-

Final assembly

04/27/2016 at 13:41 • 0 commentsNow, guess what I did. I took the electronics and installed it into the housing. Crazy. I don't want to rule out the possibility that I'll build another one soon, but for now, this project is completed.

And the back side with all the connectors and LEDs..

On the back side, there are line-in and line-out connectors, which are wired directly to the Bluetooth module. The two USB ports are wired to the DC/DC converter and serve for charging smartphones.

The device is charged by plugging in a 5V 4A wall charger. The speaker self-reliantly turns off for charging and the four LEDs underneath the connectors indicate the charging status of the four LiPo cells. Each LED represents one of the four LiPo cells. The four red-lit LEDs show that all four cells are currently charging.

Once a cell is full, its corresponding LED turns blue. Since all cells are charged independently, the whole 20 Ah bank charges within 5 hours, but it can happen that some cells finish earlier than others.

Once all LED's shine blue, all cells are full and the speaker is ready to go.

With 2 x 16 W (RMS) / 2 x 11 W (sine) the speaker gives a room-filling and full sound for it's size. The bass is certainly the most impressive part, but the two-way car speakers also deliver clear and brilliant highs, it sounds better than what I'm used to from portable speakers. I'm surprised how well the parallel charging hack worked, with the fast parallel charging trick and dual-color indicator LEDs the whole thing is quite useable.

My wife already received her new portable Bluetooth speaker, and so far she seems to be very happy with it. As said, I might continue this project with a new version, so if you have any ideas, shoot me a comment.

-

Making circuits

03/22/2016 at 10:25 • 8 commentsCharging circuit

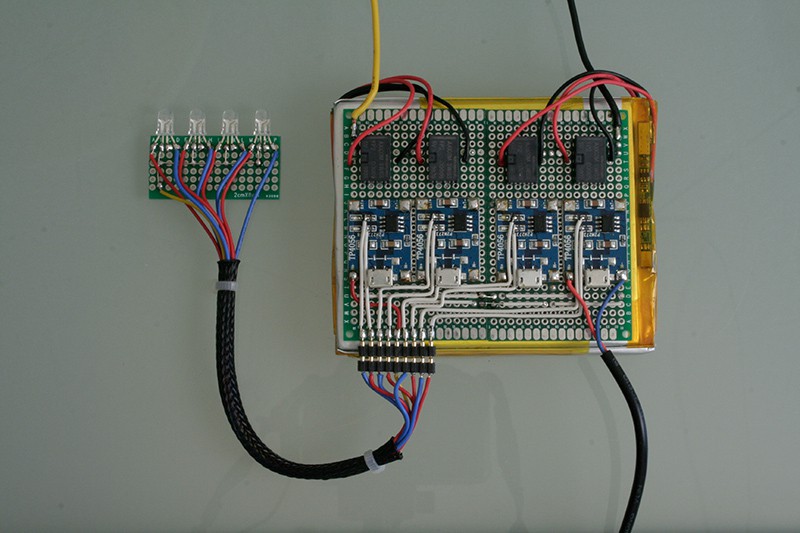

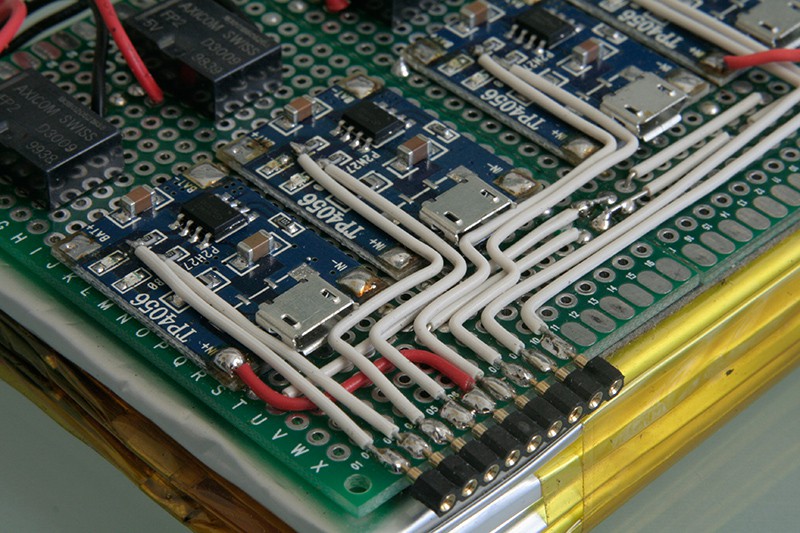

Meanwhile I've managed to fully assembled the charging circuit I described in the previous log. I backpacked it on top of the four LiPo cells.

