Construction:

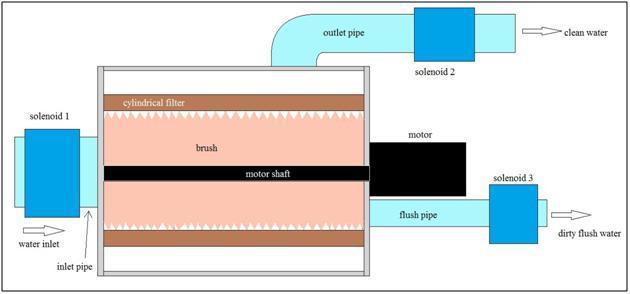

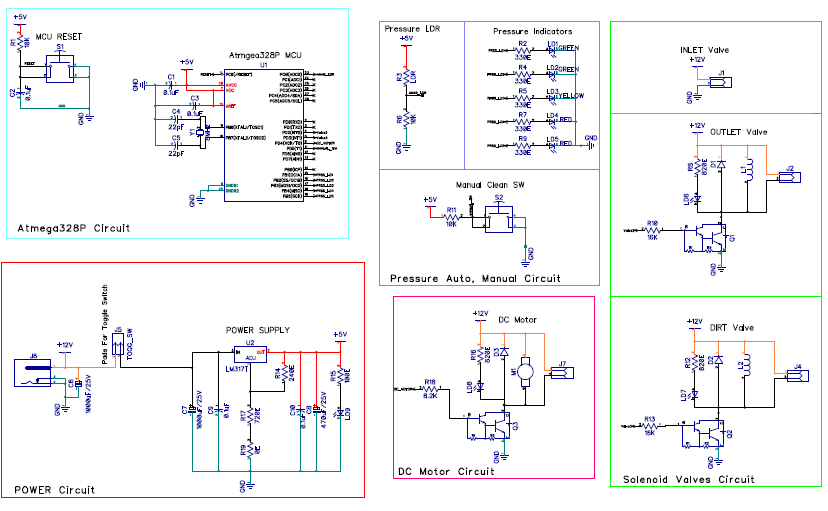

- As shown in Image Solenoid valve 1 will be connected to the INLET of the filter.

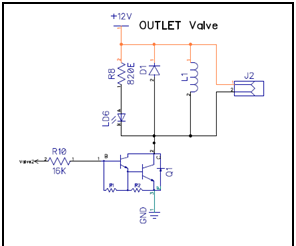

- Valve 2 is connected to the OUTPUT side as shown in figure.

- Valve 3 is to flush out all the dirt/contaminates.

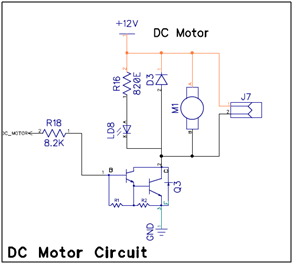

- A cleaning element (a brush) that is covering the whole length of the filter will be connected to a DC motor.

- Two pressure sensors installed on INLET and OUTLET side of the filter will continuously monitor pressure inside the filter chamber.

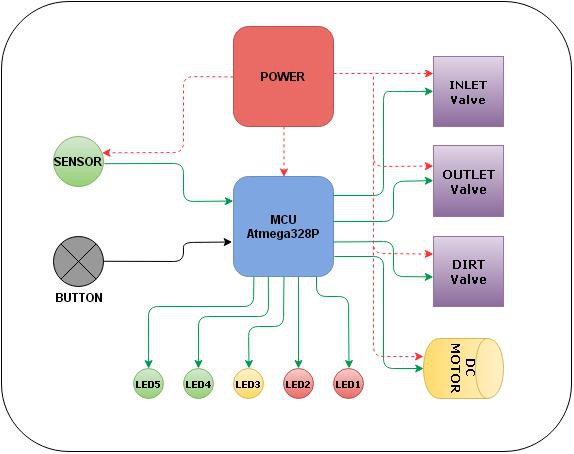

- Output of these two pressure sensor is given to the Microcontroller (In this case, to the Atmega328P) through signal conditioning.

- On defined pressure difference condition, Microcontroller will turn ON, DC motor and solenoid valves.

