-

Ferranti Packard display driving requirements

03/25/2018 at 08:17 • 0 commentsThe datasheet/brochure for the FP-00SS5-7 displays doesn't give much information about what's required to drive them. It gives an example of 16V at <350mA for 1ms, but I wanted to check how the segment flipping performed under different conditions.

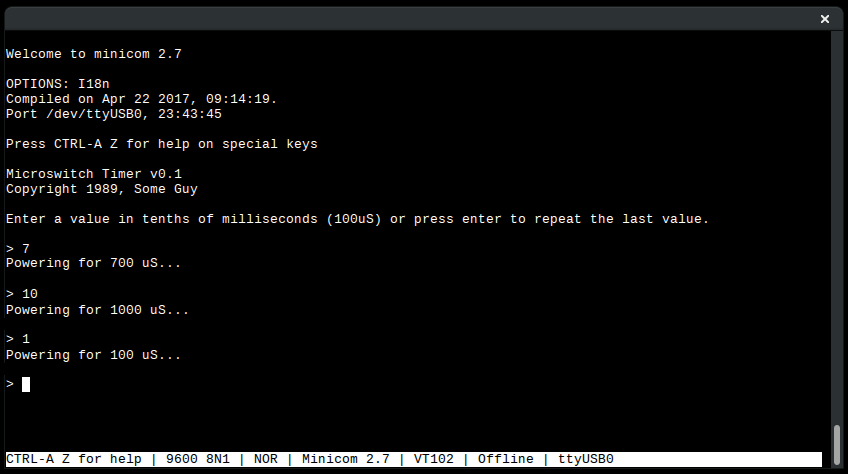

To pulse power on demand for arbitrary amounts of time, I grabbed an IRFZ44N MOSFET and hacked together a not-entirely-accurate, but good enough serial console on an AVR microcontroller (code here):

![]()

Results

As expected, the segments flip fine using the datasheet value of 1ms @ 16V.

Segments start to move at about 9V, but the field generated is barely strong enough to keep a segment held in place. From observation, 12V seems to be the minimum voltage to drive segments firmly/reliably.

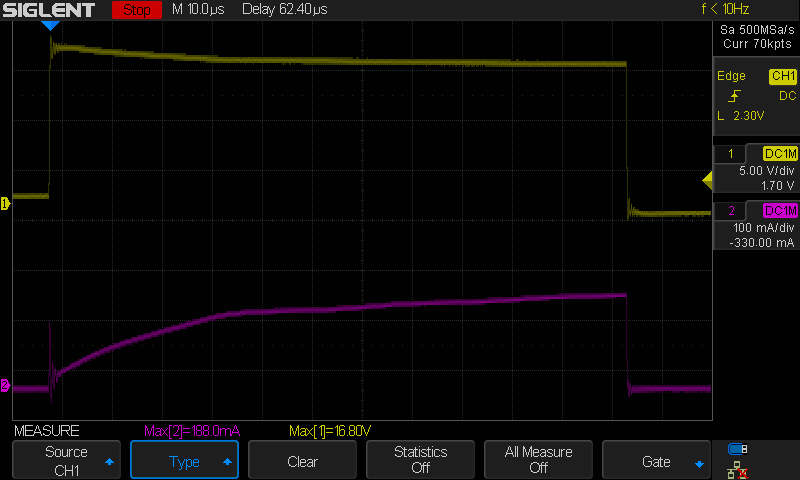

At 16V, segments will flip when powered for >100µs. The field is a bit weak at with this small amount of total power though, and rattle around if the display is moved:

![]()

