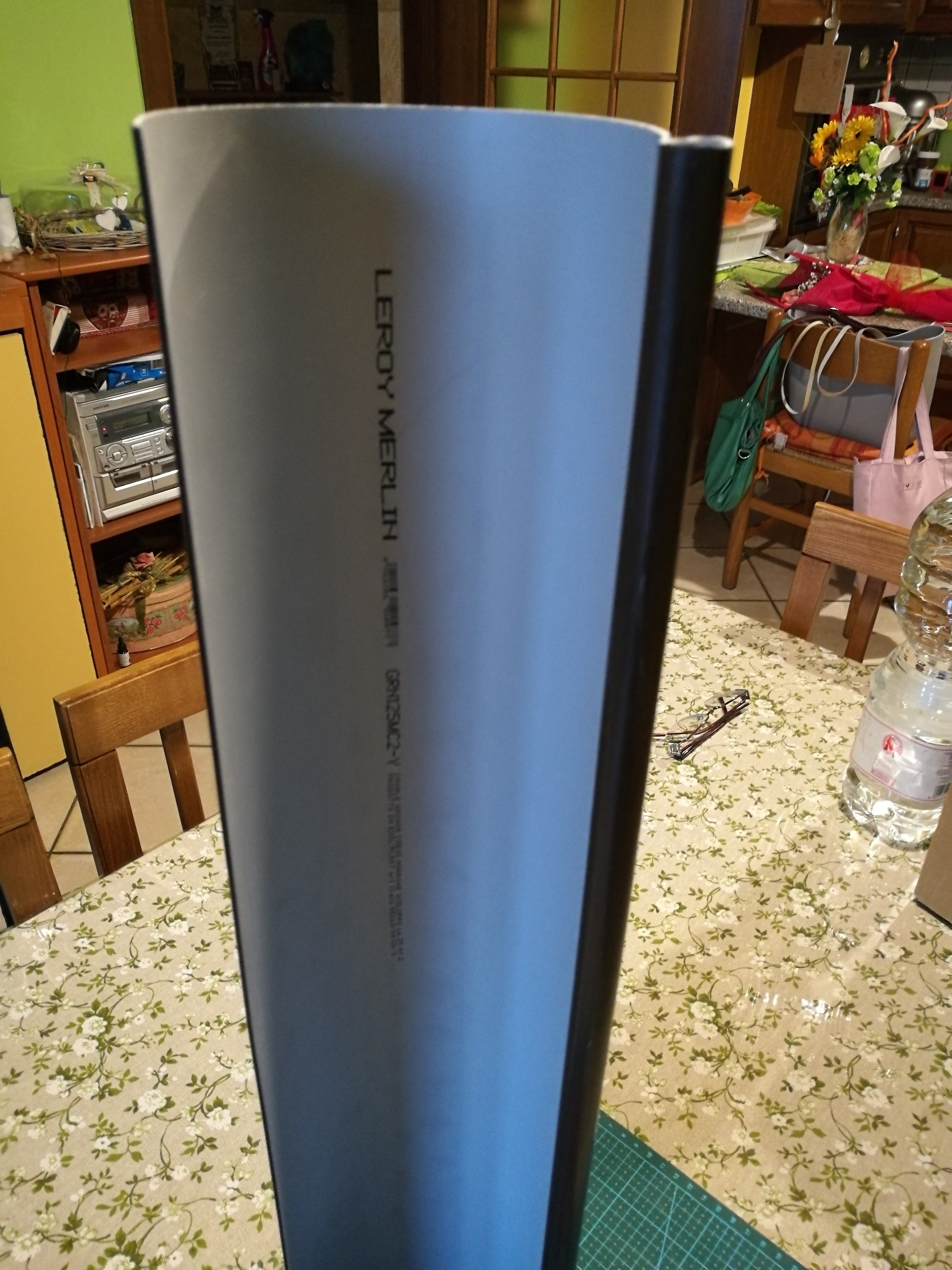

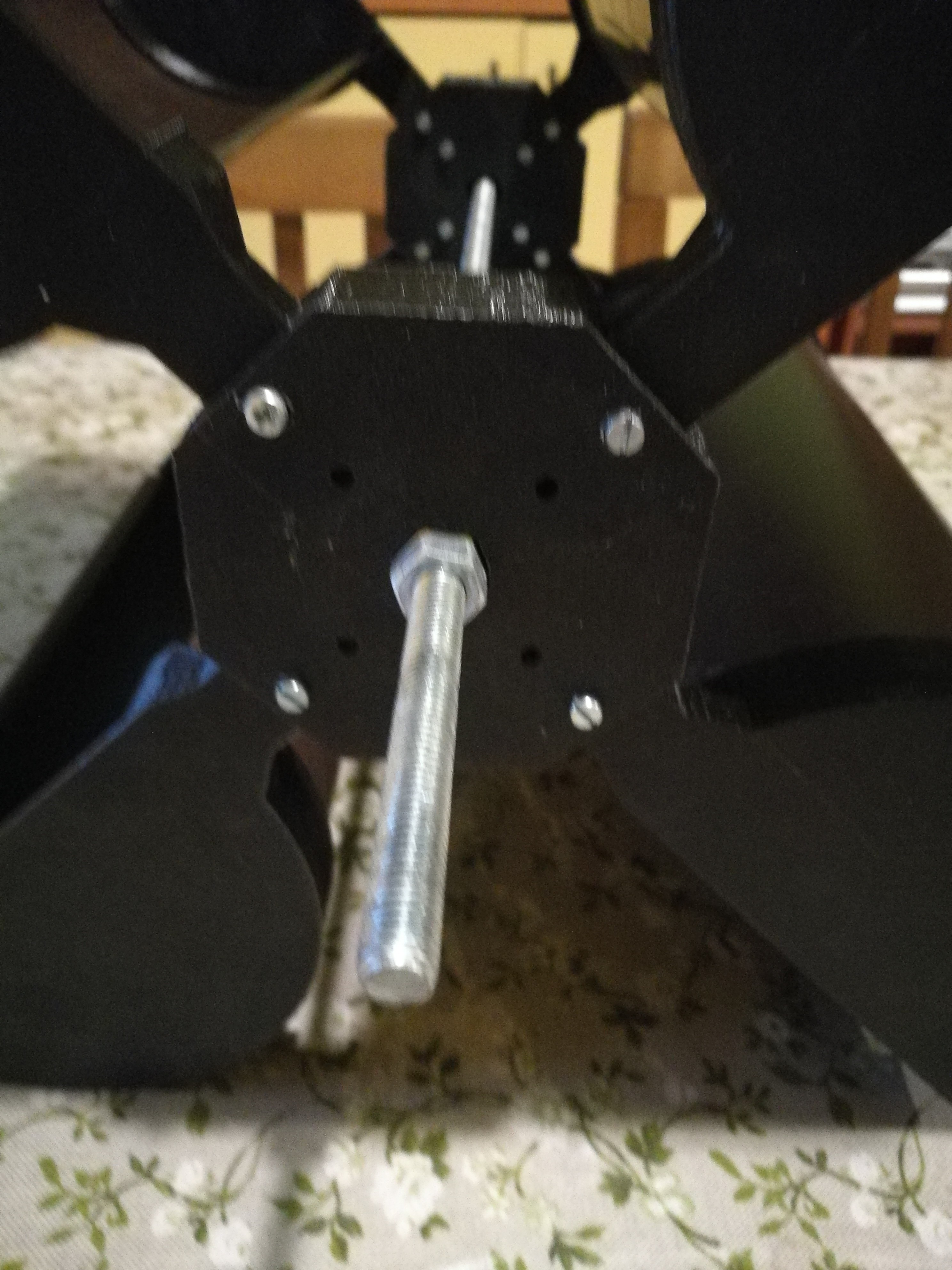

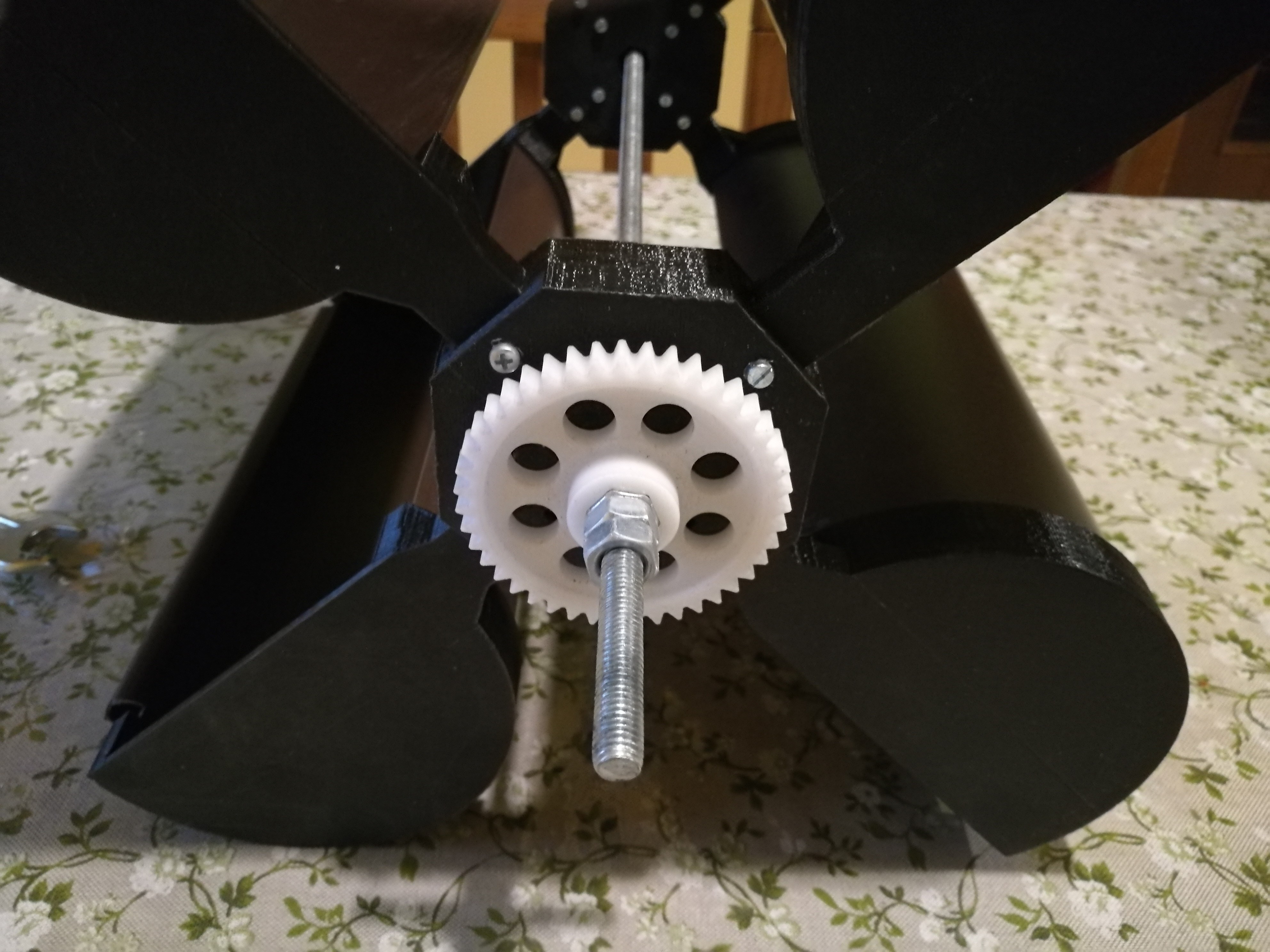

