-

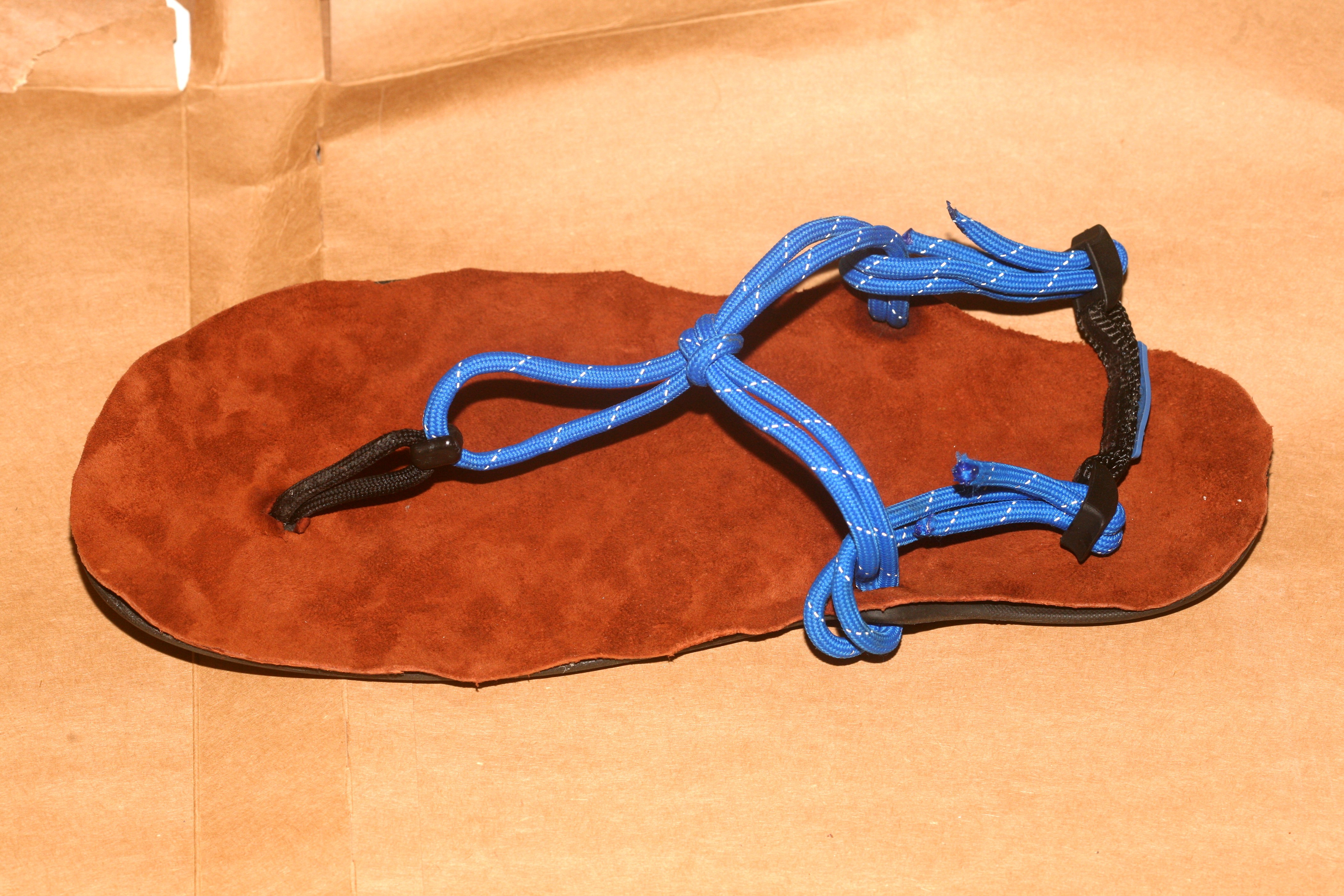

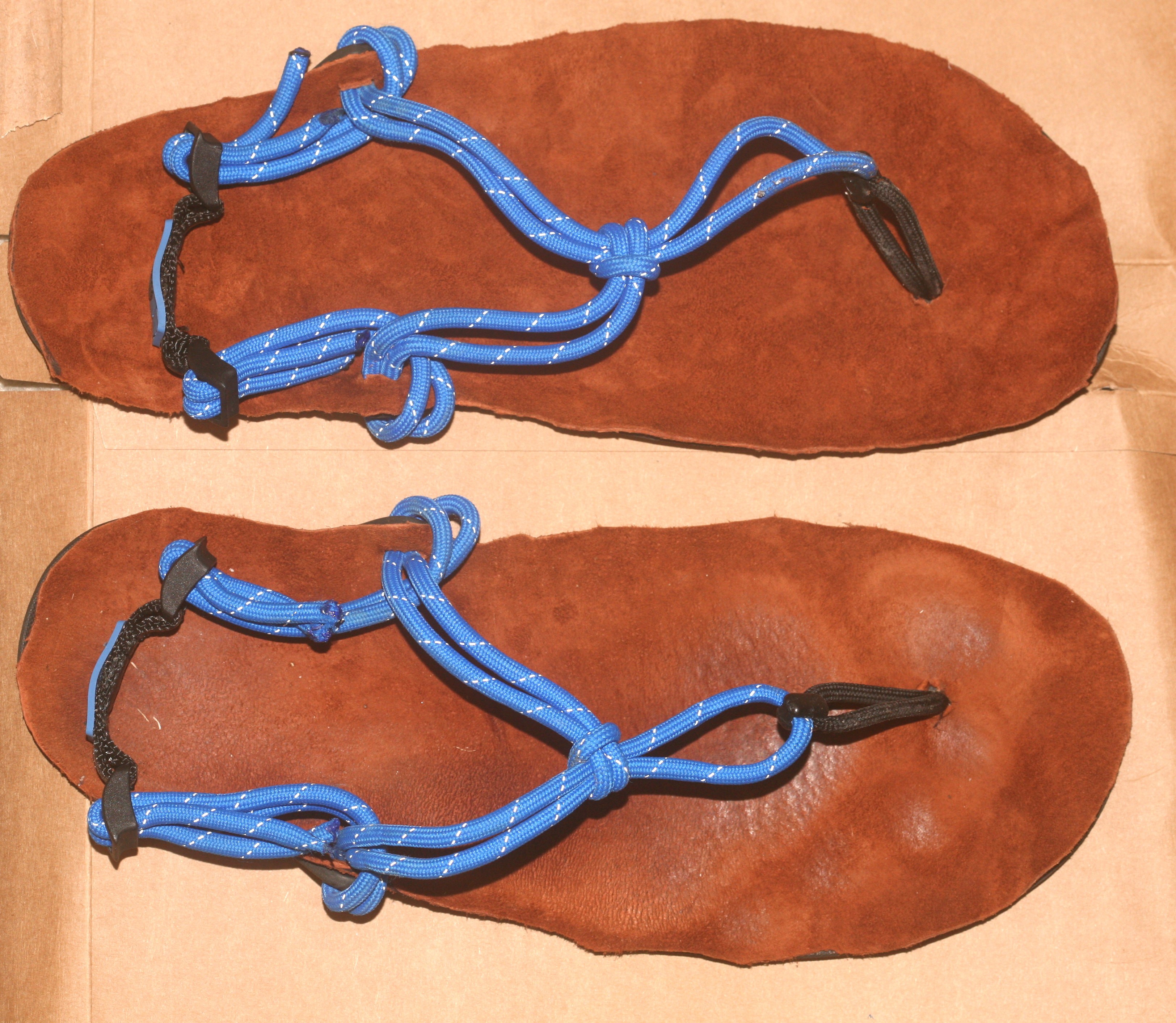

Brown Suede Sandals

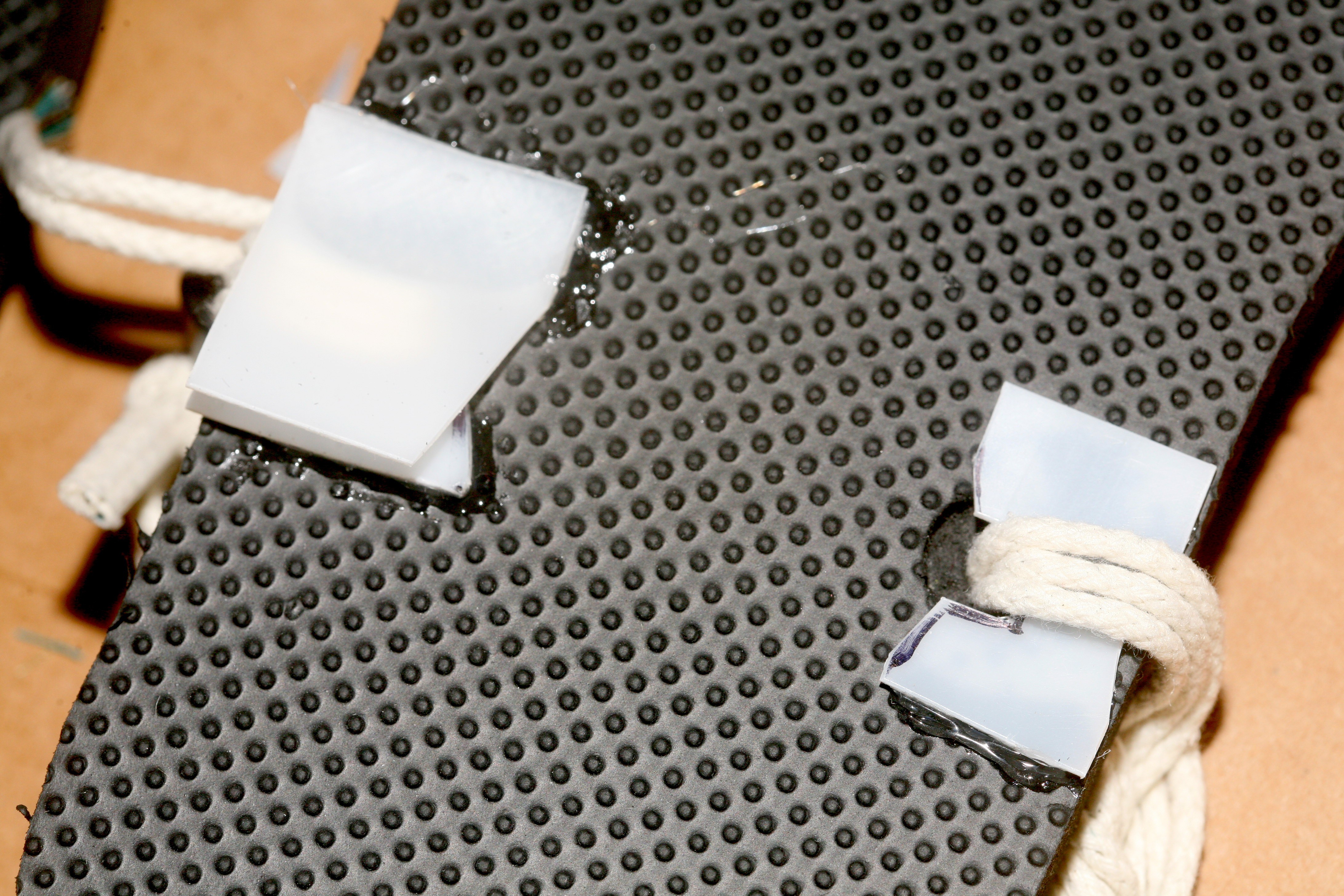

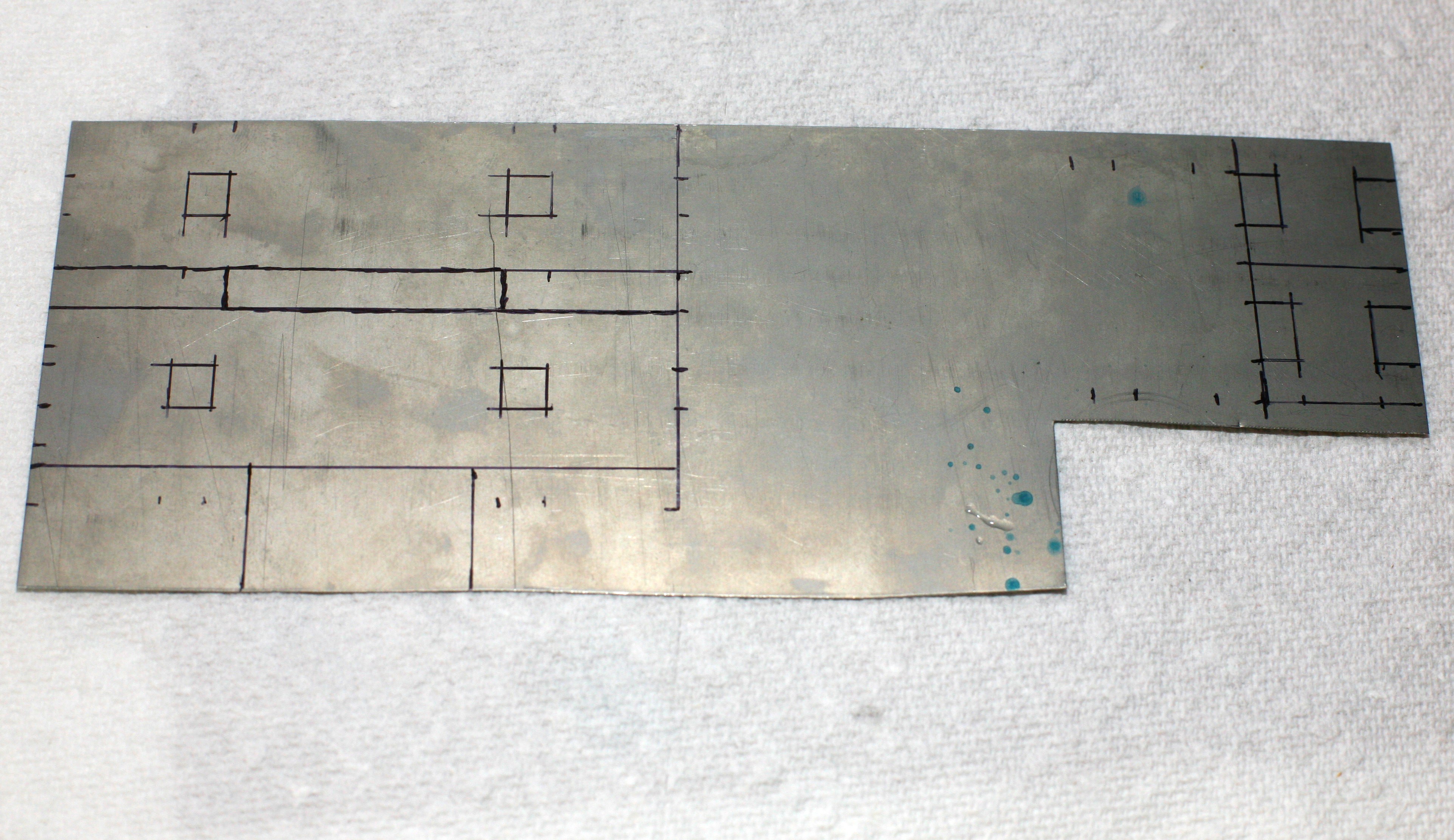

07/29/2018 at 05:31 • 0 commentsThe Target insoles on the straight Vibram worked but were quite thick. The next material was suede. $4 provided enough suede scrap from Hobbylobby to test on the Xeroshoes.

![]()

![]()

![]()

![]()

Whether or not it lasts, it looks better than any other sandal. There's also cork & vinyl. The 2 mile test revealed no problems. They might get away with no material in front & behind.

Sadly, browsing xeroshoes revealed they no longer sell the genesis & seem to be moving to traditional shoes.

