-

How I built one MrRobotBadge

05/09/2018 at 06:53 • 2 commentsThis is it. I have verified hardware, and somewhat working firmware. Everything is ready to move into production. I'm going to be spending thousands of dollars at Mouser very very soon, and thousands more are going to a board house in China. MrRobotBadge Mk 2 is happening, whether I like it or not.

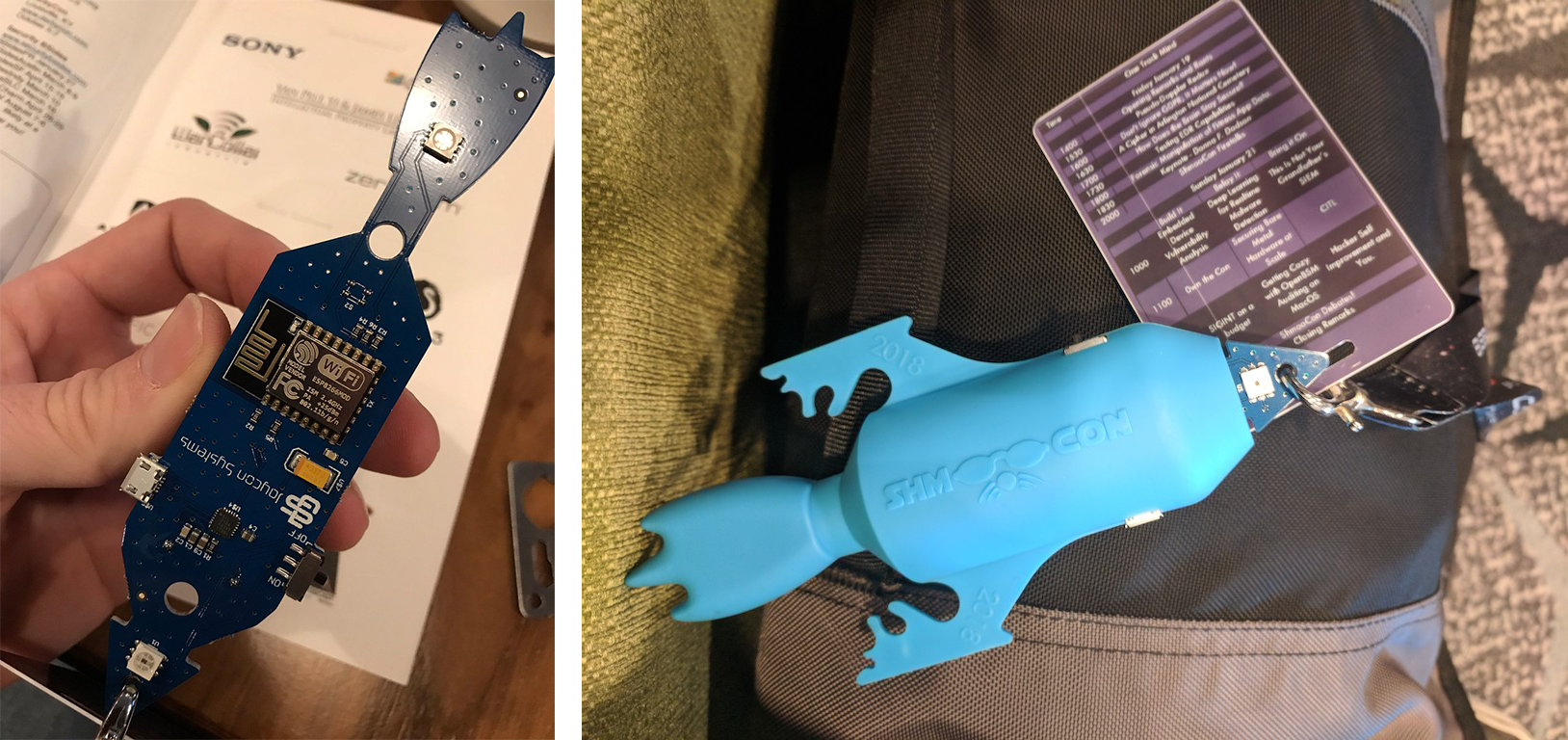

My initial plans for this badge were quite grandiose. I would have more LEDs, more blinky, and -- because I could -- an injection molded plastic enclosure. Yes, I wanted to do an injection molded plastic enclosure for this year's MrRobotBadge. This meant getting molds made, injecting hot plastic, contracting things, and spending tens of thousands of dollars for an indie Defcon badge. This plan fell apart when I attended Shmoocon in January. Someone had beaten me to the first injection molded conference badge.

