-

Leaky transistors

4 hours ago • 0 comments

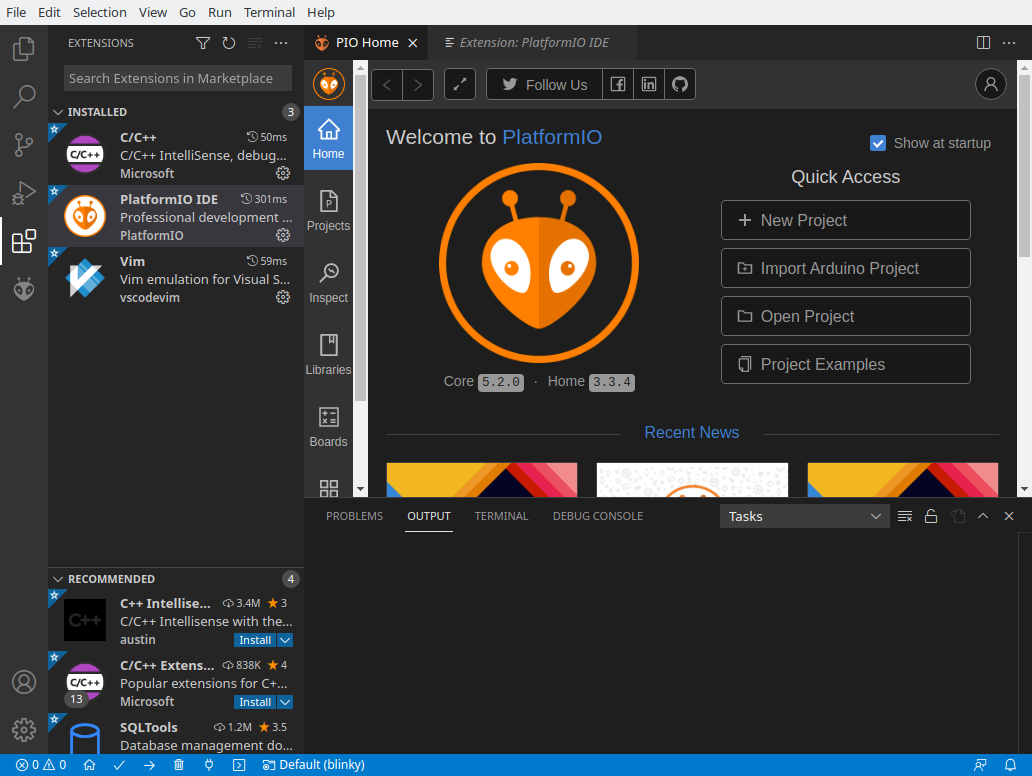

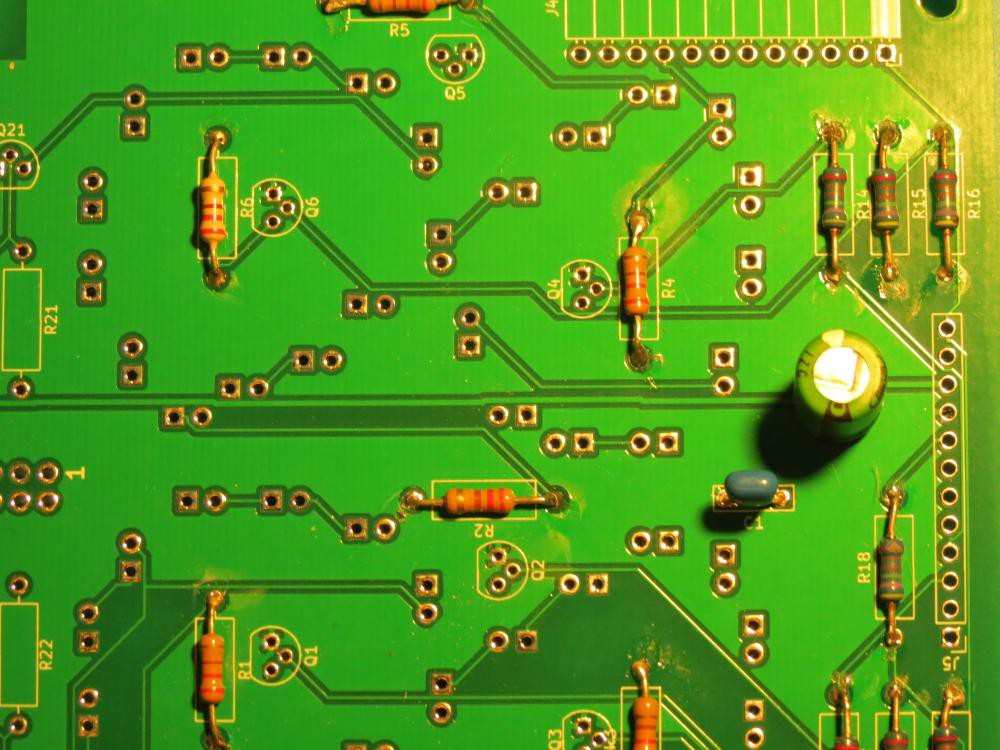

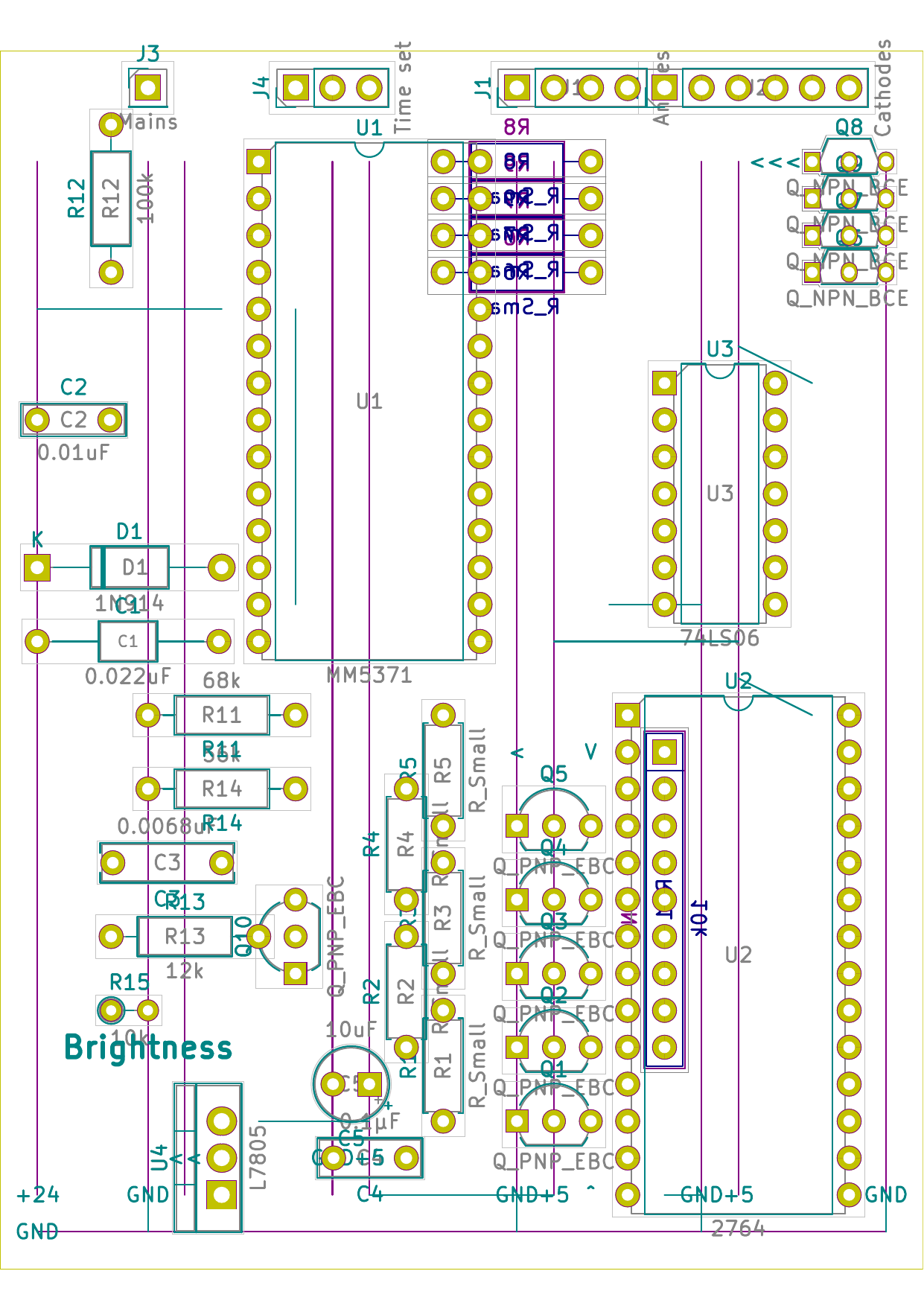

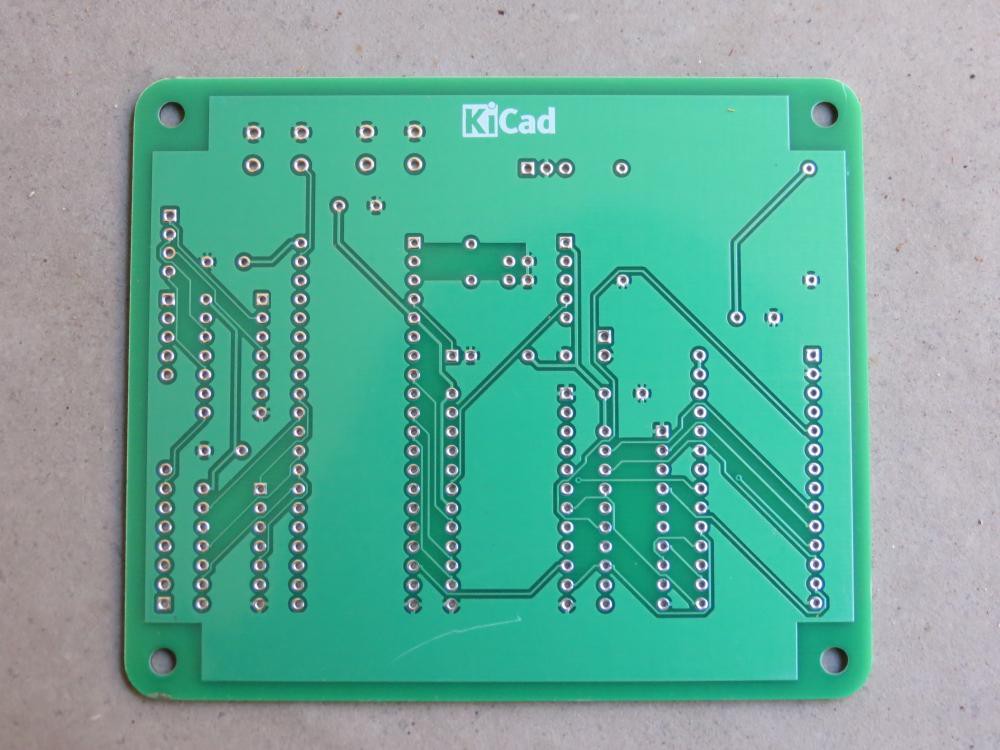

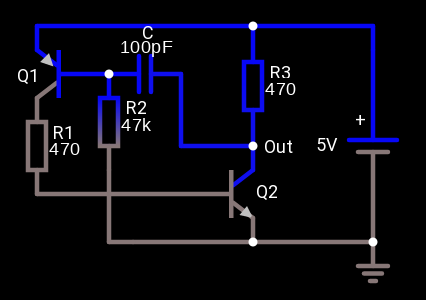

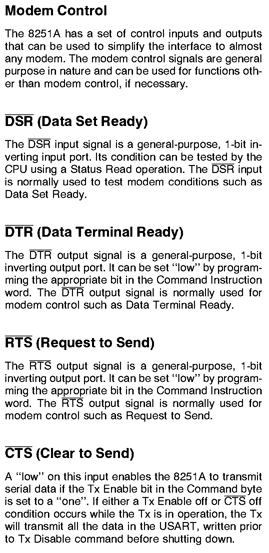

Being frustrated with encountering segments or digits that stayed partly on even when they are supposed to be off, I turned my attention to the driver transistors I was using.

I realised that these were grab bag transistors bought decades ago when I was a newbie. Being seconds (cough, rejects) they are actually poorer than pulls from circuit boards that have been verified. I had graded they by gain using a component tester. But in my newbie days I had been using them in battery driven circuits, usually not more than 6 V. Now my circuits involve higher voltages, The component tester I had used only goes up to 9 V and there is no indication of leakage or worse C-E breakdown.

