-

Lasmix plasma pump for cooling. Career change

06/23/2017 at 14:26 • 1 commentThere exists a type of gas laser which achieves much higher power densities at the cost of destroying its own lasmix. It vents the lasmix from a bottle, though the optic cavity, and from there presumably into the atmosphere. It does this for the sake of cooling.

I have been mulling on how to implement a plasma pump inside the cavity for about two years now, and just connected the dots with just enough rigor to blog about.

If the floor and ceiling of the cavity is coated with a dielectric material and the RF wave powering the thing is a phase modulated standing wave (Like an IQ modulator.), then the dielectric barrier discharge should, I hope, favor certain locations along the length of the cavity. If the glow discharge further is able to exert pressure, then what we should have is a pump with no moving parts and potential for extremely fast flow. - This ought to enable the high cooling rates needed for adding another power output multiplier to the original house-of-mirrors design I have spoken about.

(Just 16 hours ago W2AEW uploaded a video explaining how IQ modulators work, and together with my study of variable capacitance diode tuners over the past month, these were the last pieces of the puzzle. Thank you Alan, I wish you and you ankle all the best. 73 :)

p.s. If the phase modulation scheme does not work, then an array of addressable dielectric sections should. This seems inelegant by comparison though.

Since the last time I posted I have been very busy! I have completed one year of basic metalworking studies and gotten a diploma for that, and now I'm half a year in on getting one as a CNC machinist / programmer. The mystery box picture I posted almost two years ago contained a tiny lathe, and obviously I have moved on to bigger machines now. Much bigger. I have nascent plans on starting a business selling shiny consumer goods mostly made out of electroplated aluminum, so I may fund my robot army.

-

Mystery box arrives

09/21/2015 at 21:36 • 0 comments![]()

-

Fused metal deposition

12/19/2014 at 22:48 • 0 commentsAt 6:15 they tell of a camera that looks through the same optics that the laser beam passes. It's very impressive to see the molten area getting bombarded by rapidly heating titanium granules. The deposition rate of this method is also very impressive.

For accuracy, the other method has a clear advantage.

-

Well that was unexpected

11/25/2014 at 16:36 • 0 comments![]()

