-

Fast Scooters, the Easy (eBay) Way

01/11/2018 at 07:13 • 0 commentsAfter our last update, we were flying along at 39 km/h and doing burnouts all over town! But all great things must come to an end, including the poor MOSFETs we'd crammed into that stock speed controller.

This gave me a new opportunity - why not check out some of the off-the-shelf overvolt kits and see how they go with the ridiculous motor and battery setup? That's exactly what I did!

Fundamentally, results were just okay. The overvolt controller from Fastscooters isn't built to handle such a large motor and we only hit 26 km/h. That said, it's an easy, accessible way to get into scooter mods, and that's cool.

Naturally, we're going to cram it full of fat MOSFETs and ruin the current limits. Watch this space.

Till next time,

TK out -

Gearing - The Key to Speed

06/02/2017 at 03:43 • 0 commentsAfter our last outing, we knew we had the power, but we lacked the raw speed. What to do? Gear it, obviously! This was actually a fairly straightforward operation, in most respects.

Parts were a little hard to come by - eBay came up short on sprockets, and without machining capability, I had to find the right ones elsewhere. Thankfully Alibaba came up with the goods and saved the day. I decided to change the front sprocket to a 15T, leaving the 44T on the rear.

![]()

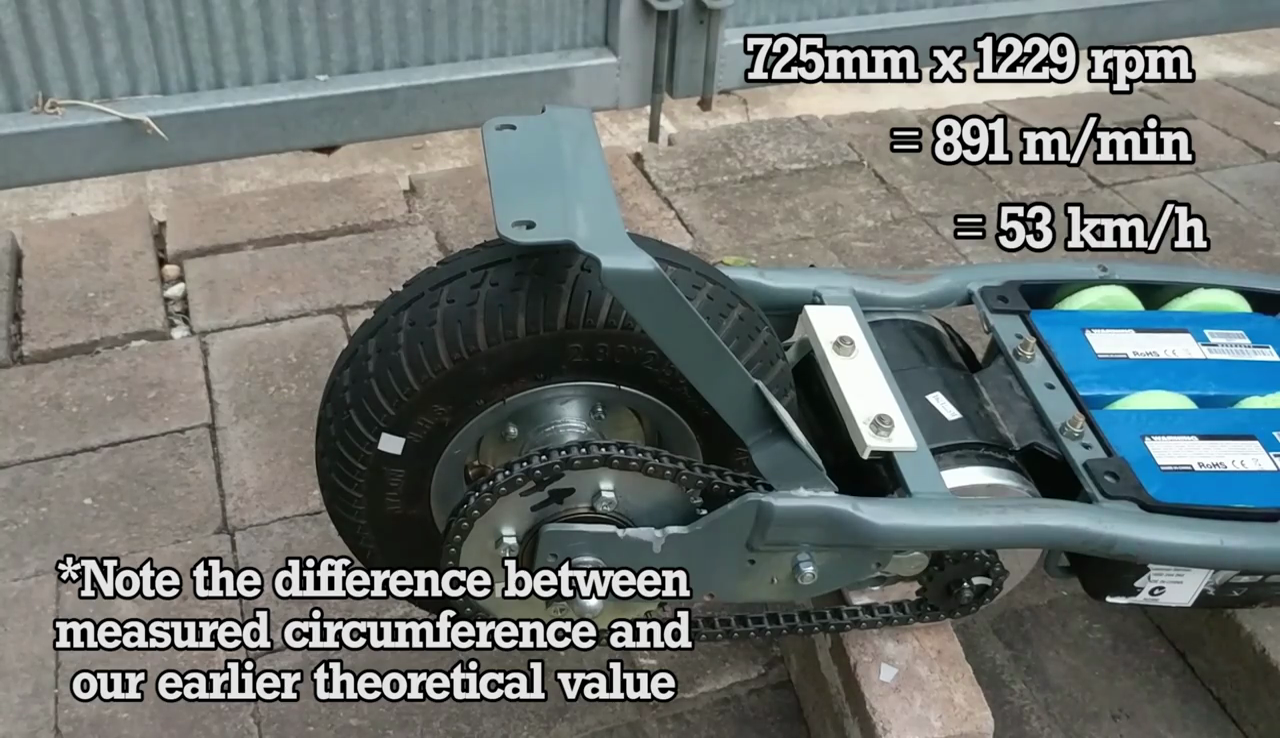

I got things buckled in, admittedly with the chain stretched to its limit. The first runs were not quite up to scratch - only 34 km/h. An improvement, but not enough. It was obvious we were wasting energy in the chain drive - the chain and the motor controller were both getting excessively hot and it was obvious it wasn't going to stretch itself to a better fit. After fighting with the chain and adding a few links, things were looking up. I measured the scooter's rear wheel diameter, and then sat the scooter up on bricks and ran the motor.

![]()

Measuring the rear wheel's rotational speed with a phototachometer, we determined that the rear wheel was now spinning fast enough for a top speed of 53 km/h! Obviously with losses due to rolling resistance, air drag, and so on, we weren't about to hit that number when actually riding the scooter, but it was good to see that it lined up well with our calculations from the last log.

![]()

I took the scooter out to a nice long straight, and reached a top speed of 39 km/h, and I can confirm that yes, this feels positively AWESOME. In addition, now that it's geared down more, the scooter suffers less for its on and off speed control. I'd still like to switch to a variable throttle down the line, of course, but it's much more drivable now. Oh, and if you were wondering, with a little WD40 to help? Yes - it'll do burnouts.

I'm really digging the scooter now that it's properly quick, and I'm looking forward to flying around the neighbourhood carrying an entirely appropriate amount of speed. It's now got me excited for the next scooter build...![]()

Till next time,TK out.

-

Big motor for the Razor E300!

02/15/2017 at 05:18 • 1 commentWe still aren't going fast enough. It's time for MOAR MODS!

Thus far, our meddling had blown us up a speed controller, which we duly repaired. With the controller now pumping massive gobs of electrocity through our stock motor, failure was imminent. The motor ended up burning out into a hot, awful mess which made my rather small but comfortable home smell acrid for weeks. I'm not even kidding. Weeks.

![]()

The 36V badboy I enlisted for the build from eBay.

We needed to upgrade. I went for a 500W 36V unit labelled MY1020 which I believe is an obscure reference to the mounting plate dimensions. If you know more on that, let me know. There were issues from the get go - it simply didn't fit.![]()

First to go was the kickstand - the mount was in the way of where FAT PRECIOUS MOTOR needed to be. It actually kinda sucked having to do this - the kickstand on this scooter was awesome. Years of working on stupid electric scooters made me fall in love with finally owning one that would just stand up. That said, I was tired of setting off with it down and then nearly stacking it when it impacted the ground at speed...

![]() Next up was the brakes. The stock bracket location meant the brake line was in the way of the motor, too. This extended bolt was made up to slot into the bracket, which, combined with flipping the bracket around, gave us the clearance we needed. Incidentally, we'd needed to shorten the sliding tube a little. The cordless-drill-come-lathe was the way to do it.

Next up was the brakes. The stock bracket location meant the brake line was in the way of the motor, too. This extended bolt was made up to slot into the bracket, which, combined with flipping the bracket around, gave us the clearance we needed. Incidentally, we'd needed to shorten the sliding tube a little. The cordless-drill-come-lathe was the way to do it.![]() Pictured: Cordless drill in lathe's clothing

Pictured: Cordless drill in lathe's clothingSimply chuck the workpiece into the drill and spin away. Then have at it with whatever the most relevant tool seems to be. We used a flap disc on an angle grinder. You can do all sorts of dangerous imprecise machining this way!

![]()

The assembled brake assembly. This reroutes the brake cable nicely.