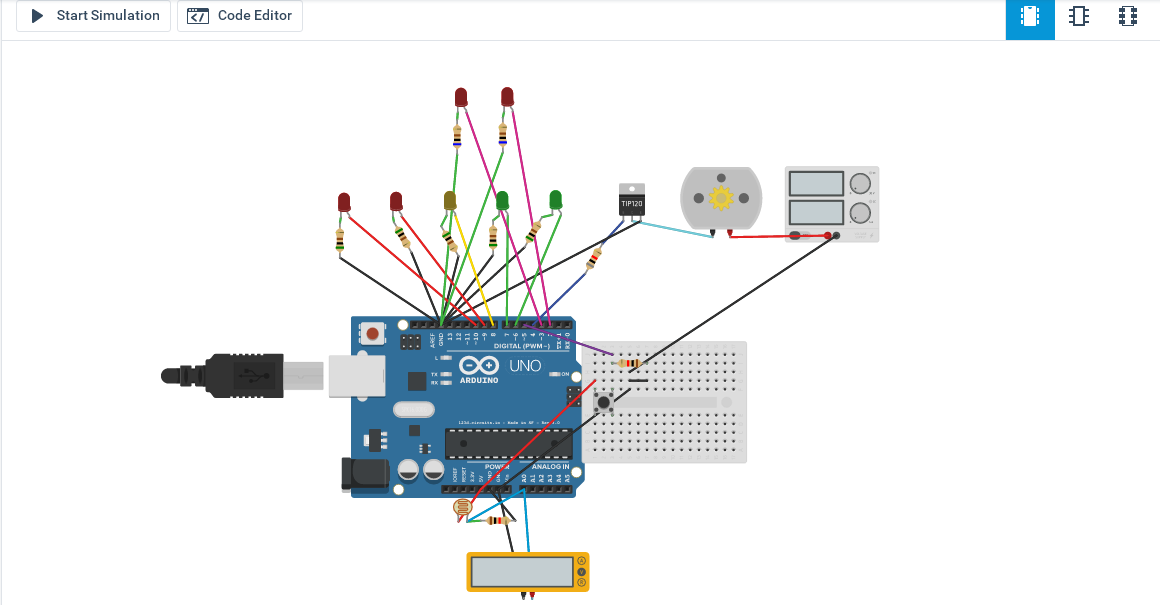

- Note: Initially, Instead of pressure sensor we are going to demonstrate the system by using LDR, in which by varying resistance of LDR will correspond to pressure sensor.

Working:

- The liquid or water flowing from the filter will clog the filter eventually, due to contaminants / dirt, which will lead to pressure difference.

- At some point, where OUTLET pressure is higher than the INLET side.

- When a preset value of pressure difference is reached the microcontroller will start the cleaning cycle.

- During cleaning the output side valve will close and the flush line valve will open, simultaneously the motor will start rotating the brush thereby cleaning the filter from inside.

- The water flowing from input will carry the dirt along with it into the flush line.

- After running this cycle for preset time the regular flow will be started with water flowing from a clean filter.

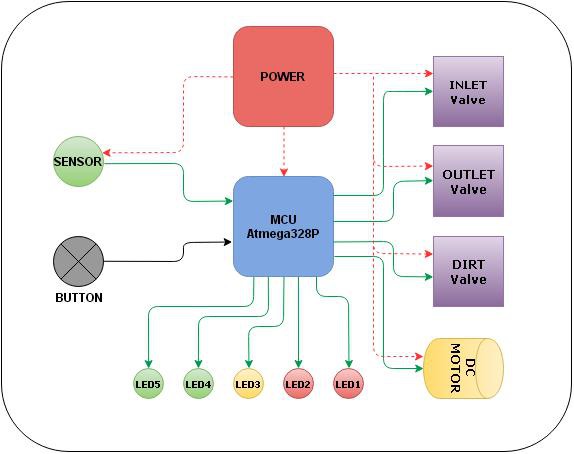

Requirements for the projects are pretty straight-forward.

- Continuously Monitor Sensors.

- Control the Solenoid Valves [INLET,OUTLET & DIRT Flush].

- Control the DC Motor.

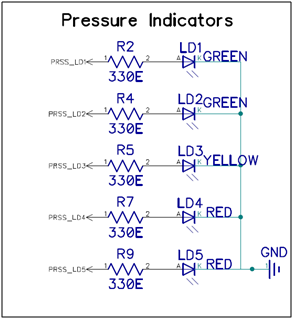

- Pressure indicator LEDs.

- Button to Manually Clean the chamber.