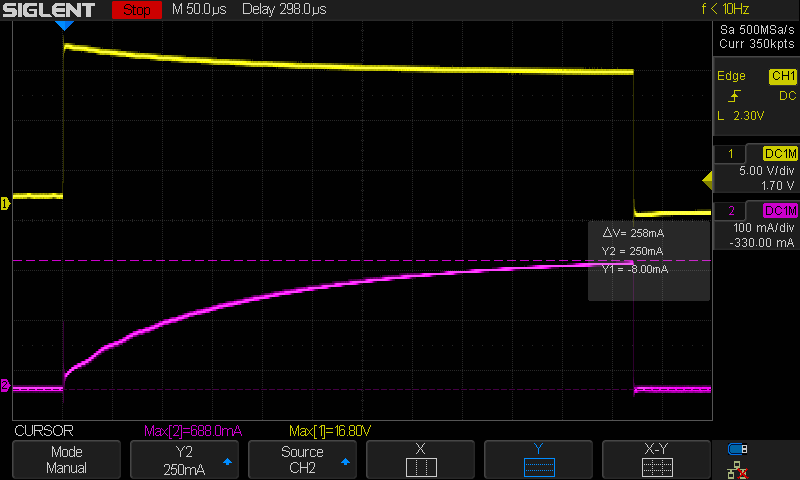

At 16V, segments work perfectly fine when energised for >=500µs:

![]()

Thoughts

Segments don't look like they'll hold position reliably with <500µs charges, but using shorter pulses does have one advantage: the display makes less noise as the segments have less kinetic energy when they hit their stops.

A reduced noise update strategy might be possible by nudging segments into place with a small pulse, then energising again afterwards with more power to hold the positions firmly.

-

Multiplexing H-Bridges (aka. discrete components everywhere)