-

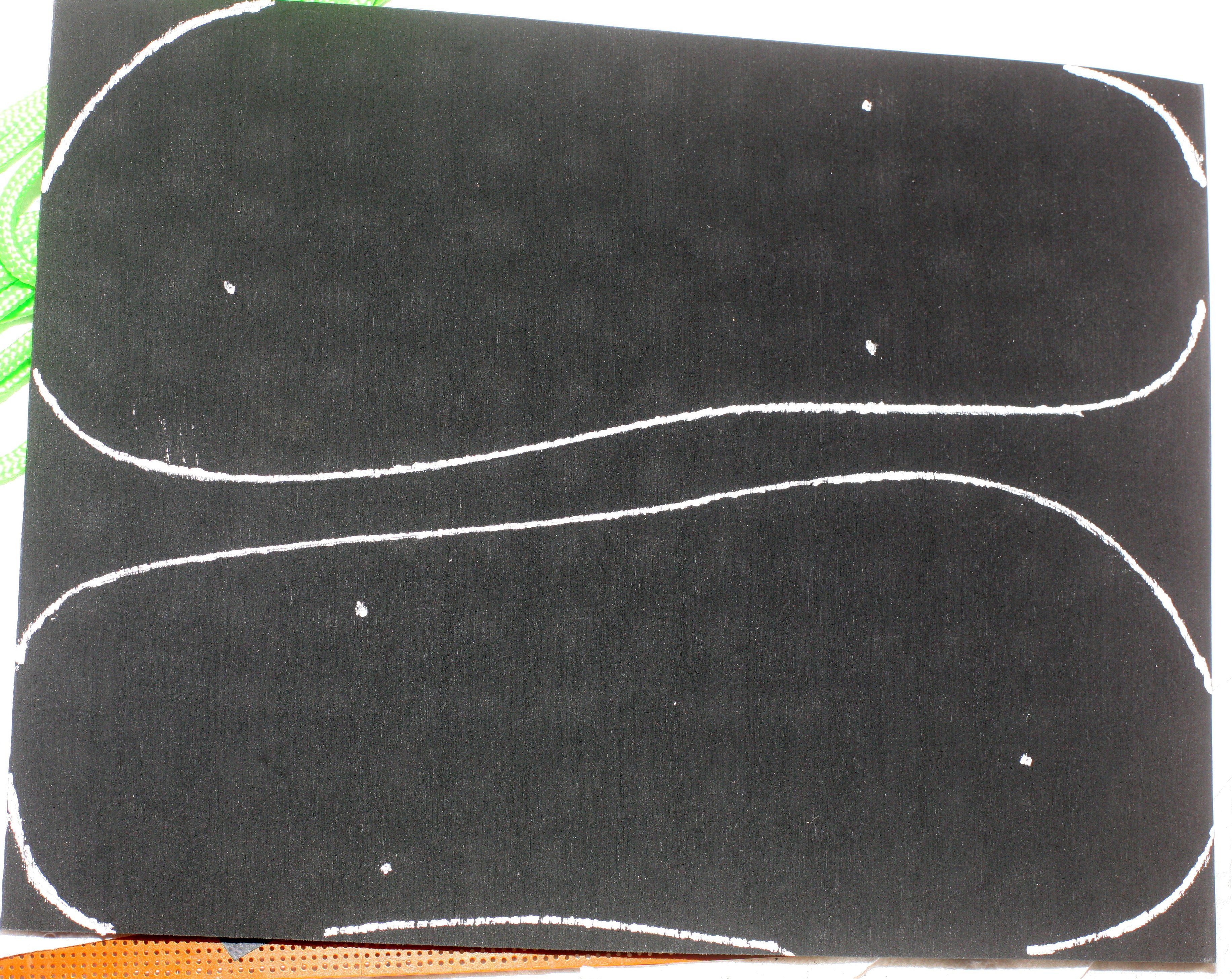

Xeroshoe DIY kit

07/23/2018 at 03:38 • 0 comments![]()

That was the medium 9"x11" sheet. The medium disappeared & the price has since increased.

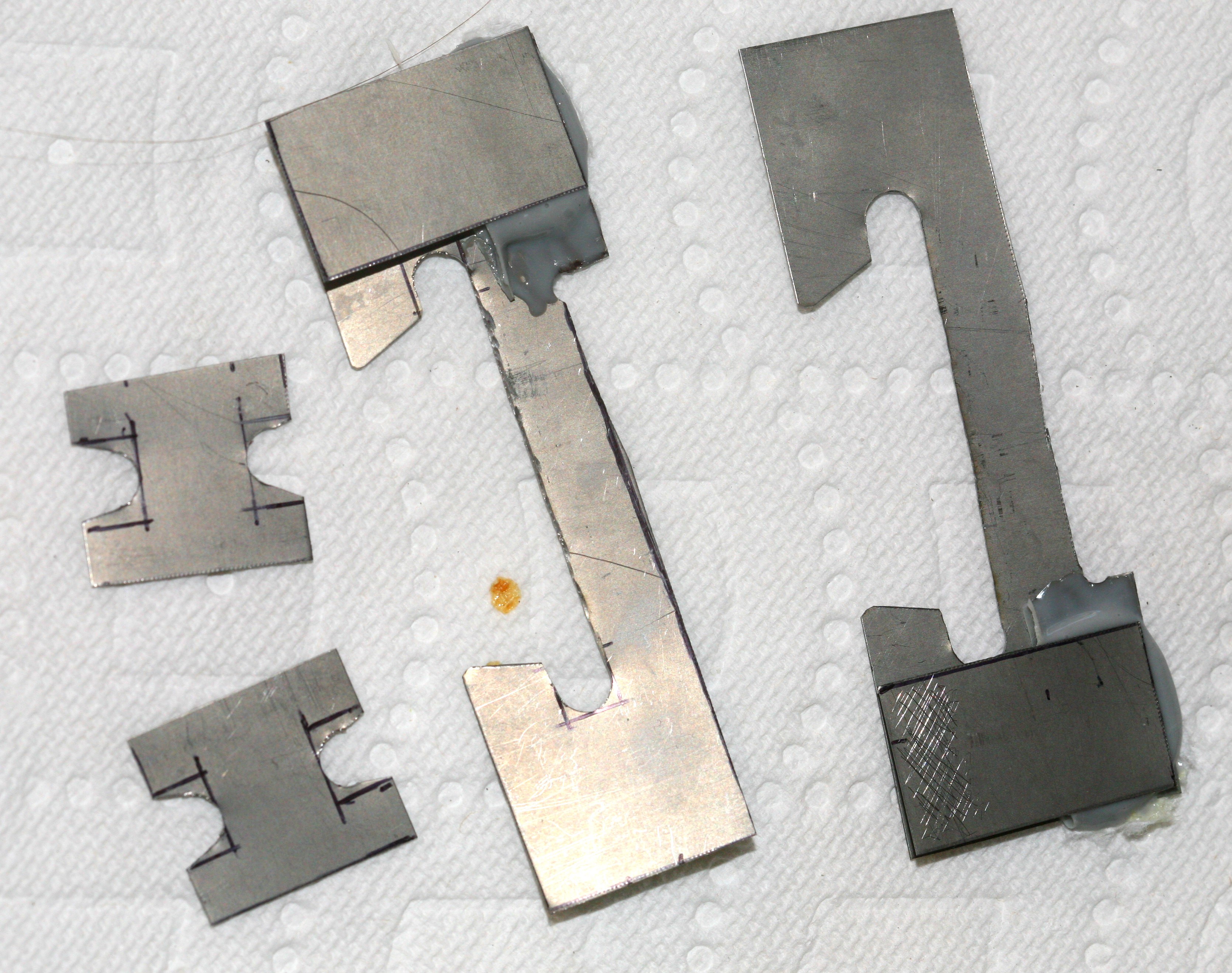

Drew whiteout markings from the mighty Walmart size 12.

![]()

Doubling up the included hole punch allowed it to punch suitable holes which could be trimmed with the knife.

![]()