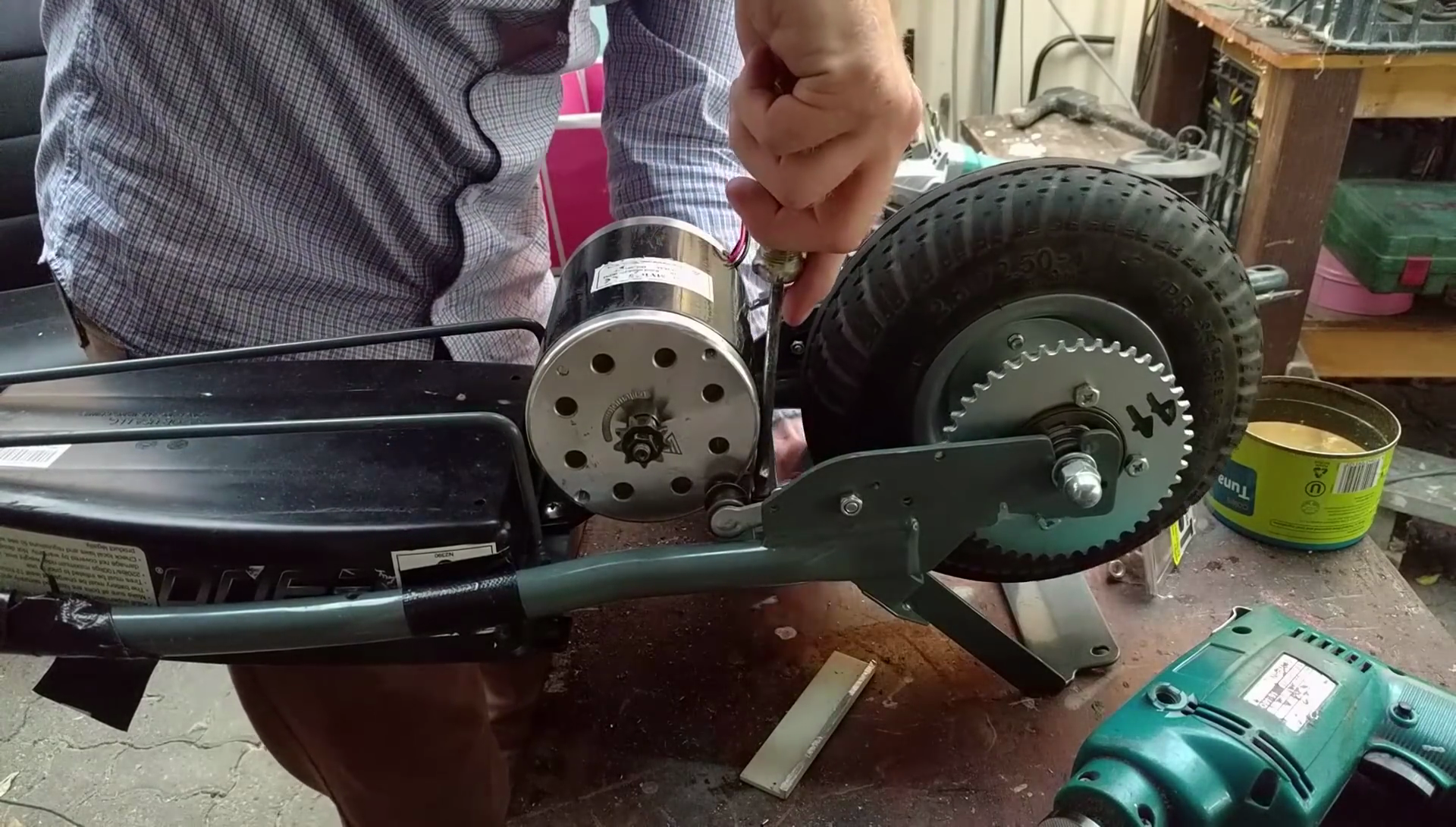

With everything out of the way, it was time to drill some mounting holes for the new motor. Straightforward enough on one side, but on the other, we had to fab up a special bracket to clamp the motor onto the mounting rail, as the rail itself wasn't wide enough to meet up with the motor's mounting faces. An unconventional solution but it should do the trick until I can weld something up later.![]() Bolting up the motor to the frame. Clamping bracket not easily visible. Note the 44-tooth T8F sprocket fitted to the rear wheel.

Bolting up the motor to the frame. Clamping bracket not easily visible. Note the 44-tooth T8F sprocket fitted to the rear wheel.

With the motor in, it was then a matter of fitting the new T8F sprocket to the rear wheel. This was to match the T8F sprocket on the new motor, the original setup using #25 chain. Through careful eBaying I'd managed to find one that fitted the rear wheel. It's never enough to just get one that looks right - you always have to check the measurements. Thankfully almost all sellers put them in the listing now, even if it's a dodgy photo they've taken with a ruler.

The original gearing was 11T on the motor, with a 55T rear sprocket. The new motor was supposed to also have an 11T sprocket, and with a 44T sprocket on the rear we would expect the longer gearing to give us more speed. But I'd ignored something that should have been blatantly obvious. That, and the motor actually shipped with a 9T sprocket. This sort of thing is par for the course on eBay.Calculating the ratios is disappointing:

Original: 55T rear, 11T front: 5:1 gear ratio

New: 44T rear, 9T front: 4.9:1 gear ratio

That's hardly any change at all! Oh well.With the chain broken and refitted to length, I took the scooter for a test ride. After just 50 meters the chain came off! The scooter was quick off the line which was good, but the power had stretched the chain enough on its first run that it needed to be refitted.

