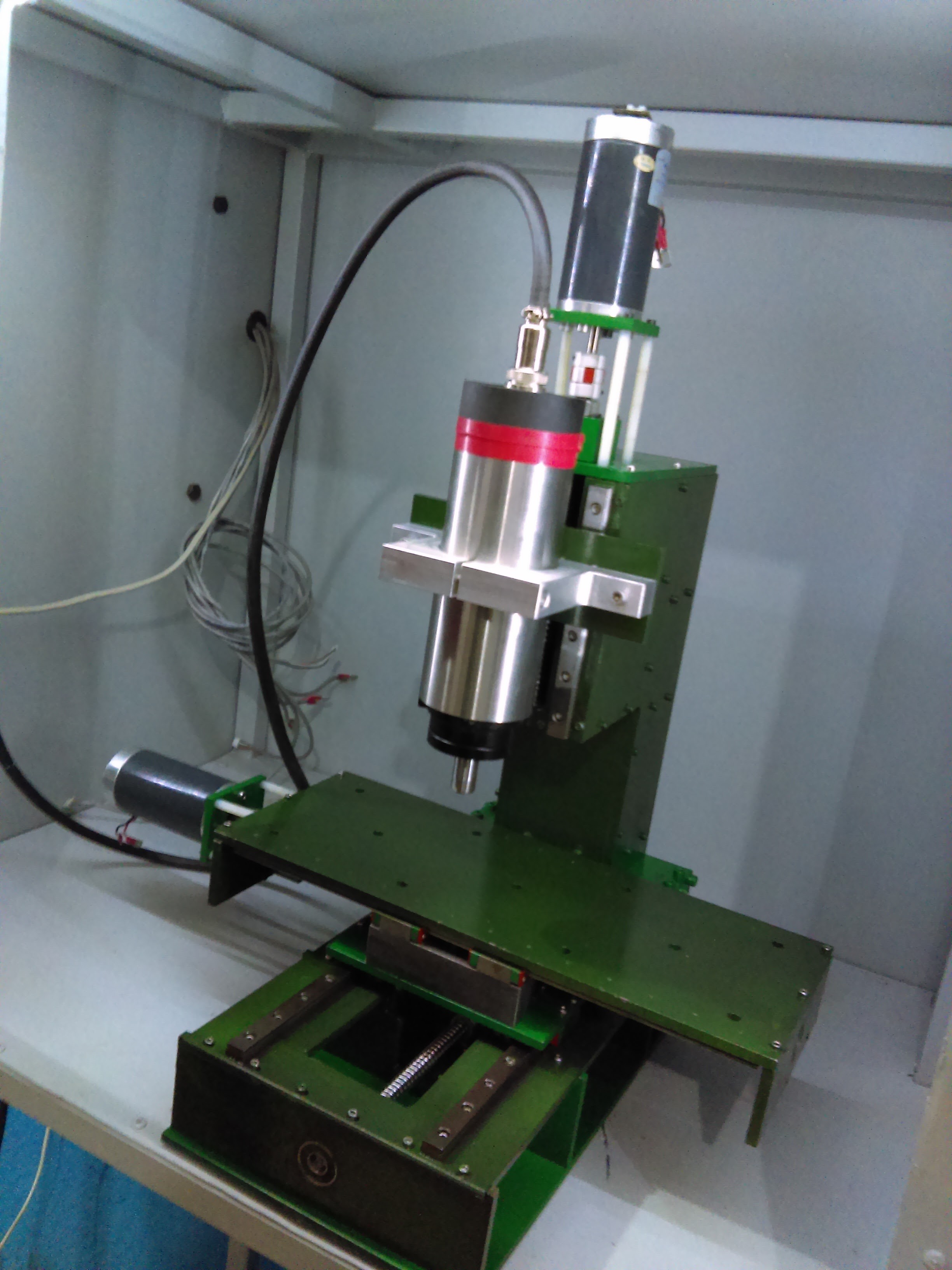

I'm finally done building my CNC mill. For the past half year I've been buying the parts and machining the structure out of 1/4 in thick steel plate on my "bigger" manual mill, a ZAY7040.