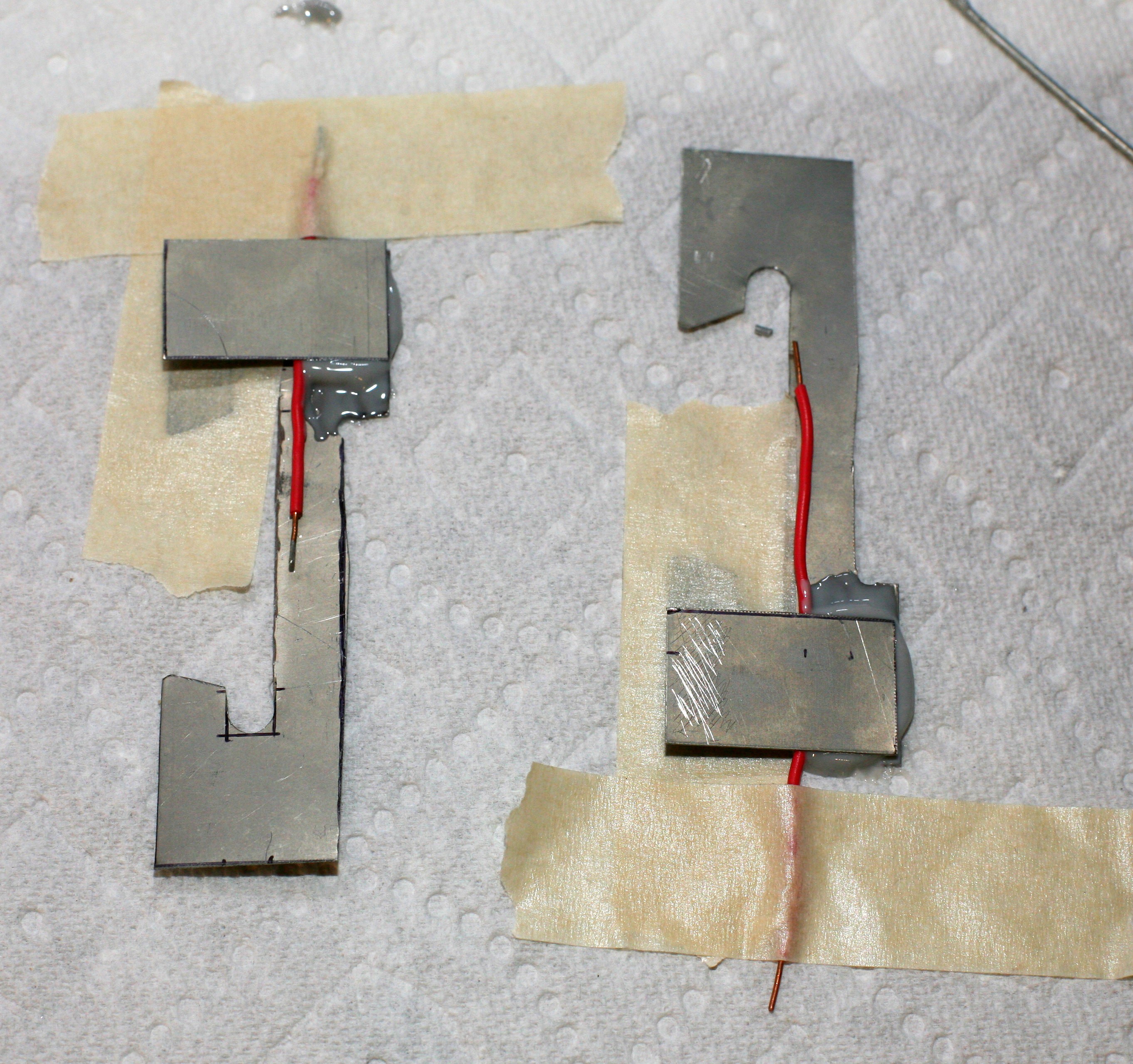

The lion kingdom's proven string, farsteners with aftermarket enlargement & mane hair.

![]()

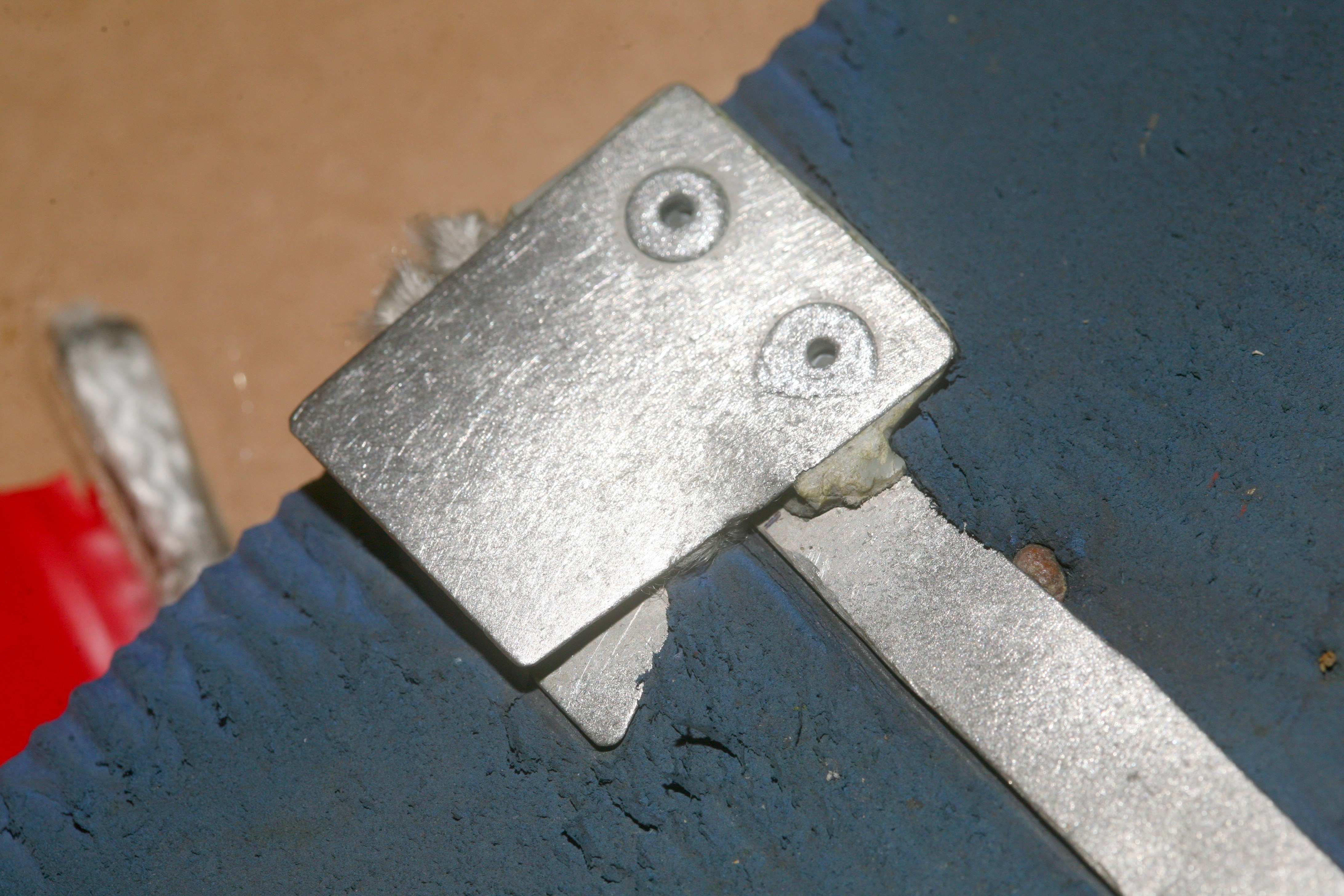

Either need a laser cutter to fabricate plastic parts or a desire to pay for stamped parts.