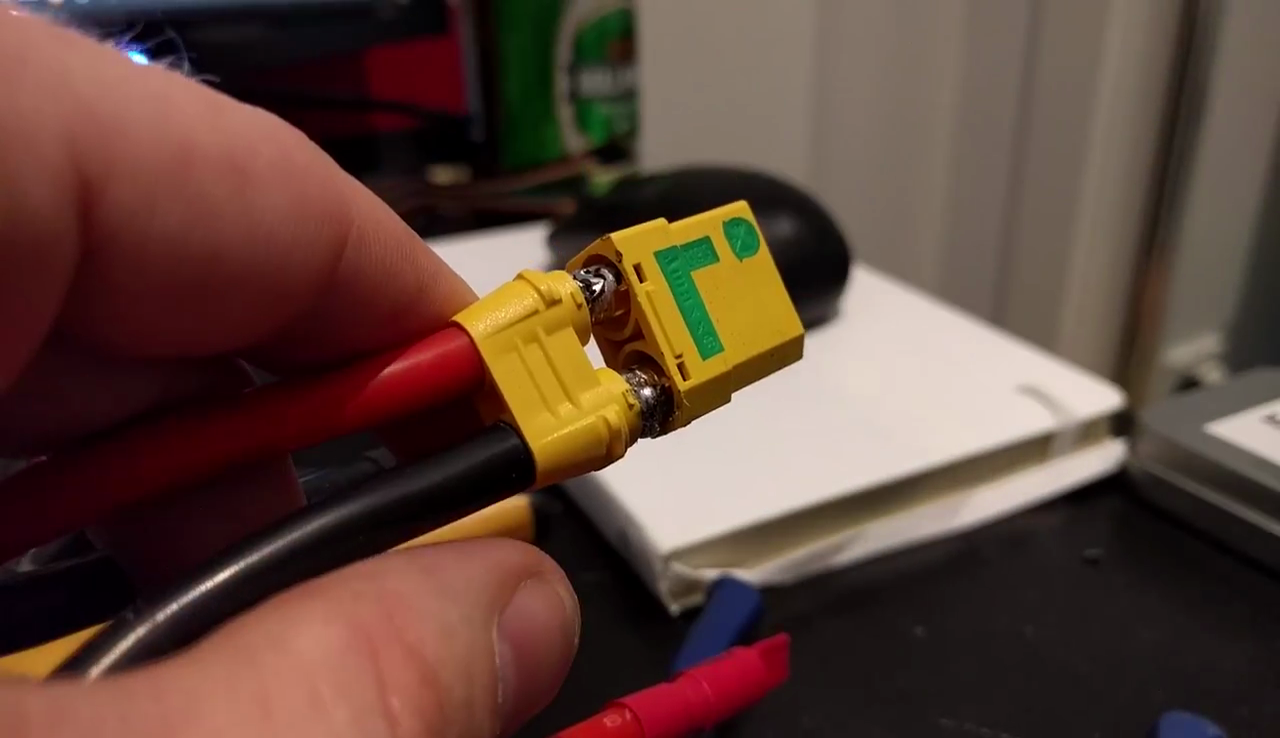

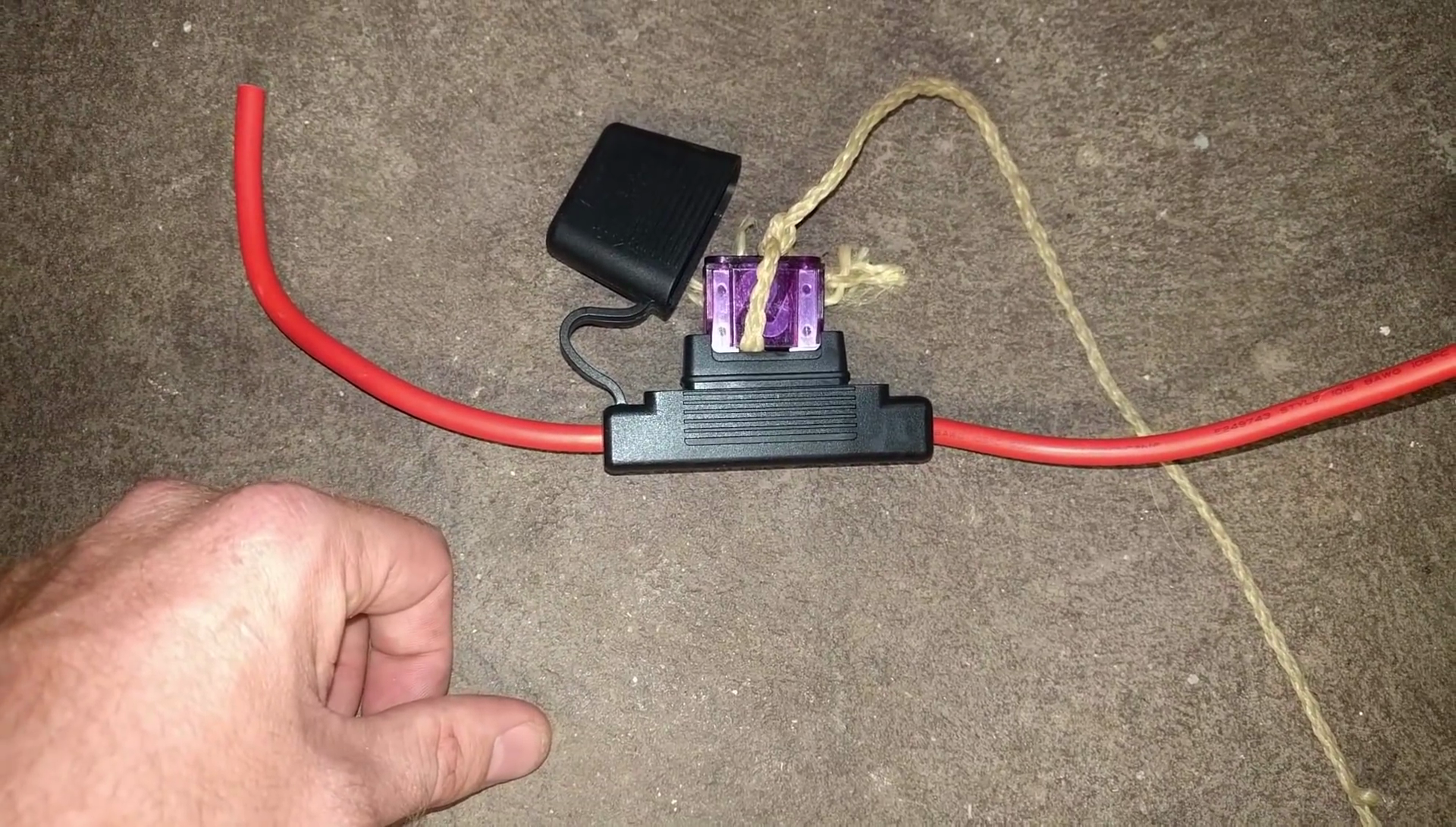

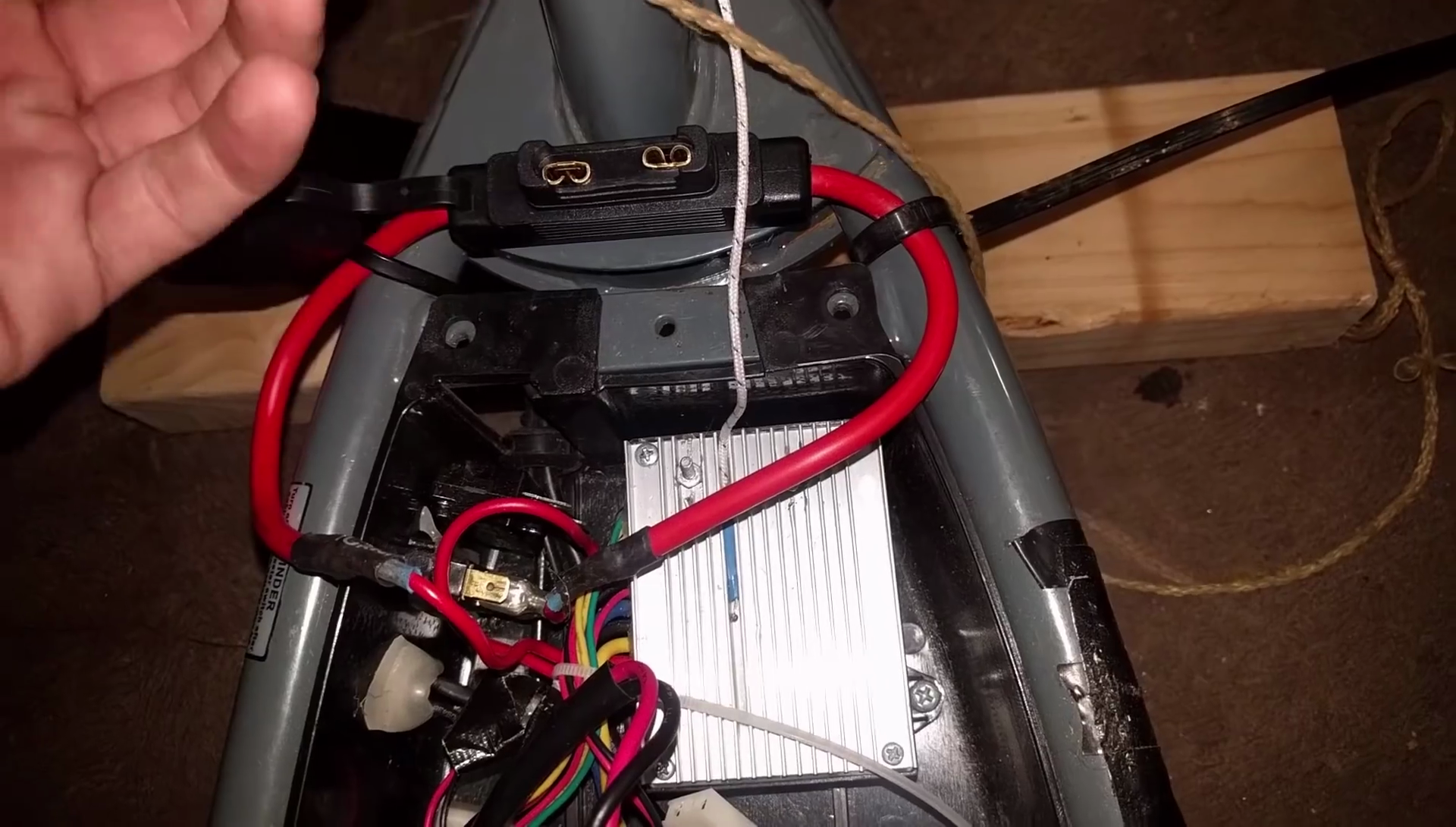

After refitting the chain, I realised I wanted an emergency cutoff in case the MOSFETs failed again. I decided to press a 100A megafuse & fuse holder into service. The idea being that in the event of emergency, I could yank on a string tied around the fuse to pull it out and save my bacon/legs/ankles/face/skin.![]() The fuseholder with fuse & YISHF (yank-if-shit-hits-fan) string.

The fuseholder with fuse & YISHF (yank-if-shit-hits-fan) string.Is this a good idea? Well, no. Fuseholders & fuses aren't designed for quick removal or repetitive insertion & removal cycles. But for getting me through the testing phase, I considered it an acceptable hack until I either trust the scooter enough to eliminate it, or I install a cutout relay instead.

