I always wanted a supercomputer, and I was one of the lucky few who was able to get my hands on more than a single Raspberry Pi Zero.

I decided that for the price of $5 per leaf, the family CEO could NOT refuse my addiction this time. Besides, she just got me a 3D printer and, really, I can only print so many geared hearts...

I had seen a couple of zero supercomputer shells in Thingiverse and thought "Wow, these could really be small and THEN I started remembering my days as an SA and all the hot-swap drives I had to, well, hot-swap. I decided then and there to build a slot-load case (8 slots for this one), WITH power distribution AND a way to hook up ethernet. Besides, who wants a Delta Burke pantsload of wires coming out all over the place?

UPDATE: I've had to switch to wifi dongles. The usb ethernet adapters I bought turned out to be duds. I couldn't even harvest anything useful!

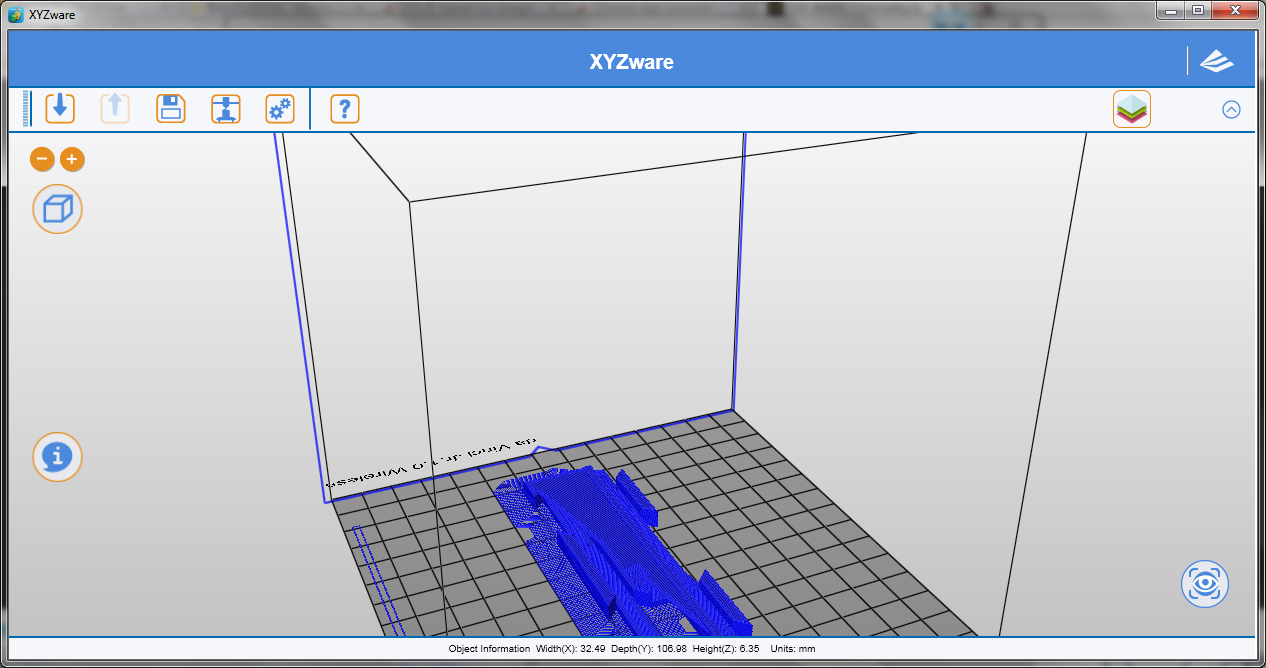

I try not to use Microsoft, out of principle, but, one thing they got right is the free STL fixing service on AZURE. All my work has been with free or really cheap tools, and the quality of a finished product can sometimes reflect the costs incurred. Luckily Azure provides a good STL cleaning service that has so far, never steered me wrong. Every time the XYZPrinting software has messed up an export to the .3w filetype, I have been able to go to AZURE and get it fixed such that I could successfully print. Here's an example. In the picture, there should be 2 distinct Models on the same printbed, but if you look in the middle, you will see they are connected. AZURE can fix that, though I don't understand why it removed the brim from the other one...