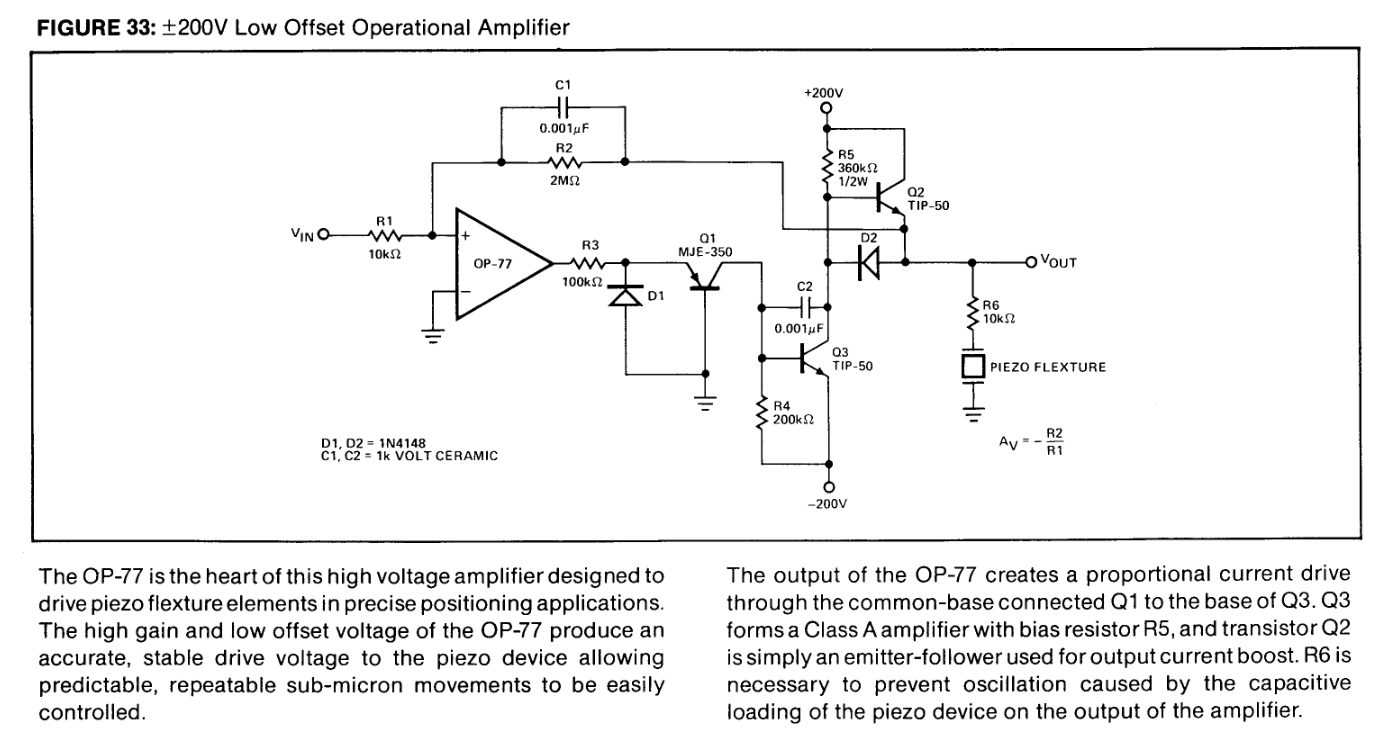

This circuit on page 15 of AN-106 by Analog Devices mentions sub-micron movement. I had browsed this document before during the hectic days of the HaD space race, but somehow I had missed this. The OP-77 is less than half the price of the LTC6090 and there appears to be nothing magical about it, at all.

I'm a little unsure of what the voltage drop across that 2M resistor at the top is supposed to be. - I didn't blow up my uC when I powered the LTC6090 with 24V volts and in a similar strategy sprinked resistors over the high voltage bits. - Instead I get exactly the performance I thought I might get. Together with this circuit I found earlier I have a pretty good refrence on how to do this without the LTC6090.

It is time to move on, and design a test jig to calibrate the movement of the piezo membrane... A laser oscilloscope, perhaps?

-

Ball mill, 405nm, Jim Williams

07/24/2014 at 10:45 • 0 commentsMaking glass frit by hand is labor intensive. A machine should do it. This is perhaps the simplest machine which will do the job:

In want of steel balls, cut-up lengths of rebar should work too. That steel is very hard. (If anybody can get the original I'd be much obliged. I'm storing a copy of this on my server in case it gets deleted.)

I might postulate a cyclone separator to get the right sized grains under the laser for sintering. It adds complexity but Hackaday readers are already familiar with those. In industry the combination ball mill and cyclone separator is commonly used in for example coal-fired power plants, which burn powdered coal.

[ED 23.08.2015 - Removed competition-specific and import-related speculation.]

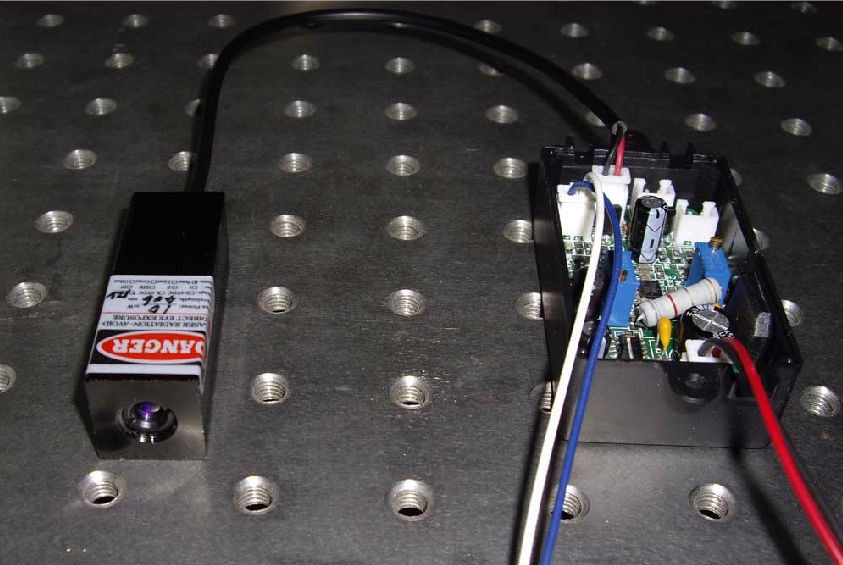

![]()