![]()

The Shmoocon badge this year was basically an ESP8266, a few serially addressable LEDs, and an extraordinarily fancy injection molded rocket enclosure. All of this was done by Jaycon Systems, which to me feels like cheating, but if you want the latest in badgelife, there you go. Go with Jaycon. They were the first badge that I'm aware of that did injection molding.

Injection molding was right out, but around the same time as Shmoocon, I came across an interesting LED driver. The ISSI IS31FL3741 is a LED driver that takes I2C in, and spits out a 39x9 LED matrix. It's the same family of chips as the IS31FL3731, the chip I used on last year's MrRobotBadge, but the new chip is significantly more blinky. If you do the routing right on the PCB, you can do an 18x18 LED matrix.

There's one problem with this chip: it was scheduled to ship in Q2 of 2018. That's early April or so. Not a problem. This gives me about four months to come up with a design, do some art, and procrastinate until the chip ships.

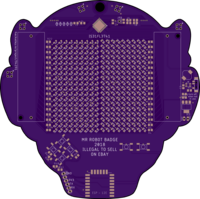

And that's exactly what I do. I sit on my ass for two or three months. Around the end of March, I start the design in earnest. I come up with this:

![]()

Basically, it's a rehash of last year's badge, only with more LEDs. There are a few changes:

- Instead of the Microchip MCP1640 switching regulator, I'm using the Skyworks AAT1217 switching regulator. A lot of the badgelife crew have used this regulator, and compared to the Microchip one, it's about the same price. It also sucks batteries dry.

- Instead of four AA batteries like last year, I'm only going with two. The design of the badge doesn't allow me to place batteries on the back, so everything here is a single-sided design. This cuts down on the area I can place components, and ultimately how large the display can be. I've learned a few things, though: I'm using keyed battery holders. Last year, I had a few misplaced battery holders that were soldered in the wrong polarity. The Keystone 1028 has a neat little plastic nub on the bottom of the positive terminal of the holder. If you put a hole in your board, this means the battery holder can only be placed in one way. That's going to be great for when I recruit friends and family to help with the assembly

- Changed around the pin mapping of the buttons. I really fucked that up last year.

- Added five shitty add-on connectors. The Shitty Add-On standard is going on a ton of indie badges this year. It's just power, ground and I2C. Enough to have fun with, at least.

- The software will be infinitely better.

With the design in place, I sent that board off to OSH Park, hit up ISSI, asked for a sample of chips, and they actually got back to me. They immediately sent me the dev board for this chip, but no chips. I needed the chips to prototype this board. I needed them to assemble this board. Without samples of chips, I couldn't do anything.I checked Mouser every day for a month. At one point, Mouser was getting one reel -- just 2500 chips -- on May 28th. While I was waiting for these chips, I started to get a little nervous. I actually made a 'safety' version of this badge using three of the LED drivers I'd used from last year. This was a four layer board which would have pushed my costs up dramatically, and buying two extra chips at $2/piece would have pushed the BOM cost right to the limit. Still, I needed a fallback plan.

On April 20th, the samples of chips from ISSI arrived. A few days later, the chips were available on Mouser. Everything was good. I got my stencil out, and started placing LEDs. Throw everything in a toaster oven, and we'll see how things turn out.