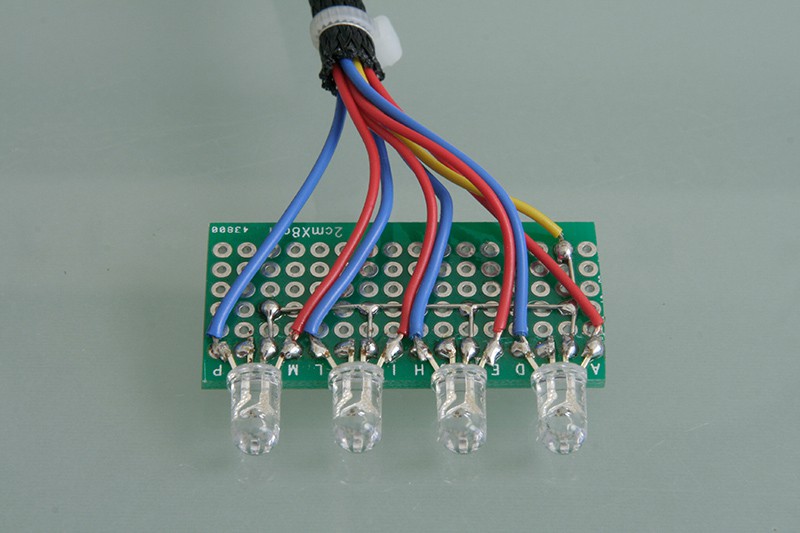

I also added an external board with four common anode RGB LEDs to display the status of each cell on the back of the speaker. "blue" means full, "red" means charging.

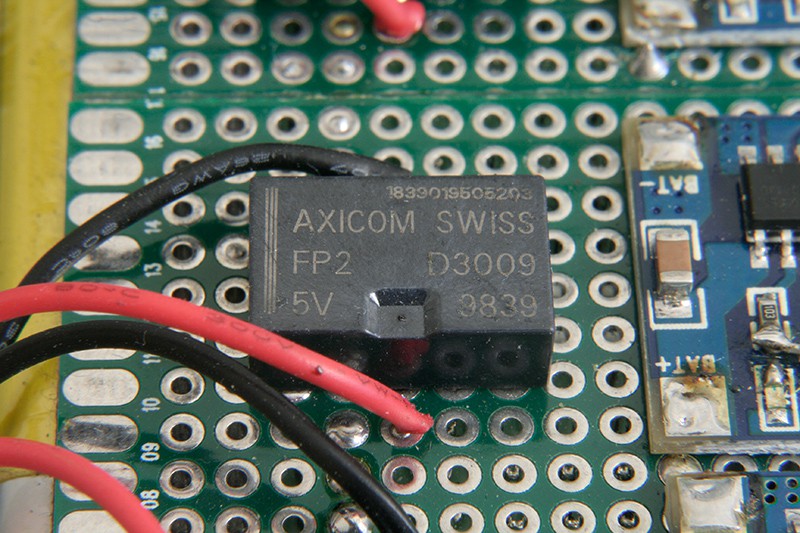

Below you can see one of the Axicom FP2 relays, it's super tiny but still can take high voltages. However, the switching current is 2A max., which is the bottleneck for this charging circuit, so per specification, the maximum charging current of an individual cell is also 2A max., and the maximum current to draw from the entire pack is also 2A max. Fortunately, the TP4056 can only deliver 1A and the amp will also draw no more than 2A.

