-

Metal prototype 1

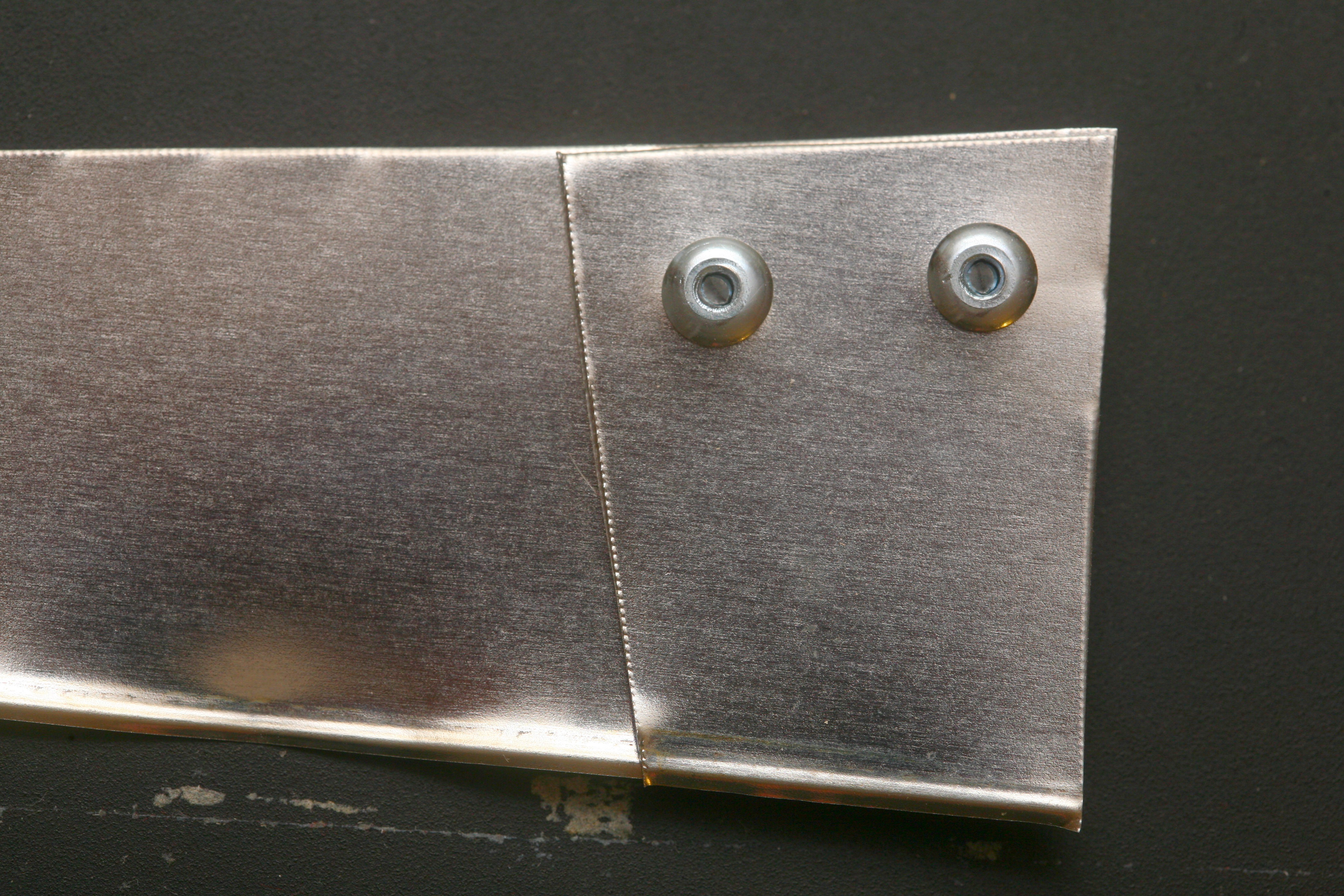

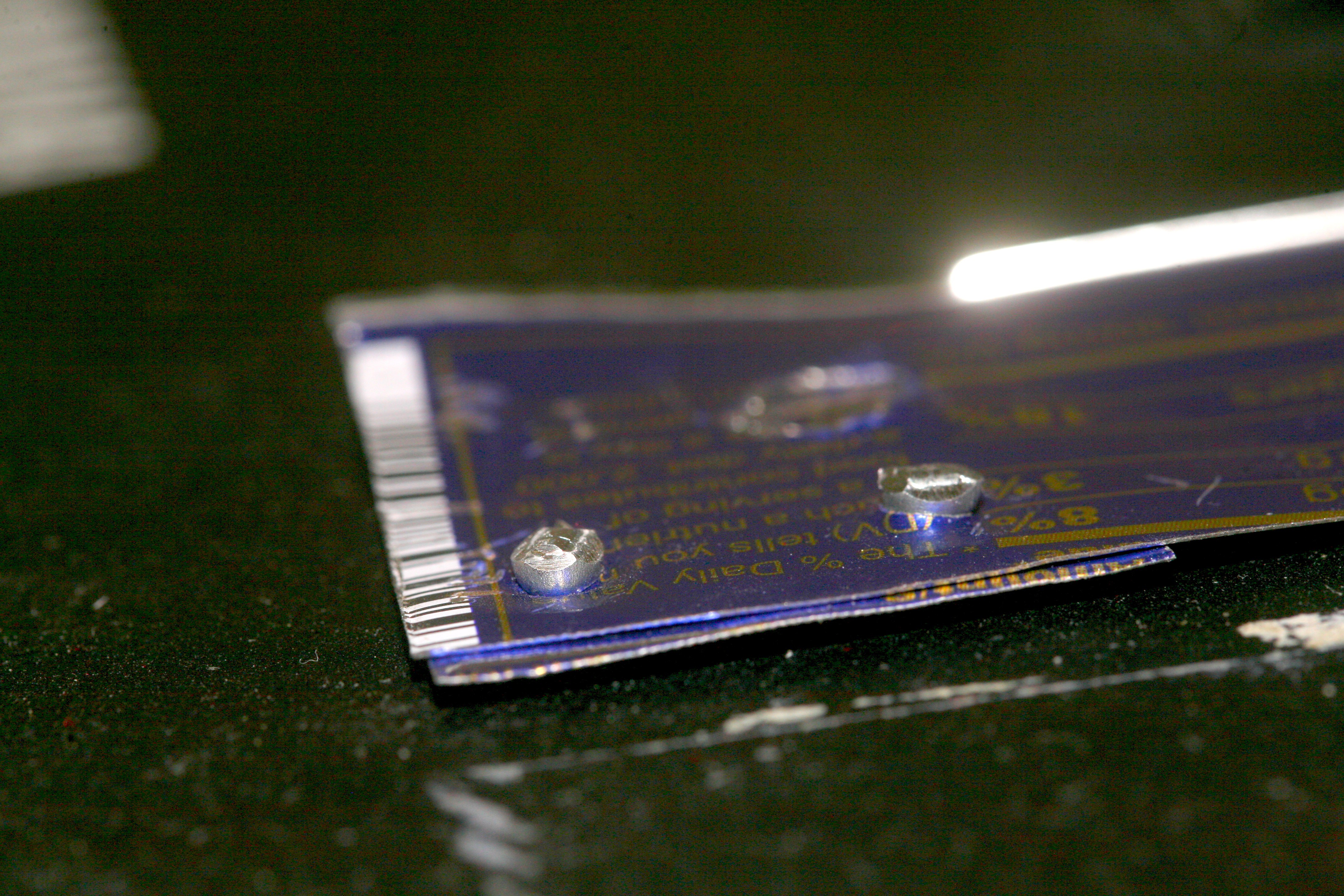

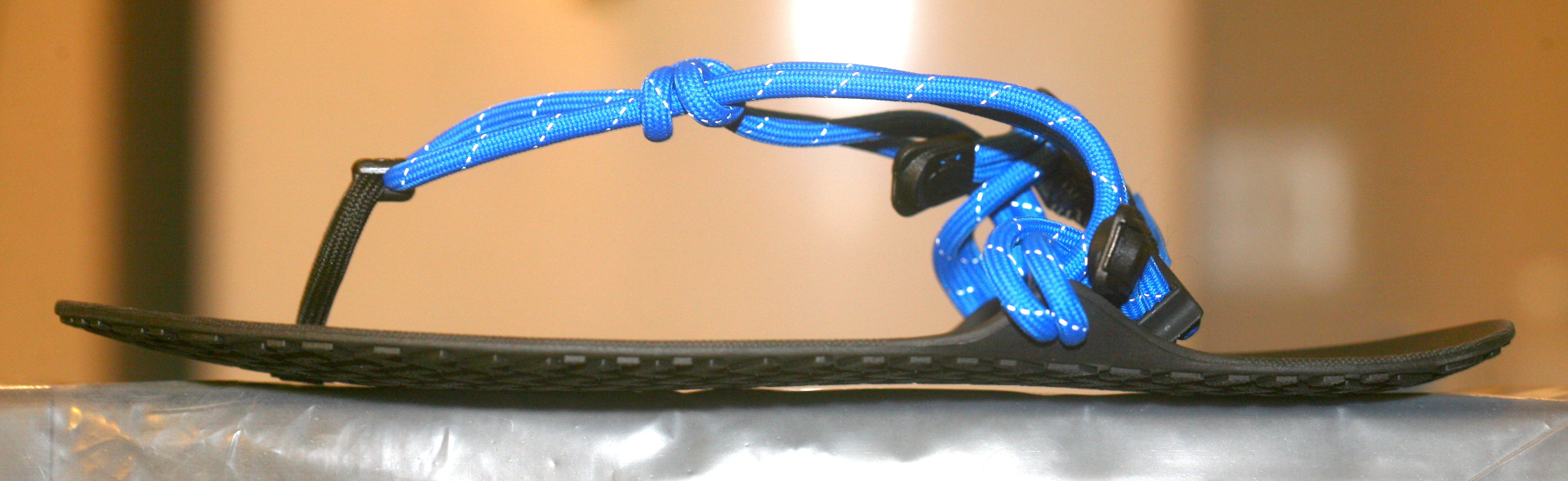

06/10/2018 at 07:15 • 0 commentsAnother $30 in the furnace & an assortment of welding alternatives arrived, along with some 10 mil steel. Actually thought it was tin & ate 12oz of cookies to obtain it, only to find out it was steel. The 2 farsteners of choice were pop rivets & staples. The staples looked horrendous while the pop rivets gave the aircraft look lions wanted.

![]()

