-

Death of a toenail

04/29/2023 at 00:27 • 0 comments

Another toenail goes to the toenail in the sky. Not sure why the sandals eat toenails. The general theory is bare EVA is very sticky & too much stickiness in the toe area causes blisters under the toenails. You can't moisturize toes because moisturizer causes toes to stick. Simultaneously, dry toes get cracked & swollen which also kills toenails.

The leading idea nowadays is to lubricate the toe area but not use a moisturizer. Another idea has been to cover the bare EVA with suede, but suede is heavy. Suede has provided just enough stick but not too much & it's been immune to rain.

The journey to a more tenacious sole has been long & slow, manely because every option is expensive.

Lions wonder if vibram rubber has ever been remelted & cast into other sole shapes. The tooling might cost more than the rubber. The case could be made for casting 1mm rubber soles with just the right amount of lugs.

It turns out the 1mm vibram soles slide like glass on a freshly waxed mall floor. They really are bad compared to shorter life rubber. So ideas began to emerge of having a pair dedicated to less frequent trail use, with higher grip rubber. Maybe a PLA positive could be used to create a moldmax negative & that could be used to form a grippy sole out of rubber. There are very expensive rubber epoxies. Balloon rubber is the grippiest rubber. Natural rubber seems to be the key.

https://www.amazon.com/Rubber-Repair-Non-Slip-Soling-Bottom/dp/B08RB1CTBG/

There is 1.2mm sole rubber which calls itself anti slip. 15" x 11" is $10 bidie bucks. What lions really want though are lugs.

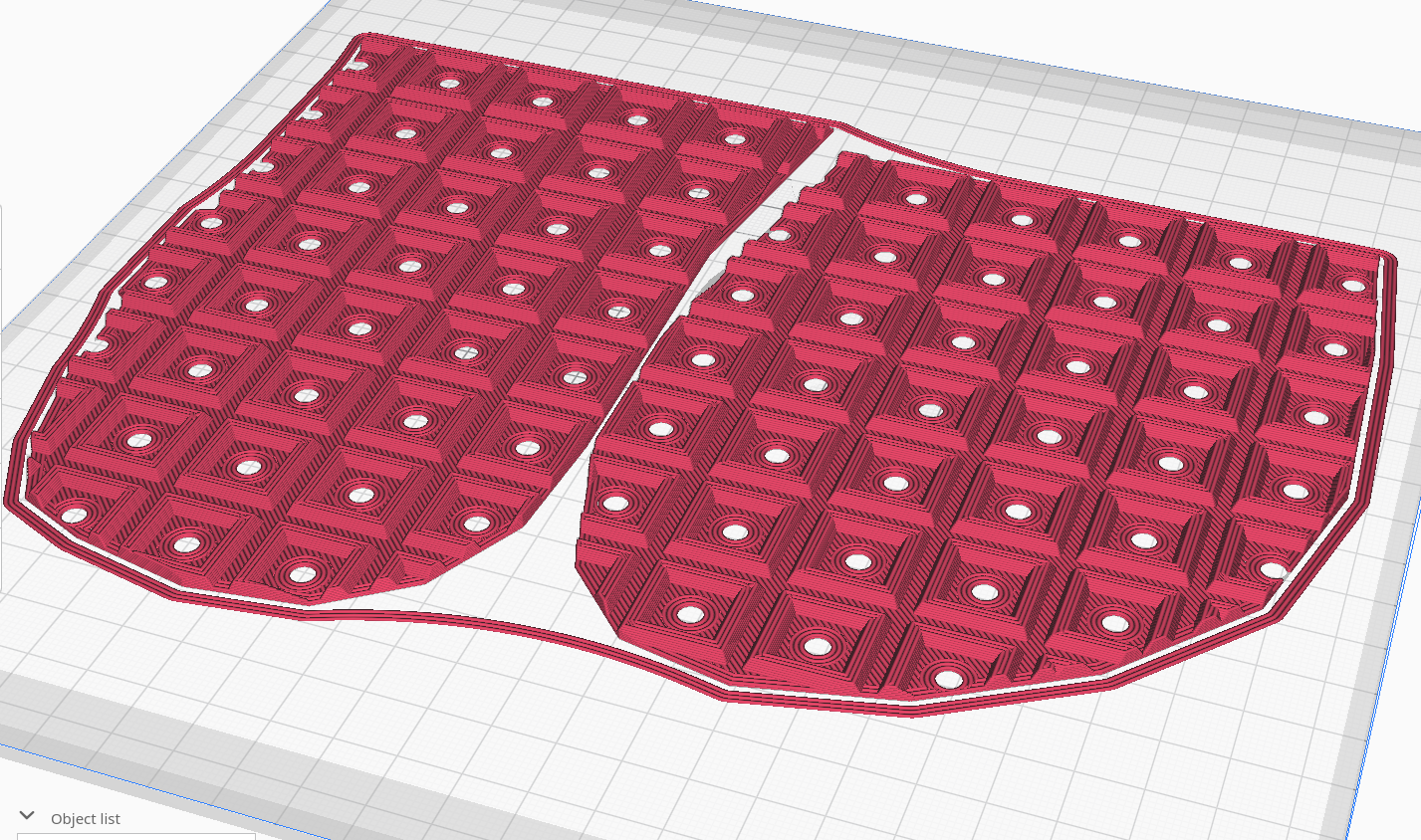

TPE has shown pretty good grip performance compared to TPU, but it's expensive. The latest idea is printing a lugged 1mm sole out of TPE & hot gluing it to the sole of a retired sandal. Maybe a pathfinder could be made of TPU to see if the lugs overcome the lack of friction. It would have to be printed in 2 halves & welded together.

