-

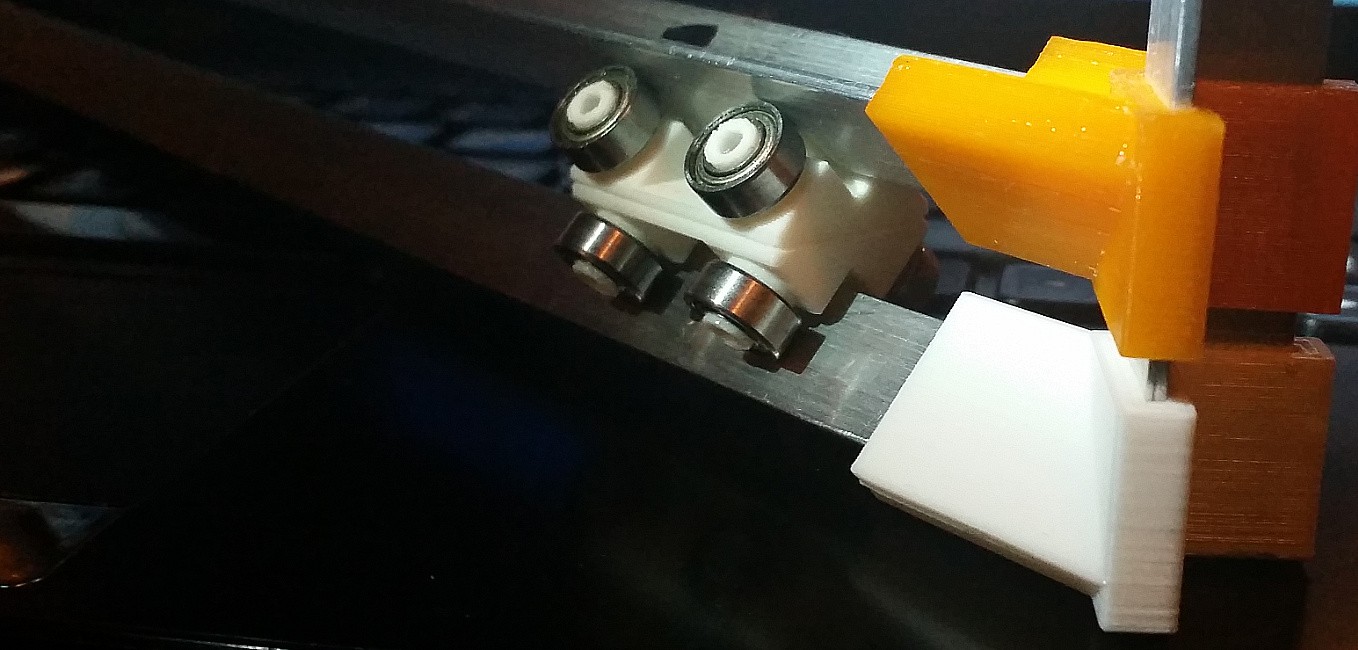

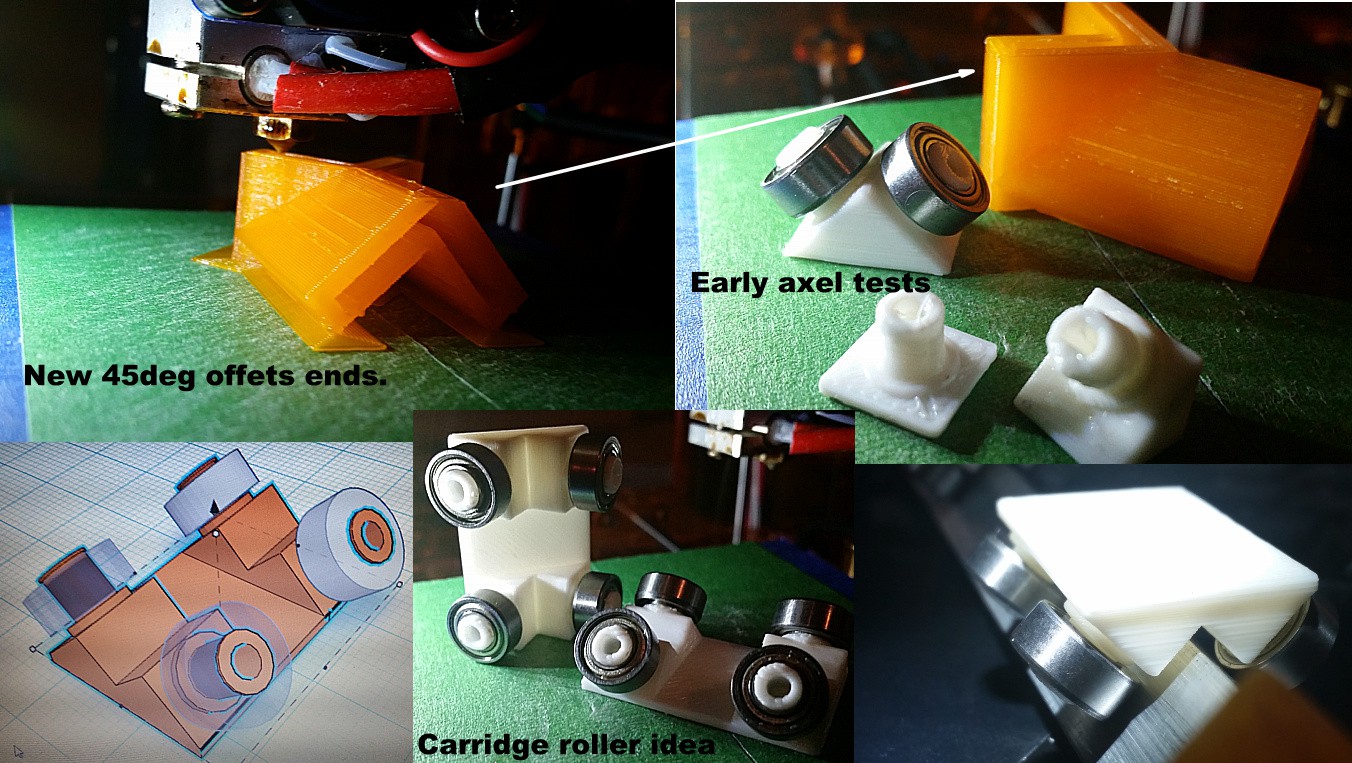

Added 45deg connectors and linear slides

02/24/2016 at 10:24 • 0 commentsI created a extra part for holing the L ch' bars in such a way that they are 45deg offset . that lets you use them as rails and all sorts .

I also worked out a example roller to make a carriage . Those are 4.7x10.1x4mm bearings .( exact measurements , as the package says 5x10x4mm )

![]()

i did a quick video on YouTube of them and the rollers working.

![]()

I will add the stl files and link to the public TinkerCad files soon as I clean them .

-

Sizing and making them stronger

01/24/2016 at 18:43 • 0 commentsI'm going to test on some other filaments I have today .

On side note i edited the instructions to include hints as to how you can adjust the scale of your part to match the wall thickness of your extrusion stock . the wall thickness on min is 1.4mm , the part was sized to print with PLA and just be a snug fit on that wall thickness .

you could just try applying % diff in the wall thickness of your stock , to print the first 3 or 4mm high of the part and abort , then when it cools check the fit of your stock in the vertical slot. the key is the thickness as there should be a small but of space at the tips of the extrusion sides. scale your part in your slicer to fit your stock perfectly .One friend has tested heating up the extrusion before insertion into slightly undersized PLA end caps, it looked to work ok , but then you cant use the vertical at places in the middle of your extrusions very easily . so im not sure if the heating that way is a good idea.

possibly passing a heat gun on finished assembly could further solidify the parts in place . That would be something to try .

I have found the PLA i use to be real strong , but can see why one would want to try to solidify the layers.

L Extrusion Endcaps

3D printed end caps that allow quick and easy construction of frames from easy to find and cheap aluminium L extrusion.

Scott

Scott