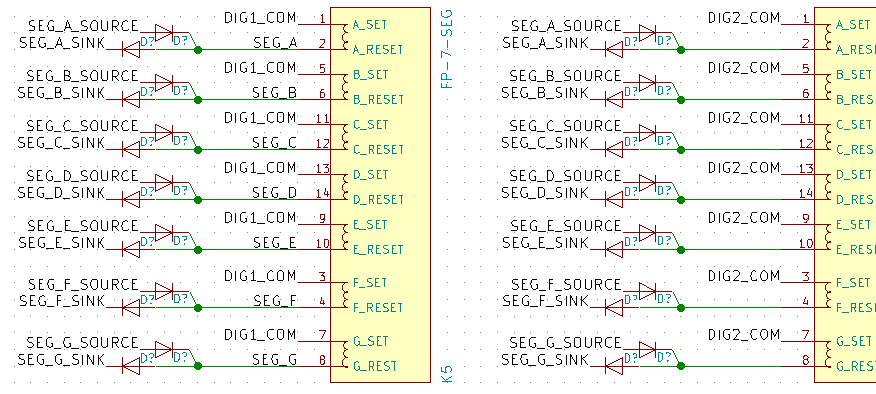

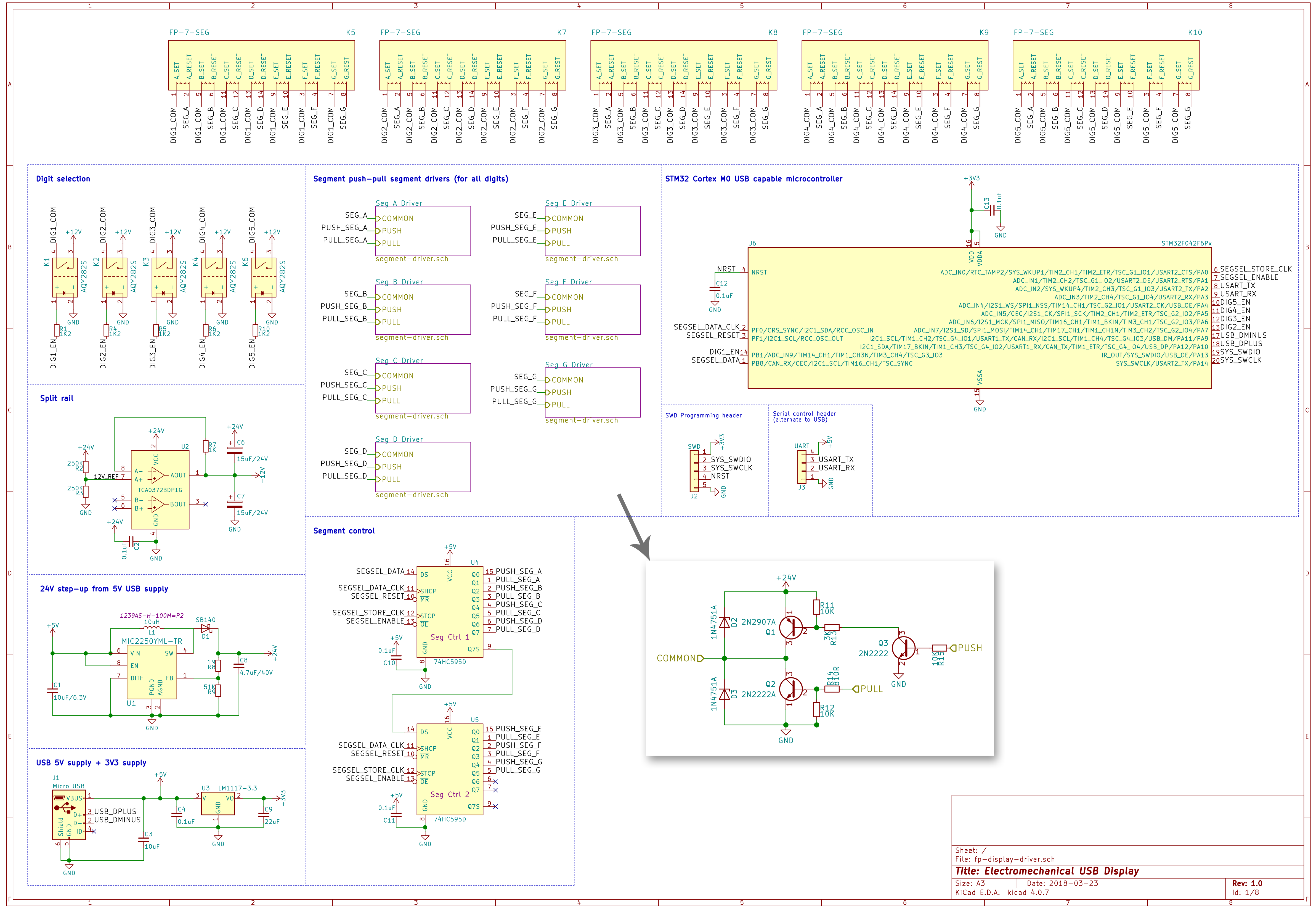

03/25/2018 at 03:11 • 0 commentsAfter feeling that the first driver design using half bridges wasn't an ideal solution, I've had a go a reworking the segment drivers to use a multiplexed H-bridge configuration:

![]()

This is similar to the design that Coyt Barringer used in his clock using these displays, though I've saved one GPIO per digit by having the digits alway connected to 16V or GND at the expense of a slightly more complex driving sequence.

Turns out, this design has its own downsides though... mainly the sheer number of discrete components involved.

The half-bridge driver design needed 86 components for the driver and digit select:

- 70 components for segment drivers (10 for each of the 7 segments)

- 10 components for digit select (2 per digit)

- 6 components for the split rail supply

A multiplexed H-bridge on the other hand requires 156 discrete components:

- 56 components for segment source/sinks (8 for each of the 7 segments)

- 30 components for each digit source/sink (6 per digit)

- 70 diodes to prevent unwanted current flow: 2 per segment, per digit.

![]()

Cost is a factor

Doubling the component count is a bit eye-watering when thinking about layout and manual assembly, but let's see what the costs are like, ignoring shared components, resistors and capacitors (since they cost about the same in each design).

Split rail push/pull

Part Quantity Per unit Subtotal (NZD) 30V 500mA NPN BJT (MMBT2222ALT1G) 14 $0.05 $0.70 -60V 500mA PNP BJT (MMBT2907ALT3G) 7 $0.05 $0.35 30V 1/2W Zener diode (D3Z30BF-7) 14 $0.206 $2.88 Solid-State Relay (AQY282S PhotoMOS) 5 $2.30 $11.50 40V 1A Op Amp (TCA0372BDP1G) 1 $1.17 $1.17 Total $16.60 Multiplexed H-Bridge

Part Quantity Per unit Subtotal (NZD) >20V 500mA NPN MOSFET (NTR4003NT1G) 12 $0.265 $3.18 -20V >500mA PNP MOSFET (DMG2301L-7) 12 $0.316 $3.79 18V 1/2W Zener diode (DDZ18BSF-7) 14 $0.206 $2.88 1/2W Diode (BAS16J) 70 $0.085 $5.95 NPN BJT (MMBT3904) 12 $0.047 $0.56 Total $16.36 ...Well, that doesn't help the decision process much! Even though the H-Bridge design has more components, I'm going to continue with it for now. I'd rather have a greater number of generic components than locking the design into vendor specific parts.