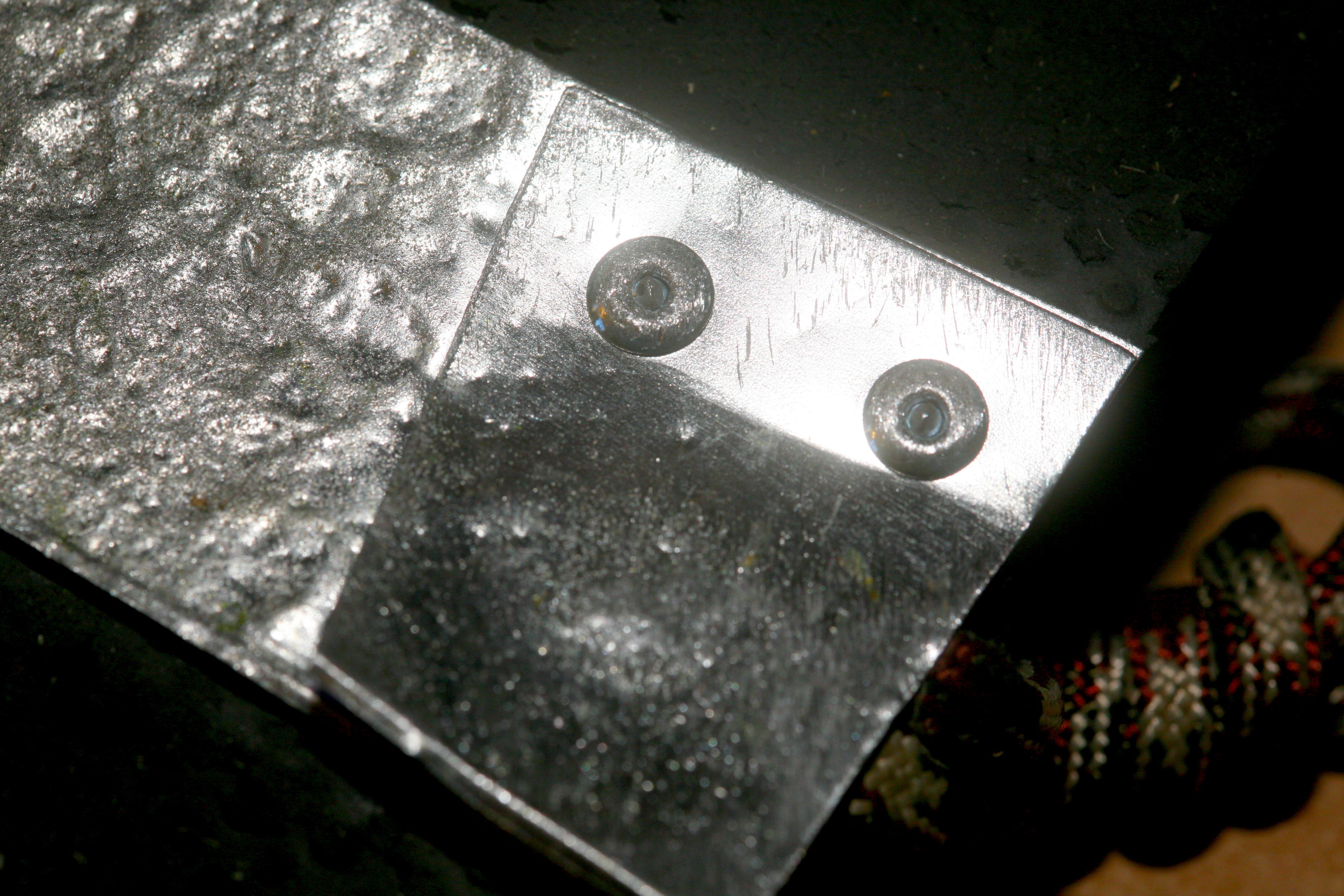

They just created horrendous plugs which had to be painstakingly machined down.

![]()

![]()

The staples were much easier to install & were flatter.

Drilling the 1/4" & 5/16" holes in 10mil steel also was problematic. They either need to be ground or thicker metal is needed.

![]()

The final problem was the need for a spacer. The only reason the laces fit is because 10 mil steel can bend, while titanium can't. There's no way to adjust the laces, once they're installed. Thicker metal with rounded edges is a must. Metal may not be worth it. Teflon can go at least 50 miles.

![]()

![]()

7 miles later, the steel looked worse than teflon after 50 miles & the rivets were also pretty chewed. It was a pretty convincing case for teflon & all its limitations.