![]()

The hole punch was destroyed from hammering into concrete.

The 1st run ended just as badly as the genesis. The search for a less grippy coating continued.

Aquarium sealer: the material on the genesis heel strap, but it was actually more grippy.

E-6000 coating: smooth enough to do the job, but delaminated just like duct tape.

Target Insoles: The only thing that works, so far. They stay in place without adhesive, but holes for the strings. Weight of the toe section & thickness makes them want to flop around. They wear out fast. The fabric alone may be the key.

![]()

-

Sandal disintegration

07/21/2018 at 07:38 • 0 commentsThey started grinding up in a hurry, somewhere around when lions stepped up their HIIT to a 5:30 pace. Either hot weather or changing running form started going through them like Trump cabinet members. The maximum range dropped from 50 to 27 miles. The decision was made to burn the $31 for the cheapest source of suitable rubber, the Xeroshoes DIY kit & $10 for another set of farsteners. It was hoped the $1 sandals could be lightweight footwear for speed. All hope hinges on another material just as light but stronger, which Vibram soles aren't.

![]()

The Vibram cherry smelled like a car shop & had a tenacious camera strap upper side, the same as the genesises. A leather coating seemed certain. There's also temporarily adhering common insoles. The key is a temporary adhesive. Would need to continue experimenting with the genesises.

![]()

The patterned lower side.

-

Linguini laces

07/09/2018 at 04:09 • 0 comments![]()

8 strands in the toe plug, 12 strands in the heel. More about getting rid of leftover string than comfort, but they were the most comfortable. It can't make knots, so the toe plug needed a farstener. This too proved easier than a bowline, since the toe plug needs adjustment. Real pain to fabricate.

![]()

Tried adhering the reinforcers. Sadly, these soles died after only 35 miles & adhering made the reinforcers wear out faster. Because they were immobilized, all the rubbing was concentrated on the side facing the pavement. The 1/16 string also broke in a few places.

-

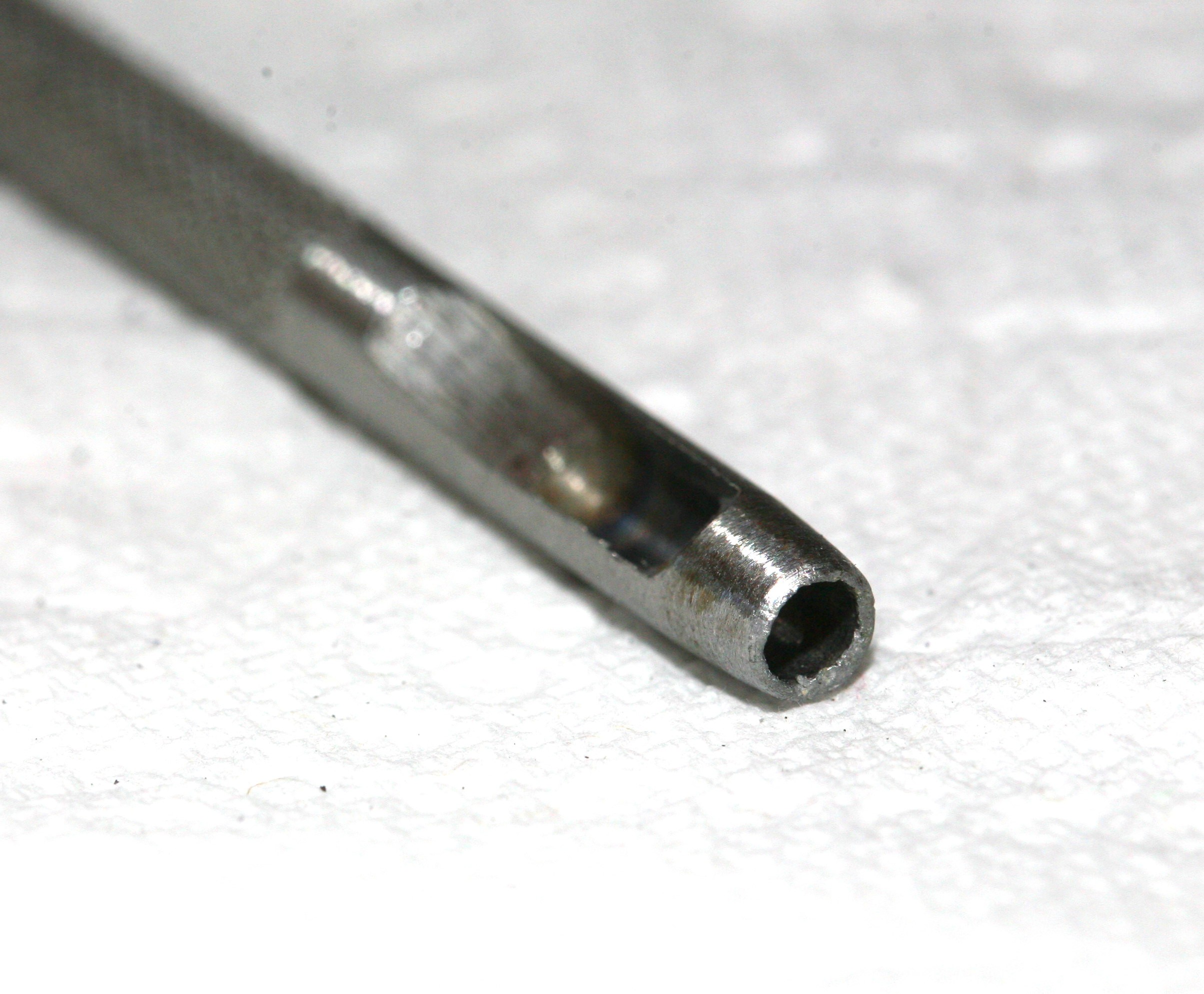

Death of titanium

07/07/2018 at 03:46 • 0 comments![]()

It showed a definite finite lifespan & the steel rivets were wearing down. The space required to build it without adhesives was problematic. They made a lot of clanking & felt like running on tin cans.