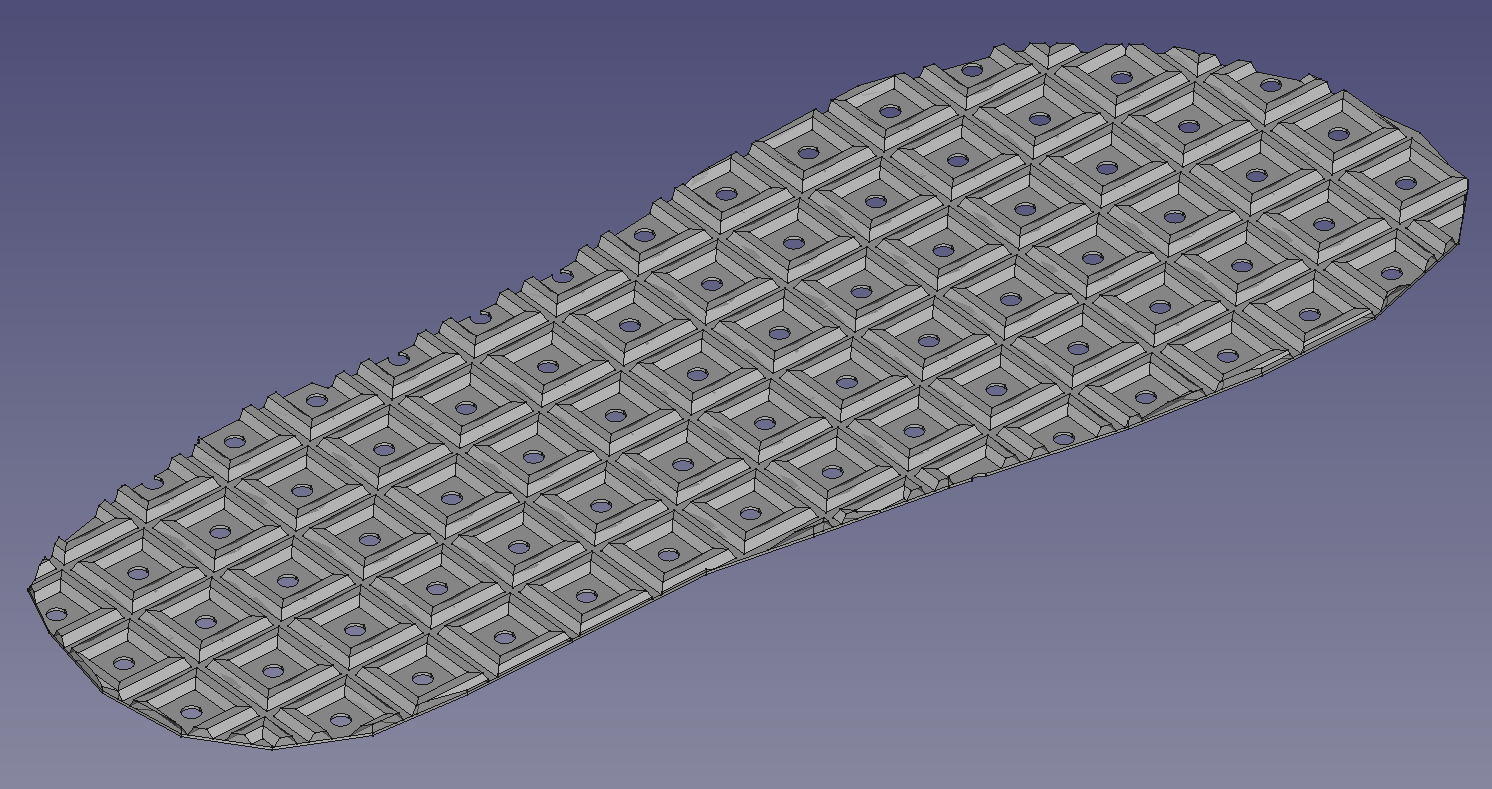

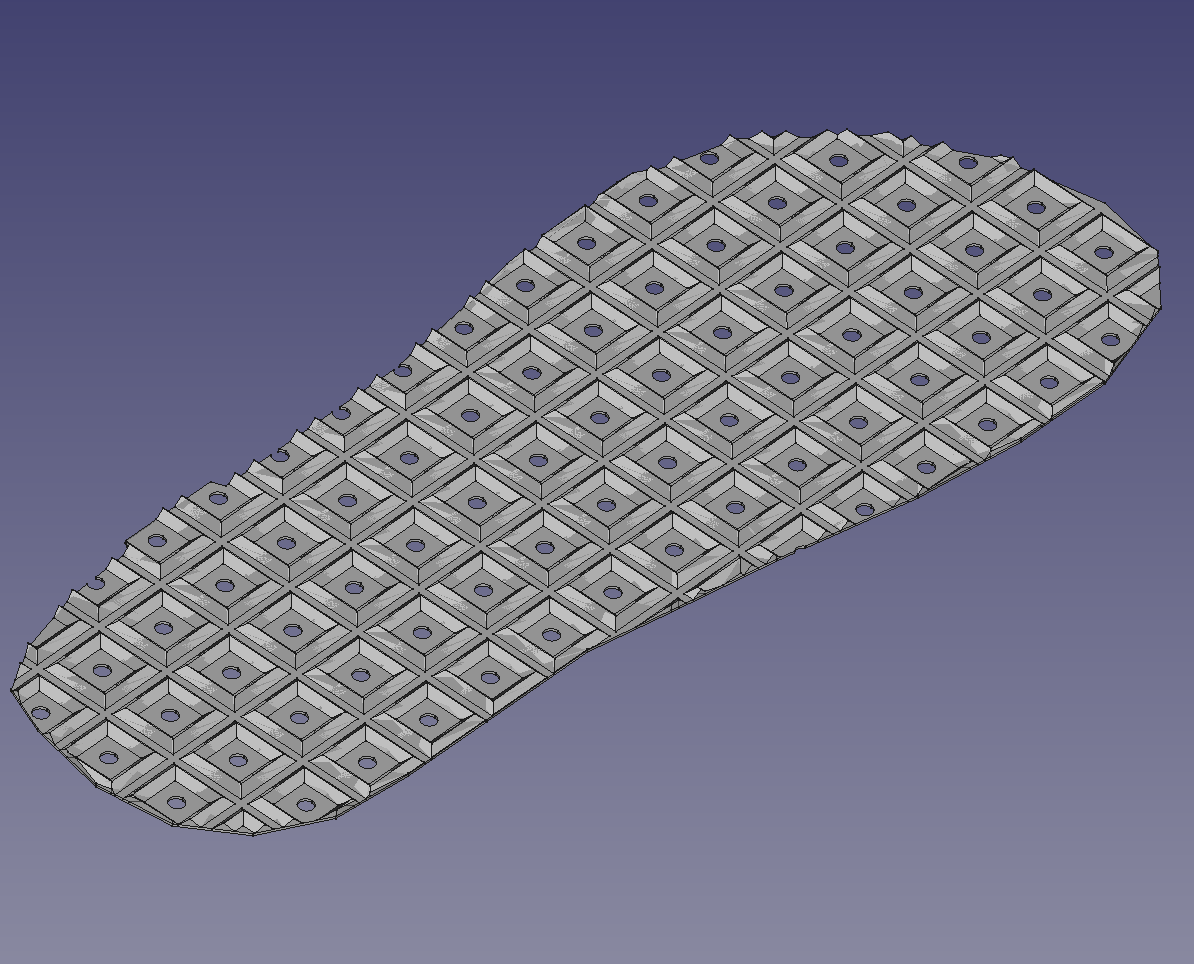

The preferred lug design is just a regular pattern of square outlines.

Hot glue rivets would go in the holes.

In today's price of $60/500g it would be $6.

A pointier lug might dig in more & reduce the price to $5.

Then comes testing it. The only place demonstrating the traction is near the very end of a long mountain climb.