It's a 405nm, violet 10mW laser. I ordered two. After a bunch of research I determined that I need at least 10^2 voltages on the piezo discs to control a CO2 laser like I imagined. The short 405nm wavelength will let me use the 30Vmax voltage regulators to demonstrate destructive interference and also characterize the voltage/amplitude response of the piezo discs through the same mechanism.

I'll probably aim for a maximum voltage of 10^3. 1kV. This high voltage, low current has me researching CCFL tube drivers as I expect the volume they're made in to make their components cheap. Turns out that Jim Williams spent 10 years working on these things, to the point he was fed up with them. I'd very much like to stick one of his designs verbatim on an Arduino shield so I've been getting deeper, much deeper into electronics than I have been before. Current mirrors, totem poles, Darlingtons, the different breeds of TTL and the protocols I2C and SPI... Fortunately I have found a teacher who seems to know what he's talking about, presenting simple things as simple as they are. Too bad he's no longer taking phone calls...

http://cds.linear.com/docs/en/application-note/an25fa.pdf

http://cds.linear.com/docs/en/application-note/an65fa.pdf

http://cds.linear.com/docs/en/application-note/an70.pdf

http://cds.linear.com/docs/en/application-note/an118fa.pdf

Perhaps I can just refer to his documentation for this part of the project? Hmmm!

-

Novel approach to laser waveguide design

06/19/2014 at 22:06 • 5 commentsSince I could be on to something here the following maybe-formal text describes what I believe really is a new invention:

Background:

Inside a laser waveguide where laser light is 'folded' in a zig-zag pattern using mirrors, the intensity of the beam is increased by effectively lengthening the optical resonator with the mirrors. This is commonly done with multiple mirrors where the beam bounces once per mirror, which results in a requirement to align a multitude of mirrors to a high degree of accuracy. Even in large industrial lasers this alignment is done manually, often by a man with a wrench, which is costly and time-consuming.

Invention and some theory:

None of the patents for waveguide lasers I have reviewed mention that; putting one pair of parallel mirrors at nλ ± ½λ and at a small angle to them another pair of parallel mirrors at nλ means that only the nλ pair causes light amplification, as the other pair interferes destructively. This lets the beam that is stabilized by the nλ pair of mirrors be folded a large number of times between the pair of mirrors at nλ ± ½λ.

Prior art, and such:

I assume that the reason the industry has not adopted this approach lies in the perceived difficulty of maintaining a pair of mirrors at a set half-wavelength from each other while the entire device flexes, expands and contracts from thermal expansion. It is however possible to have this degree of accuracy and control for laser light; which is especially true at the longer, mid-infrared wavelength of the CO2 laser where it can be done cheaply.

Piezoelectric devices respond with small movement to high voltage, which translates to a ultra-fine precision when the voltage is well-behaved. Usually piezoelectric actuators built for the purpose cost hundreds of dollars, but according to my interpretation of https://www.comsol.com/offers/conference2012papers/papers/file/id/13148/file/13943_garcia_paper.pdf the degree of control needed for laser mirror alignment of a CO2 laser can be had for a mere pittance.Conclusion / claims:

My plan, (should some soulless greyface attempt to claim this invention as their own...) is to actuate the mirrors of a CO2 laser with piezo disks and to drive the actuators with e.g. a 8051 microcontroller. To alleviate friction the mirrors can be mounted on an air cushion. The distance between the mirrors is constantly monitored,e.g. by a laser beam power meter, and the output of the sensor is fed back through the automation system to adjust the voltage of the actuators and keep the laser's power at the desired power level.

Homebrew space exploration program

New laser, DIY chip fab, hollowed out mountain & space ship, terraform Venus with orbital atmospheric heater, backyard nucleosynthesis

ganzuul

ganzuul