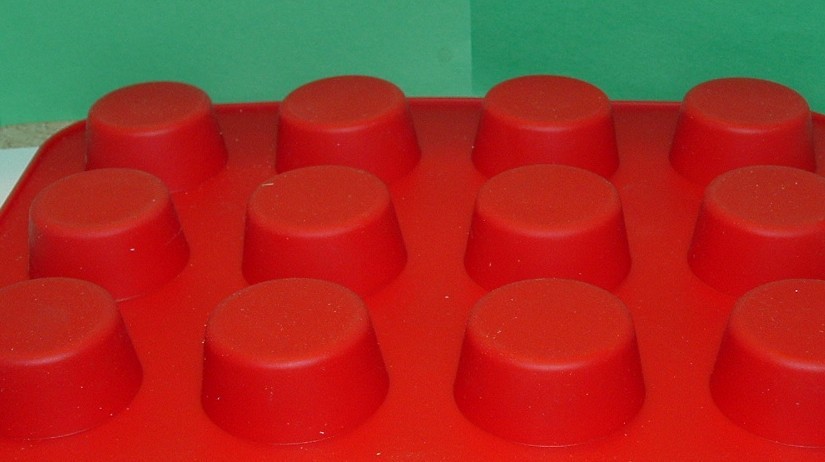

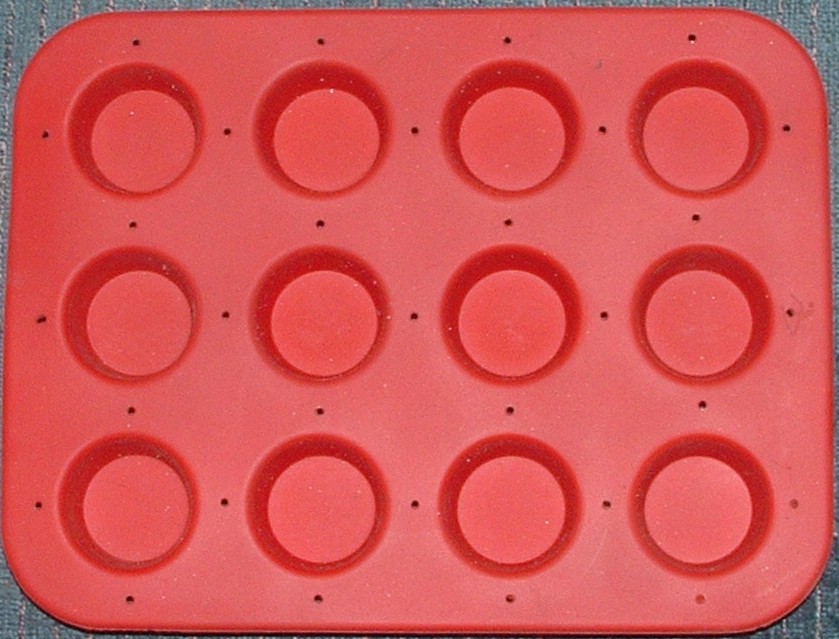

Silicone muffin maker

This is the first part to construction of the Actator.