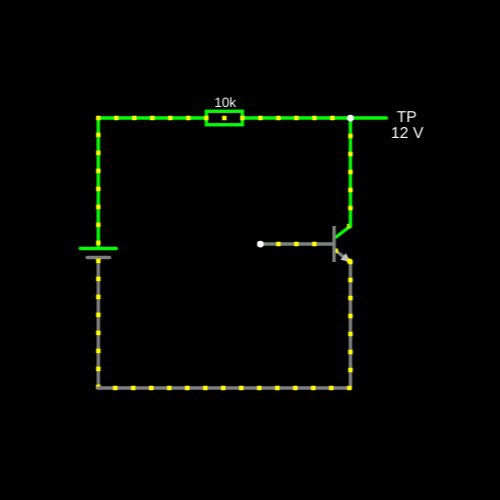

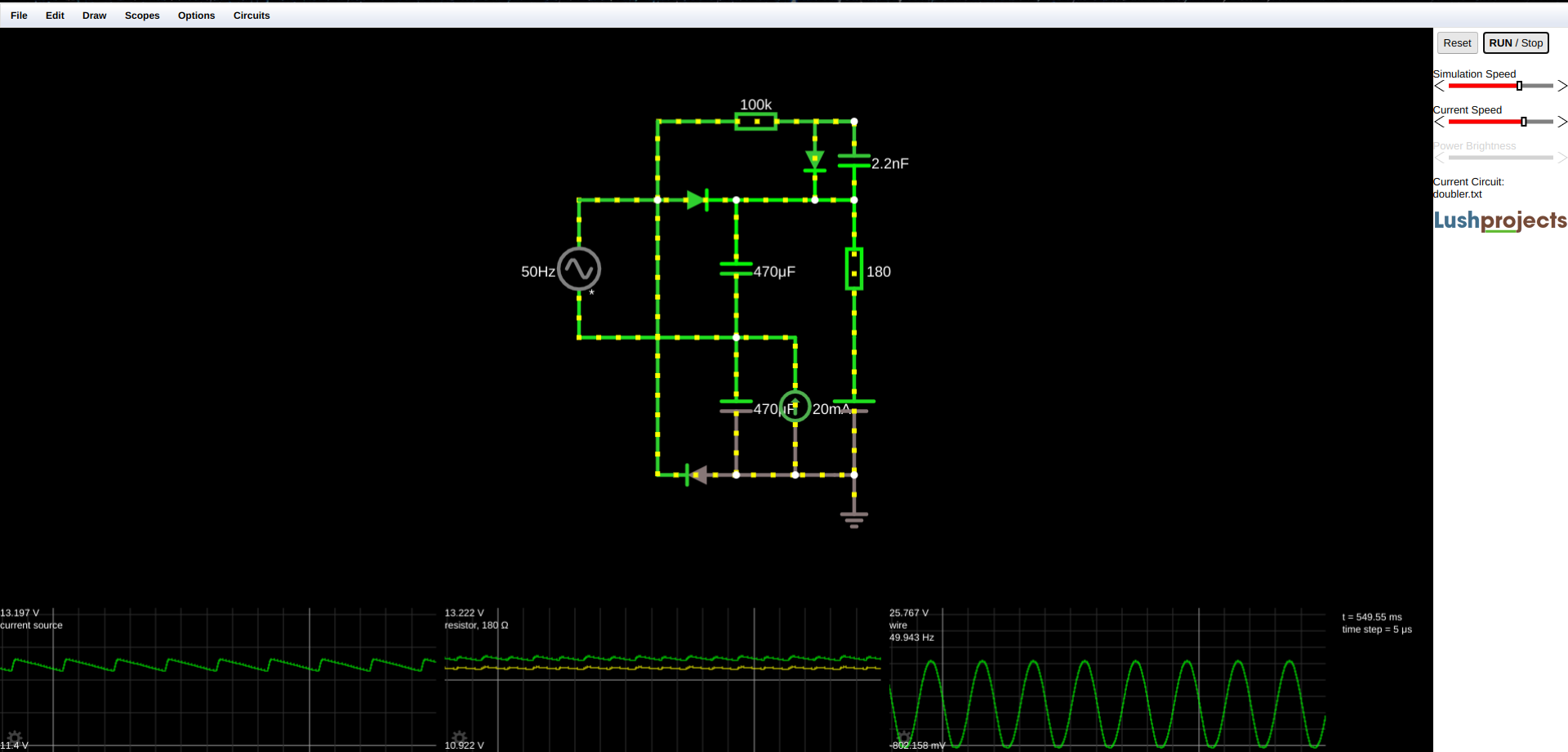

I whipped up the circuit above. I dialed up 12 V on the bench supply and connected a voltmeter across the C-E terminals. Originally I had a 100 k resistor between B and E but I decided to omit that, the better to detect leaks as any C-B leakage current would get amplified. I decided that any measurement below 12 V indicated a dodgy transistor. For example a voltage of 11.99 V corresponds to a leakage current of 1 µA.

For PNP transistors, I just reversed the power supply. Result is I culled about 15 - 20 % of the grab bag stock. Now I can use the OOS (Old Old Stock) with greater confidence.

-

Delving into Picolibc

04/05/2025 at 10:48 • 0 comments

Picolibc is a set of standard C libraries, libc and libm, for smaller embedded systems with limited ROM and RAM. It's derived from newlib and AVR libc. It is actively developed and can be cloned from Github. ARM and RISC-V are the main testing targets.

As you can see from the screenshot, there is a link to a very informative presentation about the history of Picolibc. Keith Packard is familiar to me from his previous work with Freededsktop and the X desktop server. I must look into the other interesting projects in Keith's rabbit hole.

The reason I started looking into picolibc was the need to have a crt0.o for an upcoming bare metal MCU project. The libc and libm might be used later. Surprisingly there were few source candidates on the Internet for the MCU architecture I had in mind, but I found one under the picocrt subdirectory of picolibc.

A look in the newlib-cygwin source shows the difference in the size of the targets.

$ ls newlib-cygwin/newlib/libc/sys a29khif d10v h8300hms Makefile.inc or1k sh sysnecv850 tic80 z8ksim amdgcn epiphany h8500hms mmixware rdos sysmec sysvi386 tirtos arm esp m88kbug netware rtems sysnec810 sysvnecv70 w65Compare this to the list of picolib targets for crt0.o:

$ ls picolibc/picocrt/machine aarch64 arc arc64 arm m68k mips msp430 nios2 powerpc riscv sh sparc x86 xtensaMany of the modern 32 and 64 bit MCUs are covered. ARM gets you the RPi, STM32, and so forth. Xtensa gets you the ESP32 family. RISC-V gets you the rising MCUs, including the newer ESP32s.

The build system is modern, it uses meson and ninja. Once configured, compiling was super-fast.

The task that took most time for me was finding and installing an appropriate cross toolchain for the MCU. When that is done, you have to write a meson configuration file to generate the MCU configuration, or use one of the existing ones. It's possible that the tool prefix won't be what the configuration expects. You can either customise the config file, or make symlinks to the tool names expected. For example I have this link in /usr/local/bin:

/usr/local/bin/arm-none-eabi-gcc -> ~/.arduino15/packages/STMicroelectronics/tools/xpack-arm-none-eabi-gcc/14.2.1-1.1/bin/arm-none-eabi-gccAfter building, several versions of crt0.o were created, for none, normal, minimal, semihosted, and hosted. I'll probably be using the normal one which sets up the MCU for a C program and then calls main().

More later when I start on the MCU project in question.

-

Cheap touch switches

04/03/2025 at 12:22 • 0 comments

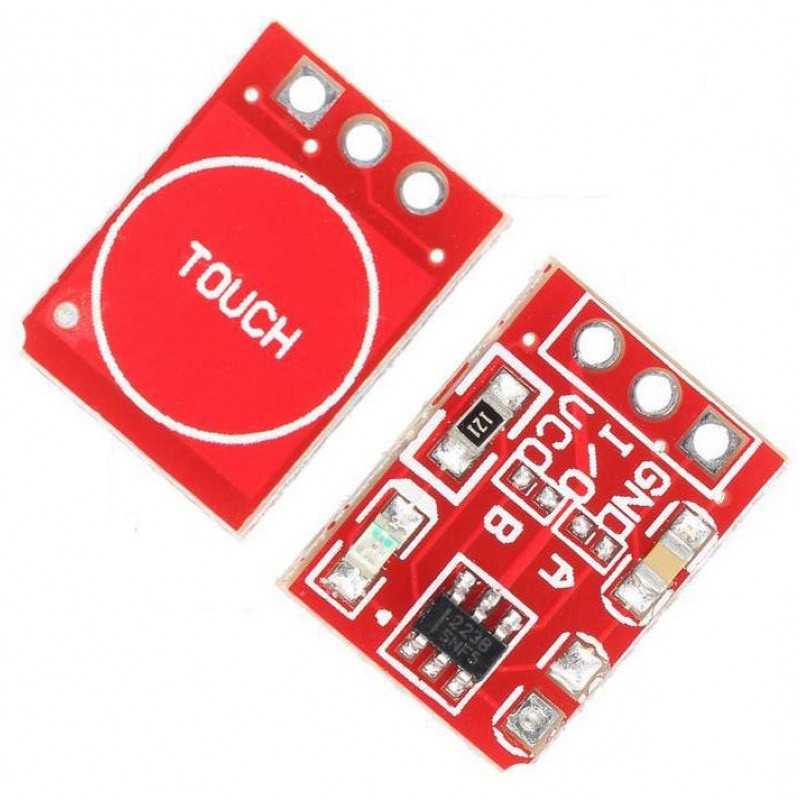

While prowling AliExpress in search of novel stuff, I came across touch sensor switches for about 10¢ each quantity 50.

They are not new. The datasheet for the TTP223 chip at the heart of this module dates from August 2009. The attraction of this combo is that it is more than just a NO SPST switch. It can output either high or low level by selecting a solder jumper. Another solder jumper changes between momentary and toggle modes. The module also does switch debouncing, so you can skip doing that in the MCU firmware. It works with both 5 V and 3.3 V logic.

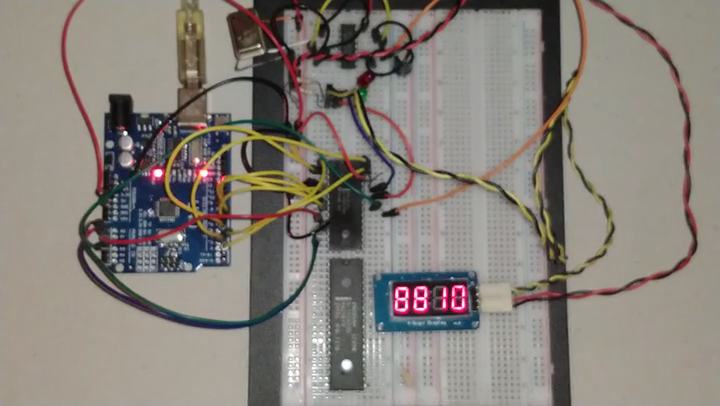

I connected one up to an Arduino (actually the ESP8266 Uno form factor equivalent) and verified that it works as advertised. I was at first disappointed because I had connected the module with jumper wires on a breadboard. But the proximity of the metal in the breadboard pin sockets disrupted the operation. Only when I moved it above the breadboard did it work. There is also a status LED on the back of the module which shines through the PCB a little. Depending on your application, this might or might not be annoying. You could always desolder the LED.

There is little point in describing setup and operation when there is a good resource from Instructables.

So, an alternative to the tactile switches I have been using, for a little more cost and surface area.