txdo.msk

txdo.msk

Nate Schroeder

Nate Schroeder

Cedric Anné

Cedric Anné

Retroplayer

Retroplayer

Magic Robots

Magic Robots

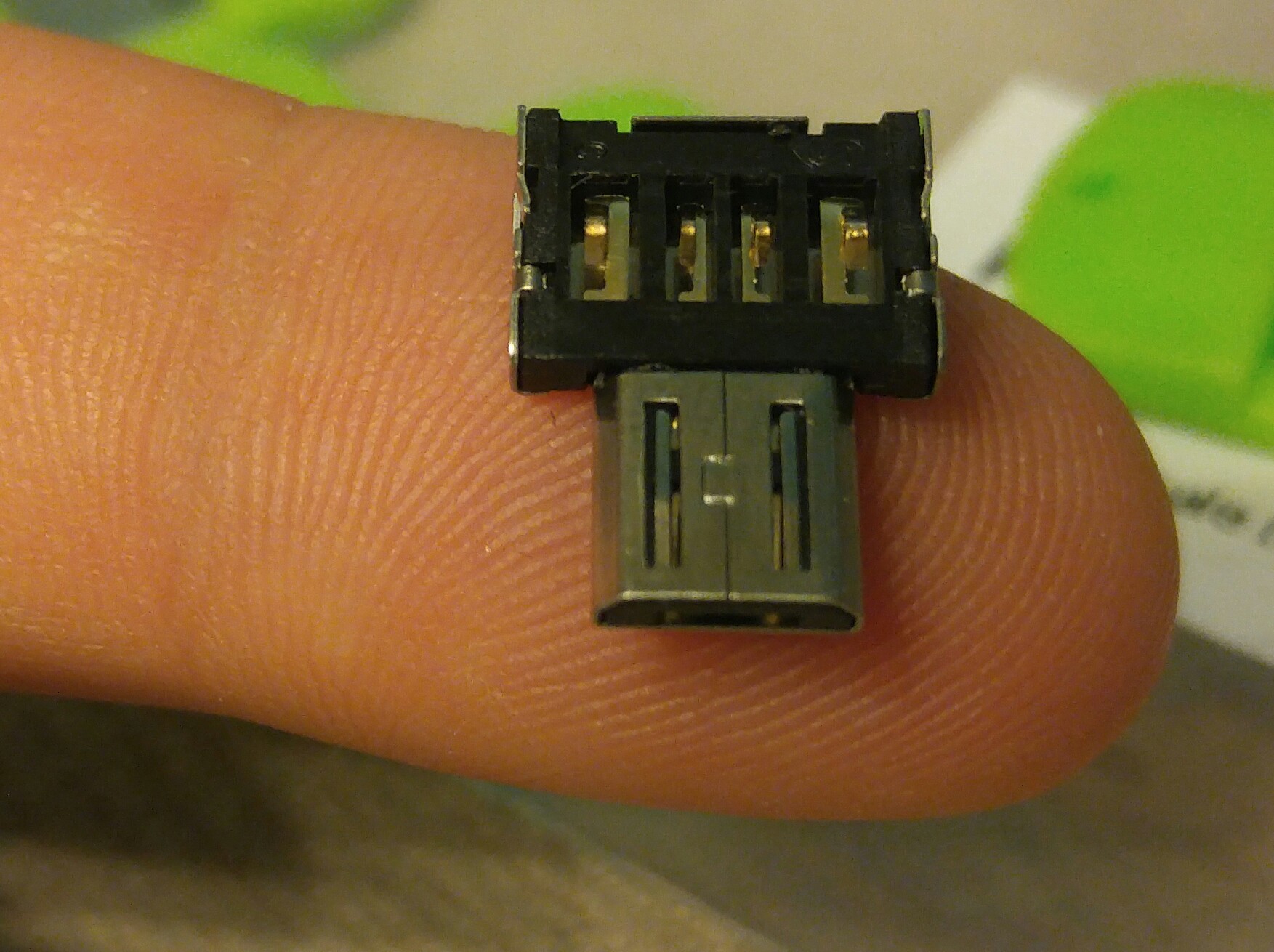

let me rephrase that. I think using the TX and RX off GPIO would be the slowest way. I intend to feed power into GPIO, but solder an adapter to use USB OTG. Once I have a good common setup, I'll benchmark and then use all common methods, to include full GPIO and compare.