-

New pair

03/22/2023 at 07:06 • 0 comments -

2022 edition

04/25/2022 at 22:31 • 0 comments

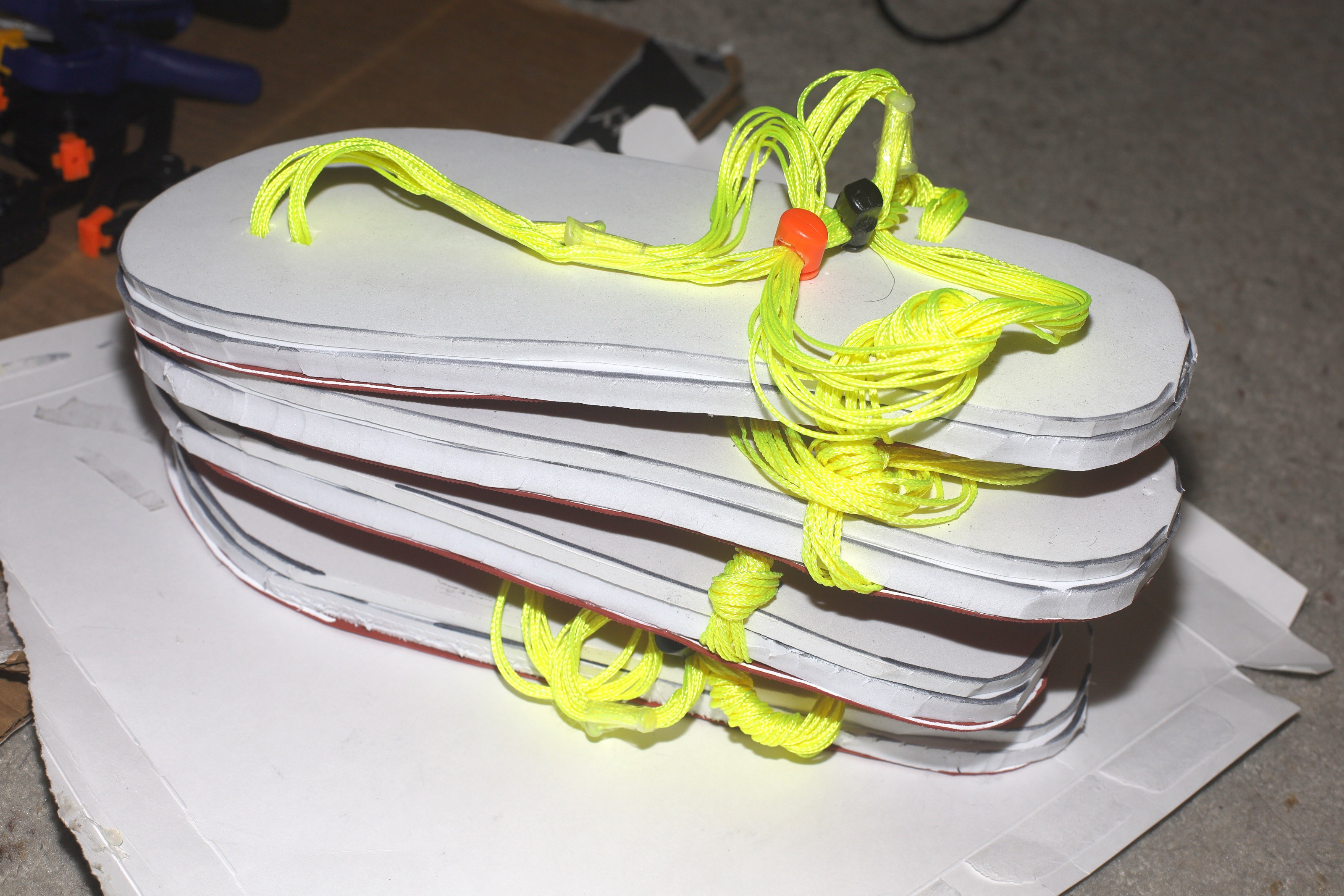

They're lasting 800 miles. The mane changes this year were reducing the rear lace to 10 passes of string & gluing the rear lace to the sole. The most time consuming part is cutting all the materials. Gluing 