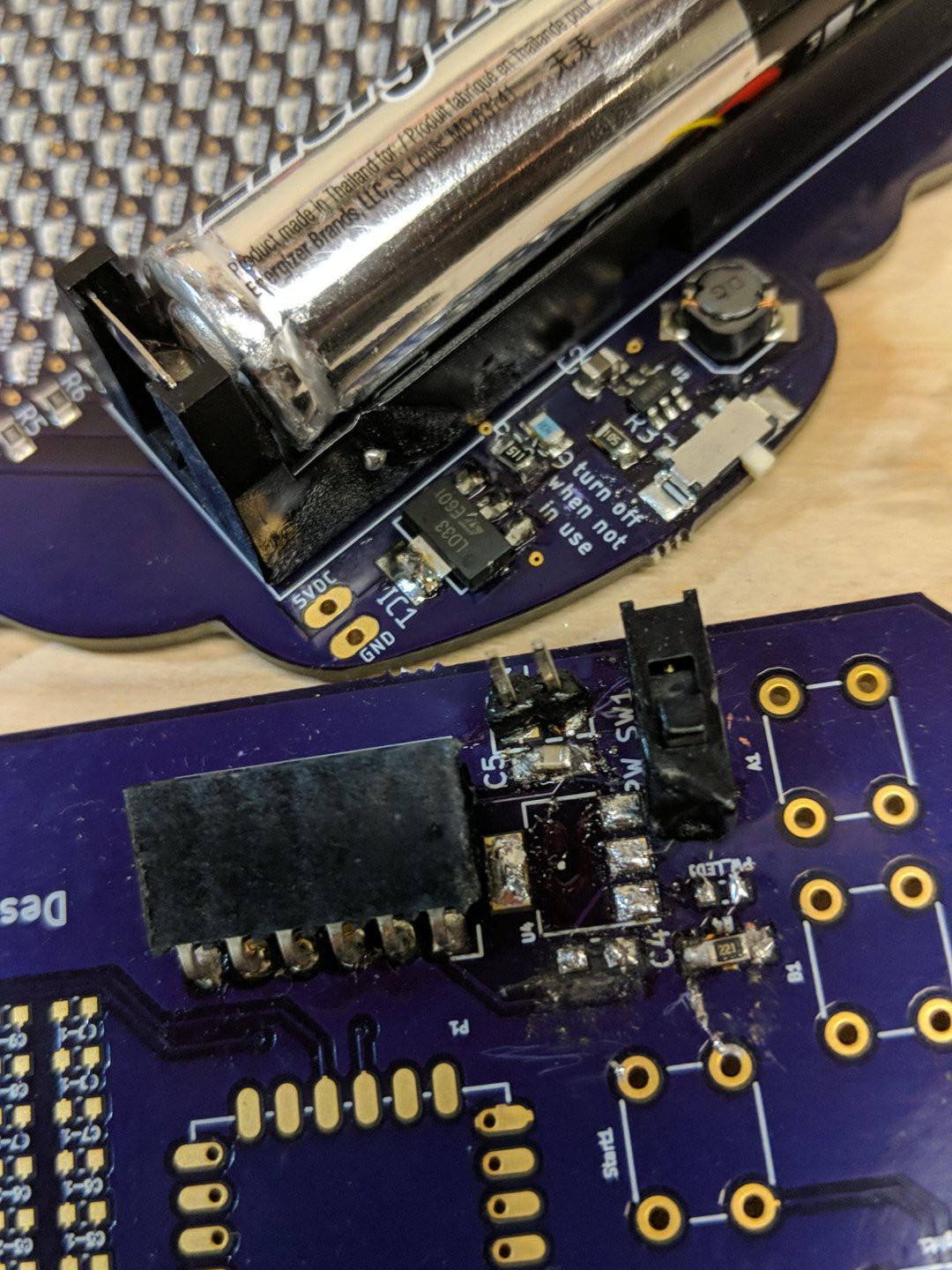

But I'm an idiot. I had planned on using the Skyworks regulator to get a 5V rail in the circuit, because that's what the new LED driver needs. For the ESP, I needed 3.3. That means a linear regulator, in this case an LM1117. I ordered a handful of LM1117s. It was right after I soldered the board that I realized the LM1117 is an adjustable output linear regulator. I should have bought the LM1117-3.3. No problem; I used one of those on last year's prototypes. I'll just steal one from that.

![]()

With the LED driver chip getting 5V, and the ESP getting 3.3V, it was time for the next step in bringing up the badge. I had to flash some firmware. But there was a problem on the 3.3V rail. It was shorted, somehow.