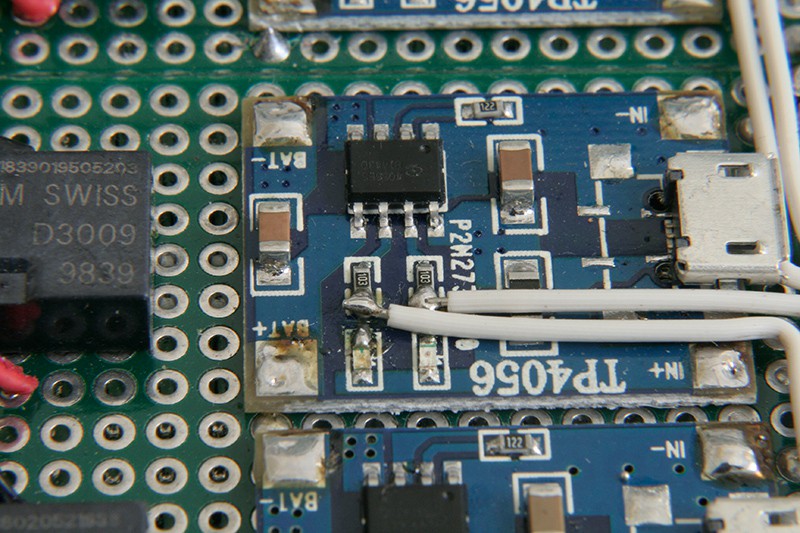

The TP4056 modules were surface mounted to the perfboard with their input and output pads. I also cut the connection to the onboard LEDs and bodged the LED signals to a pin header for connecting the external RGB LED board.

The wire bodging was tedious. Definitely an argument for having some nice PCBs made next time I use this circuit, and then of course skipping the modules and designing my own TP4056 circuit. Below picture also shows how the charging circuit sits on the LiPo cells.