![]() Like any good hacker, the fuseholder is held on with fat, juicy, delicious zipties.

Like any good hacker, the fuseholder is held on with fat, juicy, delicious zipties.

With everything in place, I retested the scooter. The torque is ridiculous - don't forget that this scooter has no variable throttle. It's all or nothing. Acceleration off the line is enough to throw you clear off the scooter. This is awesome - it shows we have gobs of power. However, there was a problem - our top speed was LESS THAN BEFORE?!? HOW?!?!

It all comes down to gearing and RPM.

The stock motor had a rated speed of around 2750 RPM... at 24V. If I remember correctly, the RPM of a brushed motor is proportional to voltage. Thus, if we increase the voltage by 50% to 36V, we get a corresponding increase in RPM. Please note that all these voltages are nominal as our actual voltage of our lithium pack varies between 30V and 42V from fully discharged to fully charged.

The stock motor has a rated speed at 24V of 2750 RPM.

2750 rpm / 24V = 114.583 rpm/volt

114.583 rpm/volt * 36V = 4125 rpm.

At 36 V, our stock motor which has been overvolted is spinning at 4125 rpm. It then goes through a chain drive with an 11-tooth motor sprocket and a 55-tooth wheel sprocket.4125 rpm * 11/55 = 825 rpm

So our rear wheel is turning at the same speed as the wheel sprocket to which it is attached - 825 rpm. The rear tyre on an E300 is usually a 3.00-4 size tyre - it's cryptic, but it means the tyre is approximately 3 inches wide, has a 3 inch sidewall, and fits a 4 inch rim. This means the tyre diameter is around 10 inches - or 254 mm. It's a simple formula to get the circumference of the tyre.

Circumference = π* 254mm = 798mmWe can then calculate the theoretical top speed of the overvolted motor setup.

798 mm * 825 rpm = 658350 mm/min = 39.5 km/h.

Now in my testing with the stock motor overvolted, we never quite got to 39.5 km/h. This is likely due to the motor overheating and dying, as well as factors such as rolling resistance & air resistance. But it's a good guide for a possible top speed to shoot for.

Now let's run the calculation again for our new motor setup. Our new motor is a 500W, 36V motor. That is, it's rated speed is 2500 rpm at 36 V! Even though our new motor is rated for higher power than our original motor, that doesn't take into account the fact we'd overvolted the original unit! You may be seeing the problem already. Let's run the calculation, taking into account our different gear ratio.

2500 rpm * 9/44 = 511 rpm

So our rear wheel is spinning at 511 rpm.

798 mm * 511 rpm = 407778 mm/min = 24.5 km/h

This is a VERY interesting value - using a GPS speedometer app on my phone, I got a top speed of exactly 25 km/h on the new setup. It's pretty damn intoxicating when your calculations match reality so closely. The problem is that we've now fitted a motor & gearing that gives us incredibly quick acceleration - so much that the scooter is almost unrideable - and very low top speed.

Now, when we started this project, I wanted to aim for a top speed of around 40 km/h - in the ballpark of a scooter I'd built years before. I could overvolt this motor but I'd likely melt it again. Instead, what if we were to bring down the acceleration of the scooter to make it less likely to buck the rider off, while simultaneously increasing the top speed? What sort of gear ratio would we choose to hit 40km/h?

Well, first things first, we don't want to change the rear gear. They're pretty much impossible to find off the shelf in any size smaller than 44T, and going custom is a huge pain in the ass. Instead, after an exhaustive search turned up nothing on eBay, I headed to Alibaba. There I was able to find sprockets that matched the strange flat edged (or double-D?) mounting my motor shaft was machined with.

Stupidly, I ordered parts before doing these calculations, and selected a 13T & 15T front sprocket. Let's run the numbers.

13T:

2500 rpm * 13/44 = 739 rpm

798 mm * 739 rpm = 589722 mm/min = 35.4 km/h

15T:2500 rpm * 15/44 = 852 rpm

798 mm * 852 rpm = 679896 mm/min = 40.8 km/h

That looks good! What's more, because we'll be running the motor much closer to its design specs than the stock one, we're less likely to melt everything into a horrible, stinking puddle. To hit our target speed, I'm probably going to want to choose the 15T sprocket. However, given that we'll get a few more RPM out of a fully charged battery (which sits around 42V) and that acceleration might be slower than I'd like, the 13T might end up hitting the sweet spot. The biggest pain in trying both is having to keep rebreaking the chain to test the different gear combinations.

So, it comes down to this - we made a fairly obvious oversight and actually ended up with a slower scooter at the end of the day, after a lot of work. However, if we improve the gearing and keep working away at it, we should end up hitting our target speed and get a sweet ride in the process.

Wish me luck.

Until next time,

TK out.

-

Speed Controller Hax - Place your FETs!

09/19/2016 at 05:00 • 2 commentsIt was time to try and get this thing burning down the street with its new batteries. We got to burning, at least. We definitely got to burning. Check out the video for the full story. Details below.

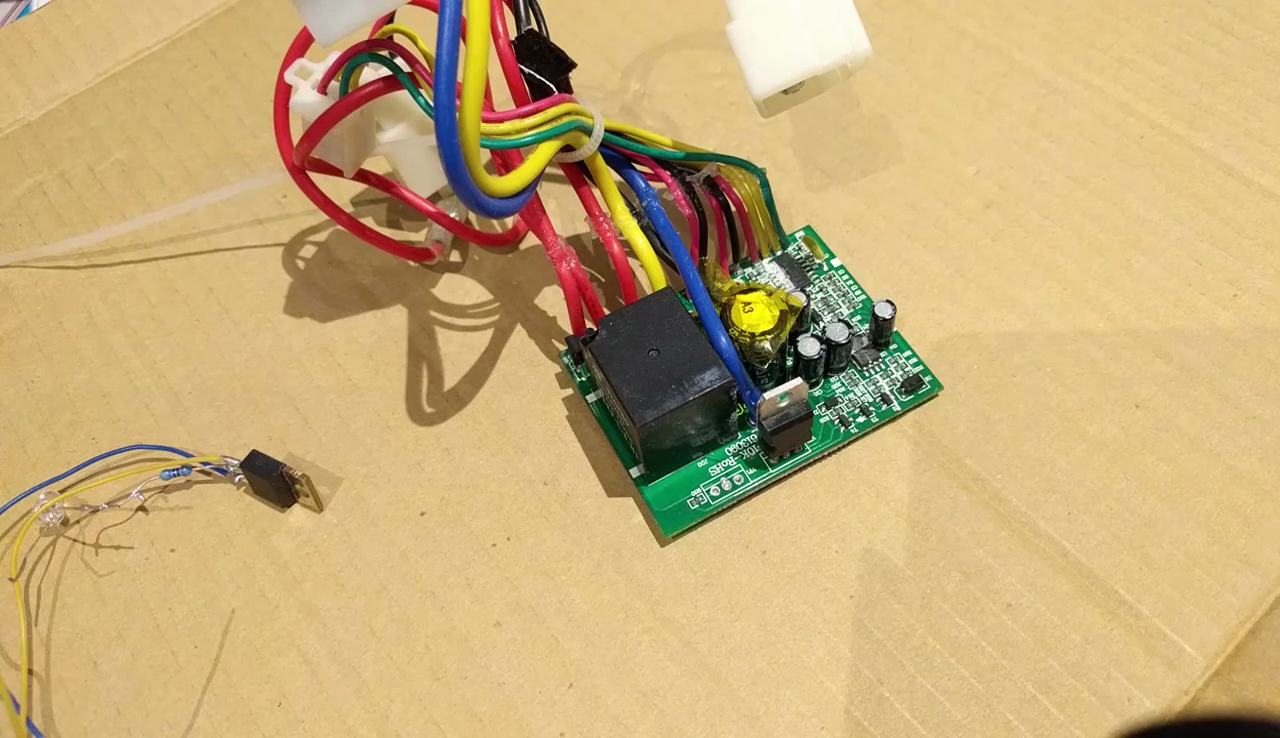

Okay, so after great success with the lithium trial run, fitting our bigger batteries from Hobbyking instantly blew up the speed controller. When we dosed it with some hot, fresh amps, the FET was killed instantly. Most disappointing! Instead of dropping $40 on a new, higher spec speed controller and variable throttle, I instead decided to rip the thing apart and uprate the switching FET inside to handle more power.