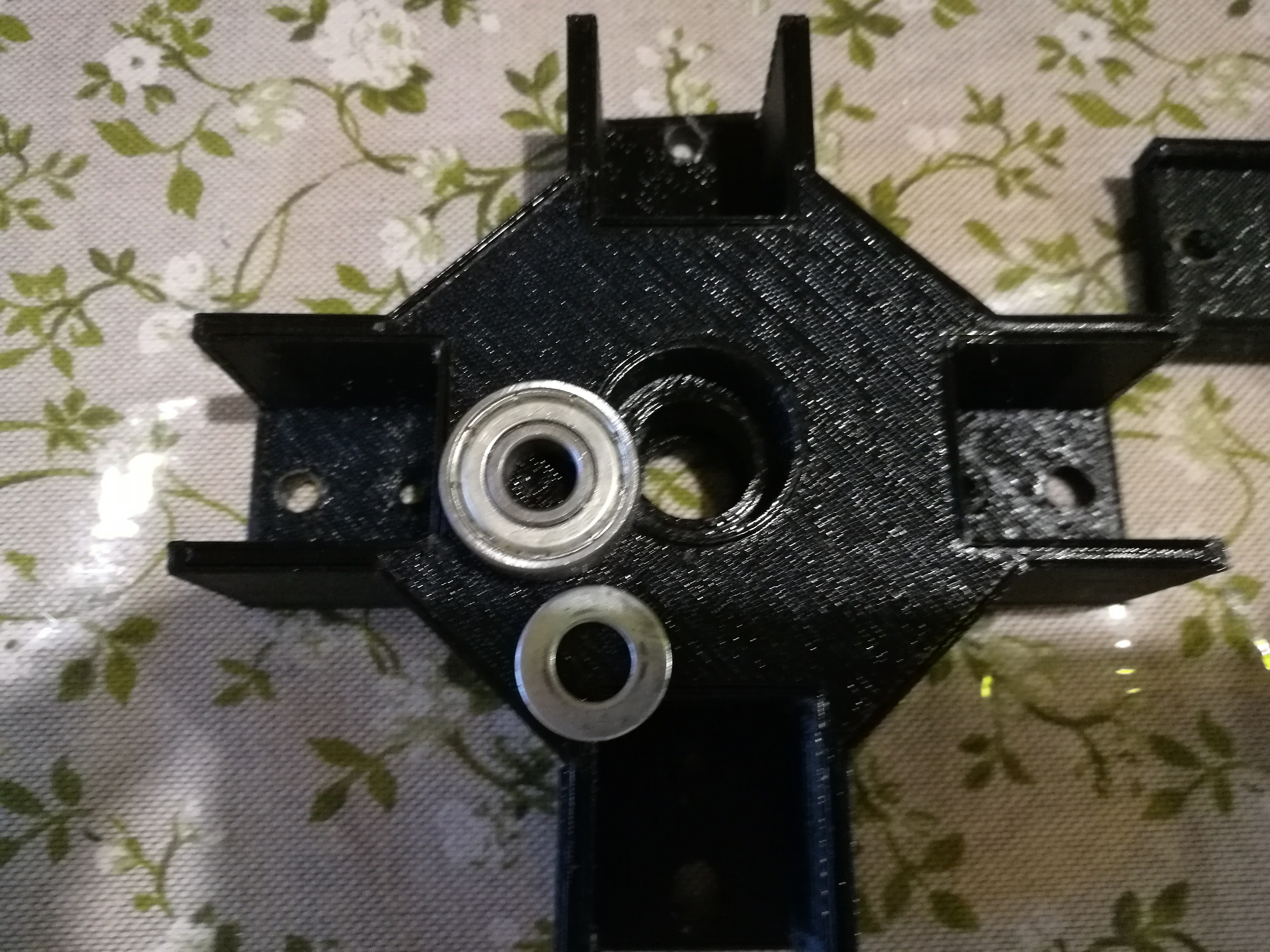

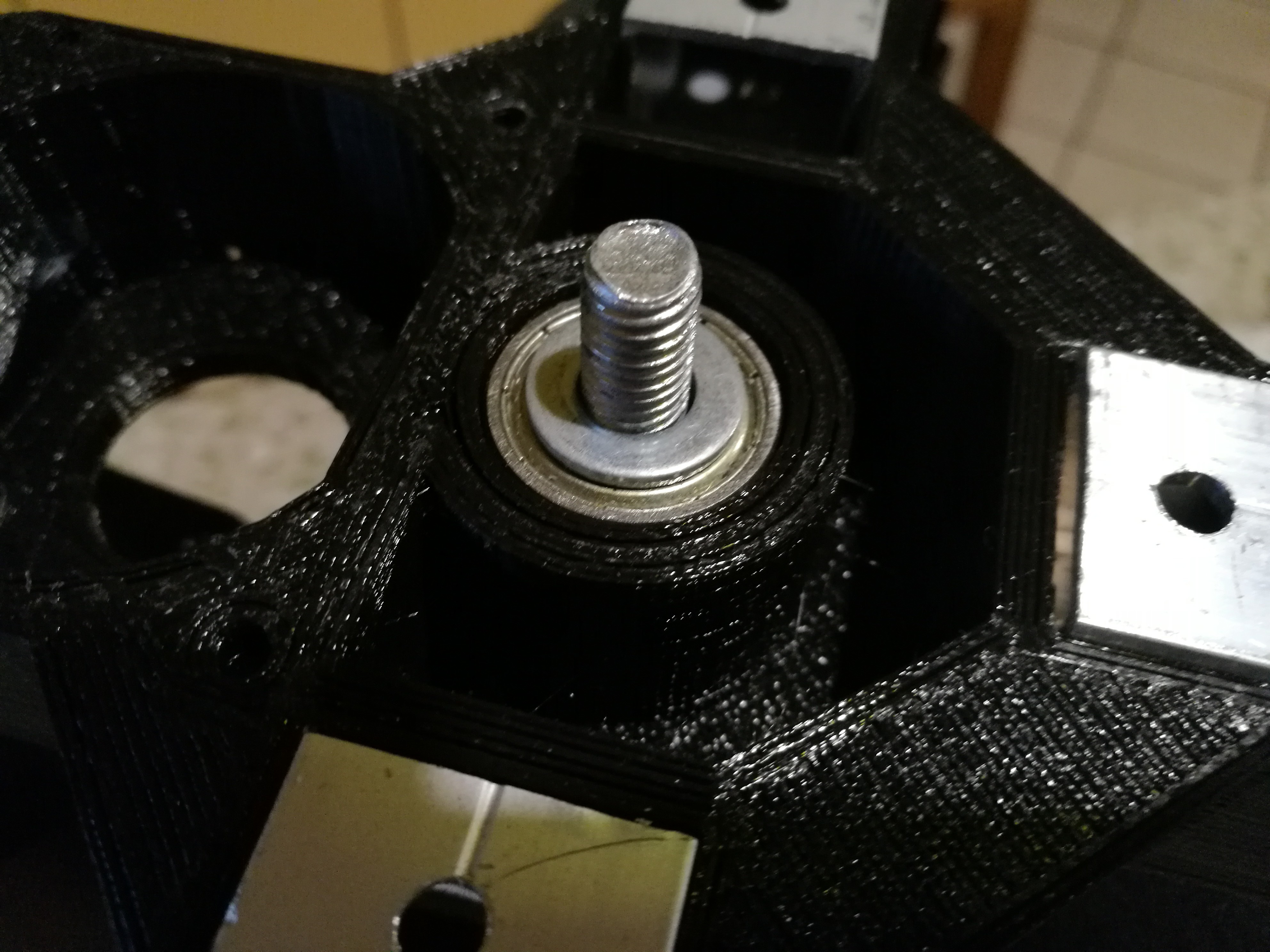

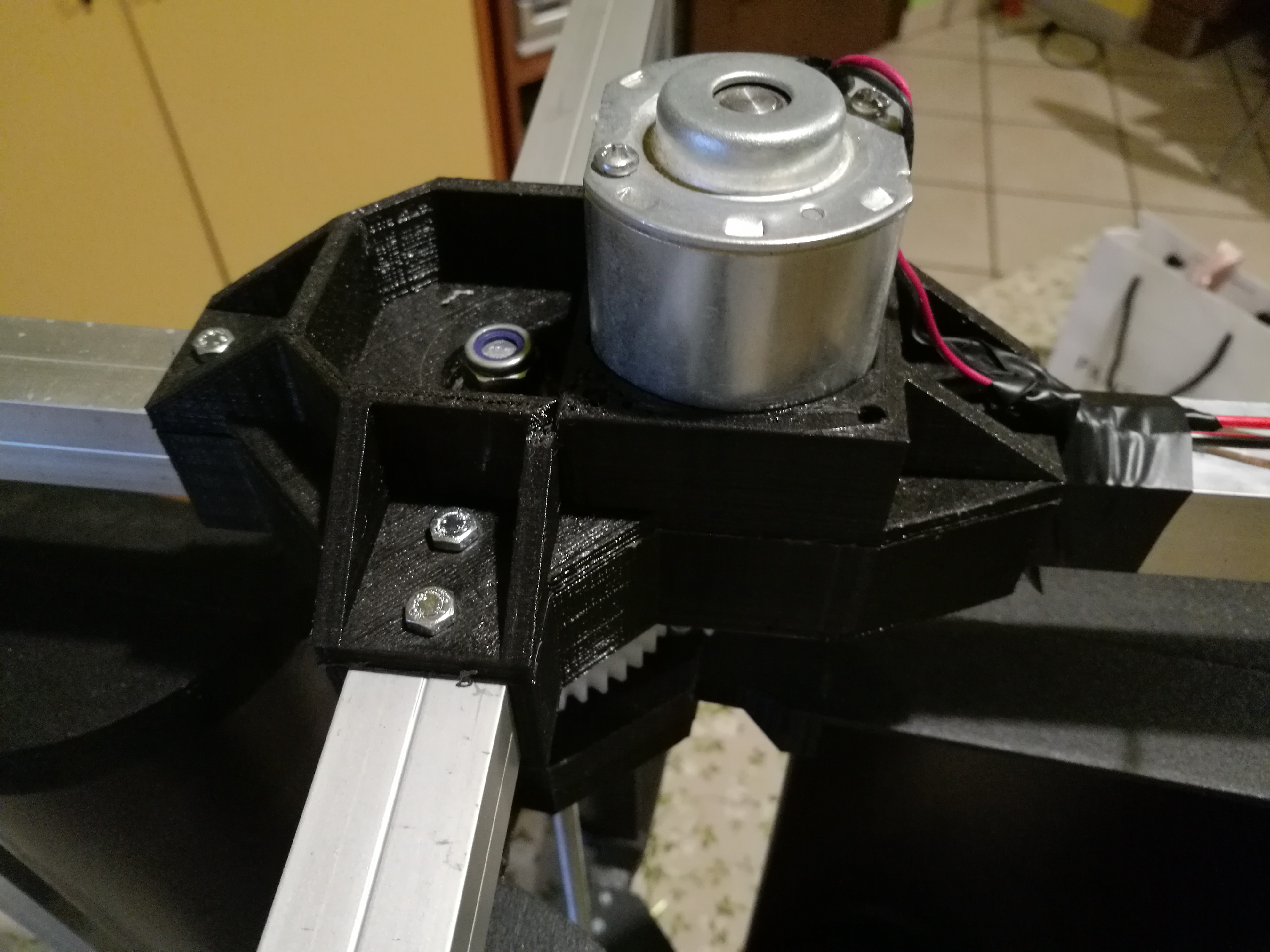

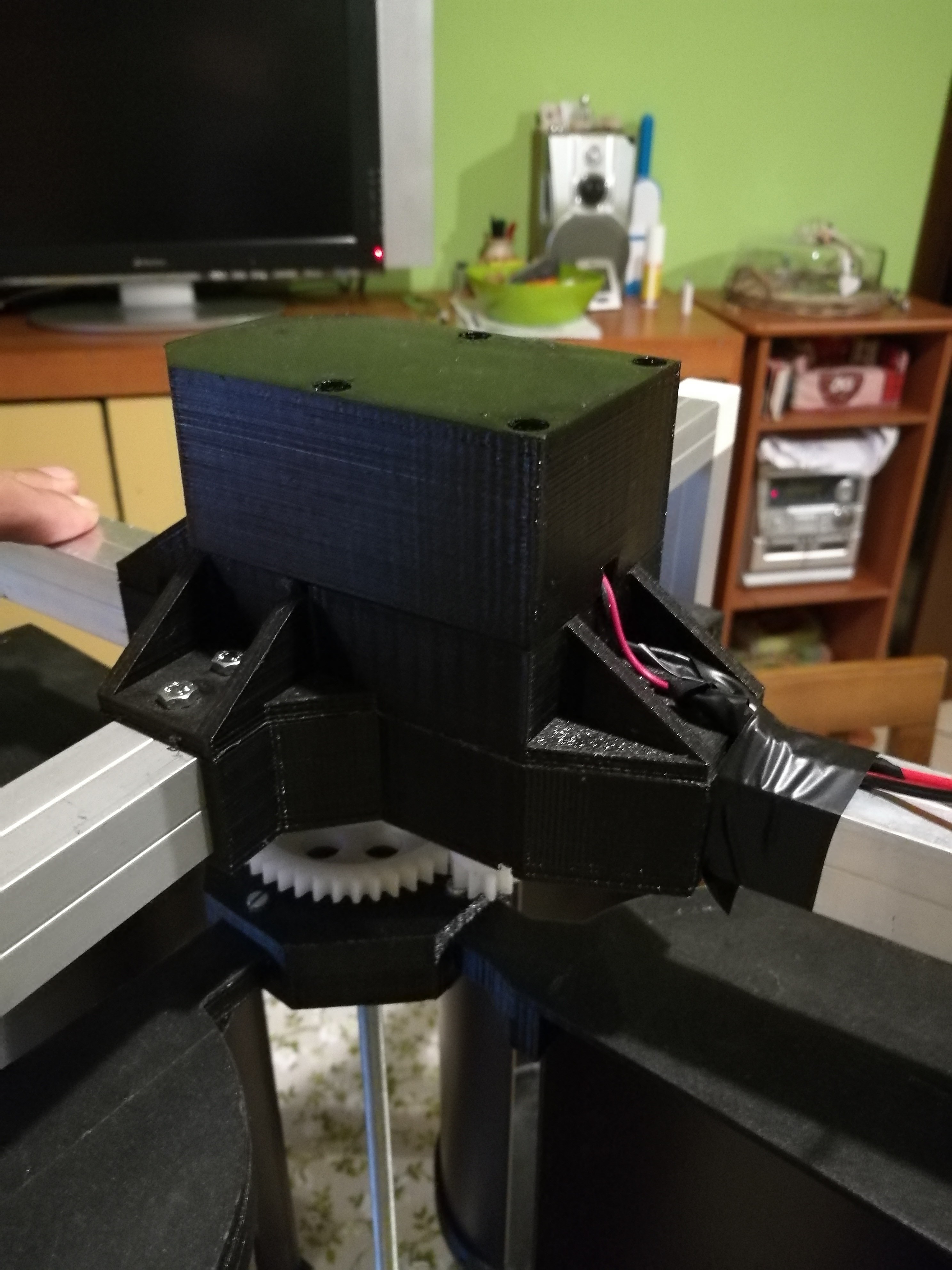