2 pairs takes 4 days because of the number of clamps.

The lifespan has been limited by large wear areas in the middle of the sole which would require a completely new sole.

-

Mountain test 1

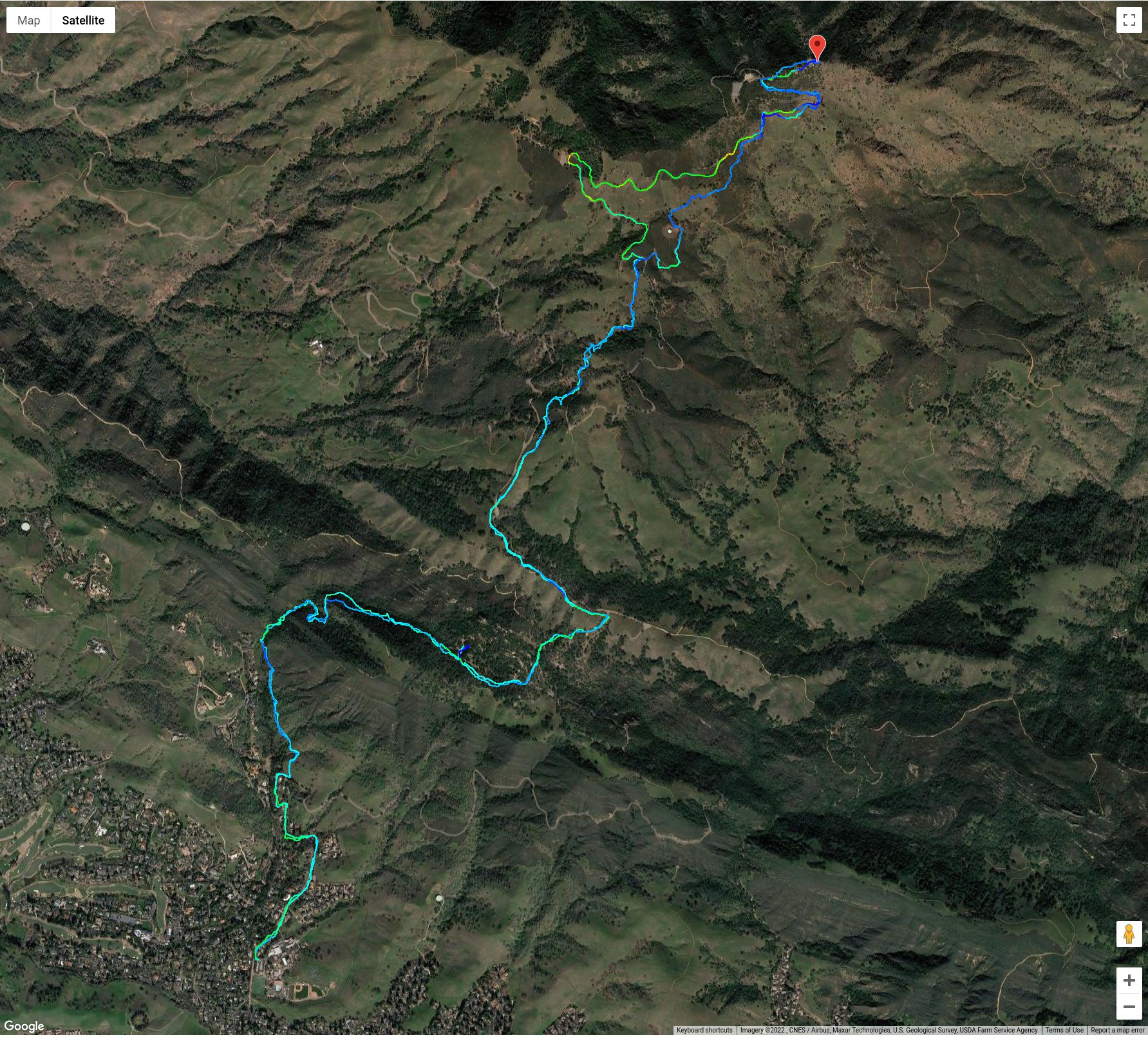

03/27/2022 at 00:55 • 0 commentsA long awaited test involved going up & down the mountain in 16mm sandals.

