-

Hack Chat Transcript, Page 2

07/05/2023 at 20:30 • 0 comments![]() I saw somewhere printing dye into gel, for jello shots.

I saw somewhere printing dye into gel, for jello shots.![]() Yeah, I think there were a few specialty chocolate shops that actually had them. In general, Brooke kind of moved on towards more bespoke 3D printers for specific industries, I remember for awhile he had a couple machines custom made for printing prosthetic limbs.

Yeah, I think there were a few specialty chocolate shops that actually had them. In general, Brooke kind of moved on towards more bespoke 3D printers for specific industries, I remember for awhile he had a couple machines custom made for printing prosthetic limbs.![]() This is an entire new side of it that I haven't worked on yet! I've been so focused on chocolate because I think it is the most difficult, especially with respect to temperature control, that once Chocolate becomes easier, some of these other applications are also possible.

This is an entire new side of it that I haven't worked on yet! I've been so focused on chocolate because I think it is the most difficult, especially with respect to temperature control, that once Chocolate becomes easier, some of these other applications are also possible.![]() Oh that's cool @Tom Nardi. I wonder what he's currently working on. I know he had a couple of machines in the works, but I never saw if they shipped or not

Oh that's cool @Tom Nardi. I wonder what he's currently working on. I know he had a couple of machines in the works, but I never saw if they shipped or not![]()

![]()

![]() Now I'm going to go down the new idea rabbit hole haha

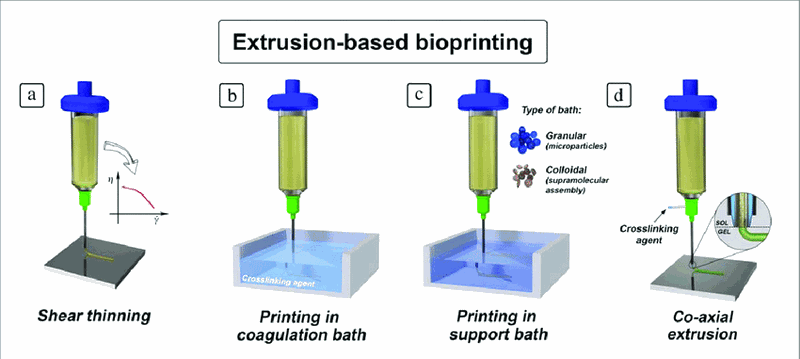

Now I'm going to go down the new idea rabbit hole haha![]() Bioprinting is a fun area, certainly. And shares problems with many other materials.

Bioprinting is a fun area, certainly. And shares problems with many other materials.![]() The Hack Chat is a good rabbit-hole maker

The Hack Chat is a good rabbit-hole maker![]() coextrusion or a tool changing chocolate printer would also be really fun. I'm working on making colorful chocolate (dyed white chocolate). That could work really well in the tool changing settings

coextrusion or a tool changing chocolate printer would also be really fun. I'm working on making colorful chocolate (dyed white chocolate). That could work really well in the tool changing settings![]() Haha @Dan Maloney I can see that 😄

Haha @Dan Maloney I can see that 😄![]() My machine is hacked with the head mounted on a load cell. The cell is a rectangular bar that could be friendly for tool exchange.

My machine is hacked with the head mounted on a load cell. The cell is a rectangular bar that could be friendly for tool exchange.![]() Some wearable tech uses magnetic connectors. Phone chargers too. That can be leveraged for the electrical wiring to the head.

Some wearable tech uses magnetic connectors. Phone chargers too. That can be leveraged for the electrical wiring to the head.![]() Have you mentioned yet about the nozzle? Are different sizes planned?

Have you mentioned yet about the nozzle? Are different sizes planned?![]() Multihead machine would also allow having one nozzle big and fat, for the bulk, and the other fine, for the surface details. But the slicer would be likely a nightmare to write.

Multihead machine would also allow having one nozzle big and fat, for the bulk, and the other fine, for the surface details. But the slicer would be likely a nightmare to write.![]() I generally print in a 0.8mm nozzle, but I am planning a 1.6mm nozzle too! Not sure if/when I'll launch that. I am curious how cooling time will be affected with 4x the flow rate

I generally print in a 0.8mm nozzle, but I am planning a 1.6mm nozzle too! Not sure if/when I'll launch that. I am curious how cooling time will be affected with 4x the flow rate![]() Thought that may work with relative ease. Manually swappable heads. Print the part with one chocolate, swap head, print the surface details.

Thought that may work with relative ease. Manually swappable heads. Print the part with one chocolate, swap head, print the surface details.![]() Consider a thermal camera, to watch the material behavior at the nozzle?