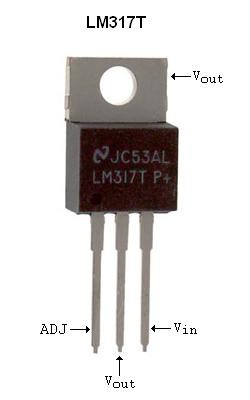

- And of-course Power Supply, with enough current rating to drive the Solenoid Valves and DC Motor.

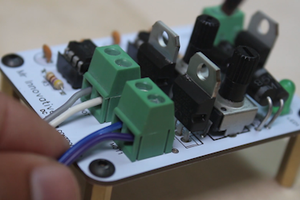

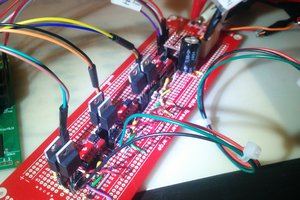

Block Diagram: Electronics Control Unit:

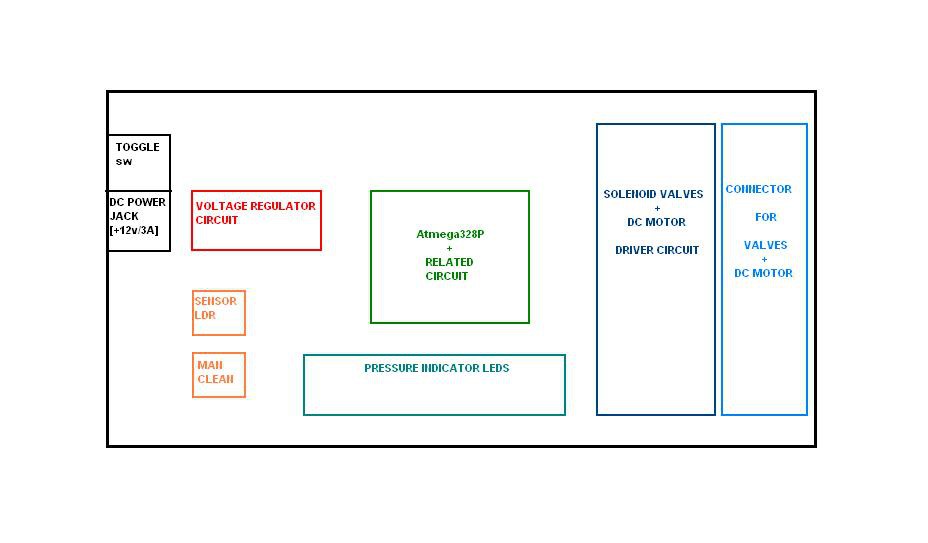

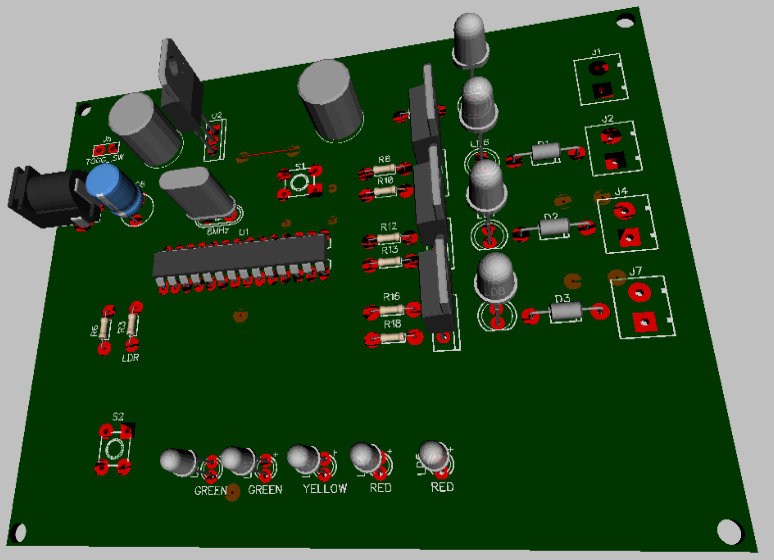

Hardware Look-Up:

| Component | Quantity | Power Rating |

| Solenoid Valve (8 mBar) | 3 | +12V / 5Watts. |

| DC Motor (30 RPM) | 1 | +12V / 400mA |

| LEDs (3 mm) | 5 | 5V / 20mA |

Working - System level

System works in two modes.- Idle Mode

- Clean Mode

- Idle mode operation, that is when pressure inside the chamber is below threshold value, system functions normally such a that.