-

Experiments with LED filaments

03/25/2025 at 10:17 • 0 comments

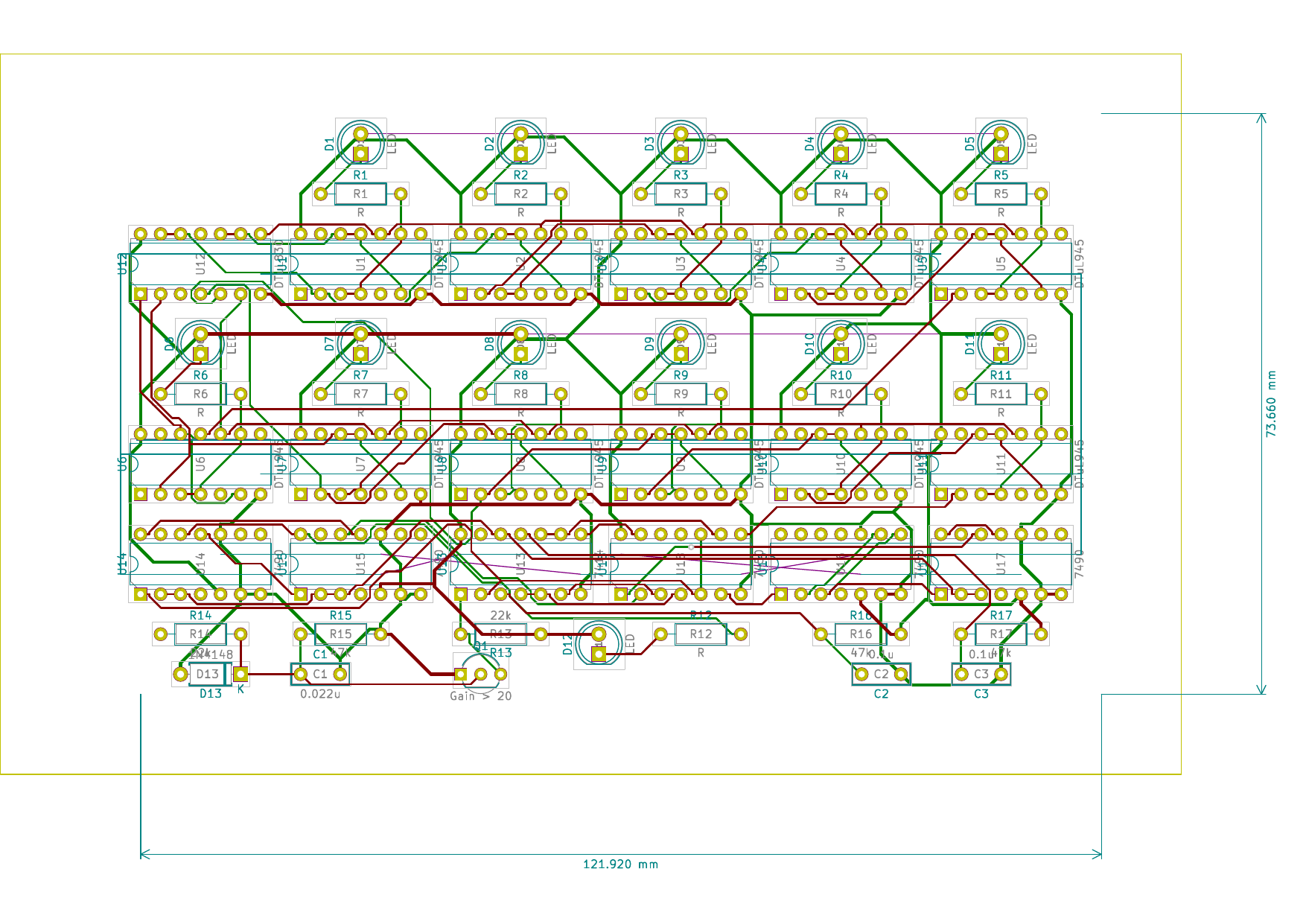

Ok, time to take a break from playing around with OOS (Old Old Stock) and explore LED filaments with the goal of making large segment displays from them.

These cost around 30¢ each from AliExpress. They come in various lengths, from 20 mm to 68 mm; in various colours; and in various voltages, starting at 3 V. They are called hard filaments as opposed to the flexible fllaments that are even more decorative. They are smaller than you might expect from the photos which are larger than life-size. They are more like toothpicks in thickness. I picked 38 mm because that size could make a digit to fit within a 100x100 mm PCB, 12 V to reduce the current requirement, and three colours: red, green and blue.

I connected it up to the power supply I described in https://hackaday.io/page/398950-assembling-a-120-w-bench-power-supply which allows me to limit the current while cranking up the voltage.

I had questions I wanted answered:

- The scanty information on the webpages don't say if there is a current limiting resistor in the filament. I doubted it.

- The nominal voltage is 12 V but what is the current curve like as you increase the voltage? I didn't want to exceed the suggested limit of 45 mA.

- How come the different colours all have nominal voltages of 12 V? Do they use different junction meterials?

Increasing the voltage until the current limit of 45 mA was reached showed a filament voltage of just over 11 V. So it was as I suspected, there there is no resistor in the filament, and there are groups of 4 blue LEDs in series then in parallel all along the length of the filament for 4 junction drops, ~ 3 V x 4. Furthermore I'm sure that other colours are produced by phosphors excited by blue LEDs rather than different junction materials, different from single LED parts. Evidence in favour is that the blue filament is neutral white colour so that's the natural emission of the LEDs. These facts would explain why somebody measured a very high current feeding them from a 12 V supply. That I wanted to avoid as it would shorten the life.

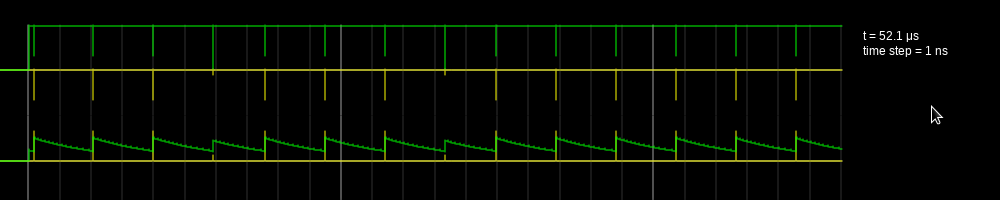

So to use them for display purposes I need to devise a constant current circuit to limit the current. They are very bright so I should apply PWM to control the brightness. The other thing I have to do is devise a way of soldering the leads to the PCB. They are quite delicate and should not be bent more times than necessary.

-

Nearing the end of my AVR adventures

03/23/2025 at 08:34 • 0 comments

AVR at the bare silicon level using my OOS (Old Old Stock) that is, because I still have a couple of Arduinos, but programming with them will be through the Arduino HAL which hides the low-level hardware stuff.

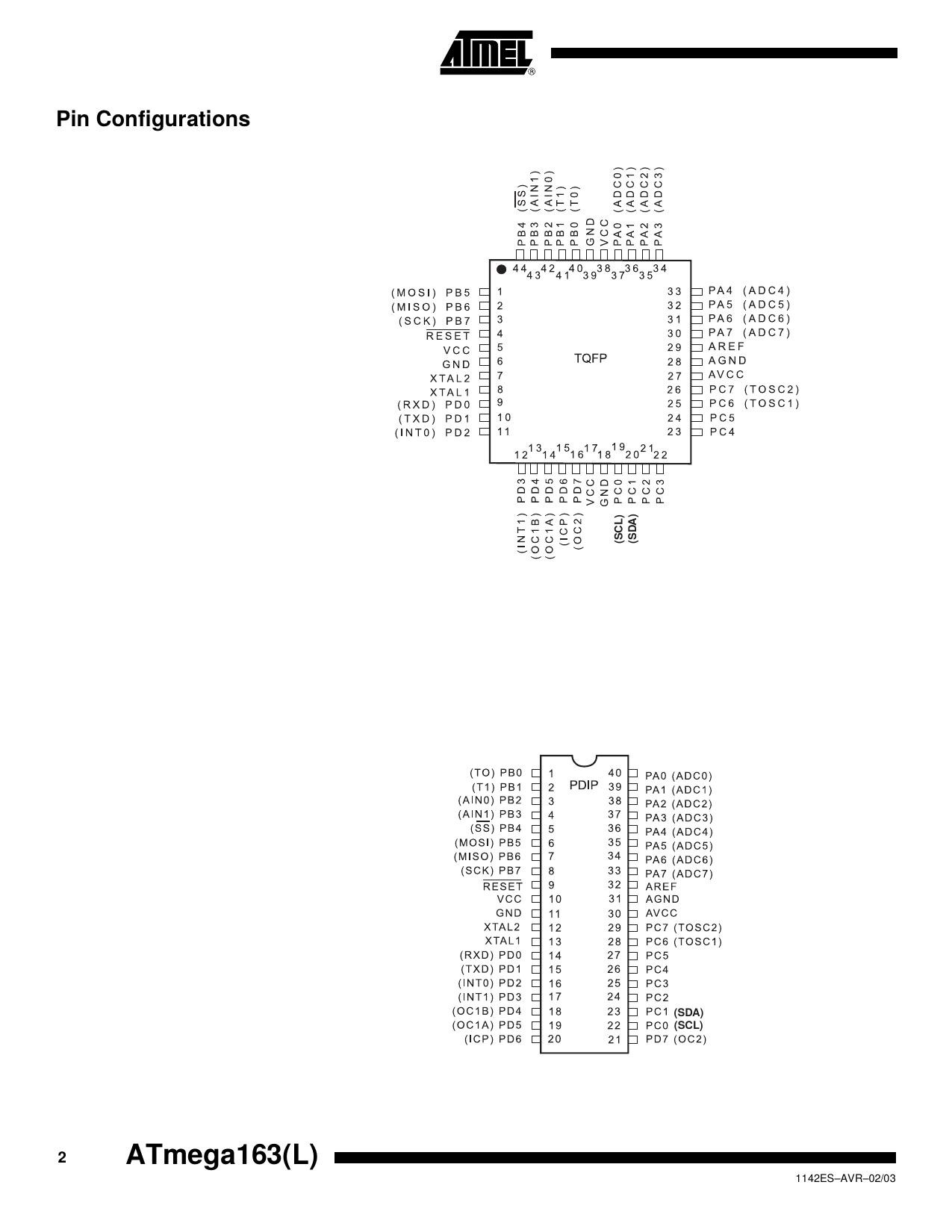

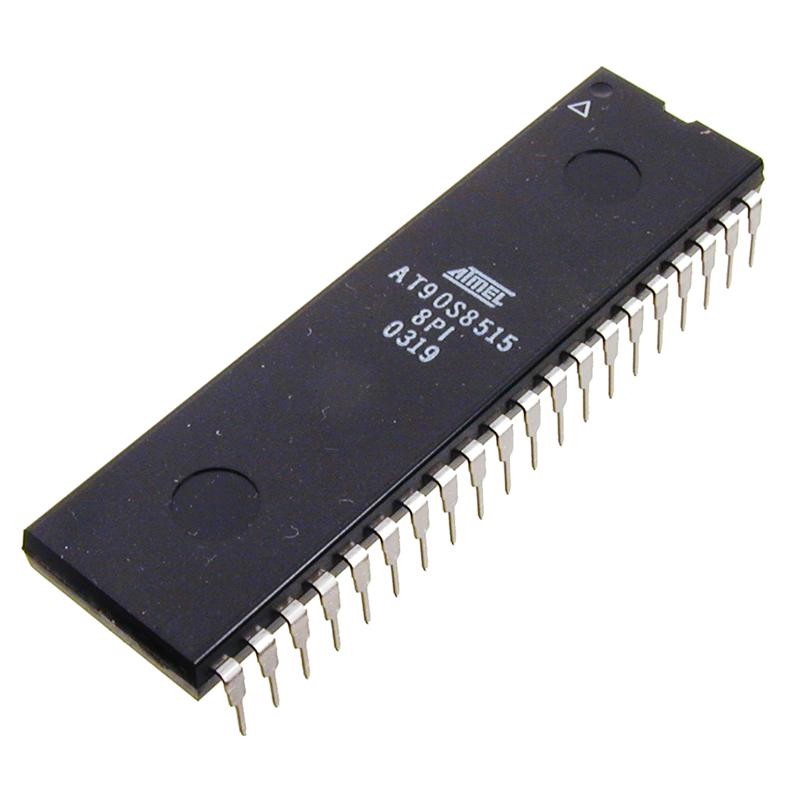

I found another AVR MCU in my junk box, and it's an ATMEGA163L. I was curious what modifications I would have to make to my build to compile code for it. Turns out, not much. Here's the section of my Makefile which looks at the command line argument MCU=ATMEGA163 to choose different settings for the build.

MCU?=AT90S8515 CSRCS=clock.c ds3231.c i2c.c BUILDFLAGS=-DLOWON -DSIXSEGMENT -DRAISEDZERO # -DDS3231 ifeq "$(MCU)" "AT90S8515" CSRCS+=at90s8515.c BUILDFLAGS+=-DAT90S8515 -DX8_000_000 # CRTs are inside the avr-gcc distribution CRT=crtat90s8515.o MCUOPT=-mmcu=avr2 endif ifeq "$(MCU)" "ATMEGA163" CSRCS+=atmega163.c BUILDFLAGS+=-DATMEGA163 -DX4_000_000 # CRTs are inside the avr-gcc distribution CRT=crtatmega163.o MCUOPT=-mmcu=avr5 endifThe MCU?=AT90S8515 establishes the default to be overriden by a command line assignment to MCU. The next two lines set the default source file list and BUILDFLAGS. As you can see the only things that change are the CRT startup file, a define that affects the source compiled, and the MCU architecture requested of the avr-gcc compiler. Fortunately the on-chip features I used are present in both MCUs. Atmel (now Microchip) did a decent job of family compatibility.