Consider a thermal camera, to watch the material behavior at the nozzle?![]() I think Prusa Slicer already has some variable layer height stuff written in. Not sure about that one yet, but with their 5 tool tool changer coming out soon, I wouldn't be surprised if that gets added at some point

I think Prusa Slicer already has some variable layer height stuff written in. Not sure about that one yet, but with their 5 tool tool changer coming out soon, I wouldn't be surprised if that gets added at some point![]() I saw somewhere a trick with ZnSe lasercutter lens for making a macro from a FLiR One.

I saw somewhere a trick with ZnSe lasercutter lens for making a macro from a FLiR One.![]() I use Prusa Slicer for all of my chocolate slicing!

I use Prusa Slicer for all of my chocolate slicing!![]() I use SuperSlicer which is a fork with some added features. Easier inspection of the g-code. (Or I didn't find how to make it easy enough in PrusaSlicer.)

I use SuperSlicer which is a fork with some added features. Easier inspection of the g-code. (Or I didn't find how to make it easy enough in PrusaSlicer.)![]() I think we are going to see a lot more camera/lidar based AI coming to printers in the future. I'm so ready for it

I think we are going to see a lot more camera/lidar based AI coming to printers in the future. I'm so ready for it![]() Same here!

Same here!![]() Also I have about 25 more minutes, so if you haven't asked anything yet, please feel free to pop in!

Also I have about 25 more minutes, so if you haven't asked anything yet, please feel free to pop in!![]() I was just about to barge in and call time, but if you want to keep going, that's fine too

I was just about to barge in and call time, but if you want to keep going, that's fine too![]() Not just for printers. CNC machines too. Imagine one that knows where the fixtures are, that sees when the workpiece moved, that will never crash the tool by a stupid operator mistake.

Not just for printers. CNC machines too. Imagine one that knows where the fixtures are, that sees when the workpiece moved, that will never crash the tool by a stupid operator mistake.![]() ...a poor man's vibration agitator is a small fan with a screw in one of its blades.

...a poor man's vibration agitator is a small fan with a screw in one of its blades.![]() or in my case an old Makerbot replicator (wood one) where I would break one fin off of a fan blade and it would all vibrate

or in my case an old Makerbot replicator (wood one) where I would break one fin off of a fan blade and it would all vibrate![]() Sometimes the blade breaks on its own. Or when you adjust something in the machine and stick in a finger. Don't ask how I know-ow-ow.

Sometimes the blade breaks on its own. Or when you adjust something in the machine and stick in a finger. Don't ask how I know-ow-ow.![]() hahaha that definitely made me laugh out loud

hahaha that definitely made me laugh out loud![]() Had to change both fans on my Replicator 2X

Had to change both fans on my Replicator 2X![]() A good thing to have around the printer, for boosting of workpiece cooling for eg. a more finicky object from PLA, is a pair of fans that you can place on the bed, side to side on the workpiece, outside of reach of the head.

A good thing to have around the printer, for boosting of workpiece cooling for eg. a more finicky object from PLA, is a pair of fans that you can place on the bed, side to side on the workpiece, outside of reach of the head.![]() After the piece starts printing and you know where the head will not go.

After the piece starts printing and you know where the head will not go.![]() Have a barrel jack with 12v on the machine for such accessories. And some USB ports with 5v power for other accessories.

Have a barrel jack with 12v on the machine for such accessories. And some USB ports with 5v power for other accessories.![]() ...and some system ground connected accessible wires to clip on the multimeter or scope probe once the machine inevitably breaks under the modifications and demands maintenance/debugging/troubleshooting...

...and some system ground connected accessible wires to clip on the multimeter or scope probe once the machine inevitably breaks under the modifications and demands maintenance/debugging/troubleshooting...![]()

![]()

![]() that definitely reminds me of my very first chocolate print, which was a Hershey kiss. Everyone called it the 💩 emoji though.

that definitely reminds me of my very first chocolate print, which was a Hershey kiss. Everyone called it the 💩 emoji though.![]() fans on the side and all

fans on the side and all![]() YESSS! Exactly like that!

YESSS! Exactly like that!![]() Well, both are made by extrusion...

Well, both are made by extrusion...![]() Another trick for food. Laser.

Another trick for food. Laser.![]()

https://www.improwis.com/projects/food_LaserEngravedCandy/

Laser engraved candy

Tests of laser cutting of pressed sugar candy

![]()

![]()

![]() recently I have been trying to laser engrave chocolate. The gameboy advance was just directly layering onto chocolate while the pride one was an attempt at using cocoa butter transfer sheets to put color on the chocolate in specific places

recently I have been trying to laser engrave chocolate. The gameboy advance was just directly layering onto chocolate while the pride one was an attempt at using cocoa butter transfer sheets to put color on the chocolate in specific places![]() both were fun experiments! I don't think they will go anywhere, but goo to know that they kinda work

both were fun experiments! I don't think they will go anywhere, but goo to know that they kinda work![]() I saw somewhere transfer of a hologram texture to chocolate surface.