-

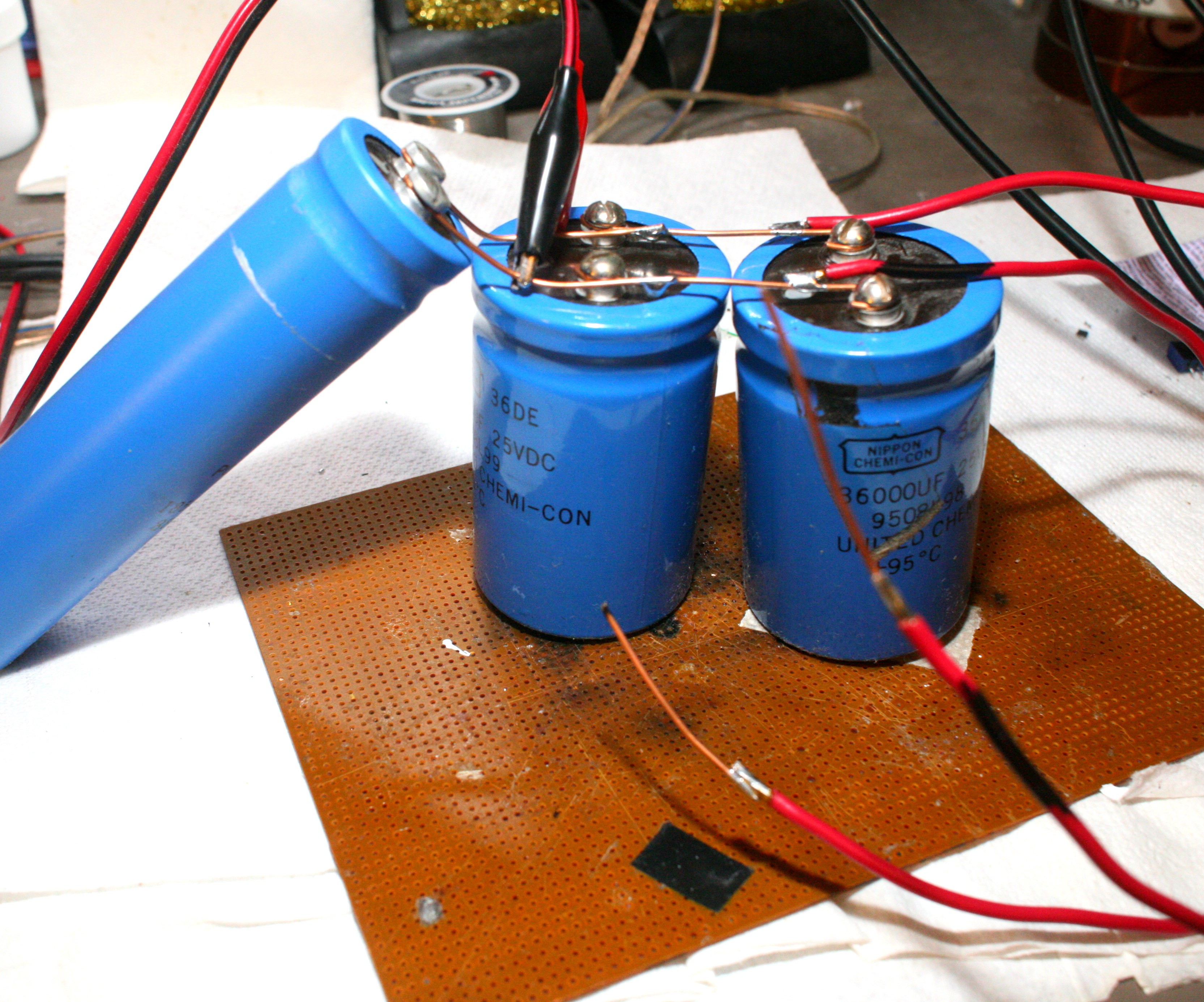

Failed spot welder

05/31/2018 at 05:40 • 0 comments![]()

Put 25V into 90000uF, but unlike the goo tube videos, it didn't weld anything but the electrodes to the material. They just show thin battery tabs being welded, but not 1/32" tin. The energy is probably being dissipated in the contact resistance. It would need a very expensive switch to work.

Why do you need a spot welder to make sandals? The best way to join titanium is welding. Lacking any money, the most promising method is riveting.