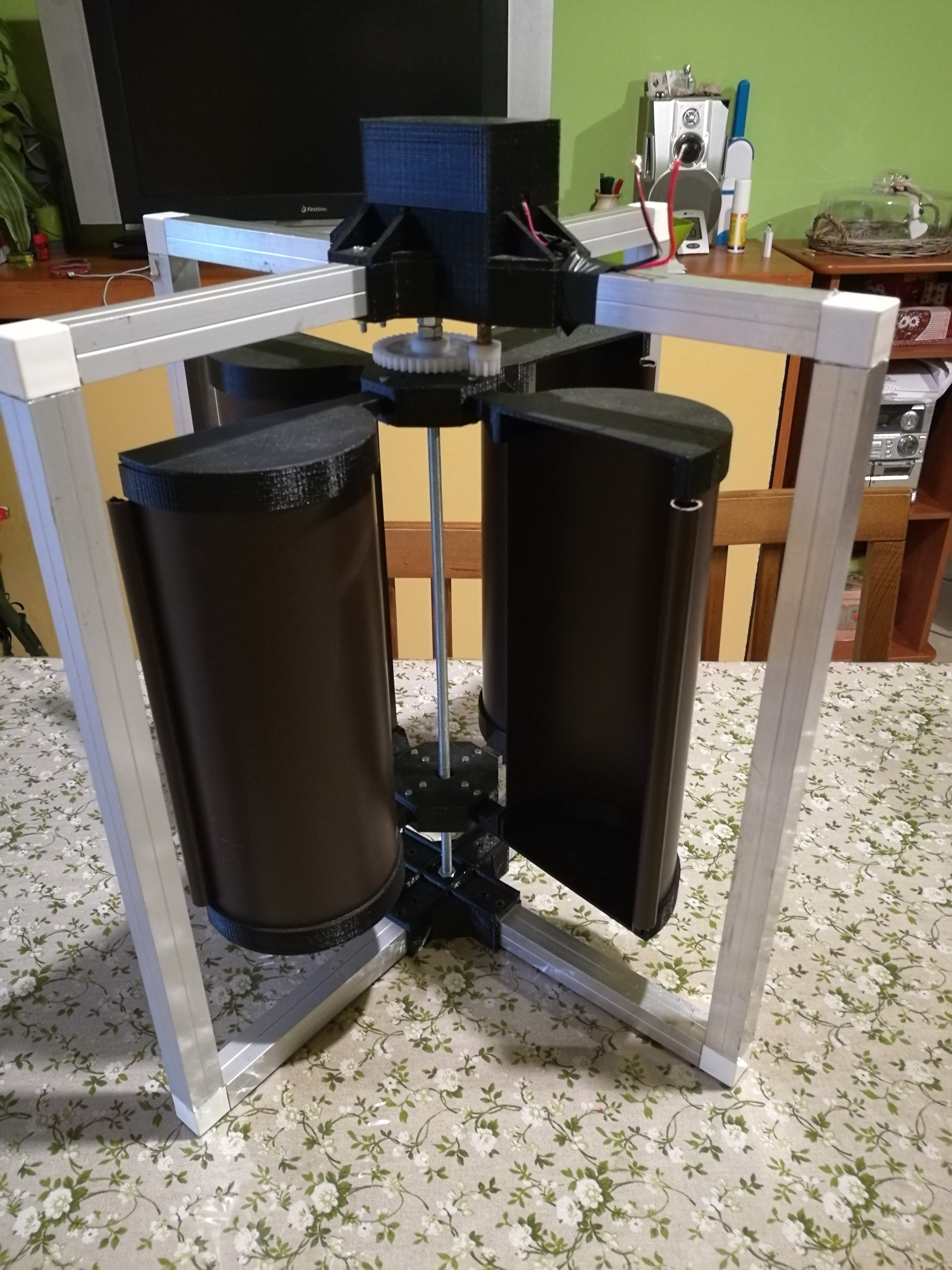

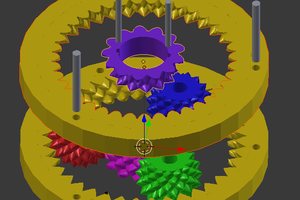

As regards the construction of the blades, various solutions are possible. In the first version we used a 2 meter long PVC gutter channel with 125 mm diameter cut into four 300 mm long parts, an M8 threaded bar to which a 67 mm diameter toothed wheel and 44 teeth were inserted, a pinion with diameter 16 mm and 10 teeth fixed to the motor shaft, supports made of ABS with a 3D printer to connect the blades to the threaded bar and four bearings 8x22x7 mm.