The 163 is the forerunner of the 164 which fixed some silicon bugs, hence not recommended for new designs. The L suffix means I have to change the declared crystal frequency to 4 MHz later. Unfortunately the 163/164 while still available in the DIP-40 package, have a different pinout from the AT90S8515. I'm loath to have 5 boards made only to use 1, or pay money for some NOS ATMEGA164s, so I might wire this up on perfboard (ugh!). I'll only need a 7805 regulator, a crystal and its load capacitors, a couple of bypass caps, and the reset RC circuit. I may live to regret using perfboard ☹️. We shall see.

-

A use for JLCPCB cardboard boxes

03/19/2025 at 07:08 • 0 comments

Every 5 or 10 PCBs I order from JLCPCB I get a 15 x 15 cm cardboard box. I have accumulated many now. They are quite sturdy and a shame to put into paper recycling after one use.

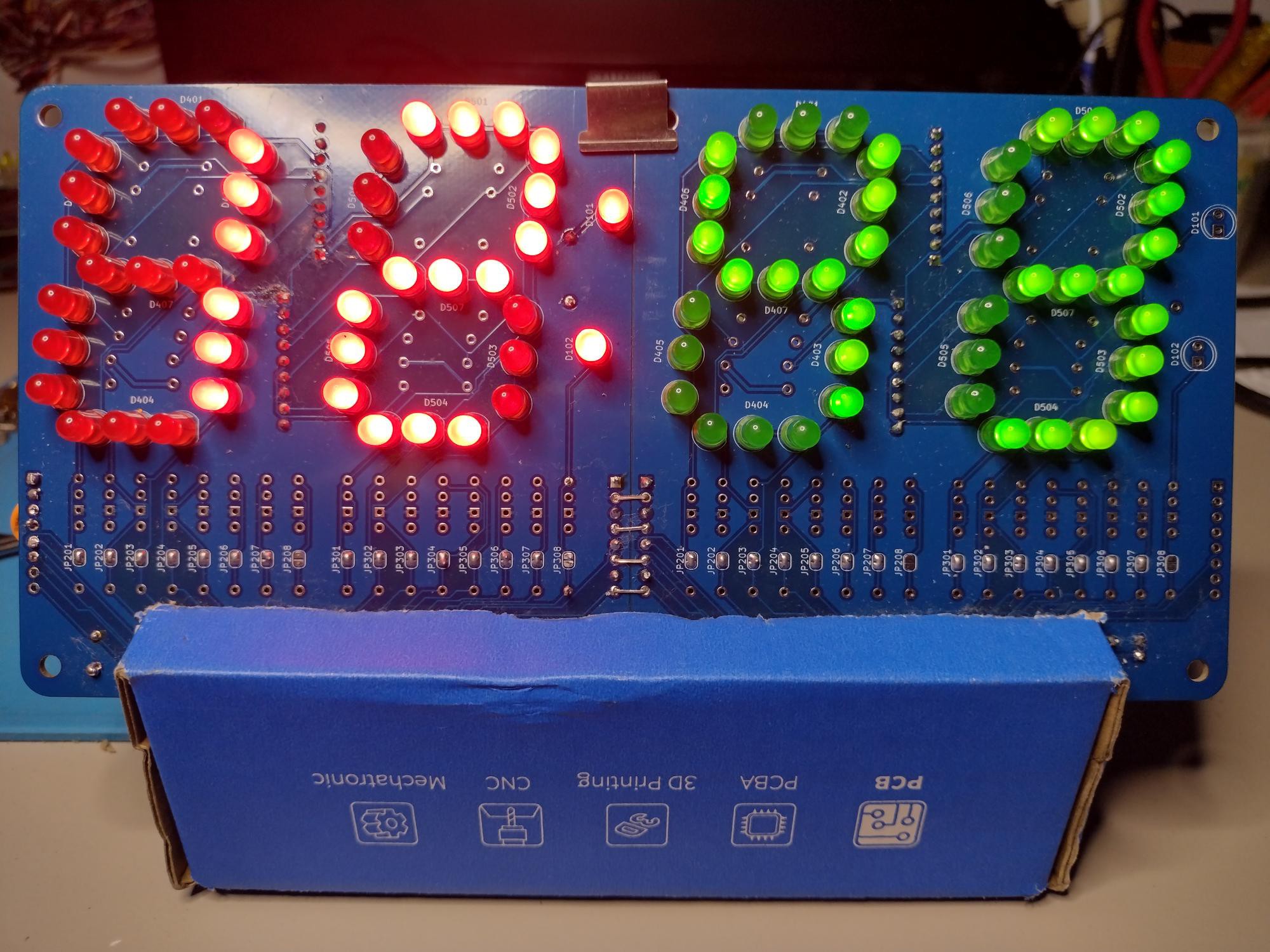

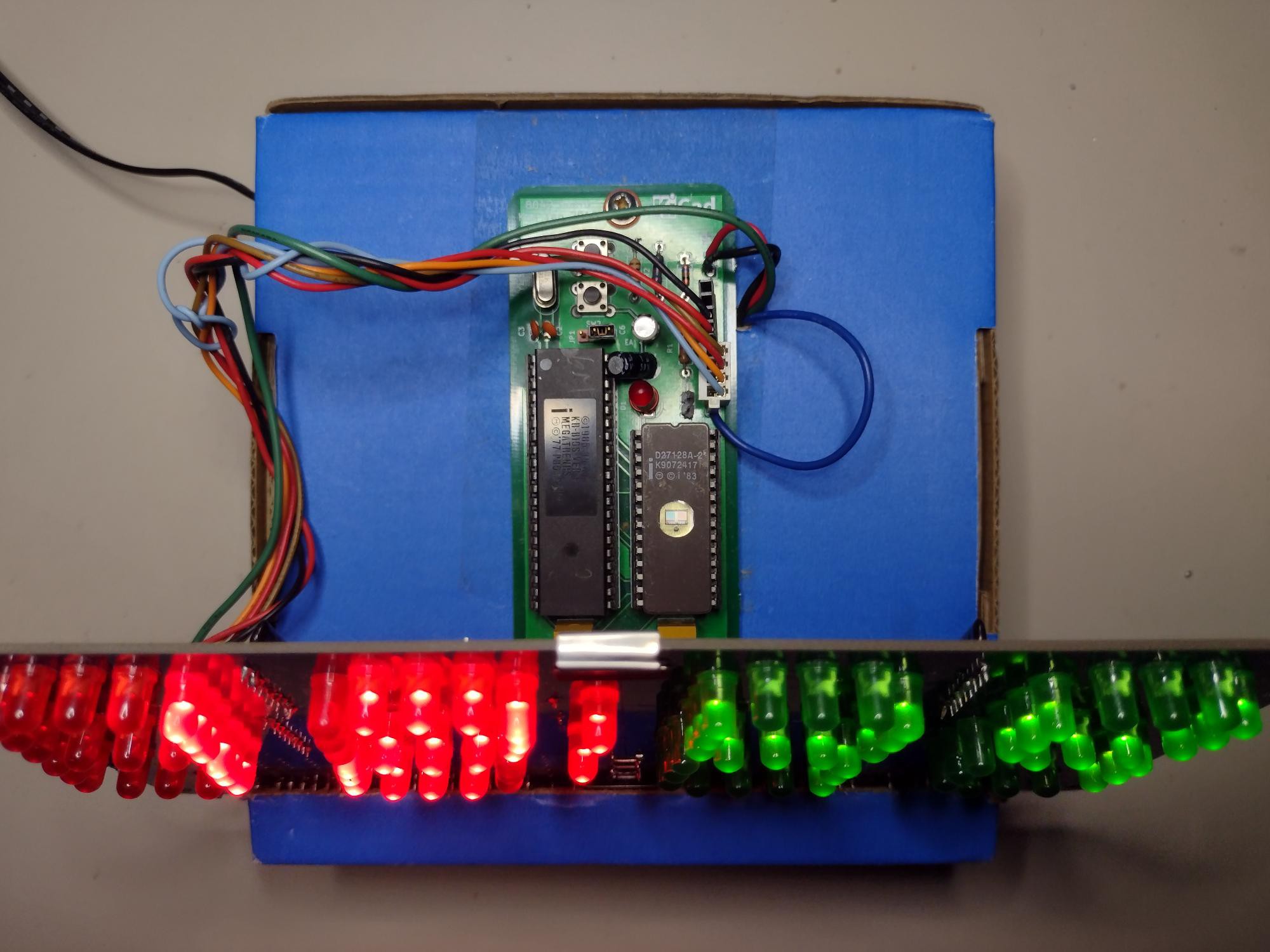

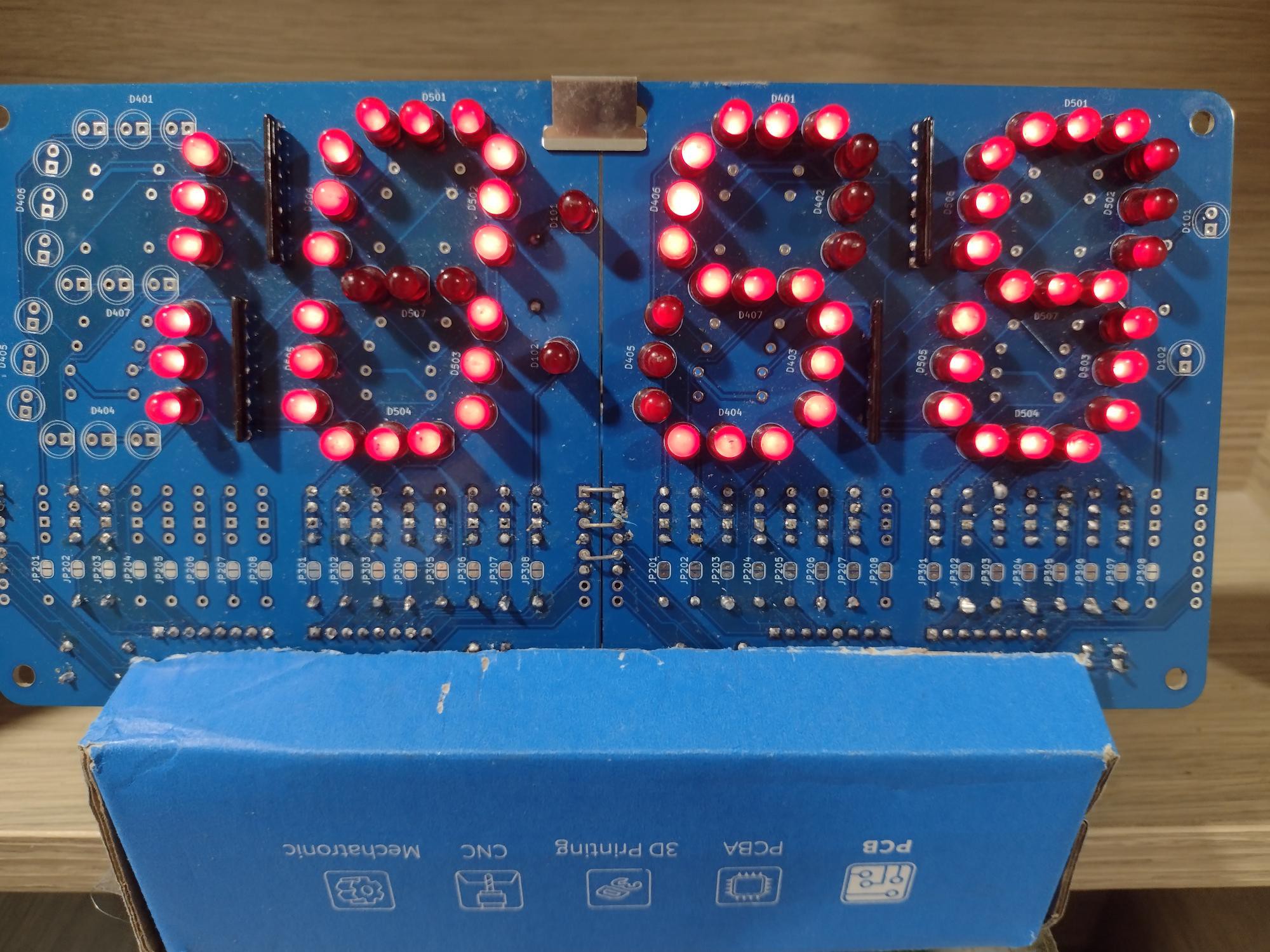

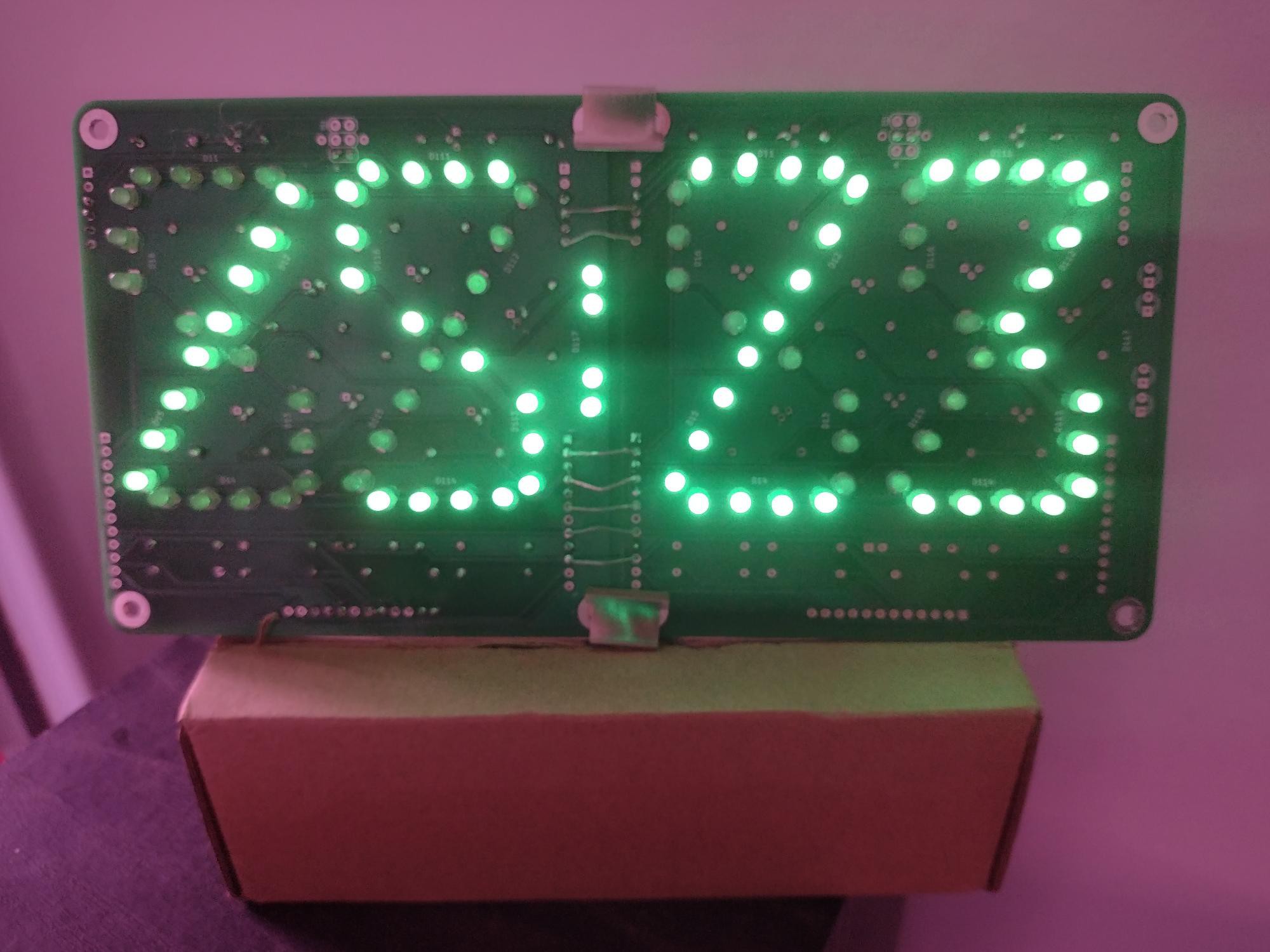

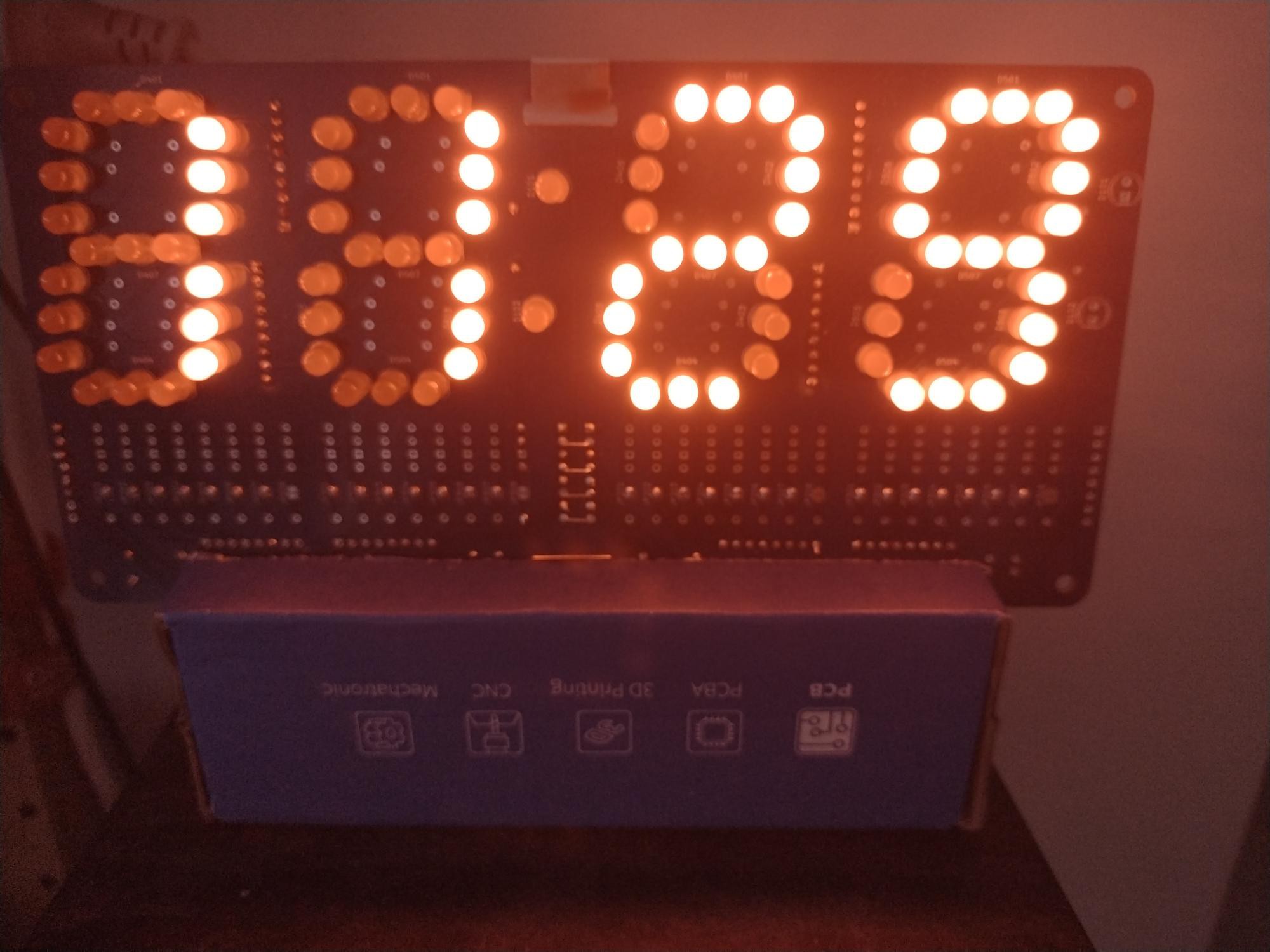

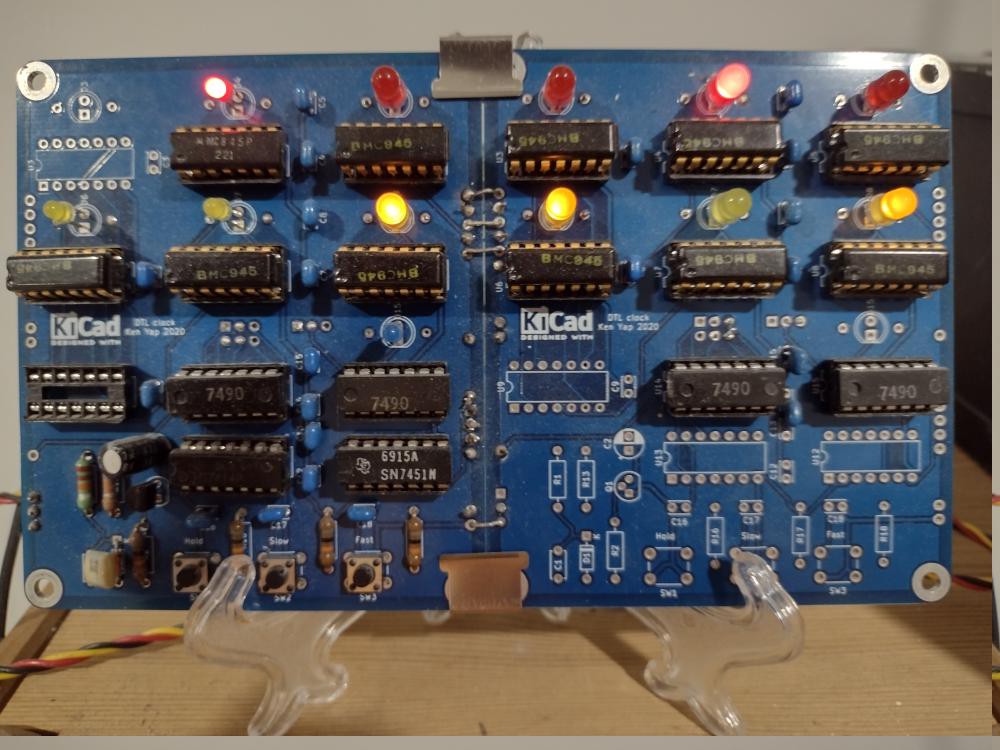

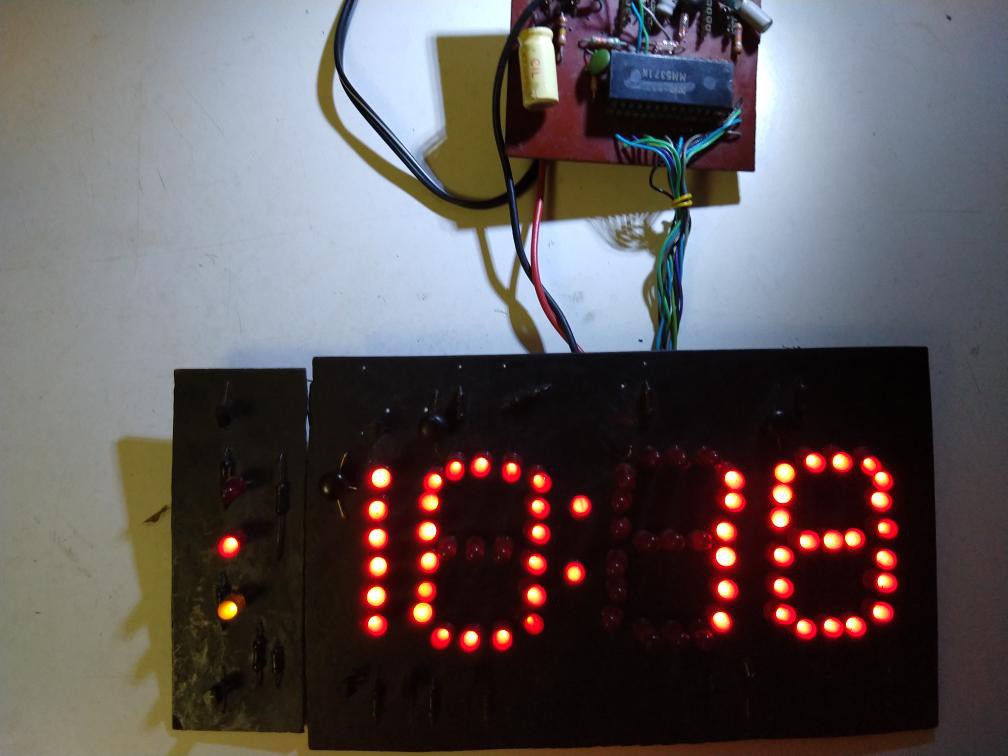

I think I now have a use for them. I cut a slightly slanting slot about 15° from the vertical from the top a few cm down the sides. Then I mounted quite recently designed boards from #Ancient 12 hour display there. The box is actually turned upside down and back to front, hence the discreet upside down logos on the front.