I saw somewhere transfer of a hologram texture to chocolate surface.![]() yes! You can use that on top of the bed for sure

yes! You can use that on top of the bed for sure![]()

https://www.youtube.com/watch?v=UsDnkrDvkBo

![]() I think I’m going to sign off in a couple mins. Thanks for asking questions and for following the chat! If you want to look up more stuff, you can follow me on Twitter https://twitter.com/elianarose66, or on just about any other social media site. You can check out more on cocoapress.com and email me at hello@cocoapress.com if you have any more thoughts or questions!

I think I’m going to sign off in a couple mins. Thanks for asking questions and for following the chat! If you want to look up more stuff, you can follow me on Twitter https://twitter.com/elianarose66, or on just about any other social media site. You can check out more on cocoapress.com and email me at hello@cocoapress.com if you have any more thoughts or questions!![]() Re laser and food... I saw somewhere a paper from Wisconsin about lasercutting cheese. Turned out the UV laser is the best, the IR ones were melting the cut too much.

Re laser and food... I saw somewhere a paper from Wisconsin about lasercutting cheese. Turned out the UV laser is the best, the IR ones were melting the cut too much.![]()

![]()

![]() Thanks Ellie, great spending time with you today, I really appreciate it. Great chat, really fun topic. Thanks all for the great discussion!

Thanks Ellie, great spending time with you today, I really appreciate it. Great chat, really fun topic. Thanks all for the great discussion!![]() Thanks again for inviting me!

Thanks again for inviting me!![]() Random thought. Thermal analysis of the chocolate. How much energy goes in during slow heating.

Random thought. Thermal analysis of the chocolate. How much energy goes in during slow heating.![]()

https://en.wikipedia.org/wiki/Differential_thermal_analysis

Differential thermal analysis - Wikipedia

From Wikipedia, the free encyclopedia Differential thermal analysis ( DTA) is a thermoanalytic technique that is similar to differential scanning calorimetry. In DTA, the material under study and an inert reference are made to undergo identical thermal cycles, (i.e., same cooling or heating programme) while recording any temperature difference between sample and reference.

![]() like this. would show the temperature and magnitude of phase transitions within the material.

like this. would show the temperature and magnitude of phase transitions within the material.![]() Could make adjustments for a new material easier, by knowing where the key temperature points are.

Could make adjustments for a new material easier, by knowing where the key temperature points are.![]() My first time here. Very interesting and informative chat with Ellie. Possible to have a copy of this entire session?

My first time here. Very interesting and informative chat with Ellie. Possible to have a copy of this entire session?![]() Yep, transcript coming right up

Yep, transcript coming right up![]() Thank you very much.

Thank you very much.![]()

-

Hack Chat Transcript, Page 1

07/05/2023 at 20:29 • 0 comments![]() OK, now that we've whet our appetites, let's dive in. I'm Dan, I'll be modding today along with Dusan as we welcome Ellie Weinstein to the Hack Chat to talk about 3D printing food.

OK, now that we've whet our appetites, let's dive in. I'm Dan, I'll be modding today along with Dusan as we welcome Ellie Weinstein to the Hack Chat to talk about 3D printing food.Hi Ellie, welcome aboard! Can you tell us how you found yourself printing food?

![]() Hi Dan!

Hi Dan!![]() Hi all!

Hi all!![]() welcome everyone!

welcome everyone!![]() So just a quick intro on me and then I can share more about my journey to printing food and answer whatever questions you all have!

So just a quick intro on me and then I can share more about my journey to printing food and answer whatever questions you all have!![]() I started working on Cocoa Press in 2014 during an intro to engineering class in high school. I graduated from Penn Engineering in 2019 and began working on Cocoa Press full time after 5 years of it being my hobby.

I started working on Cocoa Press in 2014 during an intro to engineering class in high school. I graduated from Penn Engineering in 2019 and began working on Cocoa Press full time after 5 years of it being my hobby.I have also appeared on the Battlebots TV show as a part of team Mammoth and am passionate about the ways we can use 3D printing across industries. When not 3D printing I sing and enjoy weaving, woodworking and glassblowing while fighting for trans rights across the US.

![]() As for Cocoa Press - if you haven't checked it out before you can see some cool pictures of printed chocolates here! https://cocoapress.com

As for Cocoa Press - if you haven't checked it out before you can see some cool pictures of printed chocolates here! https://cocoapress.com![]() But the basic and slightly unsatisfying answer is that I fell into it during that insured and sharing class, then, as time went on, I realized that there was a real market for personalize chocolates, and that you could do things with 3D food printing that you can't make any other way

But the basic and slightly unsatisfying answer is that I fell into it during that insured and sharing class, then, as time went on, I realized that there was a real market for personalize chocolates, and that you could do things with 3D food printing that you can't make any other way![]() The two examples, I always give are making unique textures like the gyroid infill, and creating personalized designs without needing to use a custom mold

The two examples, I always give are making unique textures like the gyroid infill, and creating personalized designs without needing to use a custom mold![]() But that's enough of the sales pitch, I'm happy to chat about how I got here, about food printing, about the tech aspects, chocolate aspects or anything else you all want to know!