![]()

The speed controller, right, with the old blown IRFB3607, left.

However, I had a problem - the IRFB3607 inside was rated to handle 80A & 75V. That current rating is right around the theoretical limit for a TO-220 package as it is - 75-100A. Replacing it with another TO-220 wasn't going to cut it. Instead, I had to get creative - I decided I'd go with parallel FETs to handle the strain.

![]()

Modifying the heatsink and mounting hardware for parallel FET GOODNESS.

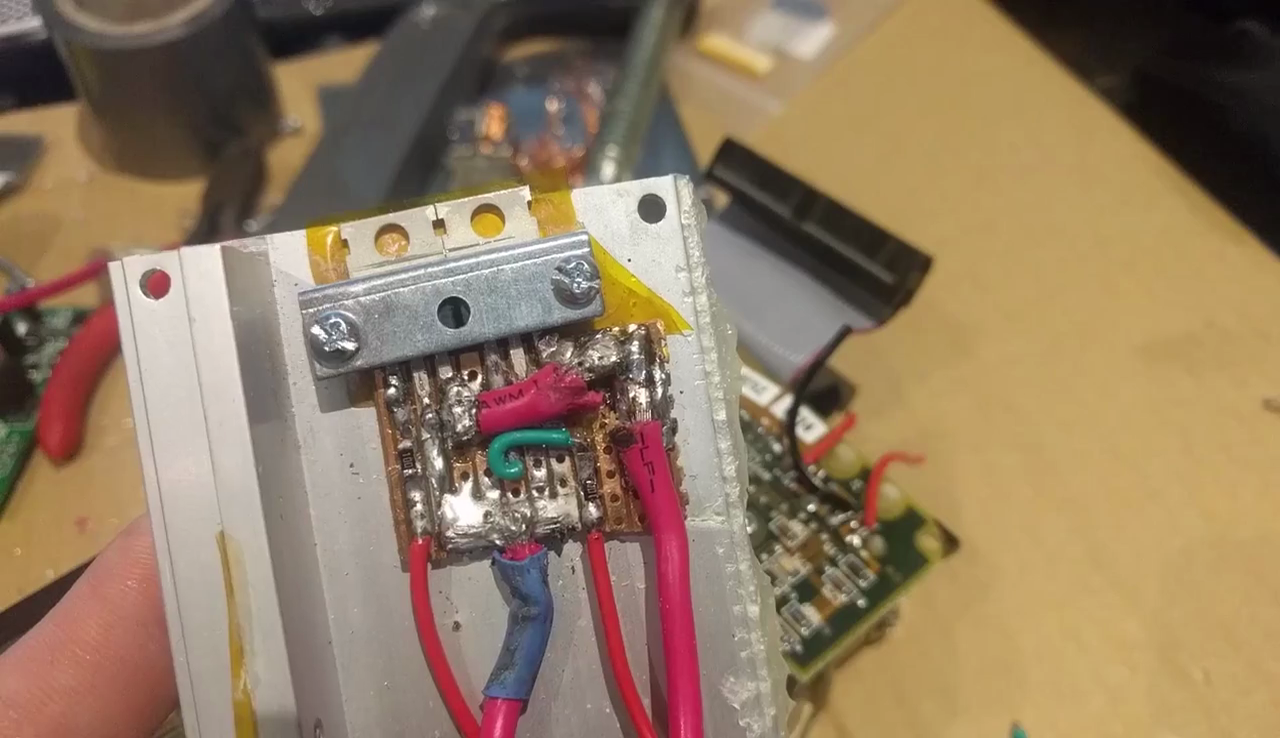

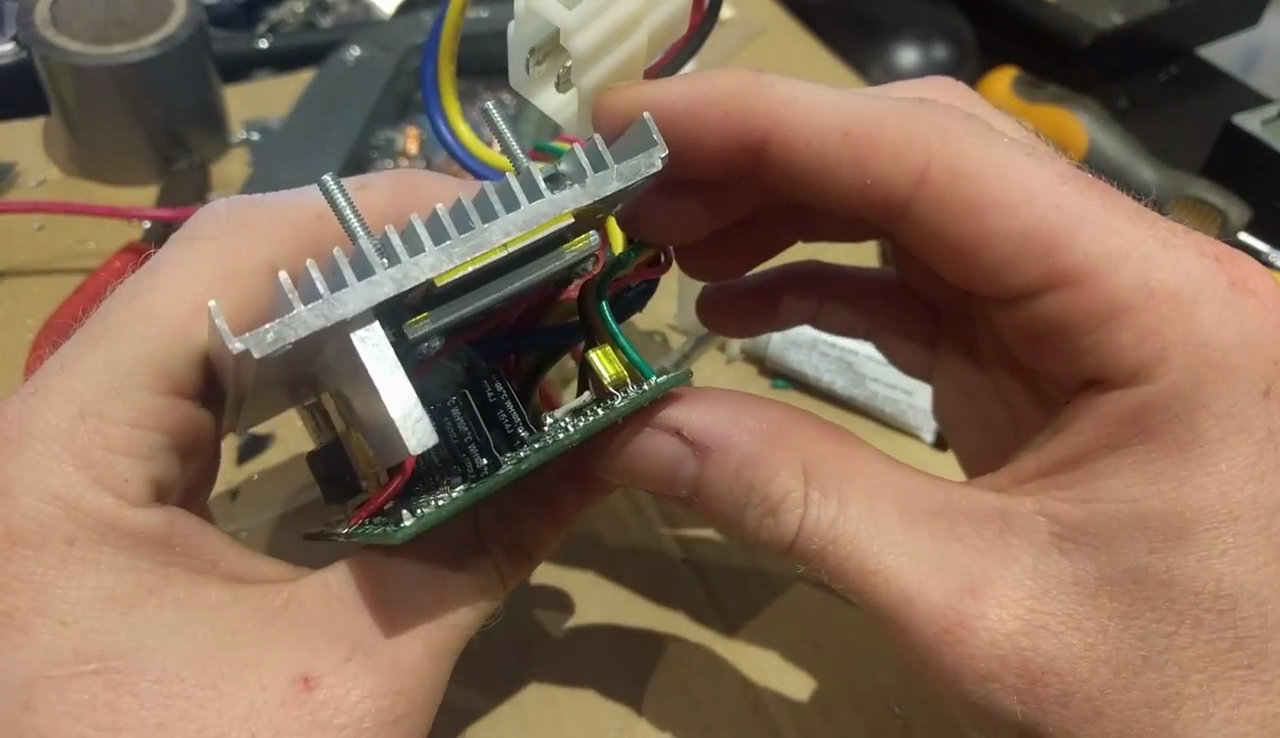

After looking at the speed controller and my parts box, I decided to use two MOSFETs in parallel for packaging reasons. I chose the TK100E08N1, rated at 214A & 80V. This is an example of the manufacturer rating the gate current capability of the silicon, ignoring the fact the device package can't effectively handle in excess of 100A.

I used a small piece of veroboard and modified the existing mounting hardware to fit the parallel FETs to the original heatsink. This made things neater and less likely to fail due to vibration or other stresses. Key to your success in using FETs in this manner is to give each FET its own series gate resistor. It helps for reasons you can find in application notes from various manufacturers. Oscillation is the biggest problem. I used a couple of SMD 10 ohm resistors I scavenged from an old hard drive.

![]()

The parallel FET assembly. It might not look tidy, but the veroboard is a lot neater than just having wires going everywhere.

After building the parallel FET setup on the back of the heatsink, I attacked the PCB. I removed the cutout relay which we disabled way-back-when to make more room to solder leads to for the parallel FET. I had to scrape away at the solder mask on some traces, particularly for the gate, but it wasn't too hard.

![]() Reassembling the speed controller. The new FETs are a good fit and make excellent contact with the heatsink.

Reassembling the speed controller. The new FETs are a good fit and make excellent contact with the heatsink.After reassembling everything into the scooter, it was time to test. AND IT WORKED.