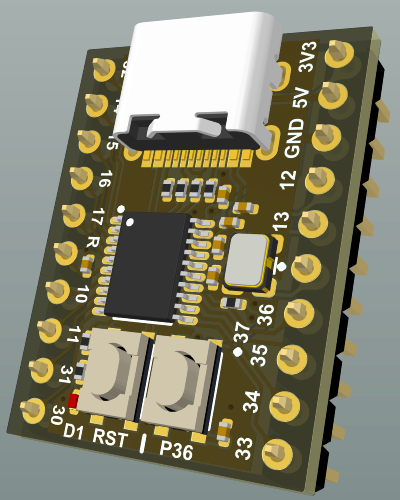

Here is the top view with the MCU module, although any MCU module will do. It's mounted outside because of the setting buttons. The power supply board is inside. It's supplied from a wall wart so low voltages.

I'll need to judiciously apply some hot glue to prevent joints and wires from going astray. Also to secure the clips at the middle top and bottom.

Another box. This is the clock from #Ancient 12 hour display

Yet another box. Though strictly speaking this is not from JLCPCB but from another PCB fabricator.

It's extremely difficult to show in a picture, but the colour of light from orange LEDs resembles that of nixies for those wanting that warm glow.

This project was not sponsored by JLCPCB. But I still thank them for the boxes. 🤣

-

The two button mode-set UI

03/14/2025 at 22:01 • 1 comment

The two button mode-set user interface is a design to allow changing many settings with only two buttons. It is used in many devices, even my ancient Casio F91-W watch from 45 years ago used it. Here is a simple example used in a 4 digit clock:

Indication Button 1 Button 2 Notes Normal display Time displayed Go to set hour Leaving normal display may require holding down the button for a while so that it's hard to activate accidentally Set hour Hour displayed Go to set minute Advance hour Set minute Minute displayed Go to set brightness Advance minute Set brightness All 8s displayed Go to normal display Change brightness In some implementations pressing both button 1 and 2 together does this As you can see, button 1 loops through the various modes, and button 2 is an increment button, which also loops on wrap around. Sometimes a third button is provided to decrement the counter, but I feel this detracts from simplicity. With autorepeat it doesn't take long to wrap around anyway.

Notes

- The advance will wrap around appropriately.

- Holding down button 2 will after 0.4 seconds, autorepeat at 4 times per second.

- The hidden seconds counter is set to zero whenever the minutes are advanced. To synchronise the time to a reference clock, set the minutes to the current minute. When the minute ticks over on the reference clock, click once on button 2.

- If the mode is not at normal display, it will revert to normal display after 64 seconds of button inactivity.

By contrast, the clock chips from National Semiconductor used a multi-button scheme. On the MM5316, I count: Fast set, Slow set, Seconds display, Alarm display, Sleep display, Alarm off, and Snooze. Fast set and slow set require estimating how close one is to the target to change buttons instead of setting the relevant counter directly. A bedside clock has room for more buttons, but I feel that there are too many buttons.

Here is a more elaborate example where the clock stores the date also. Let's put aside how or when the date is displayed. It could be alternately with the time as some old clock chips did, or a separate display:

Indication Button 1 Button 2 Notes Normal display Time displayed Go to set hour Set hour Hour displayed Go to set minute Advance hour Set minute Minute displayed Go to date Advance minute Date Month and day displayed Go to set month Set month Month displayed Go to set day Advance month Set day Day displayed Go to set brightness Advance day Set brightness All 8s displayed Go to normal display Change brightness Here is another elaborate example for an alarm clock radio with sleep timer which is turned on by an alarm match, or by manually setting to non-zero. Notice that button 2 has a function in normal display mode:

Indication Button 1 Button 2 Notes Normal display Time displayed Go to set hour Turns off alarm by zeroing sleep timer Set hour Hour displayed Go to set minute Advance hour Set minute Minute displayed Go to alarm time Advance minute Alarm time and status Alarm time Go to set alarm hour Toggle alarm Colon indicates if alarm active Set alarm hour Alarm hour displayed with steady colon Go to set alarm minute Advance alarm hour Set alarm minute Alarm minute displayed with steady colon Go to set sleep minute Advance alarm minute Set sleep minute Sleep minute displayed without colon Go to normal display Decrease sleep minute If at zero, will wrap around to 59 and turn on alarm (sleep output) The alarm is actually the radio, whose power is switched by the sleep output, doing double duty as an alarm and a sleep radio. Notice that we arrange it so that the display also indicates which mode it is in, to avoid having more indicators. This is not so important when the display technology can provide indicators, like LCDs, and LED raster displays.

The implementation is quite straightforward. It consists of a switch statement for both buttons, and a switch statement for button 2:

static...Read more -

Another skirmish with the avr-gcc toolchain

03/09/2025 at 06:02 • 0 comments

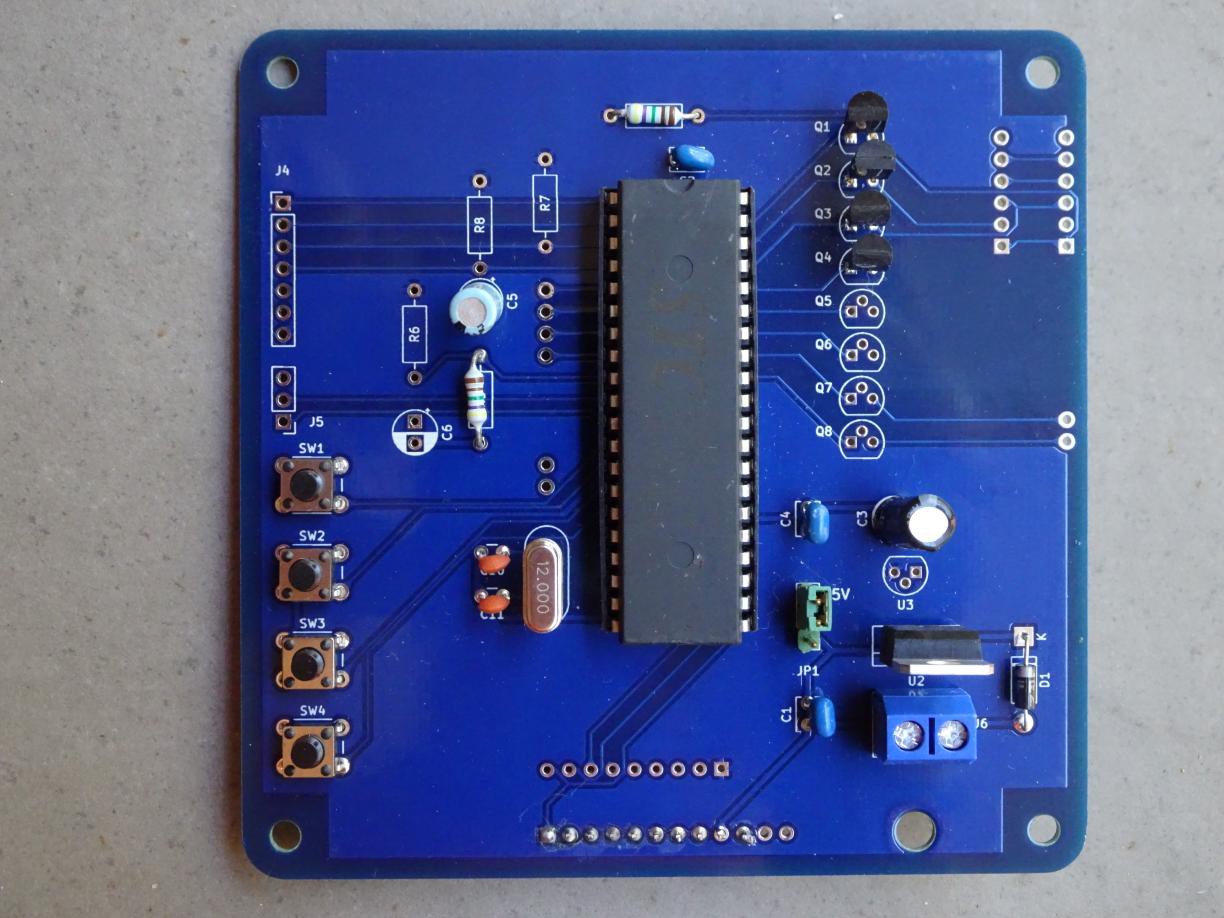

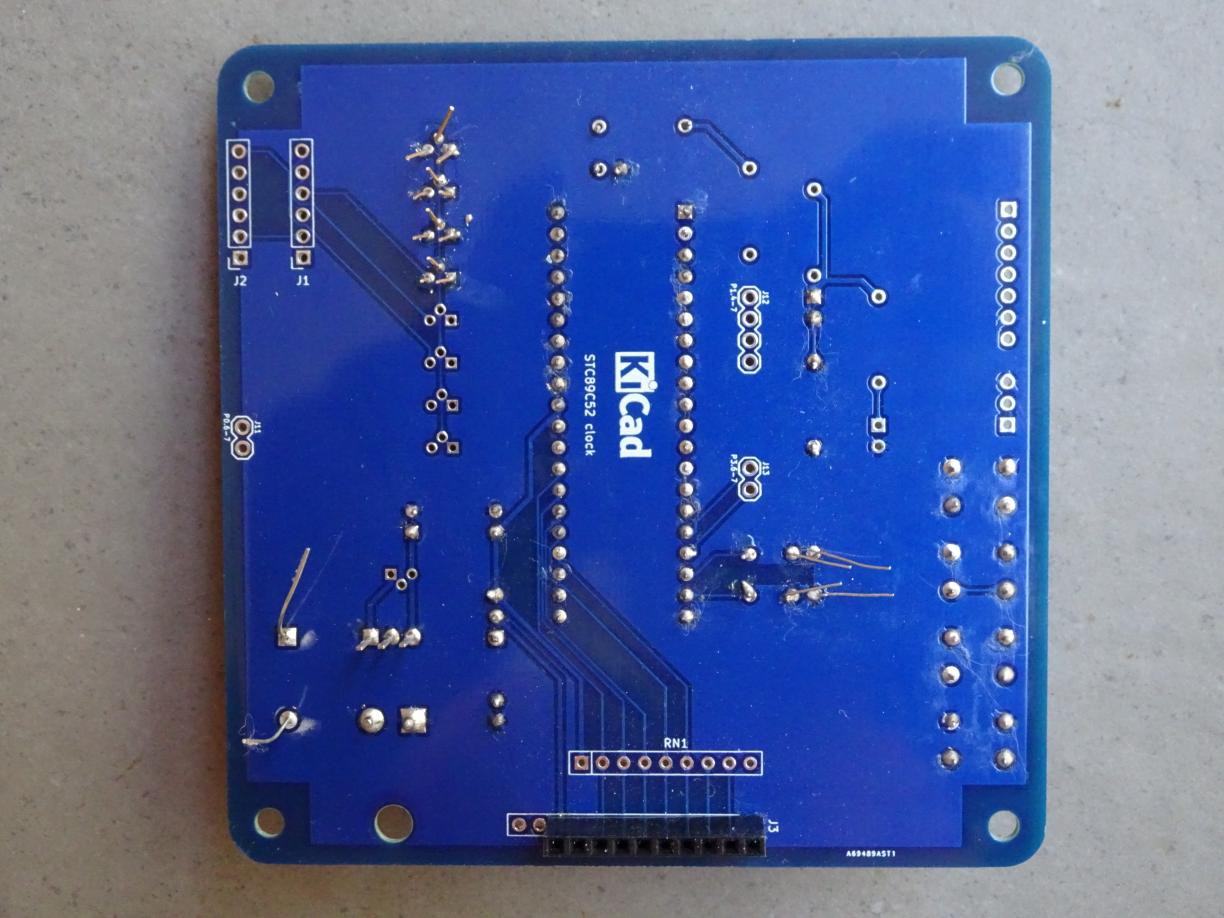

Wow, it's been almost 5 years and one pandemic since I tried to do something with this chip, first by installing, or rather piggybacking on, the gcc-avr toolchain. This MCU is pin compatible with the 8051 except for the polarity of the reset pin. I tried to get it working in the dev board in #Adventures with a STC89C52 development board but no joy.

Today I decided to try to get it working (or determine that it's bust) once and for all. I flashed a clock program onto it and watched the voltages on the port pins. All high. But the oscillator pins seemed to be ok. Time to look at my firmware.