But that's enough of the sales pitch, I'm happy to chat about how I got here, about food printing, about the tech aspects, chocolate aspects or anything else you all want to know!![]() also thanks for having me Dan!

also thanks for having me Dan!![]()

![]()

![]()

![]()

![]() sweet!

sweet!![]()

![]()

![]() Did you pick chocolate as a material because it's easy to work with, or because of the market demand?

Did you pick chocolate as a material because it's easy to work with, or because of the market demand?![]() My guess is both, but...

My guess is both, but...![]() I forgot I can put pictures in here! The first one is a print in place articulating fish (my favorite print), the second shows the infills and textures I was talking about, and the third some personalization

I forgot I can put pictures in here! The first one is a print in place articulating fish (my favorite print), the second shows the infills and textures I was talking about, and the third some personalization![]() So I originally picked it because I thought it would be easy to work with, but I was wrong 🫣. It turns out chocolate is really difficult because it is so temperature dependent and just temperamental in general

So I originally picked it because I thought it would be easy to work with, but I was wrong 🫣. It turns out chocolate is really difficult because it is so temperature dependent and just temperamental in general![]() It's easy in that it melts at body temperature and solidifies at room temperature, so it's not dangerous, but that's about where that ends

It's easy in that it melts at body temperature and solidifies at room temperature, so it's not dangerous, but that's about where that ends![]() Are there other behavioral dependences than just the temperature-viscosity one? For a given material?

Are there other behavioral dependences than just the temperature-viscosity one? For a given material?![]() Depending on the base fat, that is used (whether that is cocoa butter, or something like palm oil), chocolate tends to behave very differently. Cocoa butter based chocolate needs to be tempered, while compound chocolate that uses palm oil with the cocoa solid, which is what I've switched to does not need to be tempered

Depending on the base fat, that is used (whether that is cocoa butter, or something like palm oil), chocolate tends to behave very differently. Cocoa butter based chocolate needs to be tempered, while compound chocolate that uses palm oil with the cocoa solid, which is what I've switched to does not need to be tempered![]() What type of chocolate is used?

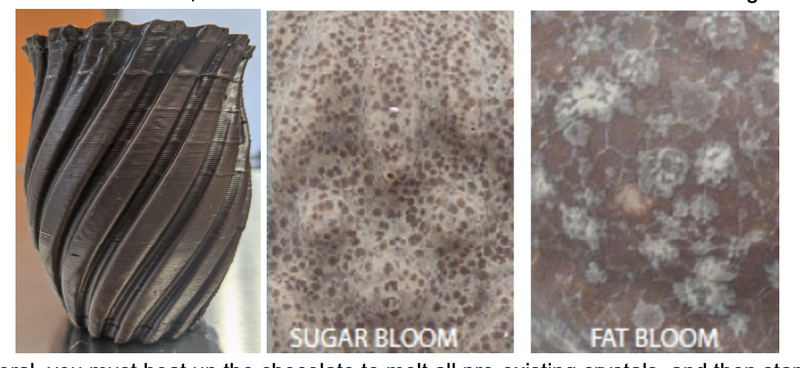

What type of chocolate is used?![]() Tempering is basically a process of heating up and cooling down the chocolate so the crystal structure is aligned. You know a chocolate is tempered when you have a nice snap when you break it. When chocolate is out of temper (like if you leave it in a hot car), you might see white, powdery finish, or even if it has returned to room temperature it may still be soft

Tempering is basically a process of heating up and cooling down the chocolate so the crystal structure is aligned. You know a chocolate is tempered when you have a nice snap when you break it. When chocolate is out of temper (like if you leave it in a hot car), you might see white, powdery finish, or even if it has returned to room temperature it may still be soft![]() Is compound chocolate readily available?

Is compound chocolate readily available?![]() I'm currently using a compound chocolate, so it has palm oil and cocoa solids. I have milk and dark chocolate and am working on white chocolate! I'm also working to make my dark chocolate vegan

I'm currently using a compound chocolate, so it has palm oil and cocoa solids. I have milk and dark chocolate and am working on white chocolate! I'm also working to make my dark chocolate vegan![]() I did some chocolate casting experiments earlier but the choc never hardened. Now I see why.