![]()

New plastic spacers using E6000 instead of hot glue worked quite well in testing.

![]()

The cord locks could be ground a hair wider to make the string bundles actually fit.

![]()

The lion accidentally got cotton instead of nylon & it was definitely more abrasive.

-

Titanium + rivets

06/28/2018 at 02:53 • 0 comments![]()

Then, somewhere between the micro apartment & Trader Joe was a piece of titanium that didn't come from a grumpy old man's bike. Because it doesn't bend, all the flexing broke it off the glue. The scratching didn't penetrate either, so the glue was ineffective. Thus the riveter returned.

![]()

The epoxy was an effective spacer. Just use something which cures faster than Loctite Metal.

![]()

Given the wear on the titanium, the rivet wear didn't look as bad as before.

-

The world's 1st titanium sandal

06/23/2018 at 05:05 • 0 comments![]()

![]()

It held up nicely, after 7 miles. It was like running on tin cans. The Loctite Metal did release near the flexing point, but it probably wasn't worse than hot glued plastic.

![]()

![]()

![]()

Fabrication involved a lot of drilling. Drilling holes bigger than 1/8" in titanium must be avoided. This process could probably be done with V cuts & grinding. Grinding titanium causes dramatic work hardening, but it hasn't been a problem for this application. That was all the titanium the lion kingdom can afford, for a long time.

Heat was the last remaneing problem with the laces. The resulting sweat would dry & attack the achilles tendon. After 11 miles in 90F, the 1/8" string solution didn't chafe anything. They could be any tightness. The farsteners were easy to adjust. Replaced the orange ones with black ones to make the toe plugs tighter.

-

Cord Farsteners

06/18/2018 at 05:35 • 0 comments![]()

If money was unlimited, the lion kingdom would have already bought every cord farstener in the world, but instead, it took a few months to finally discover them. There are a few problems. The easiest ones are at your local REI in the form of orange & black cord locks. The orange ones have holes 7.5mm across. The black ones have holes 8mm across. The orange ones have softer springs than the black ones, but are the smallest of all of them. Amazon.com has similar farsteners in the form of the mighty K238, after a much longer wait.The lion kingdom also had a 9mm holed one from a backpack & a 6mm holed one from a 1980's sleeping bag. The 1980's one had the strongest spring & represented the very 1st generation of cord locks. None are big enough to farsten bundles of 5/32" paracords, but the 8mm can farsten bundles of 6 1/8" nylon strings. The 7.5mm ones can only farsten 5 1/8" strings.

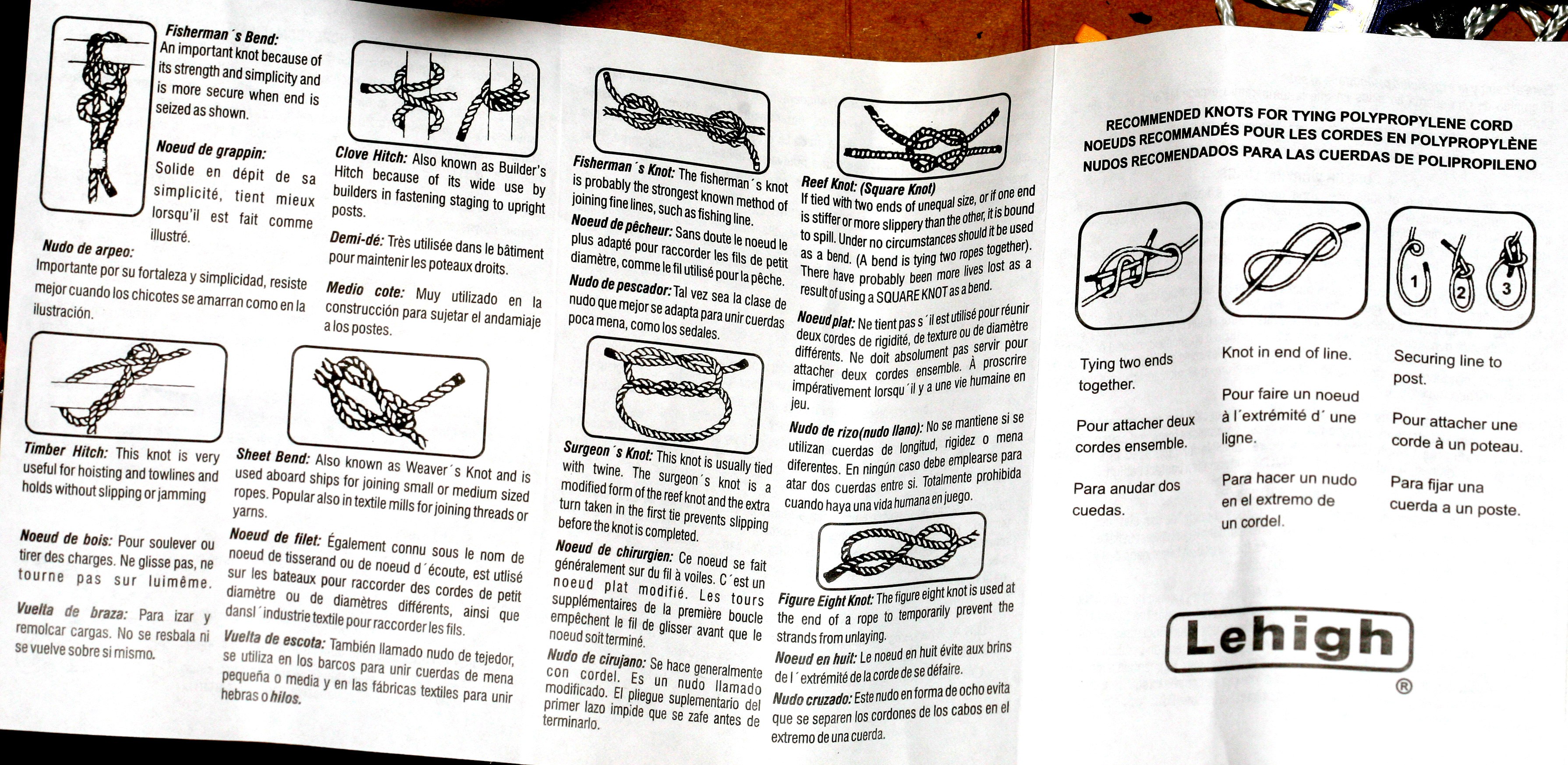

Fortunately, the 1/8" string bundles were the easiest on lion skin. They only didn't work with square knots. The polyolefin craft cord was much too abrasive. Suspect what works is larger bundles of loosely packed string. The key is to pass a single bundle of string around the paw instead of passing a single string multiple times around the paw, so it can be adjusted.