Disassembling the .elf file with avr-objdump showed the start of the executable area:

Disassembly of section .text: 00000000 <__ctors_end>: 0: 11 e0 ldi r17, 0x01 ; 1 2: a0 e6 ldi r26, 0x60 ; 96 4: b0 e0 ldi r27, 0x00 ; 0 6: ea ef ldi r30, 0xFA ; 250 8: f6 e0 ldi r31, 0x06 ; 6 a: 03 c0 rjmp .+6 ; 0x12 <__zero_reg__+0x11> c: c8 95 lpm e: 31 96 adiw r30, 0x01 ; 1 10: 0d 92 st X+, r0 12: ac 32 cpi r26, 0x2C ; 44 14: b1 07 cpc r27, r17 16: d1 f7 brne .-12 ; 0xc <__zero_reg__+0xb> 00000018 <__do_clear_bss>: 18: 21 e0 ldi r18, 0x01 ; 1 1a: ac e2 ldi r26, 0x2C ; 44 1c: b1 e0 ldi r27, 0x01 ; 1 1e: 01 c0 rjmp .+2 ; 0x22 <.do_clear_bss_start> 00000020 <.do_clear_bss_loop>: 20: 1d 92 st X+, r1 00000022 <.do_clear_bss_start>: 22: a9 34 cpi r26, 0x49 ; 73 24: b2 07 cpc r27, r18 26: e1 f7 brne .-8 ; 0x20 <.do_clear_bss_loop> 00000028 <__vector_4>: 28: 1f 92 push r1 2a: 0f 92 push r0 2c: 0f b6 in r0, 0x3f ; 63 2e: 0f 92 push r0 30: 11 24 eor r1, r1 32: 8f 93 push r24 34: 80 91 37 01 lds r24, 0x0137 ; 0x800137 38: 81 50 subi r24, 0x01 ; 1 3a: 80 93 37 01 sts 0x0137, r24 ; 0x800137 3e: 8f 91 pop r24 40: 0f 90 pop r0 42: 0f be out 0x3f, r0 ; 63 44: 0f 90 pop r0 46: 1f 90 pop r1 48: 18 95 reti

Ah, that's no good. Although the code starts at 0, the next few locations should be interrupt vectors. In particular there should be an entry for vector_4, the timer vector. The code clears the BSS, but doesn't set up the PSW and the SP; one would expect some out 0x3[def] instructions. It doesn't call main, but falls through to vector_4, the first routine in the main C program.

We need more than this. Arduino users of the AVR chips have a startup environment that calls setup(), then loop() repeatedly. When doing bare metal (bare silicon?) stuff, like I am there should be startup code. Unfortunately a search on bare metal AVR got lots of pages explaining how to do direct I/O to ports, bypassing pinMode() and digitalWrite(), that's their idea of bare metal. The closest I found was this post on StackOverflow.

Ok so I need the equivalent of what has been known since Unix days as crt0.s, the assembly code for the startup code for C programs. A bit of searching in the avr-gcc directories found crtat90s8515.o. No corresponding .s, but that's ok, I can disassemble it with avr-objdump. It's probably in the source distribution.

Adding crtat90s8515.o to the list of linker input files gets this disassembled code:

Disassembly of section .text: 00000000 <__vectors>: 0: 0c c0 rjmp .+24 ; 0x1a <__ctors_end> 2: 27 c0 rjmp .+78 ; 0x52 <__bad_interrupt> 4: 26 c0 rjmp .+76 ; 0x52 <__bad_interrupt> 6: 25 c0 rjmp .+74 ; 0x52 <__bad_interrupt> 8: 25 c0 rjmp .+74 ; 0x54 <__vector_4> a: 23 c0 rjmp .+70 ; 0x52 <__bad_interrupt> c: 22 c0 rjmp .+68 ; 0x52 <__bad_interrupt> e: 21 c0 rjmp .+66 ; 0x52 <__bad_interrupt> 10: 20 c0 rjmp .+64 ; 0x52 <__bad_interrupt> 12: 1f c0 rjmp .+62 ; 0x52 <__bad_interrupt> 14: 1e c0 rjmp .+60 ; 0x52 <__bad_interrupt> 16: 1d c0 rjmp .+58 ; 0x52 <__bad_interrupt> 18: 1c c0 rjmp .+56 ; 0x52 <__bad_interrupt> 0000001a <__ctors_end>: 1a: 11 24 eor r1, r1 1c: 1f be out 0x3f, r1 ; 63 1e: cf e5 ldi r28, 0x5F ; 95 20: d2 e0 ldi r29, 0x02 ; 2 22: de bf out 0x3e, r29 ; 62 24: cd bf out 0x3d, r28 ; 61 00000026 <__do_copy_data>: 26: 11 e0 ldi r17, 0x01 ; 1 28: a0 e6 ldi r26, 0x60 ; 96 2a: b0 e0...

Read more -

LED bargraph clock?

02/26/2025 at 07:34 • 4 comments

I found that I have a couple of LED bargraph displays in my junk box. They are the old-fangled single colour type, not even the multi-coloured type used for battery charge indicators, level indicators and the like. They were intended to be driven by the LM3914 IC. That chip can be configured for dot mode or bar mode.

At the moment I don't have anything I need to display the level of. But since the display contains 10 discrete LEDs, I wondered if I could make a 10-bit display out of it. Let's see, for a binary clock, 0-59 minutes need 6 bits, and 0-23 hours need 5 bits. Oops. Maybe a 12 hour clock, and look out the window to see if it's AM or PM. 😉

It would be trivial to wire up to a MCU and get working, but nah, I'll pass on this one. The display would be too small, straining my eyes. It's bad enough having to mentally decode the binary. I know most of my projects are useless, but this is even more useless than usual. 🤪 Just setting down the idea for my amusement.

-

Tweaking a protothreads button handler

02/11/2025 at 05:49 • 0 commentsI have written on protothreads for switch handling in the past, as a log in a 8051 project of mine, but a recent modification that I wanted to do put protothreads in my mind again so I decided to rewrite it as a page.

Interface handling usually involves keeping track of the state. The changes in state are at human pace so waiting is not feasible as the MCU has other tasks to do. An example is switch debouncing and autorepeat.

You could do it with a full fledged thread facility. Or the programming language may offer coroutines, like Lua. In other languages usually the programmer resorts to writing a state machine, where variables remember where the subtask is up to. Sometimes the state machine uses an explicit state variable, sometimes the state is encoded in the values of variables.

But state machine code can be hard to comprehend. So I thought there should be a solution with very lightweight threads. A search found Protothreads by Adam Dunkels which has been available since 2005. This is designed for low resource MCUs, only requiring one integer location to store the thread state. It is implemented in standard C, not requiring any assembler assist, so is portable to any MCU with a suitable C compiler. In fact the C code consists of preprocessor macros.

Here's an example of the code I reuse unchanged in many of my projects. The requirements are:

- When a button is pressed the thread waits until the debounce period has passed. If the button is released before this, i.e. it was just a temporary spike, the thread restarts.

- On expiry of the debounce period, the action is taken. The thread then waits until the autorepeat threshold is reached. If the button is released before this, the thread restarts.

- On expiry of the autorepeat threshold, the action is taken. The thread then repeatedly waits for the repeat period to elapse, taking the action every time this happens. If the button is released at any time, the thread restarts.

Note that swstate and swtent (tentative state) are actually bit vectors representing an array of switches, so this code handles more than one switch. The code that corresponds to each switch is called from switchaction(). To make things concrete, this design uses a debounce period of 100 ms, an autorepeat threshold of 400 ms more, and a repeat period of 250 ms (4 times a second).

static inline void reinitstate() { swtent = swstate; swmin = DEPMIN; swrepeat = RPTTHRESH; } static PT_THREAD(switchhandler(struct pt *pt, uchar oneshot)) { PT_BEGIN(pt); PT_WAIT_UNTIL(pt, swstate != swtent); swmin = (swstate == SWMASK) ? DEPMIN : RELMIN; swtent = swstate; PT_WAIT_UNTIL(pt, --swmin <= 0 || swstate != swtent); if (swstate != swtent) { // changed, restart reinitstate(); PT_RESTART(pt); } switchaction(); if (oneshot) { reinitstate(); PT_RESTART(pt); } PT_WAIT_UNTIL(pt, --swrepeat <= 0 || swstate != swtent); if (swstate != swtent) { // changed, restart reinitstate(); PT_RESTART(pt); } switchaction(); for (;;) { swrepeat = RPTPERIOD; PT_WAIT_UNTIL(pt, --swrepeat <= 0 || swstate == SWMASK); if (swstate == SWMASK) { // released, restart reinitstate(); PT_RESTART(pt); } switchaction(); } PT_END(pt); }You can see that it is programmed as a sequential routine. The structure of the handler mirrors the specification above. You have to imagine that the thread has a life of its own and waits at the PT_WAIT_UNTIL macro until the condition is satisfied. In reality, the MCU exits the routine and uses a local continuation to know where to restart when the thread is called again. It's really thinly disguised state machine code, but written like sequential code.

Unlike a real thread library, there is no scheduling. You have to arrange to periodically call the thread handler.

Now the modification that I wanted was to have a shorter debounce time for depress than release. The change turned out to be trivial:

diff --git a/clock.h b/clock.h index 9701dfb..db74d57 100644 --- a/clock.h +++...Read more -

Stitching boards with paper clips

01/11/2025 at 09:44 • 0 comments

People who follow my display board projects know that I usually design them to be cascaded for more digits. They are connected in series using either Dupont pin sockets and pin headers, or just soldered jumpers as in the photo above. Neither is satisfactory as there is still flexure. I have considered using small aluminium straps and screws to hold the boards together stiffly using the corner holes. But I would have to look for aluminium strip of the right width and hacksaw small lengths off.

Today I tried another idea, using reusable paper clips that were designed to hold multiple sheets of a document together. They are attached to a corner of the document stack with a special tool. It's a solution between standard paper clips and fold back paper clips.

It works and I would also need to put some hot glue on the clips to prevent them from sliding off. However in future I will also need to design enough clearance so that the clip doesn't short PCB connections as the one on top in the picture almost does.

-

A buglet initialising the CH552

01/05/2025 at 00:08 • 0 comments

When I finally put the two boards described in Flashing the CH552 dev board from the command line to use I noticed that button actions were faster. Counter advance worked twice as fast. The no-activity timeout for exiting set mode was 32 seconds instead of 64. At boot-up the MCU runs at 24 MHz, but this can be set to 12 MHz for compatibility with the classic 8051. The tick timer which governs the speed of button actions depends on the clock speed.

I thought I had taken care of this in the initialisation code, but to cut to the chase, here's the diff showing what I did wrong:

$ git diff 227da07..67b402a diff --git a/227da07 b/67b402a index 227da07..67b402a 100644 --- a/227da07 +++ b/67b402a @@ -200,8 +200,7 @@ void main(void) // change the clock divisor to generate 12 MHz SAFE_MOD = 0x55; SAFE_MOD = 0xAA; - CLOCK_CFG &= ~CLOCK_DIVISOR; - CLOCK_CFG |= CLOCK_DIVISOR; + CLOCK_CFG = (bOSC_EN_INT | CLOCK_DIVISOR); SAFE_MOD = 0x00; // any value will do #ifdef DEBUG #elseThe clock configuration register is protected against accidental modification by a protocol. You have to write the values 0x55 and 0xAA to the SAFE_MOD register, make your change, then exit by writing anything to SAFE_MOD. The intention of the original code was to read the bits in the CLOCK_CFG register, except for the CLOCK_DIVISOR (bottom 3) bits, then write it back with those bits modified. You can see that the first line ought to be:

CLOCK_CFG &= (0xF8 | ~CLOCK_DIVISOR);to preserve the top 5 bits.

But I also fell foul of another restriction and that is modification mode only lasts for a limited number of clock cycles. More instructions and the changes don't take. That was probably what was happening, it timed out before CLOCK_CFG was changed. So I just went for a simple one line replacement and that fixed the double speed problem.

BTW, I prefer to run the MCU at a lower clock rate rather than recalibrate the timer for a faster clock. It's more reliable at lower clock rates, and the MCU is idle most of the time anyway.