I did some chocolate casting experiments earlier but the choc never hardened. Now I see why.![]() yeah! Compound chocolate is available in most places other chocolate is. I have not done enough experimentation with compound chocolate, other than what I'm using, but that's definitely in the works for the next couple of months

yeah! Compound chocolate is available in most places other chocolate is. I have not done enough experimentation with compound chocolate, other than what I'm using, but that's definitely in the works for the next couple of months![]() yeah! Crystal structure of chocolate stuff can be wild. Let me see if I can pull up a diagram of some sort here

yeah! Crystal structure of chocolate stuff can be wild. Let me see if I can pull up a diagram of some sort here![]() Why isn't dark chocolate already vegan? Butter?

Why isn't dark chocolate already vegan? Butter?![]() What are the ballpark process parameters? Nozzle temperature? Bed temperature? Cooling air temperature? Layer thickness, nozzle diameter, print speed?

What are the ballpark process parameters? Nozzle temperature? Bed temperature? Cooling air temperature? Layer thickness, nozzle diameter, print speed?![]() What kind of feeder? Heated syringe with a stepper, or some variant on pellet-fed head?

What kind of feeder? Heated syringe with a stepper, or some variant on pellet-fed head?![]() I assume the cooling air should be chilled.

I assume the cooling air should be chilled.![]()

![]()

![]() Here's an image of a good printed chocolate (although my quality is so much better on newer machines!) and some bloomed chocolate:

Here's an image of a good printed chocolate (although my quality is so much better on newer machines!) and some bloomed chocolate:![]() I'm not actually sure what the purpose of the milk in the dark chocolate was to be honest! But it seems like it's not necessary

I'm not actually sure what the purpose of the milk in the dark chocolate was to be honest! But it seems like it's not necessary![]() I'm using a 0.8mm nozzle at about 33.1 degrees C (+- 0.1 C). I don't have a heated or cooled bed or chamber anymore! The chocolate can print in rooms up to 80F, although you can't get overhangs as good at those temps.

I'm using a 0.8mm nozzle at about 33.1 degrees C (+- 0.1 C). I don't have a heated or cooled bed or chamber anymore! The chocolate can print in rooms up to 80F, although you can't get overhangs as good at those temps.In terms of print parameters, I generally print at 0.5mm layer thickness and at a max of 45mm/s

![]() I think there may be some use of milk fat or milk protein in fine-tuning the rheology/taste.

I think there may be some use of milk fat or milk protein in fine-tuning the rheology/taste.![]() TIL there's milk in dark chocolate

TIL there's milk in dark chocolate![]() @Ellie When I first saw the Cocoa Press at Maker Faire in 2018 I remember it had a water chilling system to provide cold air to blow on the just-extruded chocolate. The modern version seems to have dropped that, is that because of improved chocolate formulation that doesn't need the extra cooling to solidify?

@Ellie When I first saw the Cocoa Press at Maker Faire in 2018 I remember it had a water chilling system to provide cold air to blow on the just-extruded chocolate. The modern version seems to have dropped that, is that because of improved chocolate formulation that doesn't need the extra cooling to solidify?![]() @Thomas Shaddack I use a heated syringe with a stepper motor based plunger system! I have a two zone heater that keeps it within +-0.1°C

@Thomas Shaddack I use a heated syringe with a stepper motor based plunger system! I have a two zone heater that keeps it within +-0.1°C![]() How to keep air bubbles out of the syringe? Heat it up enough to be very liquid and wait for the air to separate? If still present, is the compressibility of the bubble problem? Or is it not a problem at all?

How to keep air bubbles out of the syringe? Heat it up enough to be very liquid and wait for the air to separate? If still present, is the compressibility of the bubble problem? Or is it not a problem at all?![]() @Tom Nardi Yes! I have had a lot of various cooling systems. That one was fun. It used peltiers to cool the air, and a Computer water cooling system to cool, the hot side of the peltiers. The last version of the printer that I made was fully enclosed and insulated, had a double paned argon filled glass door, and was basically a mini fridge. While it worked really well, it was incredibly expensive to make, and tended to cause more clogging issues with the extruder than this one. the new chocolate formulation is definitely one of the main reasons that I don't need that extra equipment and that the printers' price has dropped so much

@Tom Nardi Yes! I have had a lot of various cooling systems. That one was fun. It used peltiers to cool the air, and a Computer water cooling system to cool, the hot side of the peltiers. The last version of the printer that I made was fully enclosed and insulated, had a double paned argon filled glass door, and was basically a mini fridge. While it worked really well, it was incredibly expensive to make, and tended to cause more clogging issues with the extruder than this one. the new chocolate formulation is definitely one of the main reasons that I don't need that extra equipment and that the printers' price has dropped so much![]() Also for reference - I opened the printer up for reservations a couple months ago and will be shipping them this fall! They are $1,499 as a DIY kit. I'll have fully assembled ones next year. The old version was almost $10k so I'm pretty happy with the trajectory 🙂

Also for reference - I opened the printer up for reservations a couple months ago and will be shipping them this fall! They are $1,499 as a DIY kit. I'll have fully assembled ones next year. The old version was almost $10k so I'm pretty happy with the trajectory 🙂![]() Can you compound your own chocolate? Eg. start with high-cocoa formulation and add fats blend to tune the processing characteristics?