The machine characteristics are:

- Weight: 55 kg/ 120 lb (99% steel)

- Rapids: up to 400 ipm/10 000 mm/min

- Motors: 24 V 20 W output power at maximum efficiency brushed motors (60 W maximum output power)

- Linear motion: 12 mm diameter 4 mm lead ballscrews, 12 mm linear rails, back to back angular contact bearings on the fixed side, deep groove bearing on the floating side, spider couplings for the motors

- Travel: 160 x 120 x 80 mm (X,Y,Z)

- Spindle: 800 W 220 VAC three phase synchronous motor

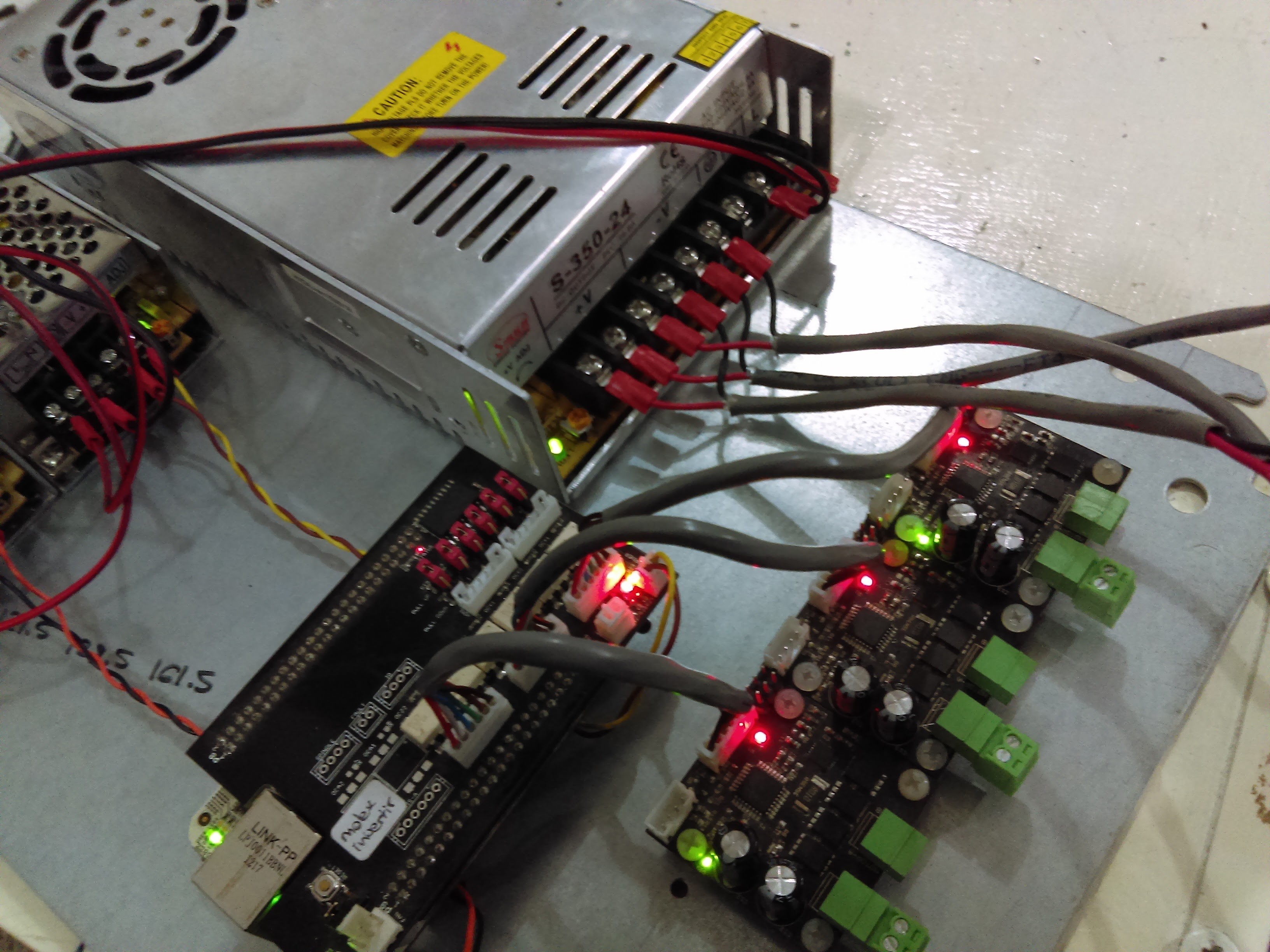

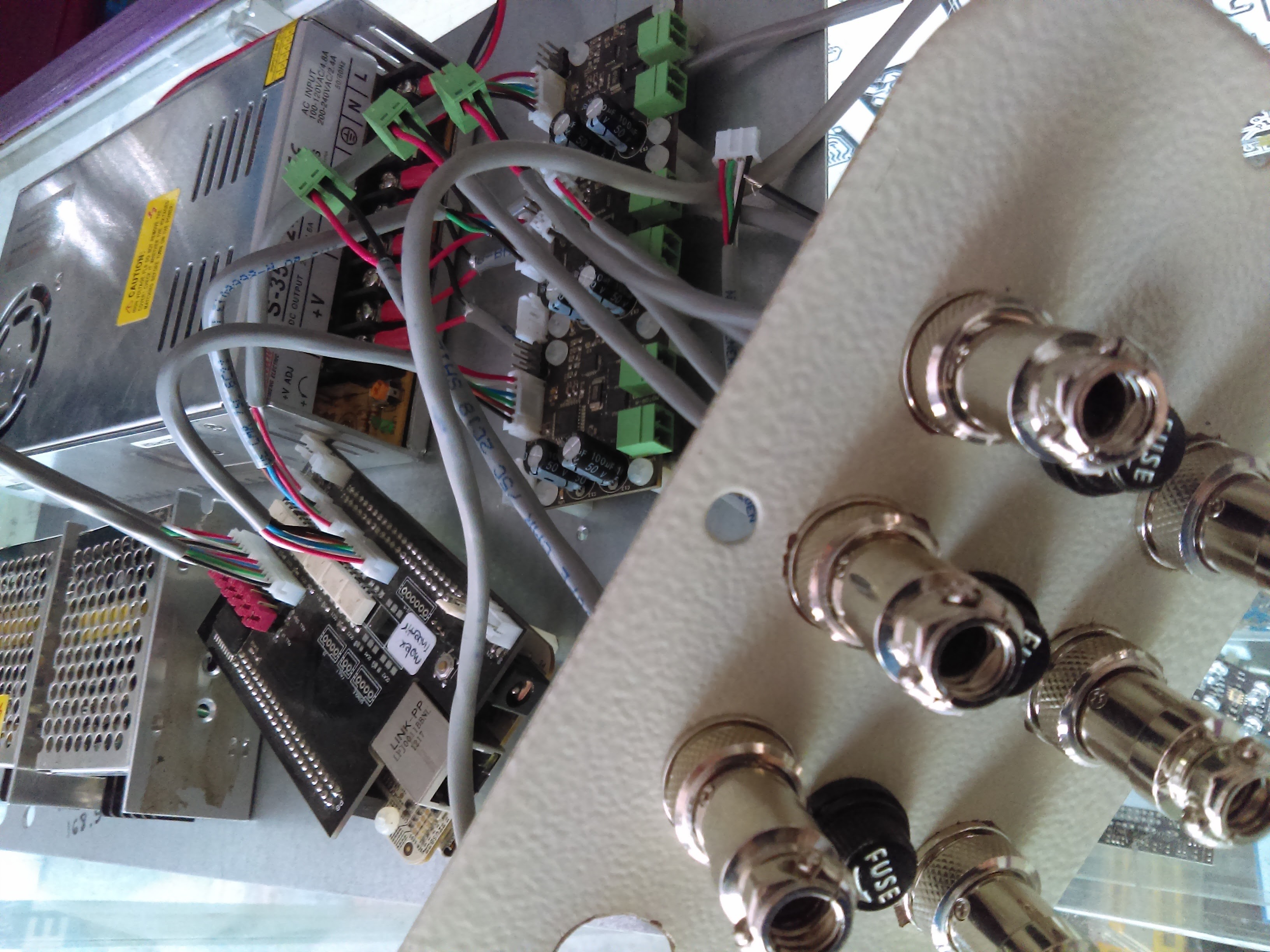

- Motor driver: pretty obvious :)

- Machine controller: Beaglebone running machinekit with a custom cape for the signal connectors, e-stop, limit switches...

ottoragam

ottoragam

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.