-

Second thoughts on the first design

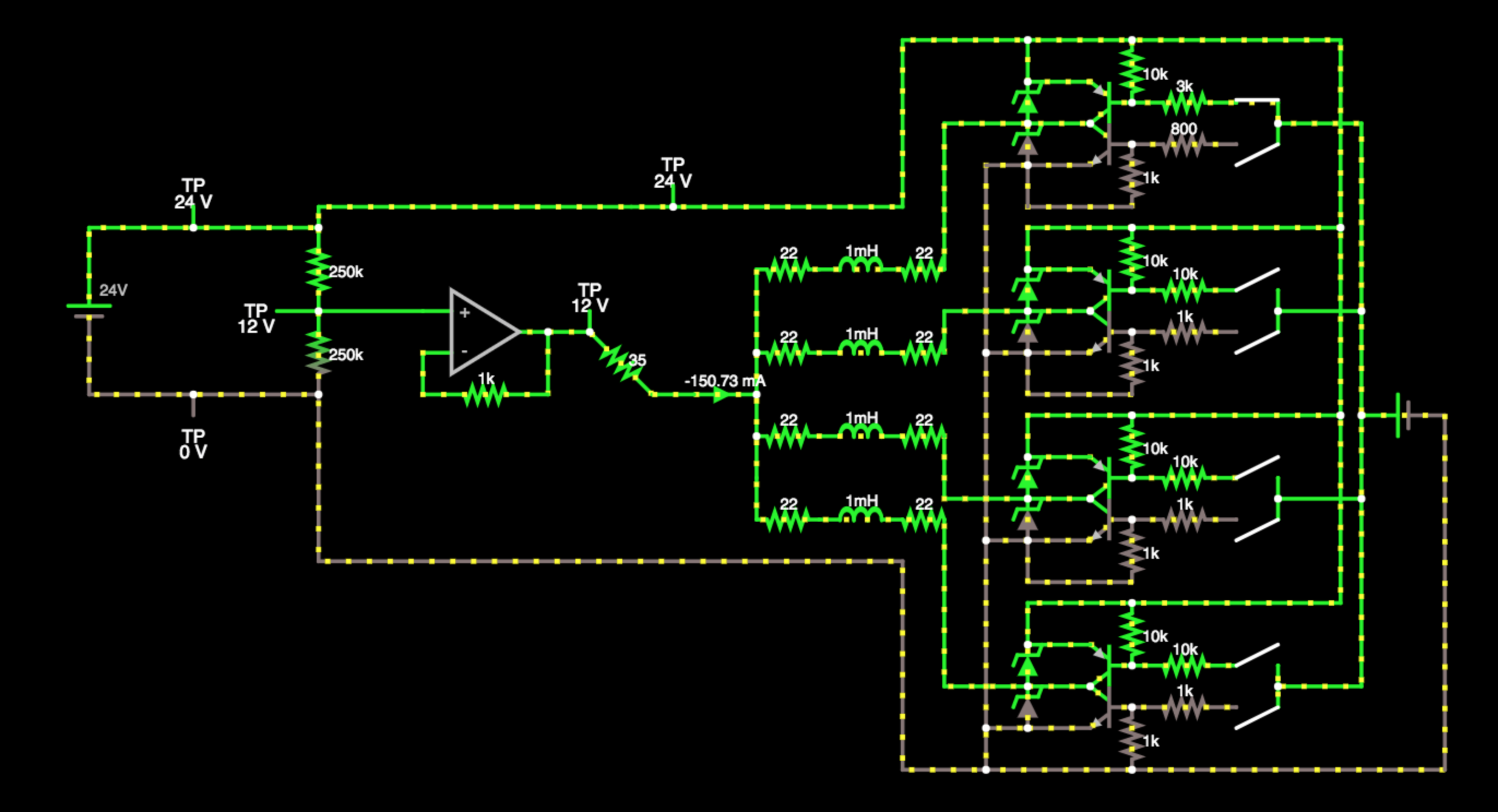

03/22/2018 at 11:51 • 0 comments![]()

I've been tinkering with this project for about a week so far. Initially I spent a while messing around in Falstad's interactive circuit simulator (above) to figure out how to multiplex and drive these displays.