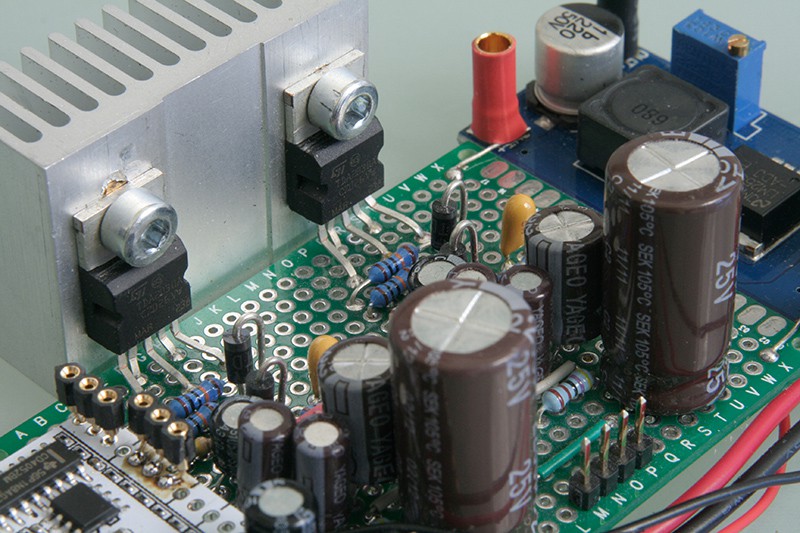

The amp

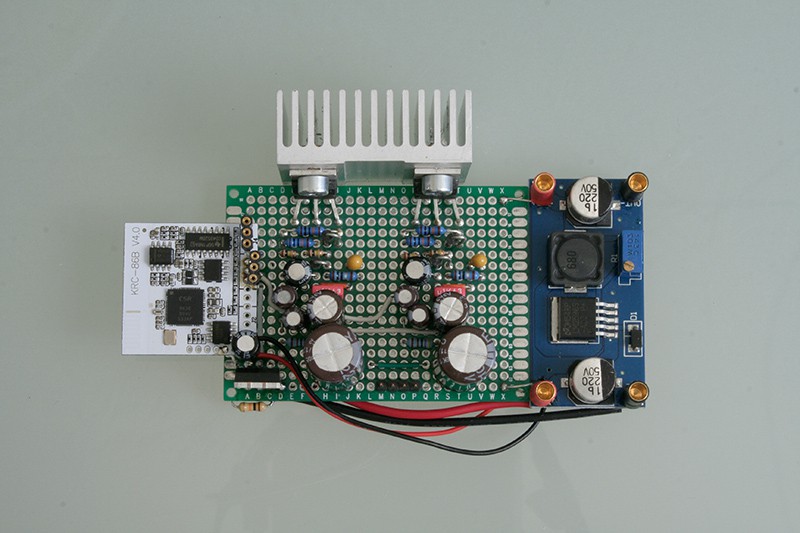

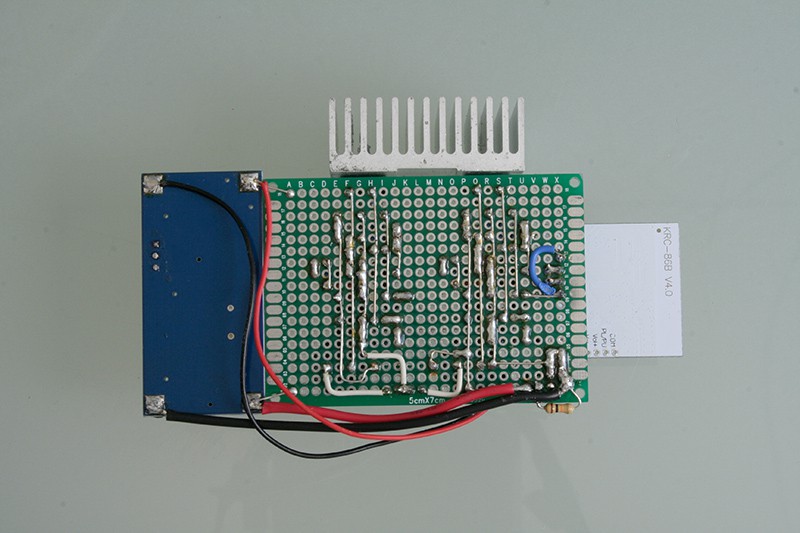

In the tradition of this project, also the amp was prepped on a perfboard, because well, why not. AB amps are dying out anyway.

The DC/DC converter was also attached to the perfboard it to save space. It supplies power to the KRC-86B bluetooth module and USB charging ports.I tried to route this as clean as possible, but then thought I might as well add a MOSFET to turn the amp on and off from the bluetooth module's 'EN' output, which goes HIGH when the module has successfully connected to a host device. So the right lower corner is a bit messy :)

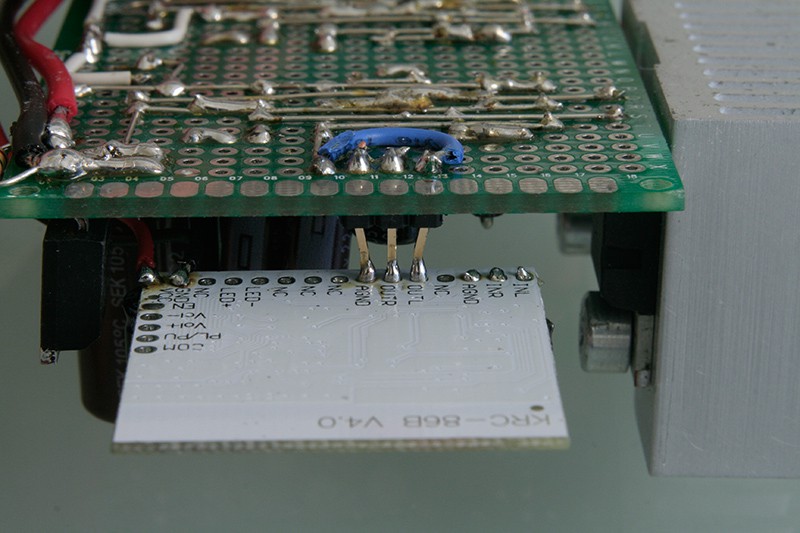

The KRC-86B bluetooth module sits on a pin header attached to the amp, which makes it easier to mount the whole thing in the shell later.