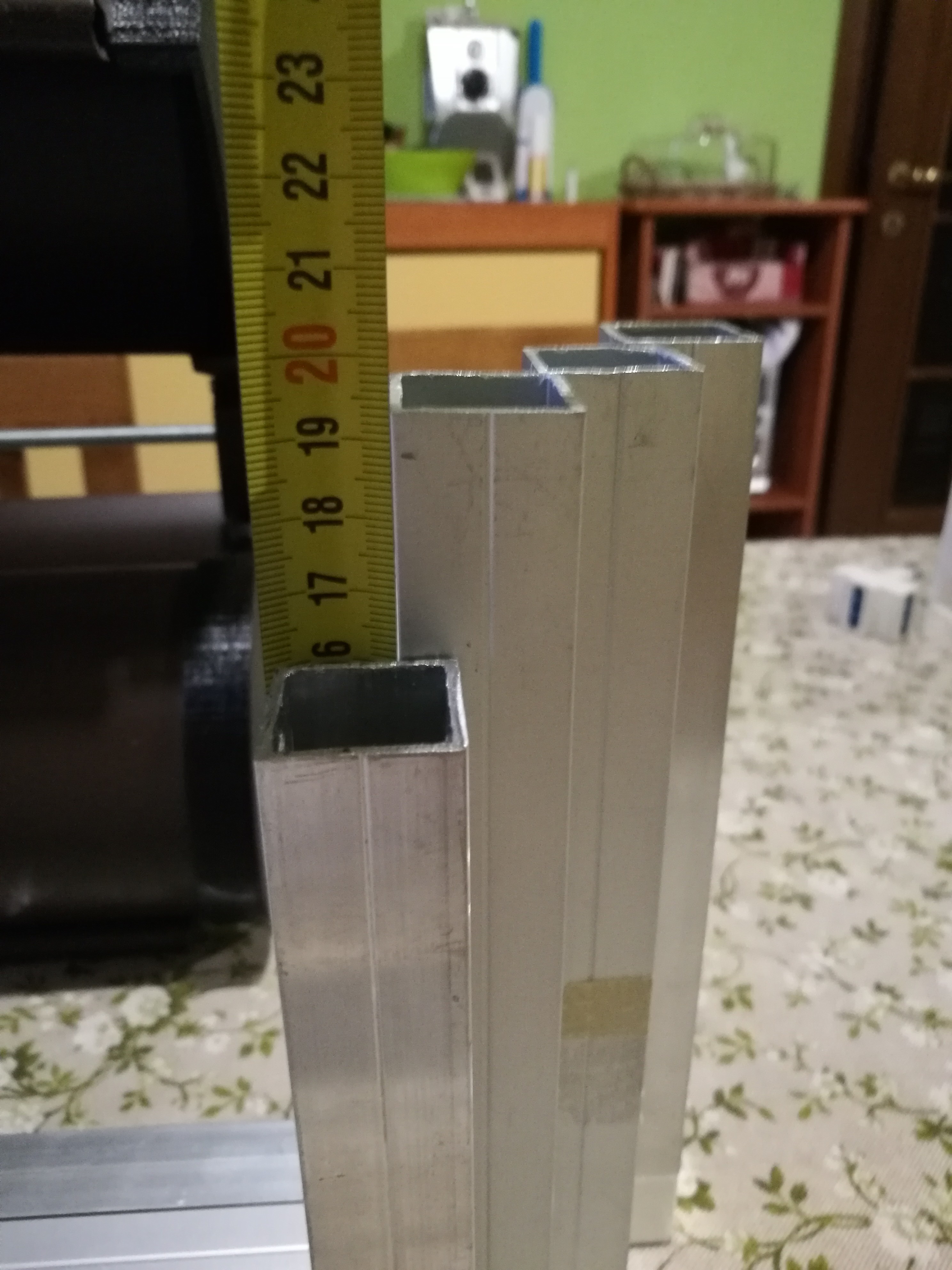

It is also possible to replace the four parts of the PVC gutter channel with four sheets of aluminum, steel, copper, etc ... with dimensions of 300x220x1.5 mm, curved on the longer side to be inserted into the appropriate ABS supports. The largest gear wheel, being in contact with the pinion teeth, allows the shaft of our motor to be rotated, generating a voltage directly proportional to the wind speed.

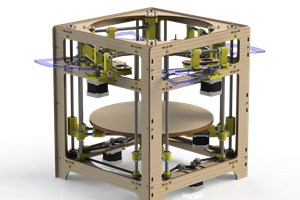

Thanks to the new 40x40x40 cm printer created by Futura Group, we have designed, again with Google SketchUp, a second version that involves the construction of the wind blades in a single block, kindly printed by the Futura Group laboratory, always in ABS. This solution made it possible to considerably reduce the parts needed for our vertical wind generator.