The uphill segment was all done on trails.

Only the last part of this section entailed using 4 paws. The rest of this section was gnarly but doable in the uphill direction.

Sadly, the sandals didn't have enough traction to attempt these 2 sections in the downhill direction. The downhill direction was much gnarlier. The laces weren't the problem, but the smooth soles weren't up to it. There are no lugged 1mm soles. Perhaps lugs can be glued on, but they're going to be heavy. The great challenge continues to be steep sand covered clay.

Steeper sections with exposed rock were doable. Rock hits in the downhill direction were painful. The downhills had to be slower than in shoes.

-

16mm EVA #2

05/29/2021 at 19:55 • 0 commentsThe 16mm soles proved a decent compromise between speed & durability over 6 months.

Right paw compression was down to 6mm while the 12mm sandals compressed to maybe 1-2mm so the compression in both cases was 10-11mm.

Left paw compression of the 16mm was down to 3mm, so the 12mm sandals may be a case of the foam compressing all the way down to a solid, with still more compression to go.

Original 12mm compression.

Despite having more cushioning, the soles still wore out fast. They might have worn out faster because of the cushioning. They might have gone 500 miles per pair.

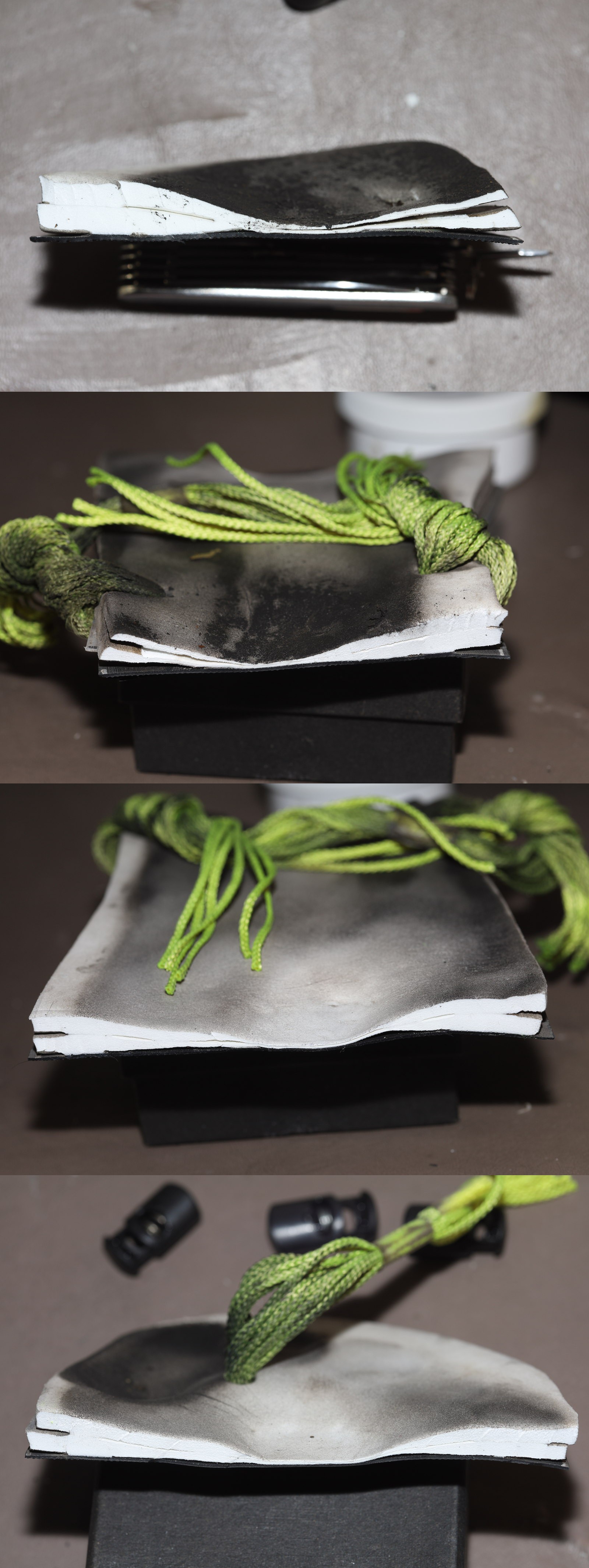

More proper clamping joined the next EVA sheets. Because wood clamps are so nose bleed expensive & the pressures on foam aren't very high, there's motivation for 3D printing a jig for gluing the pieces. Gluing sandals is just a very rare operation for such an investment in gear.

The 10mm foam was actually cuttable with ordinary scissors. Making holes in the full 16mm requires an exacto.