Can you compound your own chocolate? Eg. start with high-cocoa formulation and add fats blend to tune the processing characteristics?![]() That way we bypass all the conching and other solids-processing part.

That way we bypass all the conching and other solids-processing part.![]() Keeping air bubbles out the syringe is difficult! Some combination of heating it up warmer than you would print it, and tapping it or using a vibration table seems to work pretty well. Compressibility of the air bubbles is definitely a problem with a plunger based system. That is one of the main benefits of an air pressure base system. An air pressure base system uses constant force, where a motor controls the displacement of the syringe. Air bubbles will therefore affect motor base systems way more than pressure based systems.

Keeping air bubbles out the syringe is difficult! Some combination of heating it up warmer than you would print it, and tapping it or using a vibration table seems to work pretty well. Compressibility of the air bubbles is definitely a problem with a plunger based system. That is one of the main benefits of an air pressure base system. An air pressure base system uses constant force, where a motor controls the displacement of the syringe. Air bubbles will therefore affect motor base systems way more than pressure based systems.![]() You can definitely make your own chocolate but it's a messy process and a bit tough to repeat, since it's not just about the ingredients and proportions of those ingredients, but it's also about the temperatures at each step

You can definitely make your own chocolate but it's a messy process and a bit tough to repeat, since it's not just about the ingredients and proportions of those ingredients, but it's also about the temperatures at each step![]() Vibration table... what about attaching a little phone-class vibration motor to the syringe itself, to assist the flow?

Vibration table... what about attaching a little phone-class vibration motor to the syringe itself, to assist the flow?![]() I saw shakers for material flow assistance in industrial equipment.

I saw shakers for material flow assistance in industrial equipment.![]() That could be cool! I was at MRRF a couple weekends ago and they were suggesting that you can just use the gantry of the 3D printer to shake the cartridge which I think would be really cool for making one off chocolate cores

That could be cool! I was at MRRF a couple weekends ago and they were suggesting that you can just use the gantry of the 3D printer to shake the cartridge which I think would be really cool for making one off chocolate cores![]() Thought. This would allow us to leverage thixotropy. The vibratory excitation would keep the material fluid through the nozzle, and once still it'd solidify faster.

Thought. This would allow us to leverage thixotropy. The vibratory excitation would keep the material fluid through the nozzle, and once still it'd solidify faster.![]() Shaking the gantry may lead to fatigue and wear. Better limit it to the head itself?

Shaking the gantry may lead to fatigue and wear. Better limit it to the head itself?![]() once you have the chocolate core you basically want the chocolate at the lowest temperature that it will flow at so it solidifies quickly

once you have the chocolate core you basically want the chocolate at the lowest temperature that it will flow at so it solidifies quickly![]() I've also had a crazy idea that I would love to explore more one day, where you basically just put a ton of force on solid chocolate. That force should heat up the chocolate in the nozzle just enough to realign the crystal structure and extrude the chocolate, creating a tempered chocolate printer without heaters

I've also had a crazy idea that I would love to explore more one day, where you basically just put a ton of force on solid chocolate. That force should heat up the chocolate in the nozzle just enough to realign the crystal structure and extrude the chocolate, creating a tempered chocolate printer without heaters![]() Random thought. M600 filament-change command that moves the head off the workpiece. Can be used in conventional printing for inserting eg. nuts into the plastic. Here it could be used too, for inserting a different kind of nuts.

Random thought. M600 filament-change command that moves the head off the workpiece. Can be used in conventional printing for inserting eg. nuts into the plastic. Here it could be used too, for inserting a different kind of nuts.![]() I'm not sure it would work, and maybe you would still have to heat up the chocolate just a little bit in order to make that work, but it would be really cool

I'm not sure it would work, and maybe you would still have to heat up the chocolate just a little bit in order to make that work, but it would be really cool![]() yes! I have done experiments with putting marshmallows and edible glitter inside of hot chocolate bombs with pauses in the print G code

yes! I have done experiments with putting marshmallows and edible glitter inside of hot chocolate bombs with pauses in the print G code![]() It does well! I want to play around with caramels and other delicious inserts. I'm allergic to nuts though, so none of those for me!

It does well! I want to play around with caramels and other delicious inserts. I'm allergic to nuts though, so none of those for me!![]() Hey Ellie! Love your work~ I can imagine you tried to make chocolate filament but settled on using a seringe for now, what would be the biggest challenges if you were to go with filament?

Hey Ellie! Love your work~ I can imagine you tried to make chocolate filament but settled on using a seringe for now, what would be the biggest challenges if you were to go with filament?![]() The gyroid infill is all interconnected, there are holes within. The same insertion can allow pouring in booze, syrup, other materials... and then the object is sealed by the rest of the layers.