Segments are switched on and off by powering the appropriate coil briefly in forward and reverse polarity. The datasheet suggests driving the coils at 16V current limited to 350mA. In bench tests the segments flip from about 9V up, though the field generated is a little weak under 12V.

In the interest of lowering component count, I was curious if I could pull off a driver using half bridges, similar to a push-pull amplifier. Bi-directional driving is often done with H-bridges, but my curiosity got the better of me.

The first pass on the schematic boosts the 5V USB supply to 24V and splits it to a common 12V for the segments. There's a pair of transistors in a push/pull configuration for each segment, attached to all digits. The digits are selected by enabling a PhotoMOS solid-state relay that connects them to the 12V rail.

![]()

There's a few disadvantages with this split-rail design however:

- Need to generate twice the coil drive voltage: the voltage across the display coils will only ever be half of the total generated in either direction. Maximum ratings of components start to become a problem around 30V.

- Larger and more expensive components: the op amp splitting the rail needs to sink and source around 500mA, which I haven't found in a package smaller than a DIP-4. The PhotoMOS solid state relays work, but are much more expensive than a few SOT-23 transistors per digit.

This split rail supply works fine in theory, but the real-world components to make it work with 300-500mA pulsed currents are excessively expensive. Using a dual supply to get +15V and -15V at the required currents has similar issues with cost, though it removes the need for a big op amp.