The TDA2030A are attached to a somewhat a bit too large heatsink from the drawer. If I measured everything right, it should fit though.

From what I've heard during testing, the amp sounds really nice and has a good woof. Now it's about mounting everything in the housing. -

Talking about circuits

03/19/2016 at 13:14 • 13 commentsNow that the paint has dried, it's time to talk about circuitry.

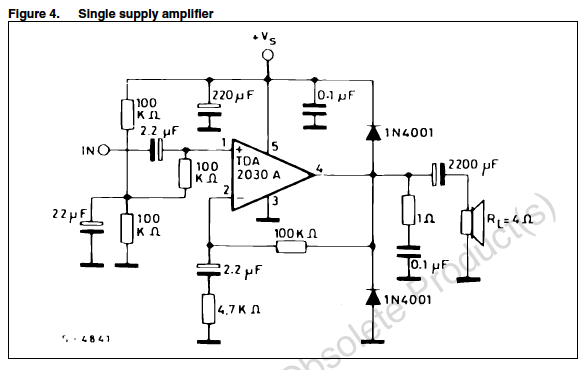

Class AB vs Class D

No doubt, a class D amp would surely be more efficient and provide some additional hours of fine music plus would save some space in the housing for other cool things. But well, I still got several TDA2030A, throwing them away would also not be very efficient. Also, they offer superior THD, and the circuit is so simple I can just solder it to a perfboard.

Schematic source: ST datasheet for the TDA2030A from July 2011, page 4![]()