The gyroid infill is all interconnected, there are holes within. The same insertion can allow pouring in booze, syrup, other materials... and then the object is sealed by the rest of the layers.![]() @Guru-san ooh that would be tough. If I were using a traditional 3D printer, I would need to make sure there are no brass pieces, and that the entire hot end assembly is food safe. I'm also not really sure how to get chocolate into a spool without it breaking. That would be a cool way to turn a conventional printer into a chocolate printer though

@Guru-san ooh that would be tough. If I were using a traditional 3D printer, I would need to make sure there are no brass pieces, and that the entire hot end assembly is food safe. I'm also not really sure how to get chocolate into a spool without it breaking. That would be a cool way to turn a conventional printer into a chocolate printer though![]() That's an interesting point -- food-safe wetted materials. I guess that basically means stainless steel, at least judging by the miles of stainless piping in the typical food processing plant

That's an interesting point -- food-safe wetted materials. I guess that basically means stainless steel, at least judging by the miles of stainless piping in the typical food processing plant![]() How easy is the printer to clean?

How easy is the printer to clean?![]() I think it'd be easier to print a new head for the printer. And either swap them or strap the choc head on the plastic head. I don't see how to make chocolate filament hold together through the feeder.

I think it'd be easier to print a new head for the printer. And either swap them or strap the choc head on the plastic head. I don't see how to make chocolate filament hold together through the feeder.![]() Yep! I use a lot of 304 Stainless steel!

Yep! I use a lot of 304 Stainless steel!![]() There are many food-grade printable polymers out there. I'm just now experimenting with polypropylene printing. For elastomers, eg. for moulds, I'm about to try out TPE (not TPU, TPE is a copolymer/blend of polyolefin and styrene-butadiene-styrene. Said to be food-safe.)

There are many food-grade printable polymers out there. I'm just now experimenting with polypropylene printing. For elastomers, eg. for moulds, I'm about to try out TPE (not TPU, TPE is a copolymer/blend of polyolefin and styrene-butadiene-styrene. Said to be food-safe.)![]() In terms of cleaning, the chocolate only touches four pieces that can all be removed without any tools and washed in the sink. Two are 304 stainless, one is an injection molded plunger (polypropylene), and one is the silicone baking mat that is my build plate

In terms of cleaning, the chocolate only touches four pieces that can all be removed without any tools and washed in the sink. Two are 304 stainless, one is an injection molded plunger (polypropylene), and one is the silicone baking mat that is my build plate![]() Then there is the indirect way of making the tooling, by printing a template and then casting silicone. Which is cheaper for baking than messing with printing PEEK.

Then there is the indirect way of making the tooling, by printing a template and then casting silicone. Which is cheaper for baking than messing with printing PEEK.![]() It's honestly easier to clean than most conventional chocolate equipment, but maybe a bit harder than some plastic printers

It's honestly easier to clean than most conventional chocolate equipment, but maybe a bit harder than some plastic printers![]() Any assistance used for bed adhesion? Or does it hold without any glue/juice?

Any assistance used for bed adhesion? Or does it hold without any glue/juice?![]() yeah silicone casting or vacuum/pressure forming over a printed or milled mold both work

yeah silicone casting or vacuum/pressure forming over a printed or milled mold both work![]() The casting-over-printed allows use of acetone polish. (Or alcohol polish, for PVB.)

The casting-over-printed allows use of acetone polish. (Or alcohol polish, for PVB.)![]() The silicone bed works great! in a cold room it could start to warp a little bit, very similarly to an ABS, but I usually don't find that to be the case, especially since we ditched the cooled build chamber

The silicone bed works great! in a cold room it could start to warp a little bit, very similarly to an ABS, but I usually don't find that to be the case, especially since we ditched the cooled build chamber![]() can you wash the parts in the dishwasher?

can you wash the parts in the dishwasher?![]() How has polypropylene printing going? I wanted to get some MJF (multi jet fusion) parts in PP

How has polypropylene printing going? I wanted to get some MJF (multi jet fusion) parts in PP![]() Does the print-friendly chocolate compromise taste/texture in comparison with the ordinary one?

Does the print-friendly chocolate compromise taste/texture in comparison with the ordinary one?![]() Yeah the steel and such can easily go in the dishwasher, the other two pieces should be fine as long as they don't get too hot. Probably top rack only type of thing

Yeah the steel and such can easily go in the dishwasher, the other two pieces should be fine as long as they don't get too hot. Probably top rack only type of thing![]() Obviously chocolate is the main goal here, but what kind of support is there for extruding other edibles like peanut butter or icing? Can you run the extruder motor with the heater off (something that normal 3D printer firmware would generally prevent you from doing) for materials that need to stay room temp?