![]()

IT WERKS!

SORT OF. The scooter was initially incredibly quick, but quickly lost power. I couldn't get close to the previous speeds I'd reached and there was a hot, burning smell. It was the motor.

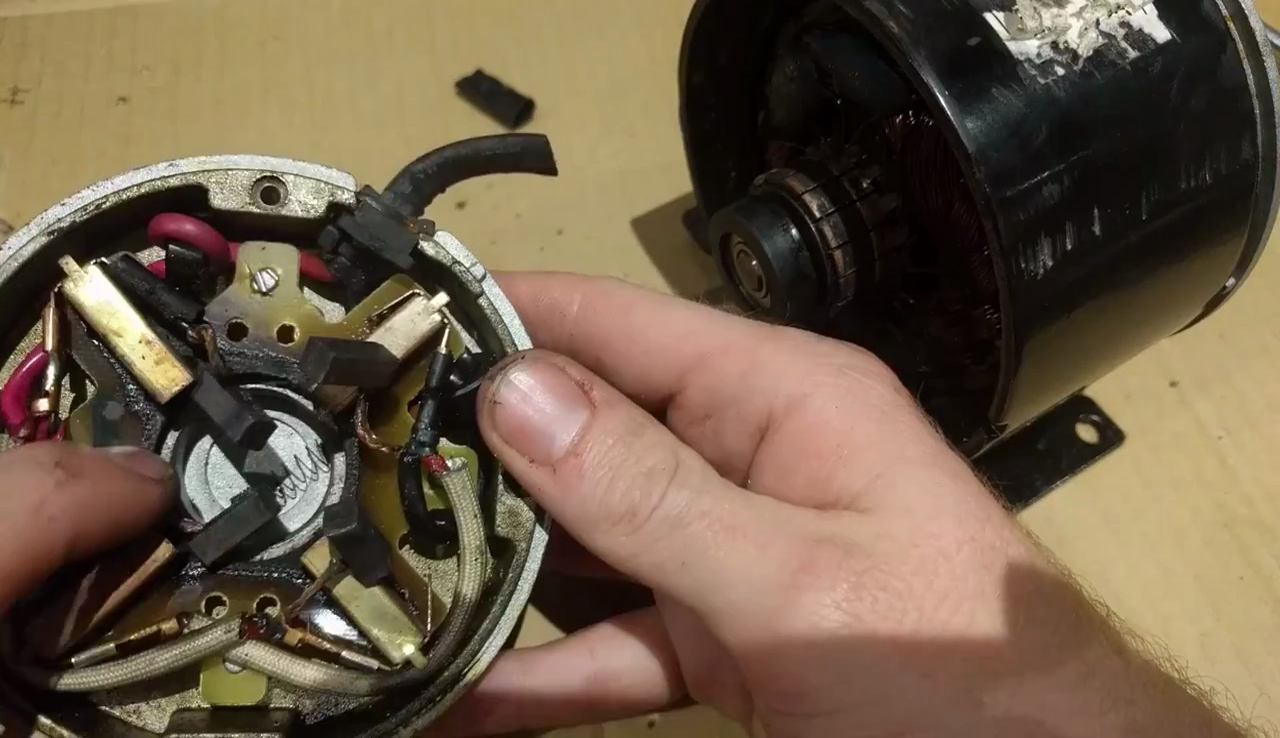

![]()

Me, glaring at the motor that just burnt me in dismay.

At this point, I cannot warn you enough. DO NOT. UNDER ANY CIRCUMSTANCES. TAKE A BURNT OUT MOTOR INSIDE YOUR HOUSE TO WORK ON. My lab space and kitchen STILL smell like fiery death a WHOLE WEEK LATER. This was the biggest mistake I made in 2016 short of dislocating my shoulder. I am not even kidding.

![]() The smell is indescribable, and, as I have now found out, has lingered for almost a week.

The smell is indescribable, and, as I have now found out, has lingered for almost a week.

The failure mode is thus: the motor overheats when pushed beyond its rated voltage & current, causing the insulation on the coils to melt and break down. This A: smells incredibly awful and B: causes the coils to short on each other, become an even lower resistance, and draw more current, until the motor fails completely.![]()

Burnt. Awful. Sad.

Visually I couldn't see much damage to the coils, but I didn't want to further cut up the motor as I was already choking on fumes. After 40 minutes out of the scooter the rotor was still hot to the touch. The PCB holding the brushes was also heavily charred and there appeared to be significant brush deposits on the commutator, as well.

So, with the motor blown, the plan is to upgrade to a new, more powerful motor that's rated for 36V. This leaves me in an uncomfortable position; with even more power than ever, I'd dearly like to switch to a speed controller with a variable throttle to make it more drivable. However, that would undermine all the cool work I did upgrading this one with parallel FETs. Someone decide for me.