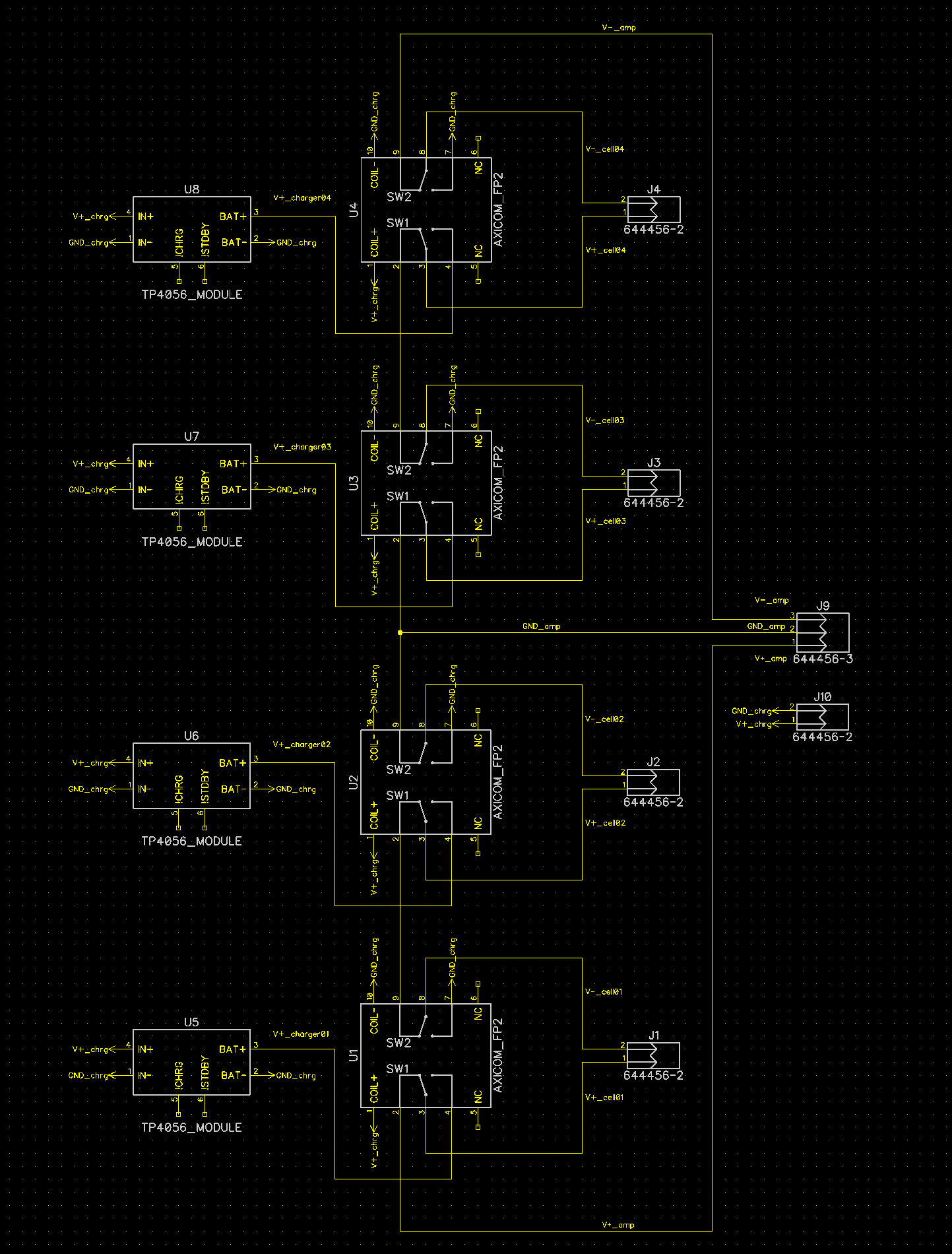

Charging

Some of you may doubt that you can/should charge four LiPo cells with four cheapo TP4056 modules in a single application. I also had doubts, but my tinkerplementation works well so far. It's based on the tiny but powerful Axicom FP2 relays.

![]()

During charging, this simple circuit isolates each battery and connects it to its own TP4056 module using the two changeover switches of one Axicom FP2. All TP4056 modules share a common ground and charging power input, but of course only charge one cell each. The charging power input also magnetizes the coils of the relays, so when no charging voltage is applied, the relays fall back to their idle state, connecting all cells in series to power the amp with +/- 7.4 V or 14.8 V respectively.

I als made sure within the expected failure modes, there's nothing bad that can happen:

- I'm drawing current from the cells in an unbalanced series connection, but all cells have their own PCM (protection circuit module), so the worst that can happen is that some of the cells are not fully discharged when the first PCM shuts down

- The relays may fail by getting stuck open or staying closed, even half open or half closed, and nothing bad happens, the speaker will simply not turn on

The circuit is damn simple, very cheap and can be assembled on a breadboard with ease. It charges four cells simultaneously with a total current of 4A max. Unfortunately, that's also the end of the benefits, downsides are that you have to charge in silence and the cells are unbalanced. So not very sophisticated.

LED charging indicator

The TP4056 has two open collector status indicator outputs for i.e. attaching LEDs. I figured I could use four RGB LEDs with common anode to indicate the charging status of each cell. While charging, a LED would light up red, once finished it would light up blue. The green remains unused for now.

Possible improvements

Have I mentioned the cells are unbalanced? That could be easily fixed by adding an Arduino to the project and configuring it to use some MOS-FETs and dummy load resistors to balance the cells while in use. The Arduino could also read the charging status from the TP4056 modules and display them in a bargraph or on a display, or instead of an Arduino something more powerful could be used, too.

Also, of course, there is still the option of adding a class D amplifier, as suggested in the comments. A class D amplifier would save a lot of space in the housing. That space could be filled with boost converters for higher sine power, or with a Raspberry Pi to do cool streaming stuff, and maybe a touch display, or just more batteries. Maybe I'll add all of those improvements in the future, we'll see.

-

Finished shell

03/15/2016 at 12:36 • 4 commentsSanding and color coating results

As you can see, the printed and assembled shell is now nice and shiny. Since I didn't want to expose my DSLR to the extremely dirty and dusty work of sanding, filling, sanding again and color spray painting, you may be content with looking at the following images of the finished results.

Actually, I'm quite happy with it. I used only what I had in the workshop, leftover racing filler, leftover sparkling black spraypaint, leftover clear varnish. The spay filler really did it's job in filling up the glueing marks and smaller imperfections of the print.