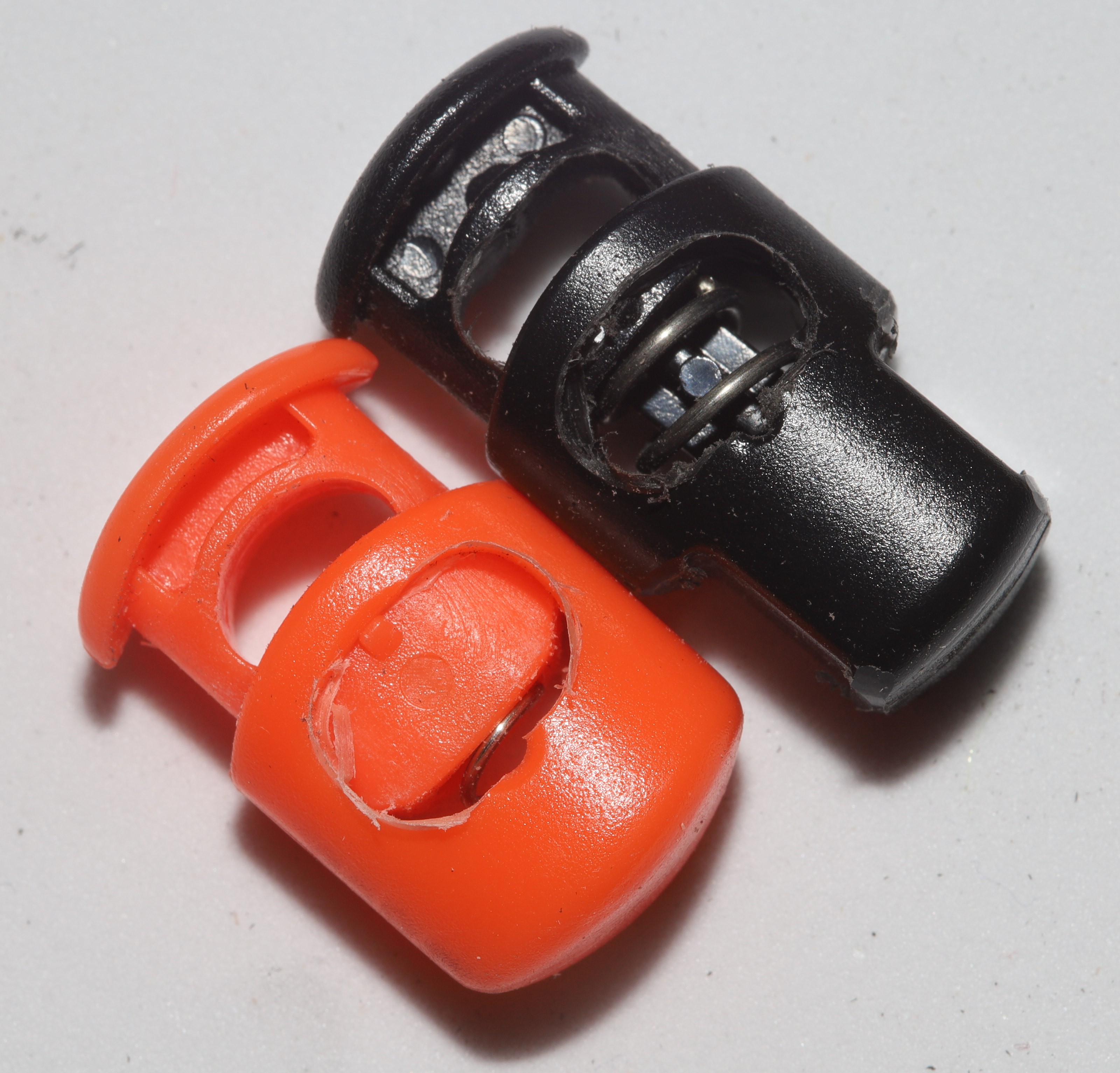

The 1st investment in cord locks in years. The orange ones look a lot better, but only fit around the toe straps.

Square plastic bits appeared to wear away the soles faster, so the they were rounded again. Extra glue was applied to keep them oriented.

The soles got a more aggressive clamping. Another 10 clamps are still required to do it right.

https://www.amazon.com/dp/B08RXW32H4

These are quite good.

The clamping led to the best edges so far.

Black soling ran out with the shortages in 2021. Extra patches will be glued to the worn areas as they wear out.

The laces swell over time, making the cord locks tighter. They're too loose when they're new.

The last set underwent a lot of patching on the soles to worn areas. They retained a lot more cushioning than 12mm. They have a few more miles left before being discarded.

Wear varied greatly, depending on the lacing variations & paw position. Right paws are getting beaten up more than left paws.

What's desperately needed are semi permanent adjustments for the rear & outside of the ankle strap. They don't have to be adjustable in the field like the existing adjustment points. Lions continue to dream of a 3D printed cord lock to fuse the 2 existing ones into 1.

-

16mm EVA

12/06/2020 at 04:42 • 0 comments -

Luna enhancements 3

08/06/2020 at 07:26 • 0 comments

Back to the 2 triangle farsteners. A new theory emerged that larger ribbon loops might make the farstener areas more flexible. 2 loops can be enlarged, but a 3rd loop is too close to the pavement. It would have to be sewed instead of hot glued. Also, eliminating the cord locks & fixing the toe strap length might improve the toe strap. The lion paws have to heal from the last experiment before trying these on.

Rubber cement has done a better job than hot glue at farstening the suede to rubber. Suede continues to work well at avoiding blisters from the rubber. Lions wash these after every run.