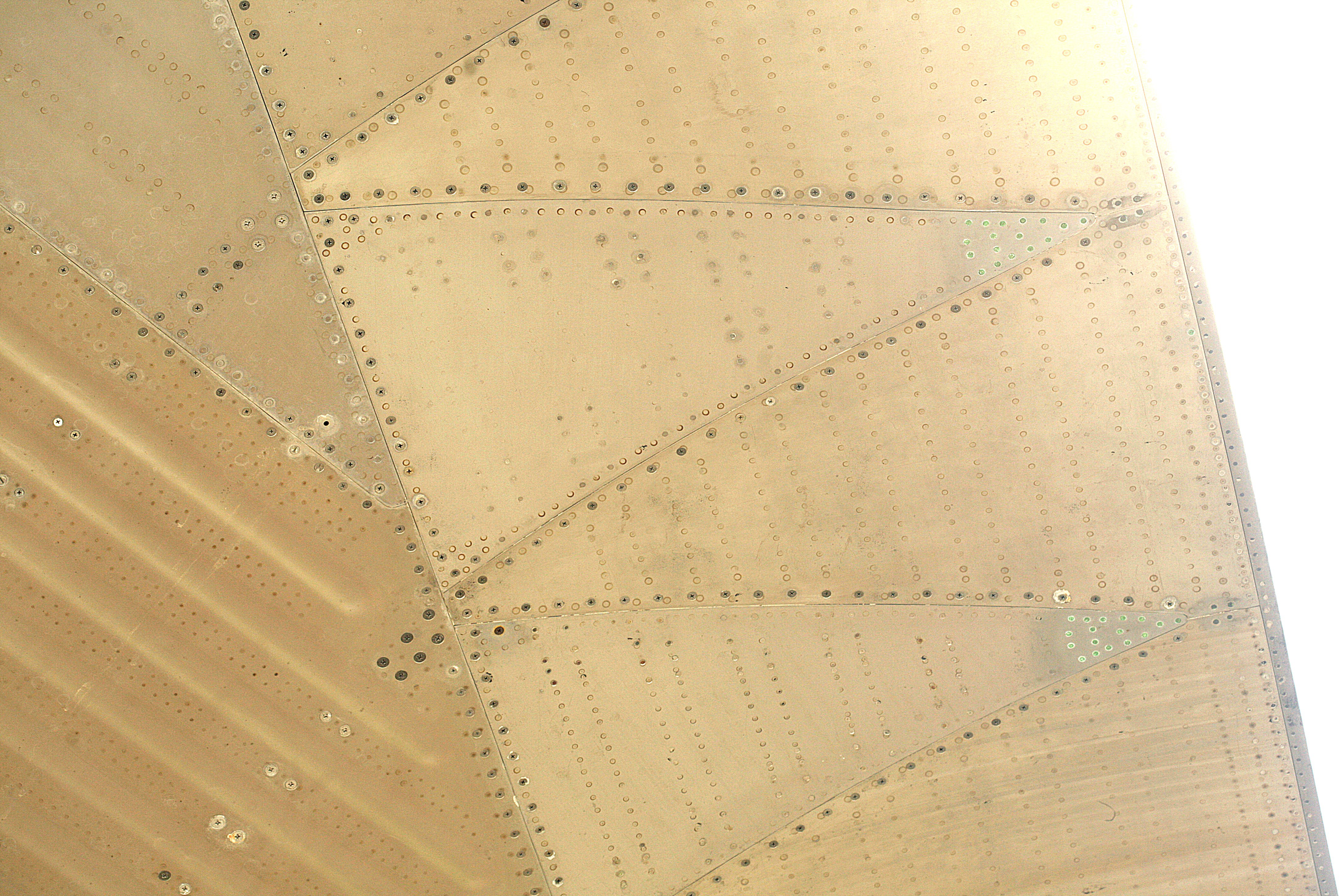

![]()

The only titanium a lion ever saw in real life was a static A-12 display in LA. It was entirely bolted. Not sure why it's covered in indentations. They might have added strength.

![]()

![]()

Progress with teflon mockups continues to slow, as the mockups last ever longer. Better knowledge of paw wear evolved it into a wedge shape & just a small tab glued over the wear area. The glue lasts longer than folded teflon.

-

xeroshoe attempt #3

05/24/2018 at 02:52 • 0 commentsMight have to bite the bullet & sew something. Kevlar strap laces in the rear, with velcro adjustments, & a common string lace in front with a knot might do it. The wide toe strap in the $125 version doesn't work with lions.

![]()

Any new design requires simultaneously continuing to build the old design, since they're consumable & lions have to get around.

![]()

The old design changed to E6000 adhered shoelace instead of nylon washers for reinforcement. They worked but were pointless & expensive.

![]()

Multiple strands of common nylon string have been easiest on the paws, can be tight enough to not slide down, so worth continuing to try despite being very hard to adjust. Really need a way to eliminate knots.