Obviously chocolate is the main goal here, but what kind of support is there for extruding other edibles like peanut butter or icing? Can you run the extruder motor with the heater off (something that normal 3D printer firmware would generally prevent you from doing) for materials that need to stay room temp?![]() There are different choc blends for different markets just because the average temperature/weather in the area. Different for Morocco vs Finland...

There are different choc blends for different markets just because the average temperature/weather in the area. Different for Morocco vs Finland...![]() You should be able to trick the firmware by using a fixed resistor instead of the thermistor, and disconnecting the head heater. Then setting it to temperature that equals the temp reported by the resistor. May work. Patching firmware may be easier.

You should be able to trick the firmware by using a fixed resistor instead of the thermistor, and disconnecting the head heater. Then setting it to temperature that equals the temp reported by the resistor. May work. Patching firmware may be easier.![]() Yes! You can definitely print without the heater. I haven't done a ton of work on printing any other materials besides chocolate. I really want to try printing candle wax, cheese, and even ice sculptures if you put the whole machine in the freezer

Yes! You can definitely print without the heater. I haven't done a ton of work on printing any other materials besides chocolate. I really want to try printing candle wax, cheese, and even ice sculptures if you put the whole machine in the freezer![]() Not just icing. This is a kind of material with generic uses. Chocolate, icing, pottery clay, silver art clay... anything that is or can be a paste.

Not just icing. This is a kind of material with generic uses. Chocolate, icing, pottery clay, silver art clay... anything that is or can be a paste.![]() Candle wax may be tangentially similar to the Moldlay material, which is a filament for printing lost-wax casting things.

Candle wax may be tangentially similar to the Moldlay material, which is a filament for printing lost-wax casting things.![]() Good point, lot of exciting possibilities for past extrusion that aren't necessarily food related.

Good point, lot of exciting possibilities for past extrusion that aren't necessarily food related.![]() yeah! Some people have approached me for using the printer in medicinal settings and as a less expensive glue dispensing bot for low volume manufacturing

yeah! Some people have approached me for using the printer in medicinal settings and as a less expensive glue dispensing bot for low volume manufacturing![]() The viscosity of everything needs to be known...

The viscosity of everything needs to be known...![]() And we can go multimaterial then. Use table salt in binder, for dissolvable supports that can survive sintering temperatures for metal. For internal supports, variation on salt inserts for casting hollow things inside engine pistons.

And we can go multimaterial then. Use table salt in binder, for dissolvable supports that can survive sintering temperatures for metal. For internal supports, variation on salt inserts for casting hollow things inside engine pistons.![]() Add a 3d scanner to see the bed, and you can deposit stuff on other stuff.

Add a 3d scanner to see the bed, and you can deposit stuff on other stuff.![]() ooh yeah someone wants to add the 3D scanner to print onto cookies!

ooh yeah someone wants to add the 3D scanner to print onto cookies!![]() hehe

hehe![]() currently I use a hot knife to remove any supports, and then that's my snack for having done it 😄

currently I use a hot knife to remove any supports, and then that's my snack for having done it 😄![]() A camera on the head, and then photogrammetry. Or a cheapo 1d line lidar. Or a time-of-flight camera module, I saw some that's quite cheap.

A camera on the head, and then photogrammetry. Or a cheapo 1d line lidar. Or a time-of-flight camera module, I saw some that's quite cheap.![]() I was very excited about the PrintrBot Paste Extruder add-on, but it never really went into mass production and remained just an experiment (plus PrintrBot folded not long after). Glad to see we'll finally have a DIY-friendly option out there with Cocoa Press.

I was very excited about the PrintrBot Paste Extruder add-on, but it never really went into mass production and remained just an experiment (plus PrintrBot folded not long after). Glad to see we'll finally have a DIY-friendly option out there with Cocoa Press.![]()

![]()

![]() Candle wax could be printed into water. For immediate cooling after exiting the nozzle. May cause lots of problems though with the trapped water later.

Candle wax could be printed into water. For immediate cooling after exiting the nozzle. May cause lots of problems though with the trapped water later.![]() and then fun fact, Brooke then designed the original procuisini food printer after that which did go on sale commercially, but was pretty expensive, especially for their dual extruder version. I forget the exact details at the moment

and then fun fact, Brooke then designed the original procuisini food printer after that which did go on sale commercially, but was pretty expensive, especially for their dual extruder version. I forget the exact details at the moment![]()

![]()

![]() I wonder if you could create 3D structures (instead of printing layer by layer) with printing wax inside of water like some of the bio printers can do, printing into gel

I wonder if you could create 3D structures (instead of printing layer by layer) with printing wax inside of water like some of the bio printers can do, printing into gel![]() Or print gel into water using the spherification trick from molecular gastronomy.

Or print gel into water using the spherification trick from molecular gastronomy.![]() oh yeah that would be super cool too!

oh yeah that would be super cool too!![]()

Lutetium

Lutetium