Checking the fitting

I test wise inserted the USB charging and audio connectors.. everything seems to fit.

How to get there

It's not as tedious as it reads, but patience is key. Those are the steps to get there:

- Assembling of printed parts by glueing them together using plain acetone

- Filling small gaps from not perfectly aligning parts using acetone-ABS-solution

- Drying 24 hours

- Hand-sanding (no sanding block) the whole housing with a 100 grit sandpaper

- Filling larger imperfections using acetone-ABS-solution

- Drying 24 hours

- Hand-sanding again, especially the filled areas, 100 grit

- First layer of spray filler

- Drying 24 hours

- Second layer of spray filler

- Drying 24 hours

- Sanding the whole housing with a 400 grit to a "class A"

- Dry-wiping and cleaning of debris from sanding

- First layer of sparkling black spray paint

- Drying 12 hours

- Second layer of sparkling black spray paint

- Drying 12 hours

- First layer of spray clear varnish

- Drying 12 hours

- Second layer of spray clear varnish

-

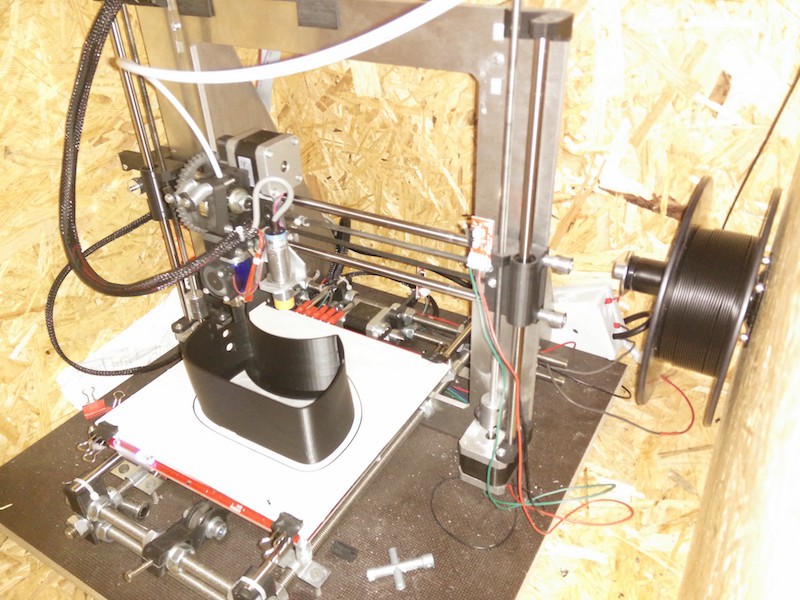

3D printing the shell

03/04/2016 at 18:29 • 2 commentsFor this project, I commited pretty much any crime in design for 3D-printing. No flats, lots of overhangs, thin shell (2mm). So the only way I could print this without excessive use of support structures was cutting the design into pieces that could be printed selfsupporting, thus maintaining a nice surface quality.

Fails

I tried smartABS and PET-G for this. In the first trial, I printed the smartABS at 255°C at 50mm/s. The bananaing was minimal, but the result (see below photo, the cracks were not caused by the switch) had many thermal cracks and would've required massive fixing.

![]()

Then I tried the PET-G, which I bought for printing large objects with less bananaing. Unfortunately, even after iterating down to 240 °C, wich is kind of the lower end in layer bonding, as well as different retraction settings, the PET-G was still very oozy and blobby. The nozzle ran into hard bumps of dripping plastic over and over again, which caused this print to fail, too (see right half of below photo).

![]()

Successes

So I went back to smartABS, which is still my favorite material, iterating upwards in temperature. I ended up printing the shell at 280 °C with 50 mm/s, way above the maximum specified temperature of smartABS (270 °C), but this improved the layer bonding enough to give me nice, banana-free shells without cracks. Below you can see my printer in its natural-wood habitat printing a center pice of the shell.

![]()

After about 30 hours of printing, I had all the parts crack- and banana-free.

The five parts were then glued together using aceton and acetone-ABS slurry. Then scotch tape holds it together until everything has hardened.

Moritz Walter

Moritz Walter