![]()

Randy Kreill revealed in a video that he wore socks for most of his sandal experience. Another swing at the xeroshoes with toesocks managed to go 2 miles without causing blisters, but left them still pretty raw. Going with common tube socks caused irritation from the toe post.

-

diy is dead

05/20/2018 at 10:04 • 0 comments![]()

diyfootwear, long a source of rubber, went away a few weeks ago. Really, how long can you go selling just rubber & shoelaces?

![]()

Pulvarized after many miles. Running partially barefoot isn't bad. Walking is problematic. While no titanium design has emerged, there's the idea of wrapping the laces in kevlar.

-

Titanium dreams

05/19/2018 at 05:14 • 0 comments![]()

Added 2 lugs to the existing teflon things which keep the shoelace from tearing through the foam. The extra lugs were hot glued down, so the laces could still be adjusted & the whole thing could be undone. This lasts much longer than the exposed laces, but still has limited life near the bend. Paracord has proven a bit more chafing while also harder to keep in a knot. The next material will be fluorescent green polypropylene recommended by xeroshoe guy, but with the new protection, it's unlikely the paracord will ever be used up.

This might finally be an application for titanium. A sandal with titanium bits just where the teflon is currently used would almost be commercially viable. While some shoes are marketed with the word titanium, it's not actually used in any shoe, but a sandal is a practical use for it. Glow in the dark rope was a fiasco, but imagine the look on the other runner's faces when they see a lion with TITANIUM sandals. Even better, titanium sandals & air force shirt.

-

Lion running form issues

05/05/2018 at 21:11 • 0 commentsSuspect if the lion kingdom complained enough about the xeroshoe, they would just give a refund in exchange for shutting up. Anyways, gave them another go, this time not relying on the length of untensioned shock cord, but the fully tensioned length. This was quite tight, but got them to fit more naturally. Added duct tape to take the bite off some of the rubber, but after only .6 miles, got blisters in another place, from the heel lugs.

It seems to be quite problematic material which requires perfection to not cause blisters & weighs a lot more than foam. Based on the wear patterns, lions probably scrape on landing instead of pawing back fully or have some other form issue. Nothing jumps out on video. Lions appear to have a better form than any human.

![]()

Why lions need to make their own shoes.

Whacked in another common shoelace made of polyester & it held up far longer than any other material before eventually shredding. It was expensive.

![]()

Broke through the 4th pair around 47 miles. They're breaking through pretty consistently around 50 miles & the left paw seems to always break through 1st. It's not the end of the world to end up partially barefoot during a run.

-

Don't wear it. Take it apart.

05/04/2018 at 02:35 • 0 comments![]()

![]()

There was hope bits of the Xeroshoes could be repurposed. The plastic shoelace terminators proved merely decoration. Those silicone coated heel straps proved just as difficult to fit as the stock Xeros. Their heft makes them want to slide down & they're too wide.

![]()

The 3rd pair of sandals was in men's size & died after 53 miles. The right paw penetrated through. Did the 1st complete interval workout in those & it was like cutting butter. No animal can catch a lion in his huaraches.

Finally tried paracord. It was supposed to be 100% nylon but it too shredded on the underside. Only shoelaces have lasted. Fortunately, a plan to reuse the Xeroshoes soles finally started emerging, involving either glueing fake leather or duct tape on the camera rubber.