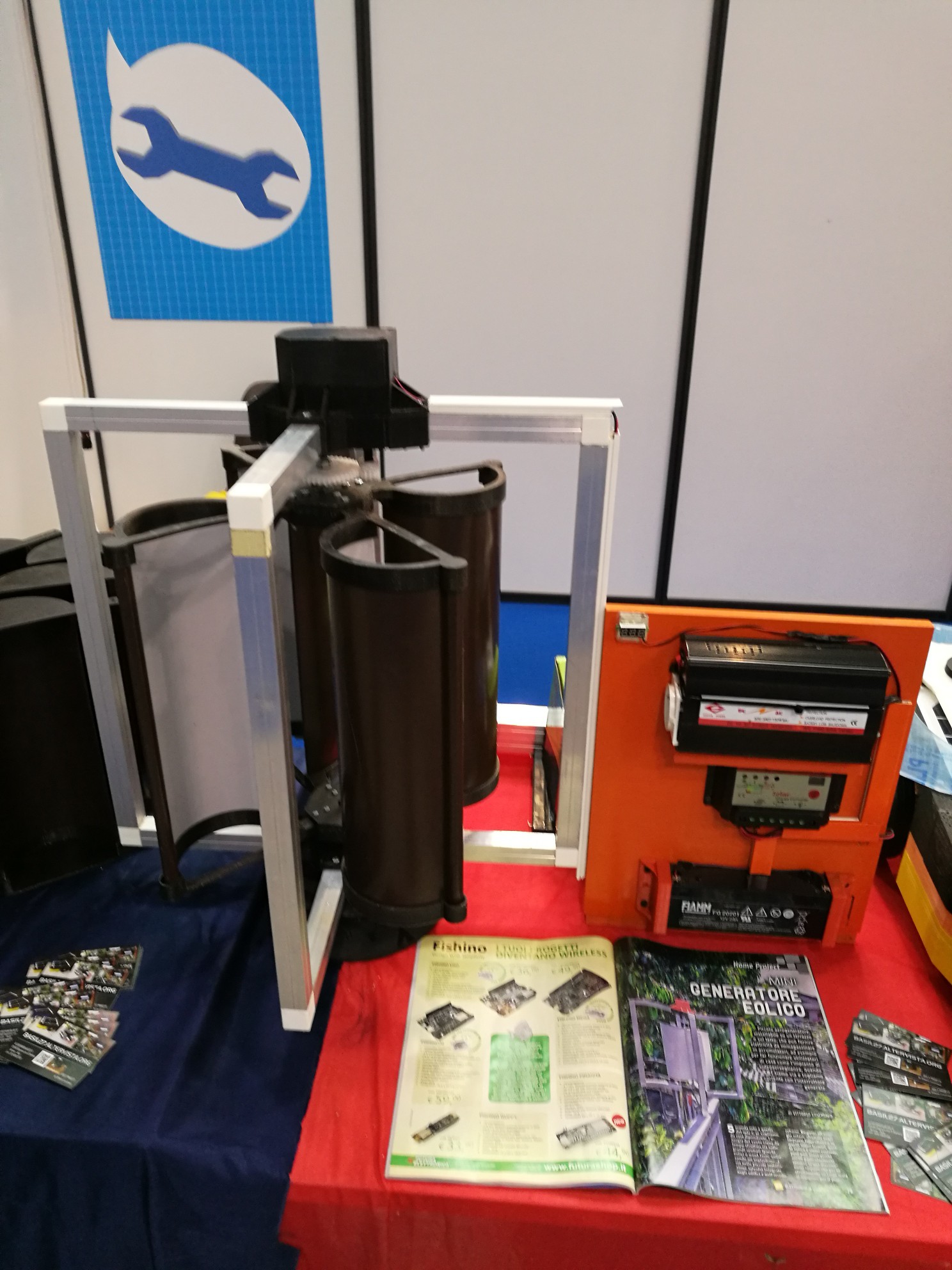

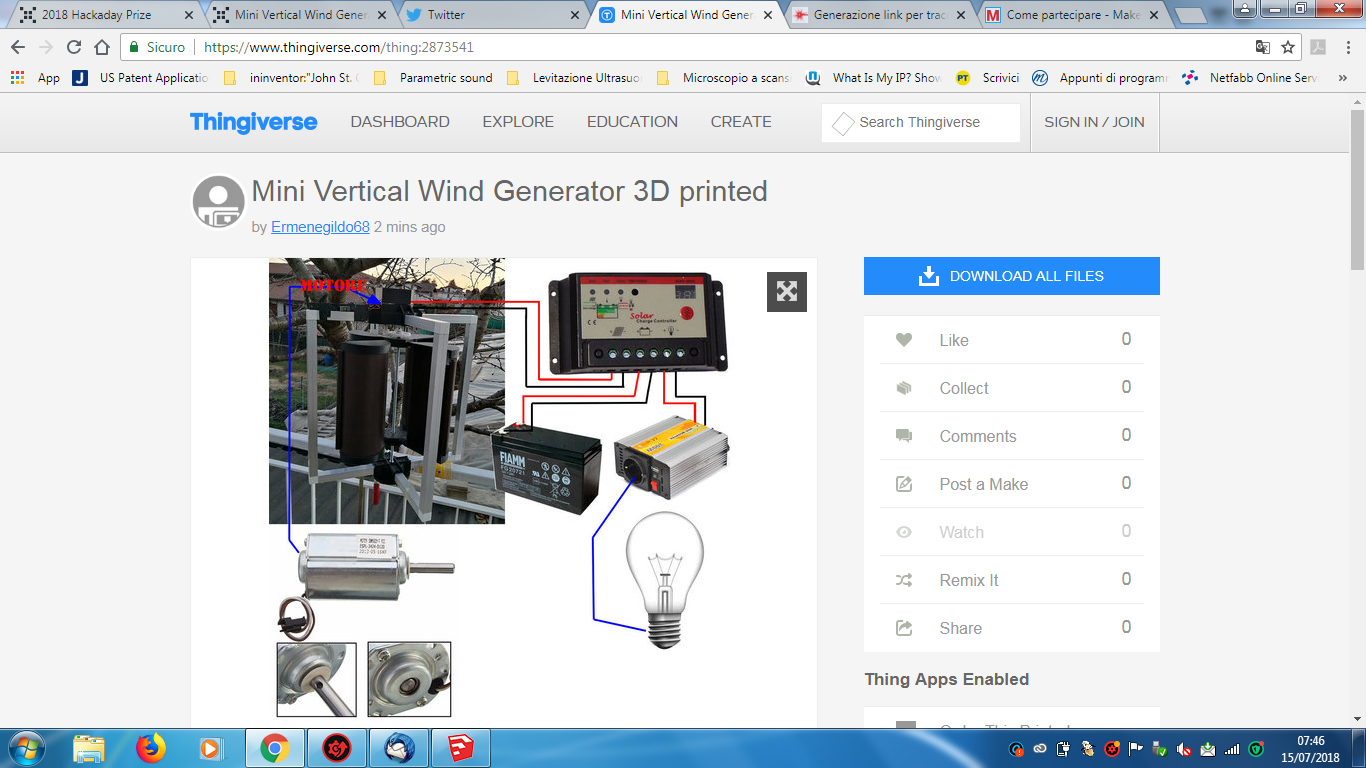

This wind turbine, as you can see, is small, but nothing prevents you from making a version with larger blades and use a motor with a greater power. As is now known, the main problem of alternative energy sources is not only the power generated, but above all the possibility of being able to accumulate it for use later, in the absence of wind (in our case) or in the absence of sun for photovoltaic systems. Also for our wind generator it shares this problem, to avoid which we decided to store the energy produced using batteries and a charge regulator.

The choice of battery capacity must be made according to how much energy we want to accumulate. The system consists of a charge regulator, one or more accumulators and if you want to power 220 VAC devices, from an inverter capable of converting a direct voltage (12/24 VDC) into an alternating voltage (220 VAC) ) ,.

Vittorio Loschiavo

Vittorio Loschiavo

Tyler Anderson

Tyler Anderson

shareef

shareef

Vijay

Vijay

Anthrobotics

Anthrobotics

https://2018.makerfairerome.eu/it/espositori/?ids=76