Until next time - TK out. -

The Big Battery Swap

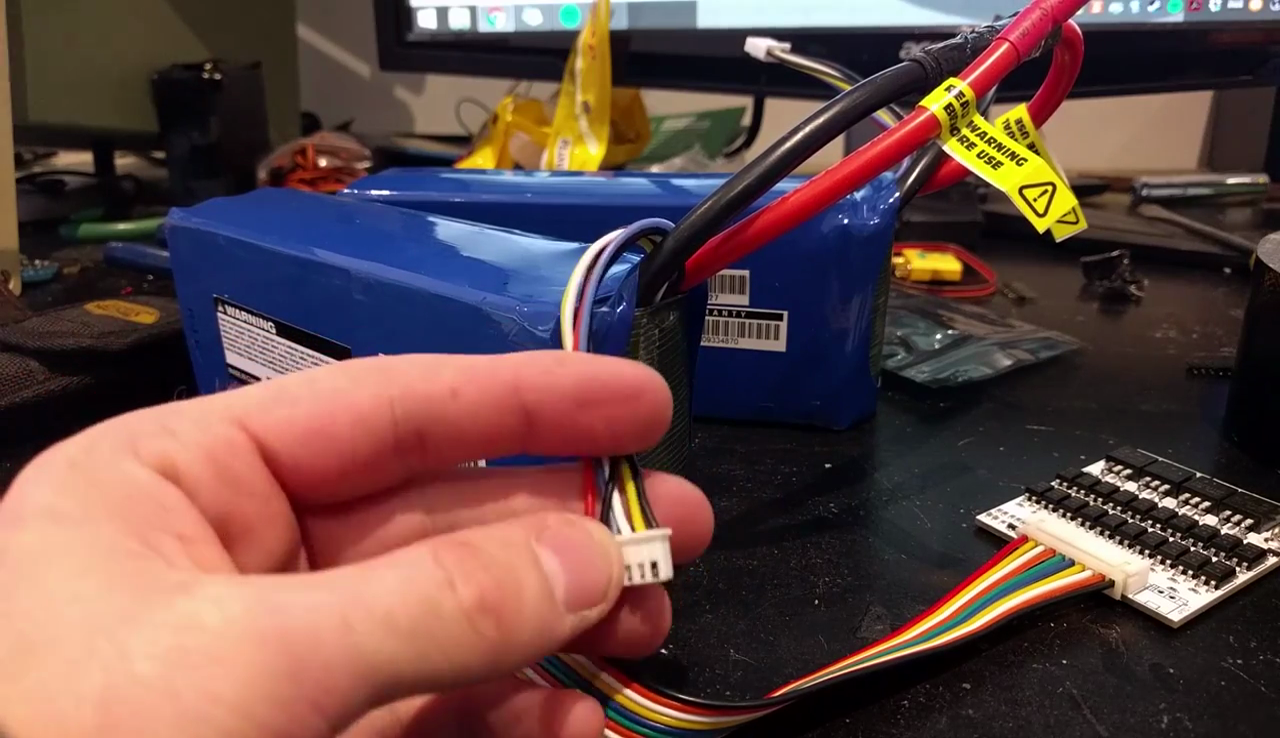

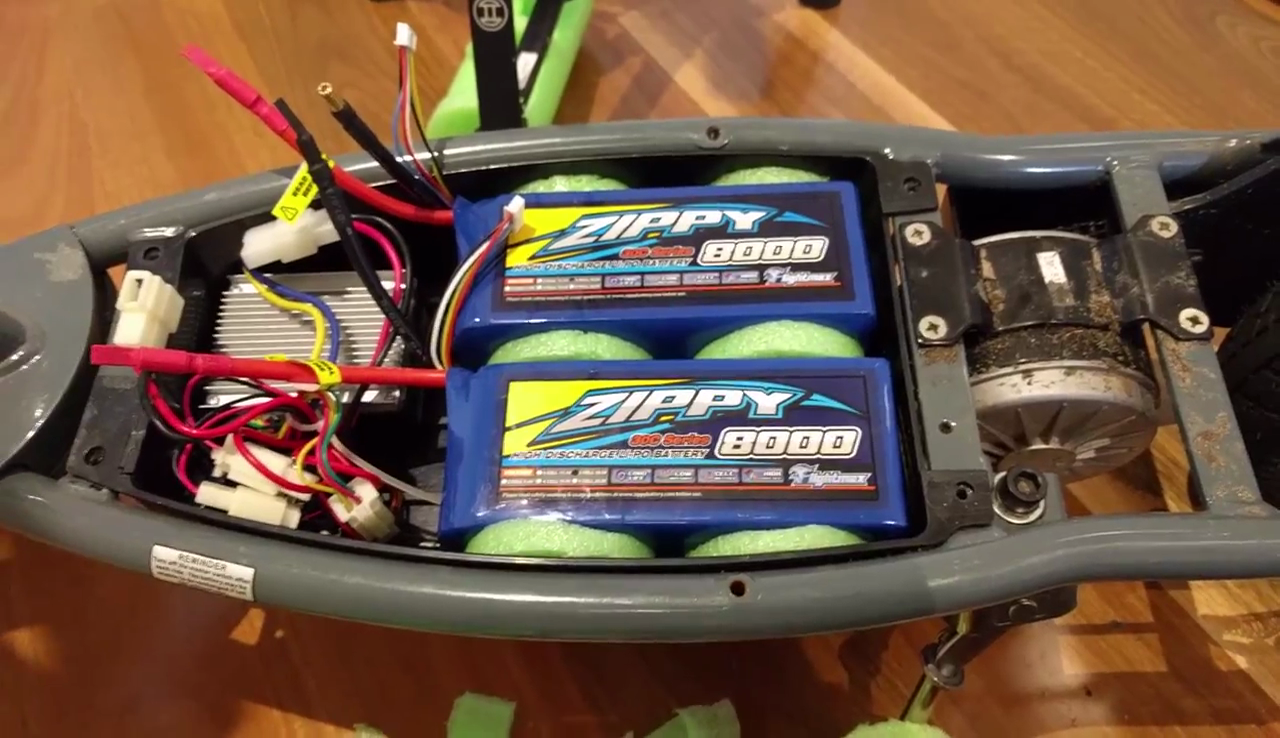

08/16/2016 at 04:18 • 2 commentsAfter the remarkably successful test with the Ryobi drill batteries, I was ready to upgrade to a proper lithium pack. I specced a couple of 5 cell, 8 Ah badboys from Hobbyking, with which I'd build a 10S pack. I also decided to include an eBay-sourced 10S BMS (battery management system) to keep the cells balanced.

![]()

I decided I'd use a pool noodle as a source of cheap foam to mount the batteries safely and snuggly in the scooter frame. This worked great and it's hard to lose for $3.

![]() Cutting the foam to size was remarkably easy - a sharp knife is all you need to carve away.

Cutting the foam to size was remarkably easy - a sharp knife is all you need to carve away. ![]() I was stoked with how neat this turned out. The batteries are held in place really well - highly recommended! Next up it was time to do the wiring for the BMS.

I was stoked with how neat this turned out. The batteries are held in place really well - highly recommended! Next up it was time to do the wiring for the BMS.![]()

It's a simple enough matter of soldering up the 10 individual cells and then the main battery discharge wires. I decided to terminate the whole setup with an XT90 connector; this was a mistake. Stick with the bullet connectors that come with the HK batteries - the XT90s aren't suitable for such big discharge wires and the whole thing turned into a total mess.

![]()

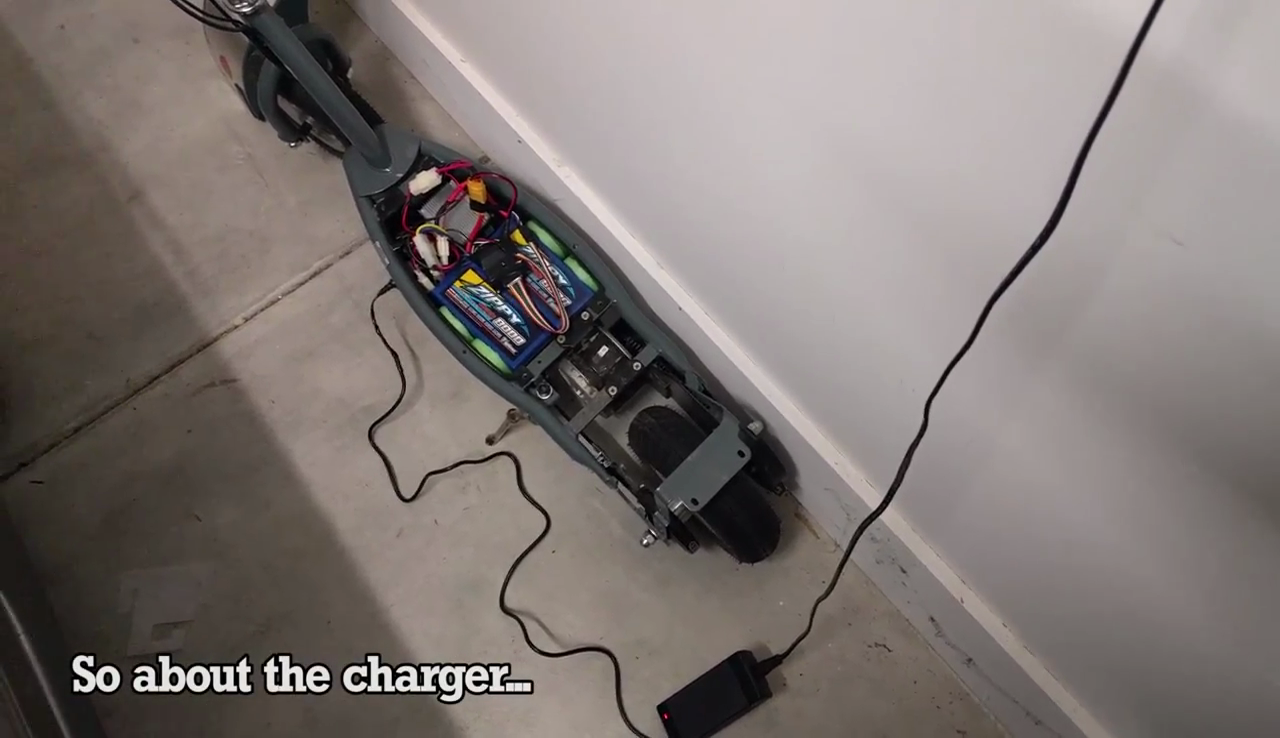

I also had to spec a 42V lithium battery charger from eBay; this one is sold for charging ebikes. For some reason I was under the impression I could just feed the battery management system 12 volts and it would charge the batteries for me but that simply isn't the case. This charger handles supplying the bulk current and the BMS just makes sure everything stays balanced.