Here's where I'm a god damned moron.

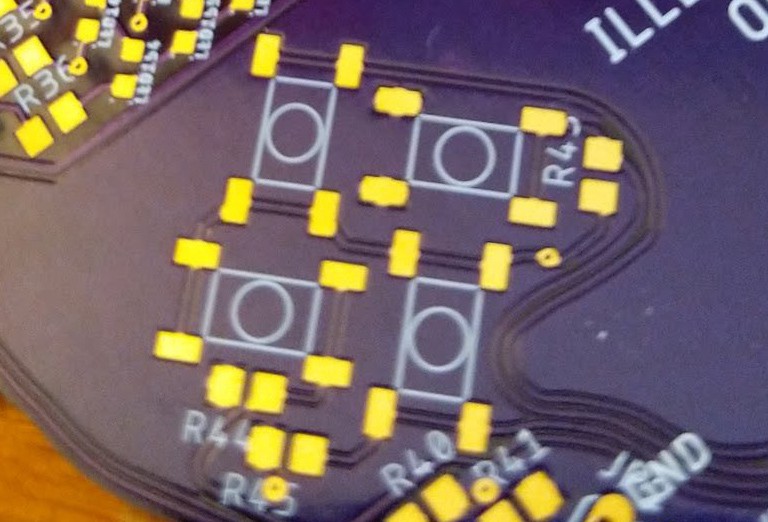

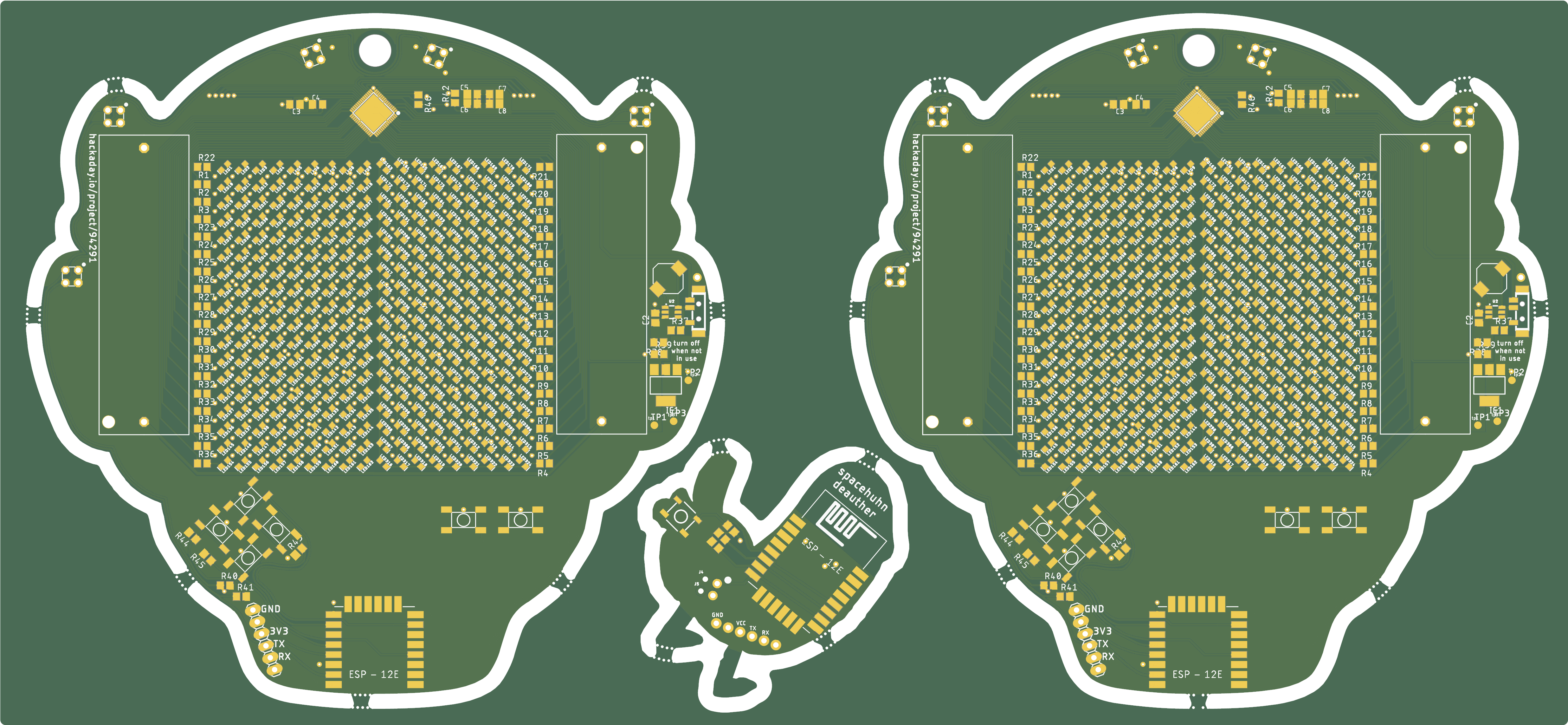

![]()

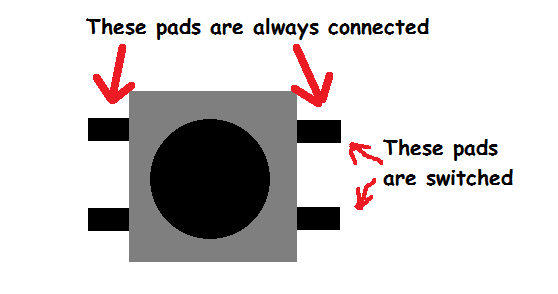

See that? Those are the pads for the buttons. Buttons, as you should be aware, have four pads. Each side of those pads are connected together electrically, Oh, but which side, you may ask? The long sides are always connected; it's the short side that are switched:

![]()

So I'm an idiot, but that's nothing some kynar can't take care of:

![]()

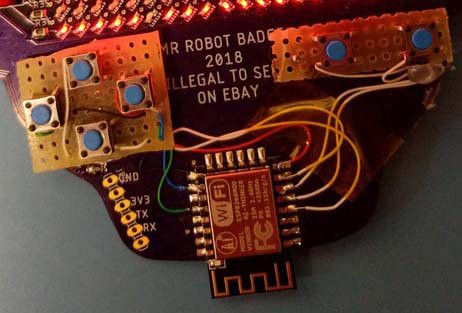

With that, I got the badge working. I could upload code, and the LEDs sorta worked. I had forgotten how hard it was to solder QFNs. I got some of the LEDs working, but to verify