![]()

The easiest string on lion paws.

![]()

It came with a handy knot guide.

![]()

![]()

Your biggest ally in this part of the adventure is the clamp. The 6 heel strands can't be installed without it.

![]()

The toe strap used 20" of double bundle with a bowline for the toe plug. The heel strap used 34" of triple bundle. 6 heel strings went through a black farstener. 3 heel strings + 2 toe strings went through an orange farstener.

![]()

They worked quite well, after 7 miles. 3 were fast. They made slight adjustments as easy as dialing it in. Though they couldn't get as tight as knots, they didn't experience any perceptible loosening.

-

Alternative pieces

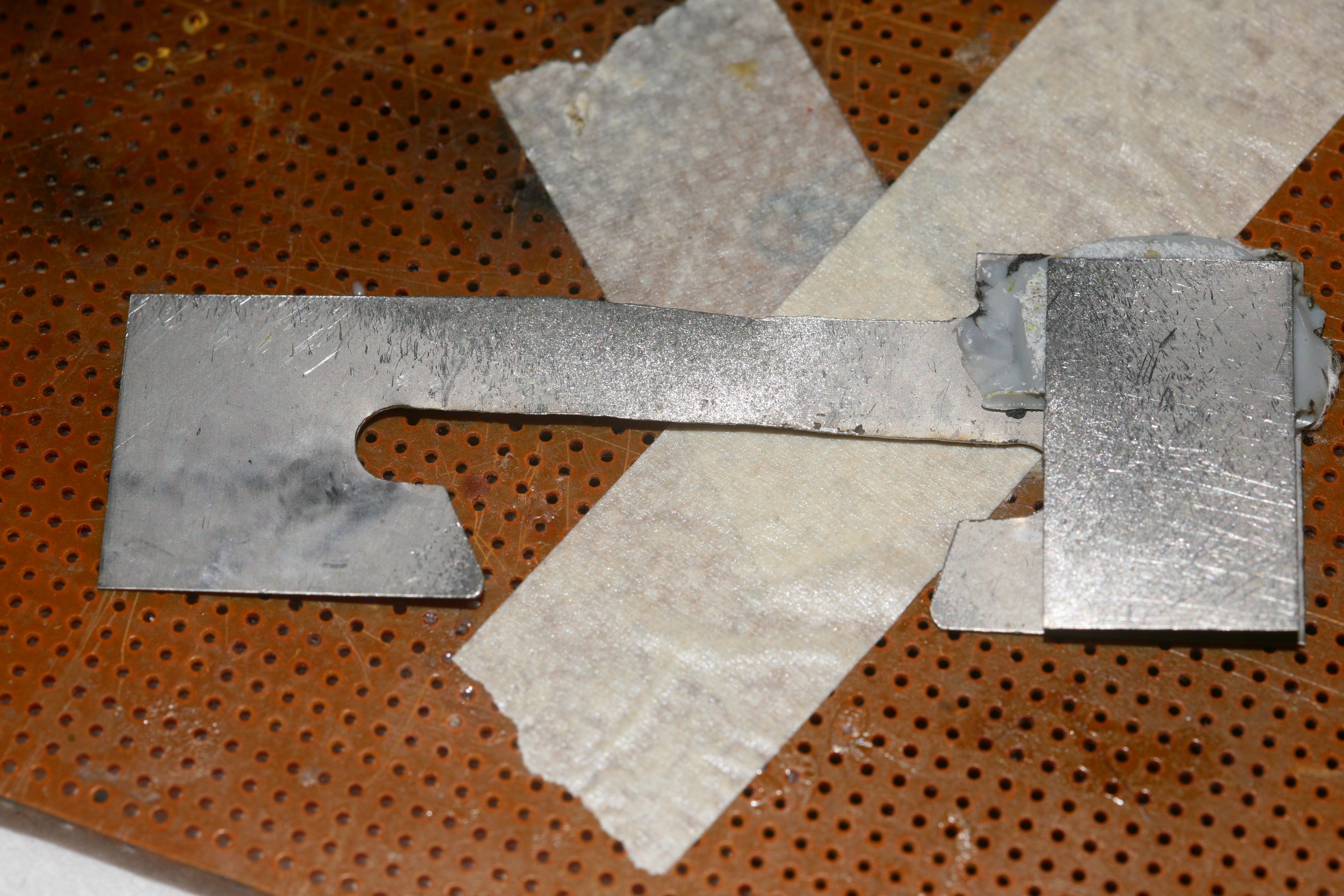

06/16/2018 at 23:11 • 0 comments![]()

Tried some alternative parts to increase the amount of exposed rubber, reduce the amount of material used & allow them to be installed after lacing. Besides taking a lot longer to fabricate, the heel change made no difference in the amount of material consumed & they can't be installed after lacing anyways. The toe change was still effective & there was definitely less feeling of running on plastic.

Tried polyolefin craft cord without getting any improvement in the chafing. Bedrock Cairn's seem to have the key to 100 mile range & they're now in retail.

-

Introducing titanium

06/14/2018 at 05:35 • 0 comments10 mil steel was well & truly worthless in the toe plug.

![]()

The decision was made to introduce the 1st titanium sample in the toe plug.

![]()

It was 12 mil, 6Al, 4V. Much harder to drill than steel & the grinder couldn't expand the hole, but the drill didn't shred it & the grinder managed to grind off the burrs.

![]()

12 miles later, it was about as pulverized as plastic. Suspect 20 mil will be more effective than any other material, but nothing will be indestructible. The mane source of titanium for consumers is titaniumjoe.com.

The farstener situation was the mane issue with the heel, so adhesives showed the most promise.

![]()

Loctite metal on metal ground with the grinding wheel showed the best results.

![]()

It was actually stronger than the hot glue which served for hundreds of miles. It can be applied after the laces & built into a spacer. The mane problem is the 12 hour cure time.

lion mclionhead

lion mclionhead