![]()

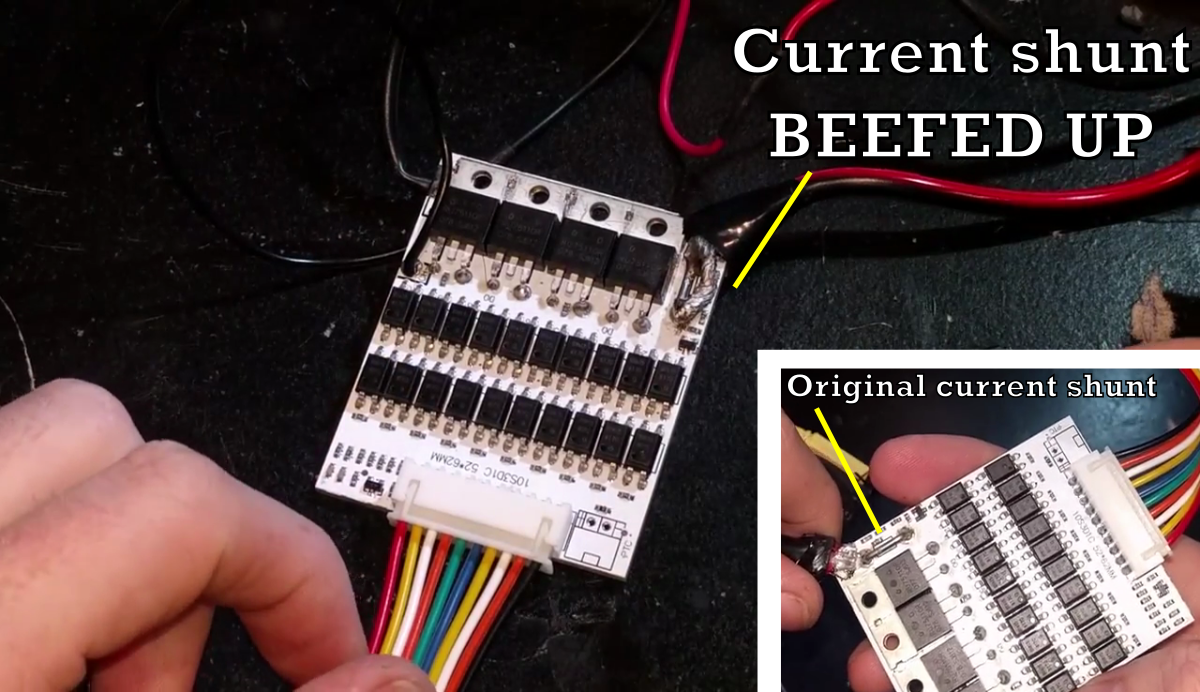

With everything wired up, I went for a test run. I jumped on the scooter and pulled the throttle but nothing happened! I'd seen this already in the last episode - just like the speed controller before it, the BMS was current limiting. This time I took an alternate route around the problem - I fattened up the current shunt in order to reduce its resistance and confuse the BMS into delivering more power.

![]()

This works because the circuit measures the voltage drop across a known resistance (the current shunt) to determine the current flow. Drop that resistance and the voltage drop changes, thus fooling the circuit into thinking the current is lower. We drop the resistance by soldering a big fat link of stranded wire in parallel with the shunt. So, how'd it go?

...

![]()

![]()

![]()

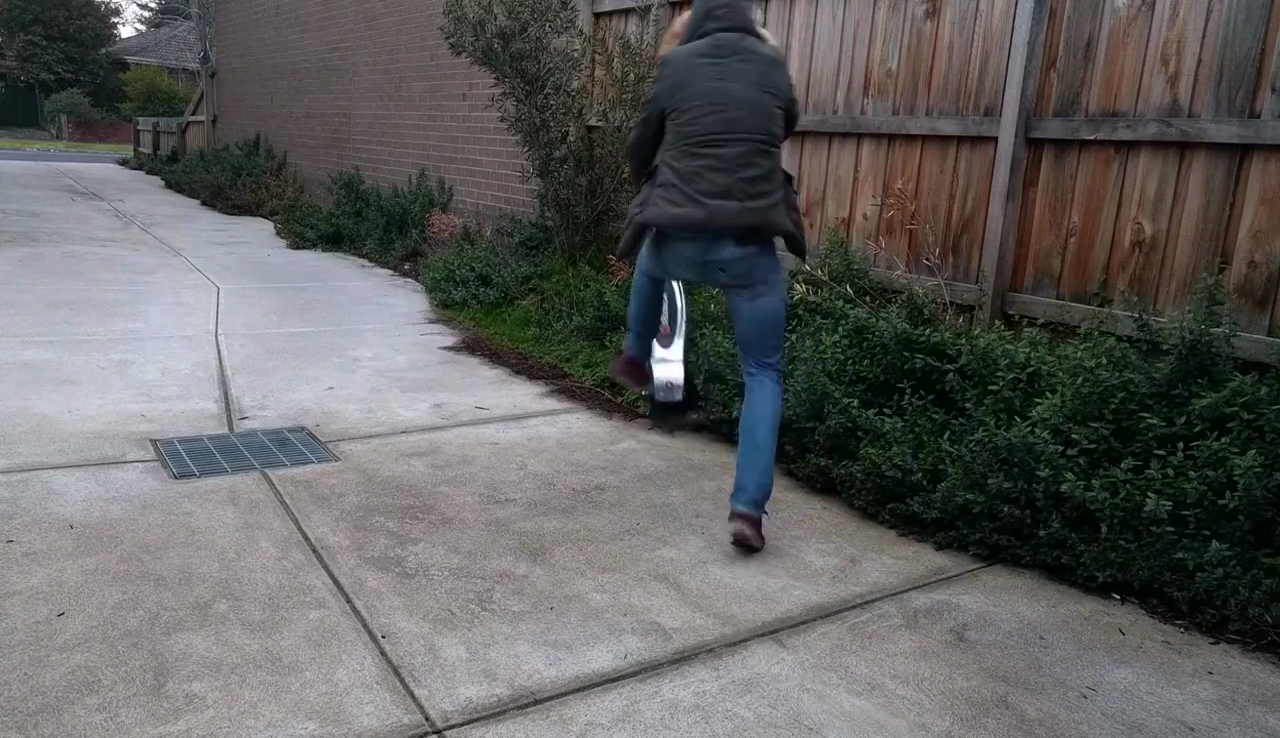

...not well! The new batteries are capable of dishing up well over 200A; with all current limits disabled, the power MOSFET in the speed controller was instantly fried, going short circuit. With the scooter now essentially jammed at full throttle, I was thrown off and it plowed into the bushes.

![]()

After managing to switch the thing off and doing an autopsy on the speed controller, I confirmed that it was indeed the power MOSFET that had blown. A shame but not entirely unexpected, I suppose. So what to do next? Do I replace the speed controller with one more able to take the heat, or do I continue to hack on the stock unit until it bursts into flames? Keep an eye out... this isn't over yet!

TK OUT.

TK

TK

Next up was the brakes. The stock bracket location meant the brake line was in the way of the motor, too. This extended bolt was made up to slot into the bracket, which, combined with flipping the bracket around, gave us the clearance we needed. Incidentally, we'd needed to shorten the sliding tube a little. The cordless-drill-come-lathe was the way to do it.

Next up was the brakes. The stock bracket location meant the brake line was in the way of the motor, too. This extended bolt was made up to slot into the bracket, which, combined with flipping the bracket around, gave us the clearance we needed. Incidentally, we'd needed to shorten the sliding tube a little. The cordless-drill-come-lathe was the way to do it. Pictured: Cordless drill in lathe's clothing

Pictured: Cordless drill in lathe's clothing

Bolting up the motor to the frame. Clamping bracket not easily visible. Note the 44-tooth T8F sprocket fitted to the rear wheel.

Bolting up the motor to the frame. Clamping bracket not easily visible. Note the 44-tooth T8F sprocket fitted to the rear wheel. The fuseholder with fuse & YISHF (yank-if-shit-hits-fan) string.

The fuseholder with fuse & YISHF (yank-if-shit-hits-fan) string. Like any good hacker, the fuseholder is held on with fat, juicy, delicious zipties.

Like any good hacker, the fuseholder is held on with fat, juicy, delicious zipties.

Reassembling the speed controller. The new FETs are a good fit and make excellent contact with the heatsink.

Reassembling the speed controller. The new FETs are a good fit and make excellent contact with the heatsink.

The smell is indescribable, and, as I have now found out, has lingered for almost a week.

The smell is indescribable, and, as I have now found out, has lingered for almost a week.

Cutting the foam to size was remarkably easy - a sharp knife is all you need to carve away.

Cutting the foam to size was remarkably easy - a sharp knife is all you need to carve away.  I was stoked with how neat this turned out. The batteries are held in place really well - highly recommended! Next up it was time to do the wiring for the BMS.

I was stoked with how neat this turned out. The batteries are held in place really well - highly recommended! Next up it was time to do the wiring for the BMS.