Other updates

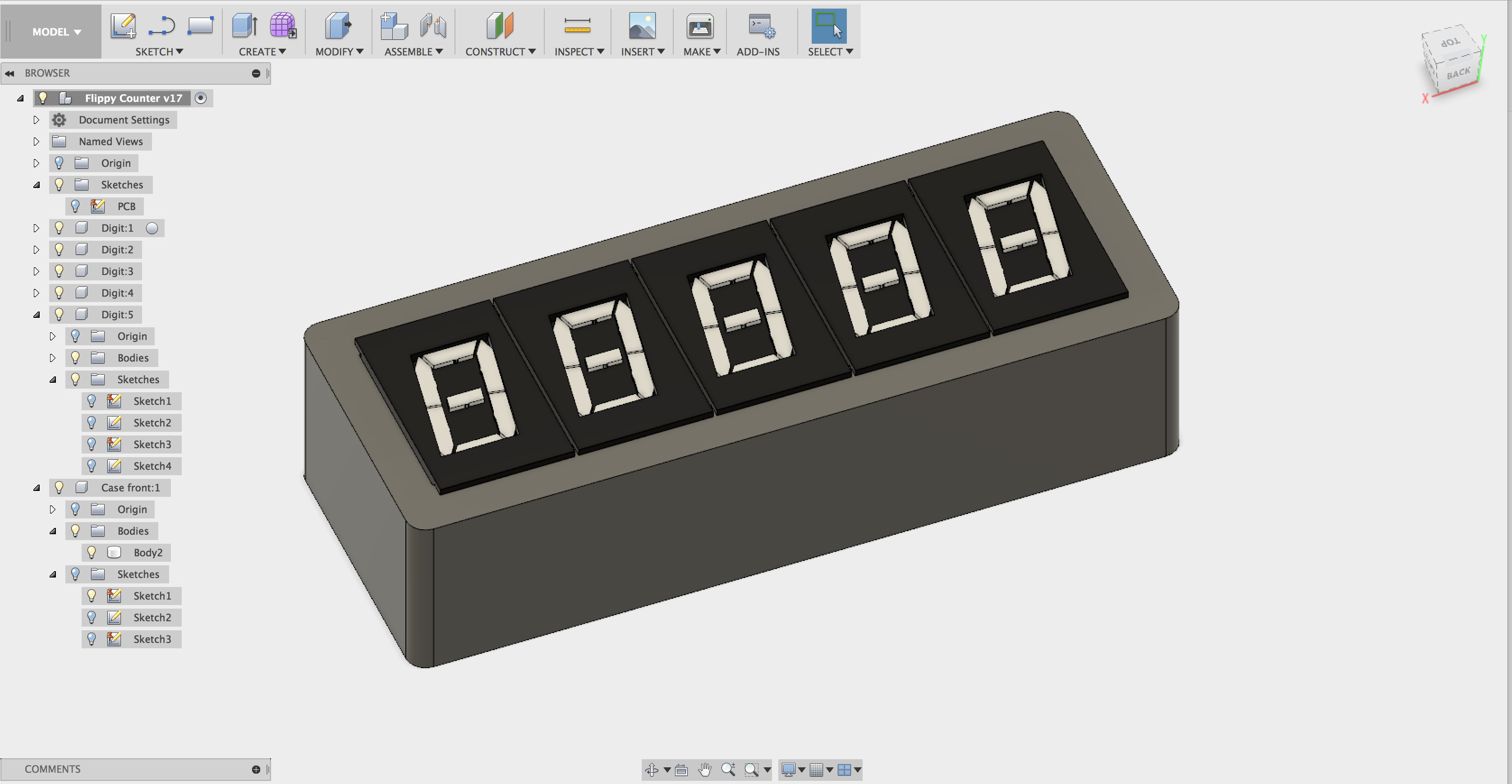

I've roughed out an enclosure design to get an idea of PCB size:

![]()

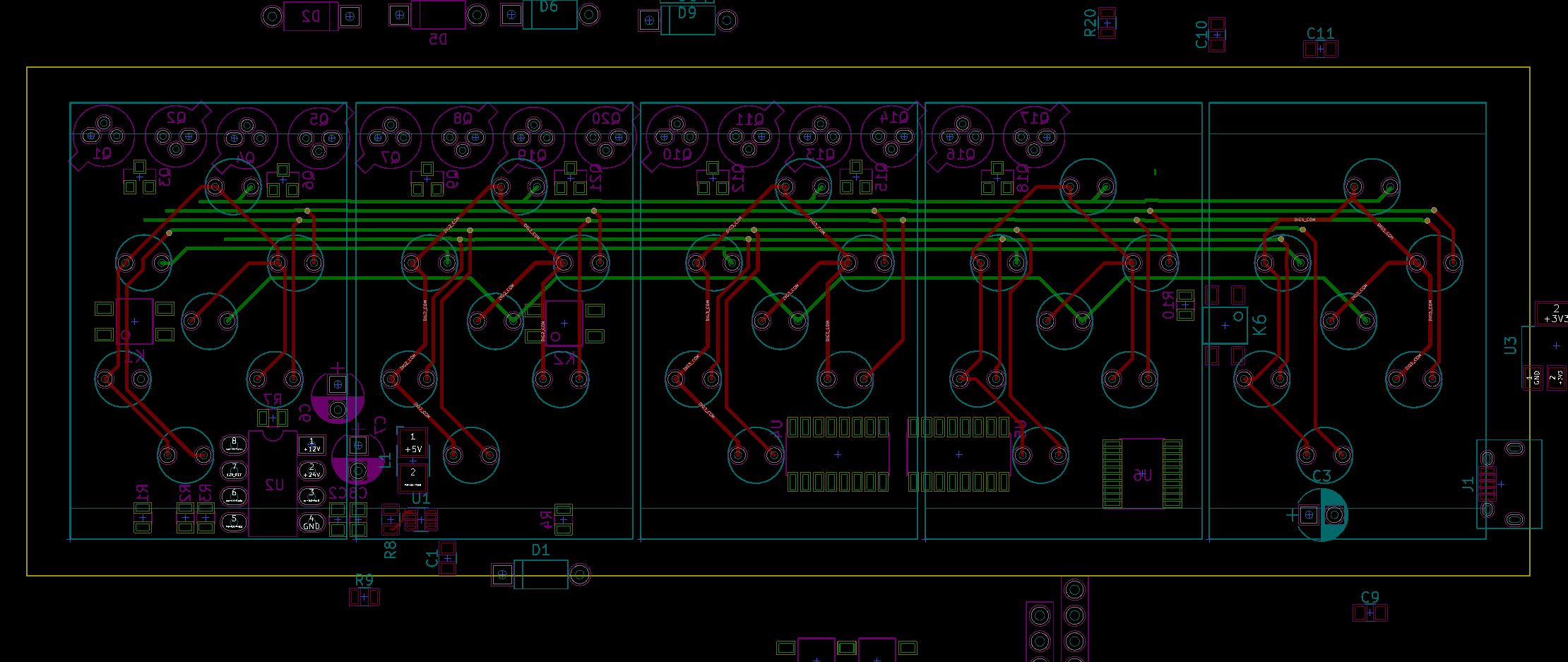

PCB layout is on hold until I've revised the schematic, but I started on this. Needs some thought about mounting.