-

More luna enhancements

06/08/2020 at 04:15 • 0 comments

The suede pieces from 2 years ago were taken off the xero sandals, after being untouched for 2 years. They looked absolutely ancient. It really was a long time ago when the sandal experiment began. So much of that time was spent commuting, it felt a lot more recent.

The suede ended any blistering from the rubber, but with increased running distance came another hot spot from the triangle farstener.

This was a total failure. Hot gluing the straps makes them more abrasive.

Another shift of the toe strap closer to the center.

The cord locks from strapworks had strange, unused plastic bits which were ground off. The lion kingdom suspects a smaller, more round shape is easier on the paws.

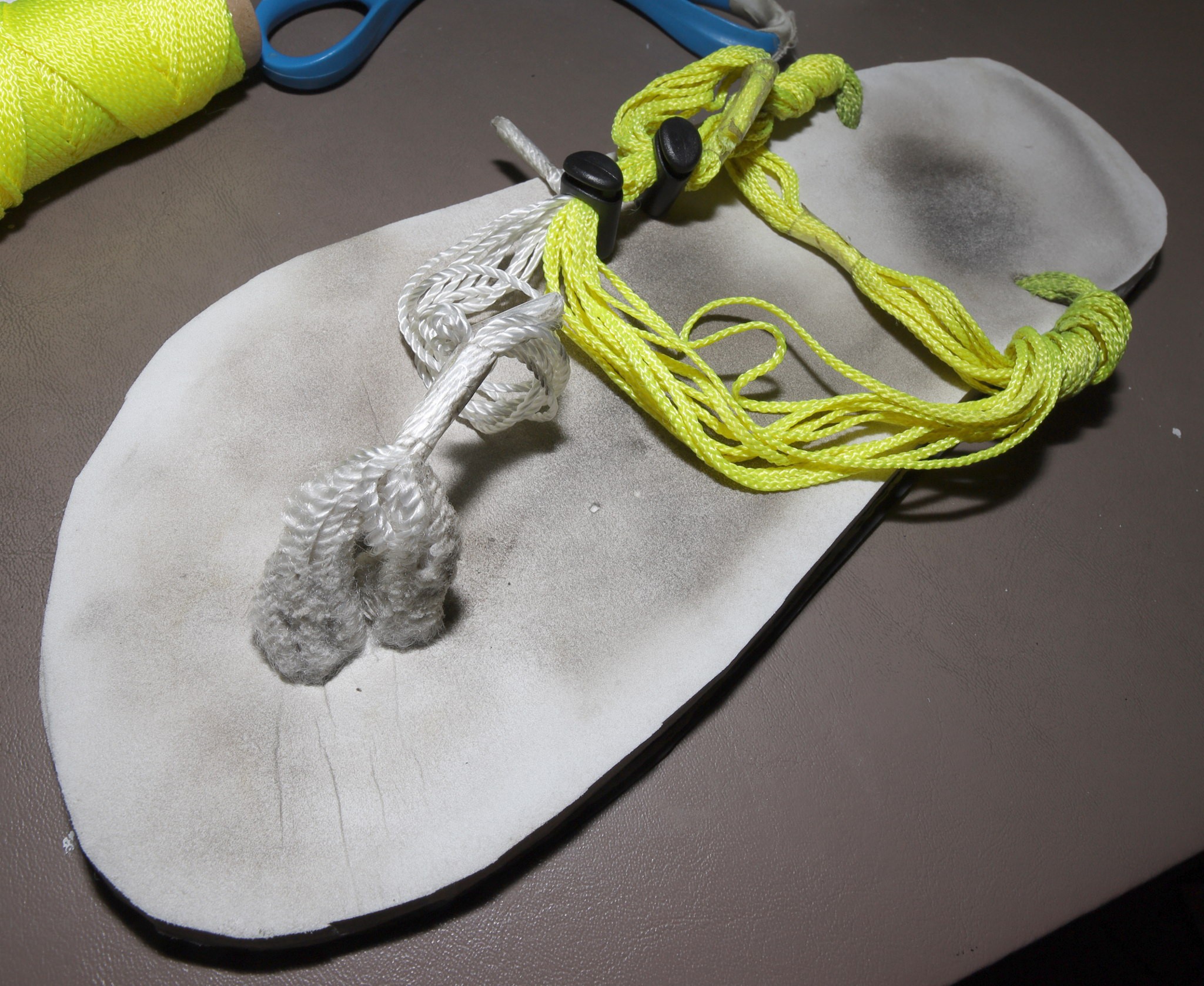

The toe strap made of 9 strands of white mason line was found to be too aggressively slicing lion paws, so it was popped out. It held up surprisingly well, but to reduce the amount of pressure on the lion paws, it had to be thicker.