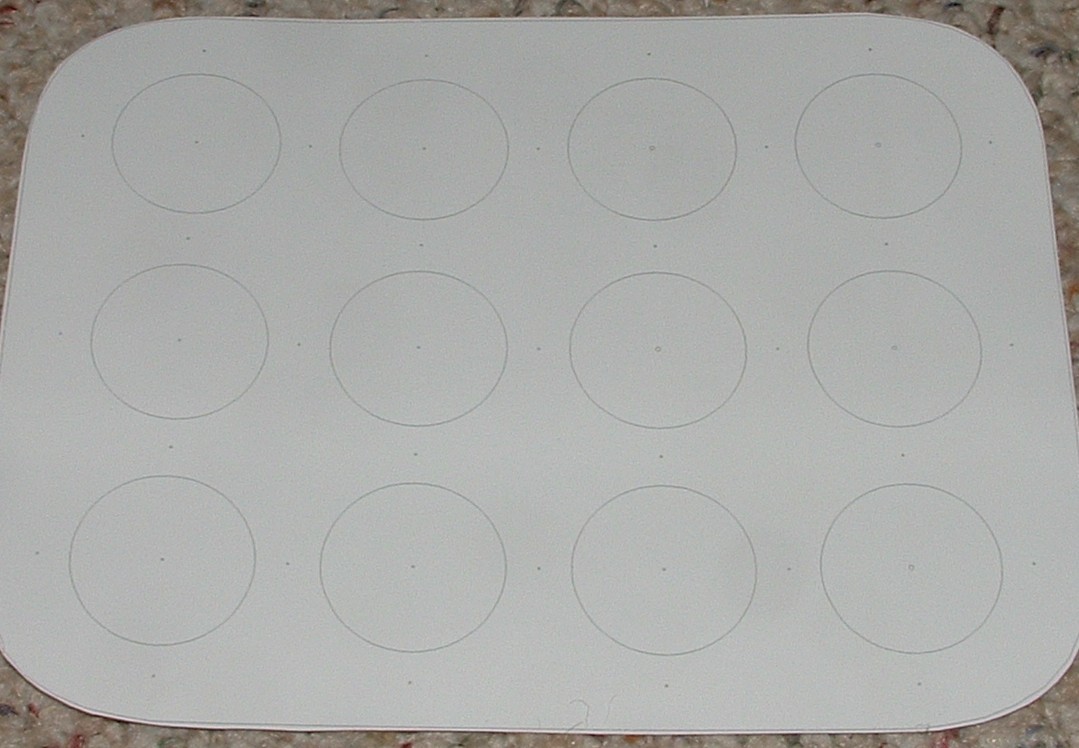

I first measured the silicone form and using a cad program created a template for hole placement.

I used this speedbor bit 1-1/2" to machine the hole in the nylon block.

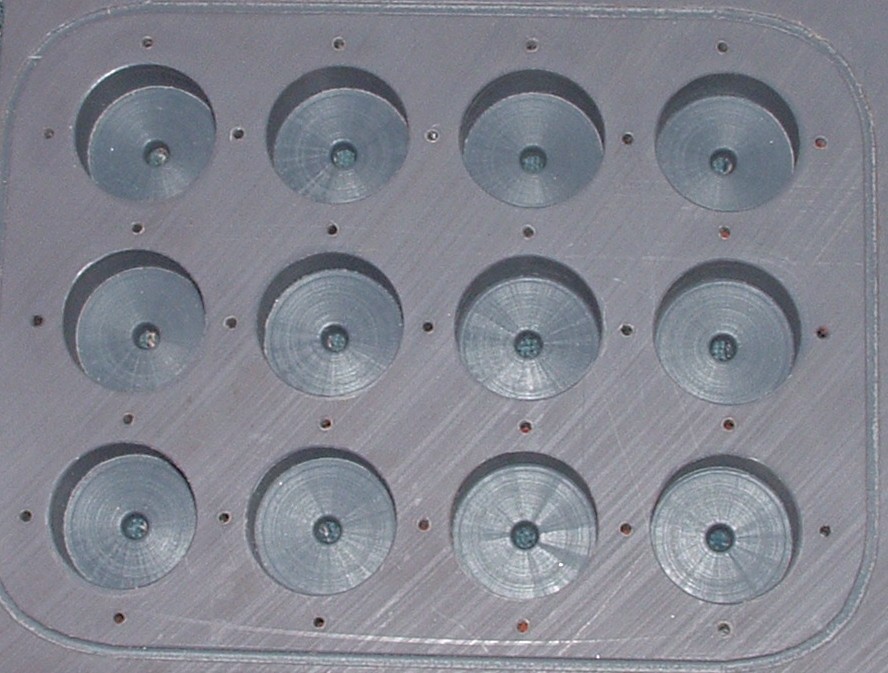

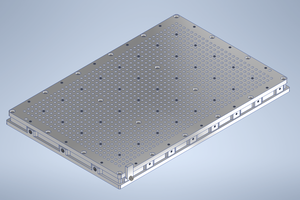

I used my cnc router to rourer a 1/8" grove around the perimeter. I also used the cnc router to make my punch holes for accurate placement of the bores. I set the depth of my drill press and bored the cylinders.