-

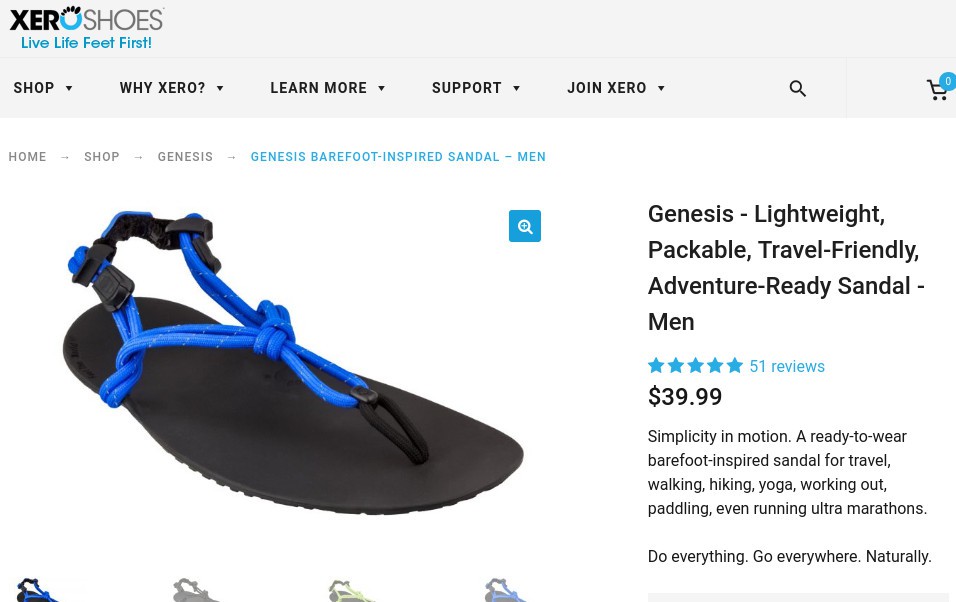

1st run with the Xeroshoe Genesis

04/29/2018 at 04:18 • 0 commentsThey're really the 1st minimal sandals cheap enough for any kind of mass adoption. Everything previous was ridiculous or too minimal to justify the price. The 1st surprise was how heavy they were. They're at least as heavy as the Asics Hyperspeeds & definitely heavier than optimized racing flats, so probably more suitable for a long trail run than going fast.

![]()

![]()

Sole thickness including the tread is 4.6mm. Without the tread, it's 3.3mm.

![]()

Thickness increases to a solid 4.8mm for the strap lugs, so they made some effort to keep them from breaking off.

![]()

The heel strap is common nylon with just a smidge of silicone. The lace has a hair of elasticity to it, but isn't bungy cord.

![]()

Contract manufactured in China, so if there's any reason Chinese investors are driving houses to 8 figures, blame their $40 sandals.

![]()

The upper pattern.

![]()

The toe plug seems to be string cast in a plastic mold.

![]()

Heavily rounded, to keep the toe flap from catching & to keep your heel from sliding back during ascents.

The 1st run was a 10 mile disaster. The right paw never did fit right, while the left paw managed to fit. Got blisters from both toe plugs & blisters under both paws, very symmetrically. They managed to hit 10mph. The problem is the toe plugs are sideways, which makes it equivalent to 5/16" of material going through. The paw facing rubber is very aggressive on your paws. They're trying a bit too hard to keep your feet from sliding around.

![]()

![]()

-

19 minutes at 7m18s per mile

04/26/2018 at 05:36 • 0 commentsThey're definitely not as slow as feared.

-

The $50 sandal

04/23/2018 at 19:58 • 0 commentsBack to men's soles, the wider sole & leaving off the washers made no difference in the rope wear. The only material that didn't cause blisters & didn't wear out were $3 Walmart shoelaces. They seemed to be 100% nylon. The next idea would have been paracord, which requires a 1 week wait & more money.

![]()

After burning $25 on experiments, the lion kingdom decided to invest in a $50 sandal. With shipping & taxes, it's a $50 sandal, but better than lunasandals, bedrocksandals, or pradas. The lion kingdom has since remembered the horror of 1st seeing these methuselahs of sandals, some reaching $200. Lions ruled out marriage over 30 years ago, because of the need to buy a wife overpriced footwear.

Yet here we are, now bankrolling overpriced footwear so a mane can feel itself flopping in the wind. After much experimentation, it's surprisingly hard to make a sandal that works. Tracking down those connectors, strings, & rubber sheets takes some research. Everything has to be sized through trial, error, & blisters.

Besides informing further experiments, it's not a solution because commercial footwear constantly has to be discontinued. According to the internet, the extra flaps for the heel quickly break off. The only solution is really going to be the lion kingdom's own dual lace system with 100% nylon & rubber soles.

lion mclionhead

lion mclionhead