Tried it!

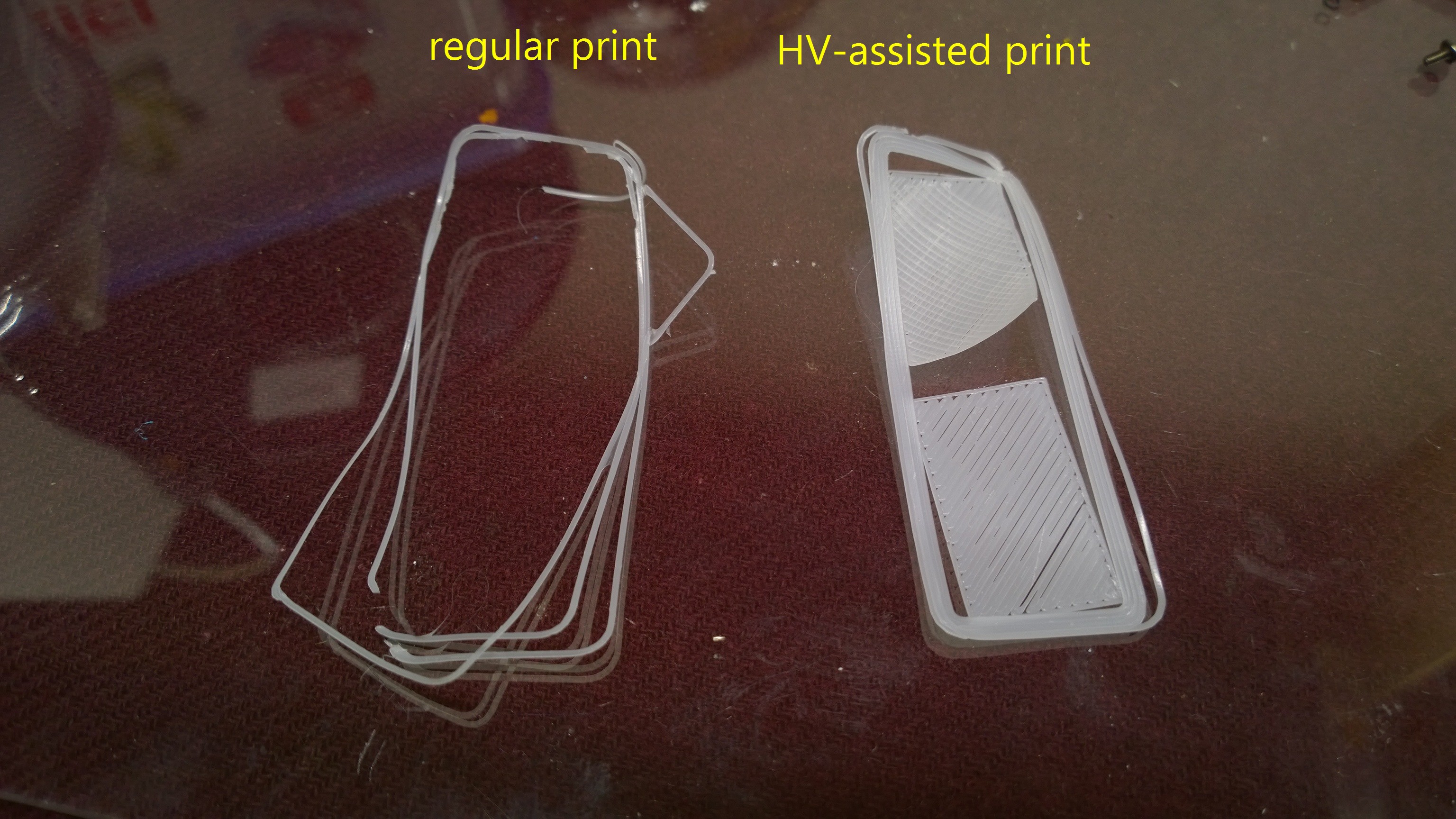

It helps. Definitely. But it's nowhere close to being good enough for actual printing. =(

This time, the deposited plastic remained stuck to glass for some 20 seconds or so. That was enough to print the first layer. But then it just curls up and I have to kill the printing.

This time, the deposited plastic remained stuck to glass for some 20 seconds or so. That was enough to print the first layer. But then it just curls up and I have to kill the printing.

With POM, it looks like the action of high voltage is how I initially wanted it to be - due to charge embedded in plastic. I think the charge dissipates quickly, and as it does, the plastic peels off. That's the theory... So it might be interesting to try lower bed temperature, maybe even no heating of bed at all.(EDIT: tried printing on cold bed. Total failure.)

Data:

first layer 0.2 mm thick, 0.8 mm extrusion width, 0.3mm nozzle

bed T = 140 deg.C

extruder T = 250 deg.C

DeepSOIC

DeepSOIC

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.