I clamped the 1/4" plate to the cylinder plate. Using the cardboard template I punched and drilled the scew holes. Next I counter sunk the screw hole to accept a Stainless socket head 6-32x3/4 " cap screw.

Next the silicone form was placed in the cylinder block, the top plate was installed and useing a small sharpend drill bit back I punched the hole through the silicone.

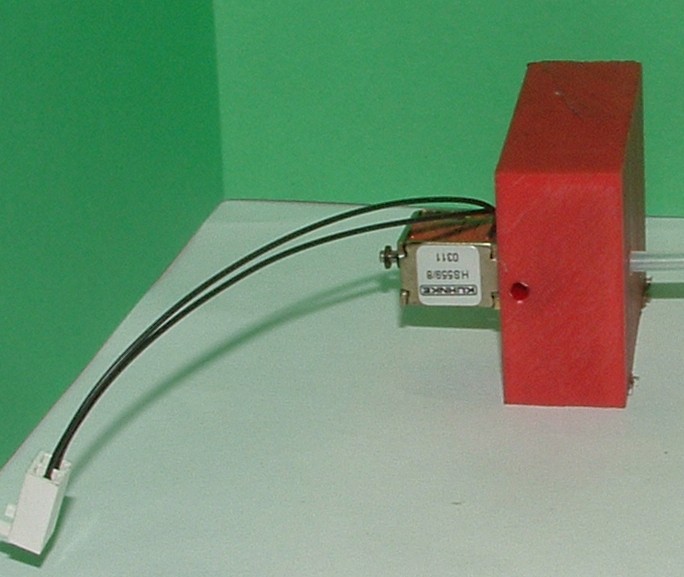

Here is the assembled unit . Time to complete 6 hours.

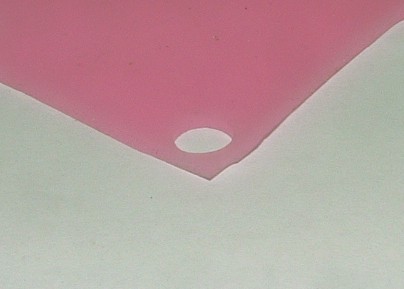

Here is a silicone sheet. I punched a small o ring with a sharpened copper pipe.

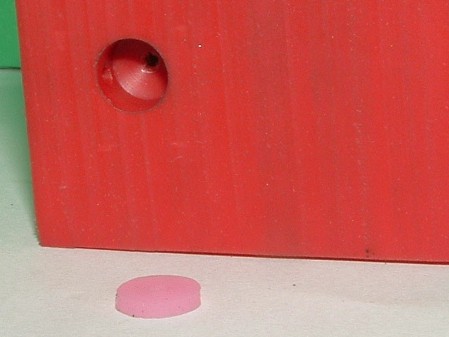

The first test valve. A tiny hole drilled in the bottom and one through the side.

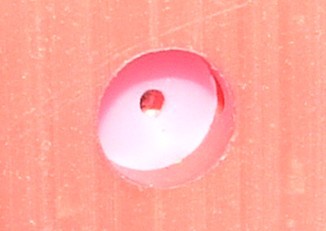

The O-Ring is now install in the bottom of the valve body. the vent hole to the right is now visable.

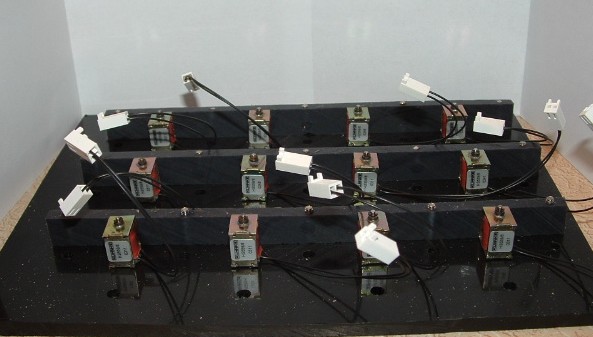

I have 12 of these miniature solinoids to seal the o rings.

I mounted the twelve on the valve plate.

Joseph Lavoie

Joseph Lavoie

Grant Giesbrecht

Grant Giesbrecht

willbaden

willbaden

I'm a maker

I'm a maker