everything, I needed a completly working badge. I can't do that by hand. I needed a pick and place machine. I turned to Macrofab. For about $100, I could get a single badge made. Thankfully, by this point, the LED drivers I needed were in stock. In ten business days, I had a prototype:

![]()

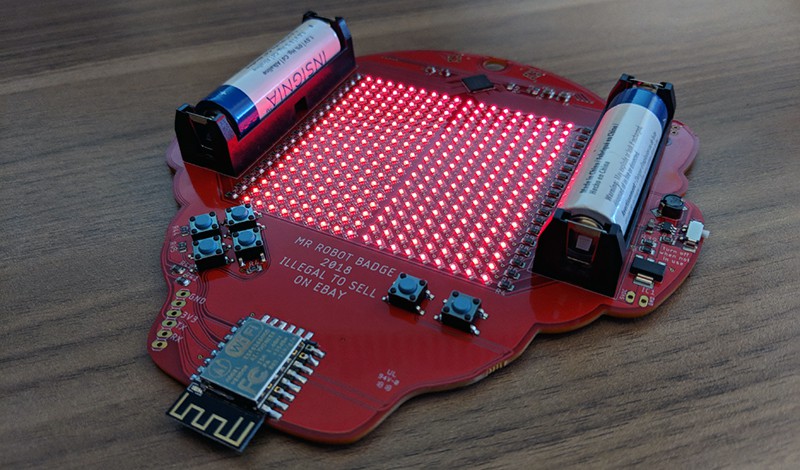

That's it. That's the prototype, and how I got to one MrRobotBadge. From here, I have a few things to do. I need to make a panel to send off to the board house. For this, I used the GerberPanelizer from

ThisIsNotRocketScience. I also included a shitty add-on in the middle of the panel, just to make things fun. You don't see the art on this board, and it's green, but trust me, it's there in the gerbers.