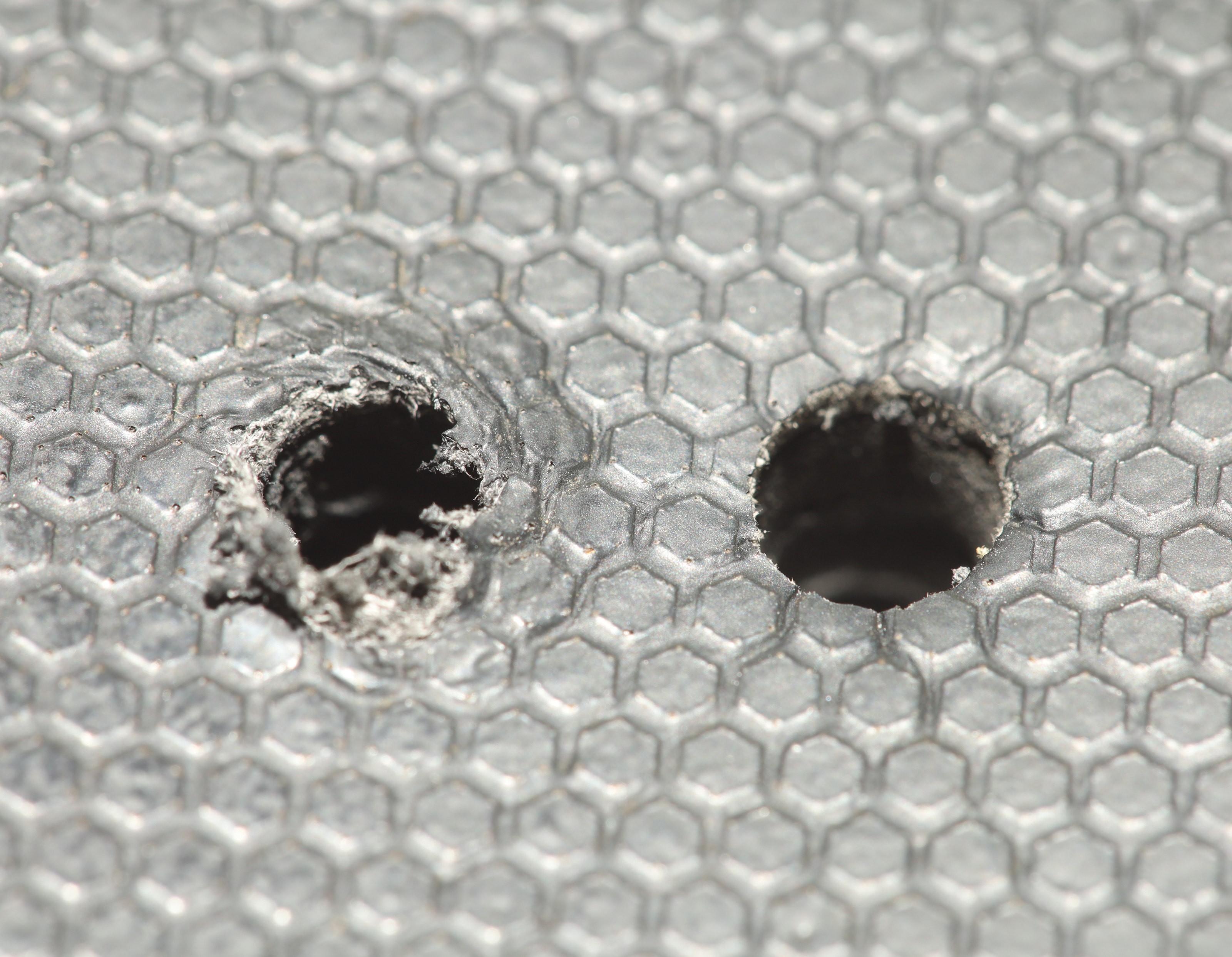

A 2nd hole was drilled with a 5/16 bit. It was found that the flexibility of the rubber prevented the hole from growing to the size of the bit.

The traditional 2nd toe strap was put in. This strap was made from 9 strands of #18 yellow mason line. It fit through the holes just like the 9 strands of white mason line, despite fears that yellow mason line was thicker. Maybe the original hole stretched from being worn. This was 2 more strands than what the EVA sandals used for their toe strap. The EVA sandals dropped to only 7 strands of yellow mason line, to allow it to fit through unmodified cord farsteners.

It came out surprisingly well isolated from the pavement.

Another lace design taking out 1 of the plastic triangles went in.

A slight twisting of the ribbon & protruding section ate lion flesh. The new toe plug worked quite well, though.

Ribbon laces have been quite a failure compared to string bundles, but there's no way to make a string bundle big enough to support such a heavy sole & fasten it. The sole has to be lighter or it needs a fabric upper. Lions have started leaning towards designing lighter soles that are better at buffering rocks, rather than trying to enhance the lunas. -

Replacing toe plugs

06/06/2020 at 07:15 • 0 comments

So with no need to commute, the lion kingdom washed its sandals after every run & the white toe plugs quickly became frayed. It was time to replace them with yellow string, which despite being more abrasive, would hopefully not fray.

Replacing the toe plug in permanently adhered soles was hard. Your biggest allies in this part of the battle are the AMD knife, tweezers & blade screwdriver.

To remove the frayed string, cut 1 side of the toe plug near the sole where it isn't frayed. Wiggle the other side while pulling it & push the cut side with the knife. The polypropylene protects the foam from pulling.

Then push the new string in a hole, 1 loop at a time & under the polypropylene with the knife. Use the tweezers to pull the loops out the other side. Use the screwdriver to keep the polypropylene in place. It's helpful to mark the position of the loops on the string.

This process passes 4 loops containing 8 strands of string. Only 7 of the strands are used, since only 7 strands of yellow string fit in the unmodified farsteners for the old toe plug. For the yellow string, the farsteners should be modified & 8 strands should be passed through, exactly like the white string.

After trimming the string & CA gluing the ends, the sandals are ready.

lion mclionhead

lion mclionhead