- INLET Valve = ON

- OUTLET Valve = ON

- DIRT flush Valve = OFF

- DC Motor = OFF

- Clean mode gets activated when the pressure inside the chamber passes over threshold value, in which case system function as below.

- INLET Valve = ON

- OUTLET Valve = OFF

- DIRT Flush Valve = ON

- DC Motor = ON

- System stays in the Clean mode, until the pressure inside the chamber drops below the threshold level, then re-enters into the Idle mode.

Working - Bits and Bytes level:

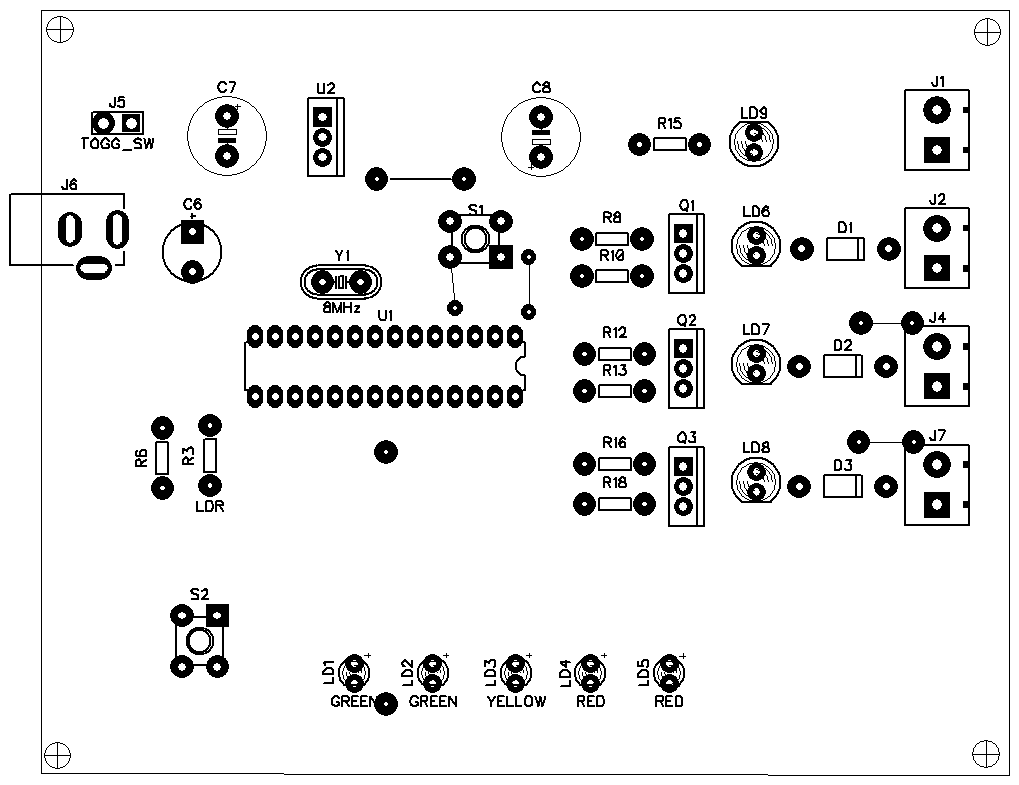

- LDR used to simulate pressure sensor, changes resistance, depending upon amount of light falling on it.

- LDR is connected to one of the ADC analog pins of MCU, where MCU carry out the Analog - digital conversion.

- Five LEDs are used for visualization purpose, indicating current pressure level inside.

- Button is provided to manually clean the filter. On Button press, systems goes into the Clean Mode.

NOTE:

This Project Will have Two Stages,

Stage 1 - We are using Light Dependent Resistor.

Stage 2 - We are going to use Actual pressure sensors.

As stated above, To carry-out demonstration of the system, We are using LDR as to simulate the pressure sensor.

So, High Pressure resistance = LDR Dark Resistance.

Amar Potdar

Amar Potdar

Mrinnovative

Mrinnovative

Jarrod

Jarrod

ridonkulus

ridonkulus

Marcos

Marcos

In only 30 words, how about we investigate the significant effect of cleaning: From mess free spaces cultivating mental clearness to disinfected surfaces defending wellbeing, cleanliness rejuvenates both climate and attitudehttps://thecleaningeffect.com/