![]()

![]()

Now, a word about costs. Like last year, I've been keeping track of my expenses. To get to this point, I have spent $4841.77. That's four thousand, eight hundred forty one dollars and seventy seven cents. I have exactly two prototypes.

This does include some of the parts that are going to go into production. It includes $350 in anti-static bags. It includes two thousand dollars in LEDs. It includes a four hundred dollar Mouser order (most of my passives for the entire run -- the cheap shit), and it includes a thousand in battery holders. However, I still have thousands more to spend to turn one prototype into thousands. This is not an inexpensive endeavor.

But this is going to happen. I'm going to have a ton of badges at Defcon. All I need to do is make a thousand more.

-

Let's Talk About Packaging

04/05/2018 at 19:14 • 2 commentsThis is putting several carts before the horse, but this update is going to talk about packaging for these badges. This is surprisingly hard, and there are a few special considerations I need to take care of.

Last year, the packaging for the MrRobotBadge was simple. It was just an antistatic bag, with each bag loaded up with a badge, lanyard, and sometimes a fidget spinner. It was small, sufficient, but didn't really have the glitz and glam I would like.

This year, I'd like to do something different. The And!XOR guys did a great job with their packaging last year -- it was custom-printed boxes -- and the Crypto and Privacy village can tell you a whole lot about ordering custom printed boxes. This is the gold standard for distributing badges. It's secure, it looks great, and it's actually not that expensive. Packline.com will do custom printed boxes for about $1/piece. That's right on the money for where I want my packaging expenses to be.

However, there's a problem with boxes. They're big. I'm going to ship 1000 units this year, and that means forty cubic feet of boxes. These need to be shipped out to Vegas somehow, and that's an entire pallet. While my car has a larger cargo capacity, it's just barely big enough. This is a huge, huge volume of stuff. Weight isn't a problem; it's volume.

This brings me around to last year's plan. Anti-static bags. This year is a little different, though, and I have a few requirements:

- There must be some sort of branding on the packaging. Anti-static bags are just... too chintzy.

- Some part of the packaging solution must be opaque. I'm doing shitty add-ons this year, about 100 each of 10 varieties, distributed randomly throughout my inventory. I don't want to know which shitty addon is in one package. This is part of the game.

- It needs to be anti-static

- It needs to be small. Again, I'm shipping a massive volume of stuff here, and I have to carry it around the vegas strip.

The obvious solution is bags. Here's what I've come up with:

Uline has some anti-static bubble mailers that would be perfect for the job of holding a badge. This is actually cheaper than the plain silver anti-static bags I can find on AliBaba. This is what I'm using for the MrRobotBadges.

These bags have a problem: they're not opaque. I need a solution to hide a shitty addon, and possibly add some branding. I've come up with a few solutions.

The first is poly mailers from StickerMule. They're opaque, padded, and I can do some custom branding (on only one side, but whatever. I can throw the anti-static bubble mailer in there, a shitty addon, batteries and a lanyard, and call it good.

The second solution is a two-part deal. Uline also has some mostly-opaque bags I can use for the shitty addons. These can be thrown into the padded anti-static bags. For branding, I can get a roll of printed labels for the outside of the anti-static bags. It's not ideal, but it is a good solution that meets all the criteria.

There are a number of things I need to consider, but the most important are cost and size of the packaged product. Between the two, I'm just going to go with the Uline anti-static bubble mailers. That means buying thirty five pounds of bubble wrap. Do you have any idea what thirty five pounds of bubble wrap looks like?

![]()

That is what thirty five pounds of bubble wrap looks like.

My solution to hide the shitty add-ons was to buy... dime bags. From Uline. They're ziplock poly bags that are just too translucent.

![]()

It's not good. I wanted to hide the shitty addons. I guess I'll just cover it with creatively packing the badges.

That's packaging sorted, now it's time to make a badge.

Benchoff

Benchoff