![]()

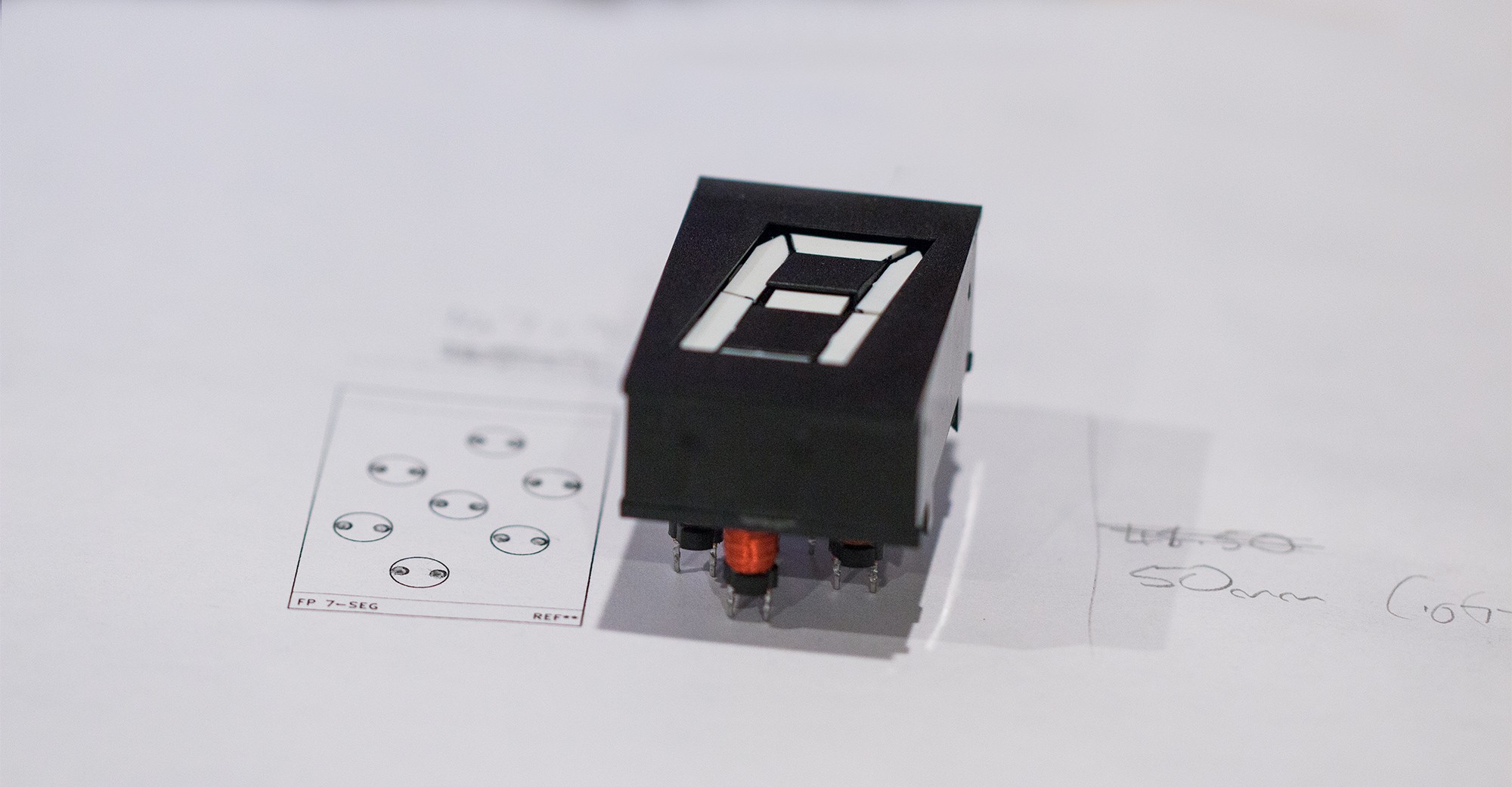

Tested the footprint for the displays - it fits well:

![]()

Retro Flip Display

A USB electromechanical display using Ferranti Packard 7-segment digits.

Stephen Holdaway

Stephen Holdaway