-

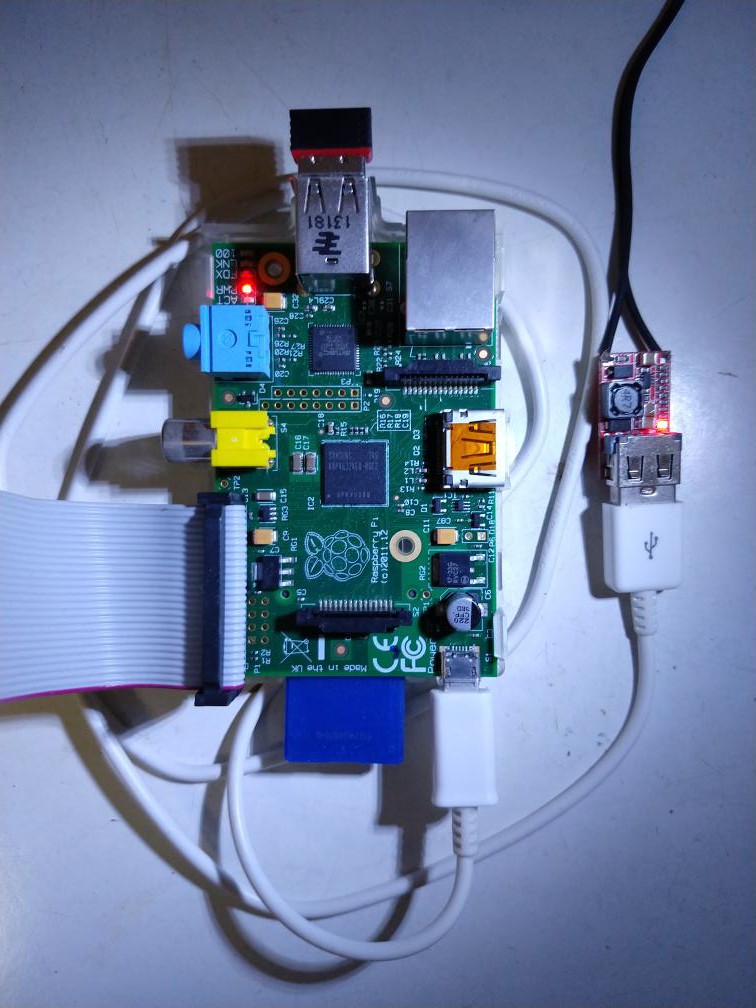

Recording Internet radio with a Raspberry Pi 2B

01/04/2025 at 07:42 • 0 commentsInternet radio is great, you can listen to stations all over the world. You may wish to save some programs. I have been doing this for a while from my Linux workhorse. I recently looked into doing this from an ancient Raspberry Pi 2B. It took a couple of battles with the DietPi distro and the mplayer packages, but it's done. Here are the articles I wrote in my technical blog:

-

A tale of DS1287s

11/27/2024 at 12:11 • 0 comments

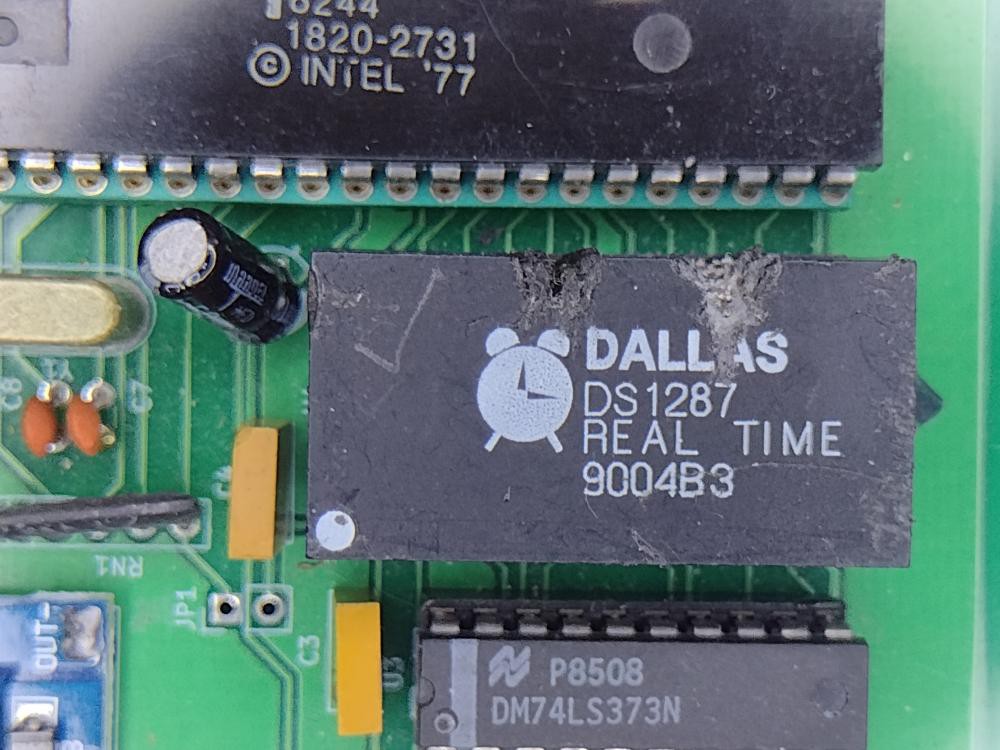

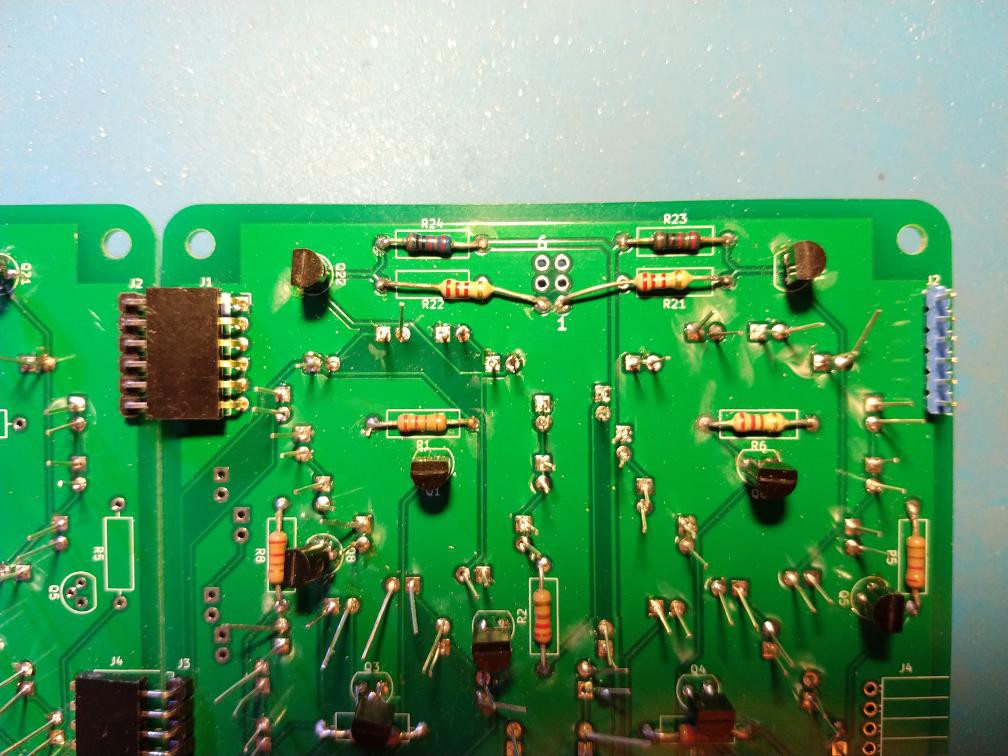

Among the junk in my box are a handful of RTC modules scavenged from old PCs. They are the DS1287 and DS12887 from Dallas Semiconductor which are basically the Motorola MC146818 with a 32.768 kHz crystal and coin cell attached and encapsulated in a tall 24 pin DIP package.

Of course the coin cell drained long ago, so I applied this rework hack (with a hacksaw too, you can see the notches in the photo above) to disconnect the cell. I had incorporated a socket for this RTC in my 8048 board and written firmware for it. You see a section of the board in the photo above. The idea was that if I powered the RTC module with an external battery it could maintain time without power. This was not successful. Only some of the RTC modules could be made to work, and not very reliably, even when powered by the same 5V supply as the 8048 microcontroller.

Finally with curiosity killing me I decided to get to the bottom of matter. I wrote an Arduino sketch to initialise the RTC (basically the same sketch I used to test the freestanding MC146818s I had) and then read the time registers. I also enabled the SQW (square wave) output of the chip and attached a scope to that output.

What I discovered was that only a few of the modules I had could keep updating the time registers and also provide a 32 Hz square wave output. A few couldn't update the registers but could supply the SQW.

So I tossed out 2 modules that couldn't even generate a SQW, obviously the crystal oscillator or MC146818 inside were bust. For the remaining ones I modified the board and firmware a little to use the SQW as a pseudo-mains timebase, and set the clock going. The 2 DS12887s and 1 of the 3 DS1287s were a bit erratic, and sporadically stopped oscillating. That left only 2 usable DS1287s. But they kept pretty good time only a few seconds out per week, considering they are an old generation of RTCs, whereas the current generation has temperature and ageing compensation. This may be because they are running indoors where the temperature only varies a couple of °C around 24°C.

So I now know that I have 2 usable modules for my boards. The rest I can send to e-waste heaven.

-

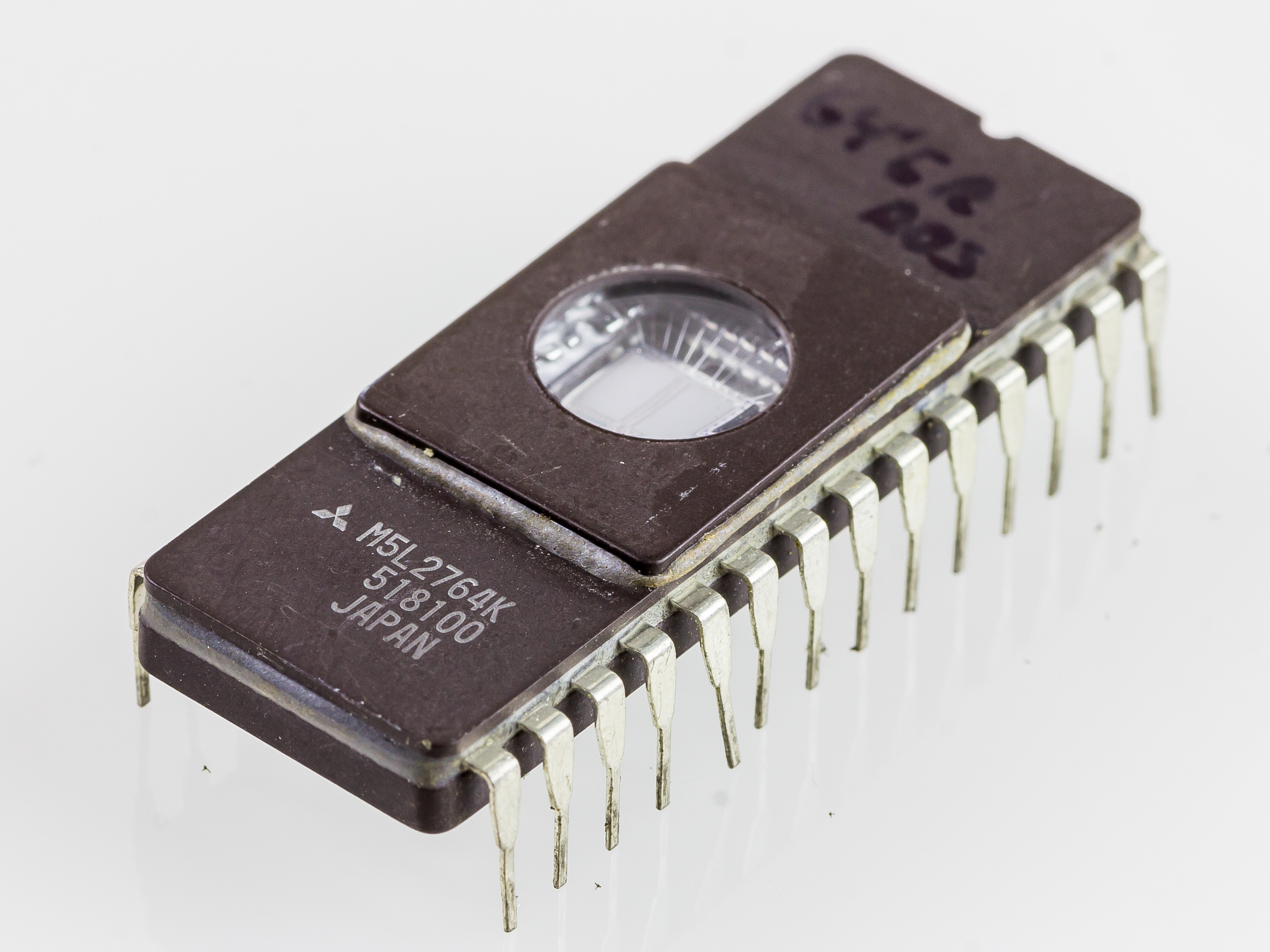

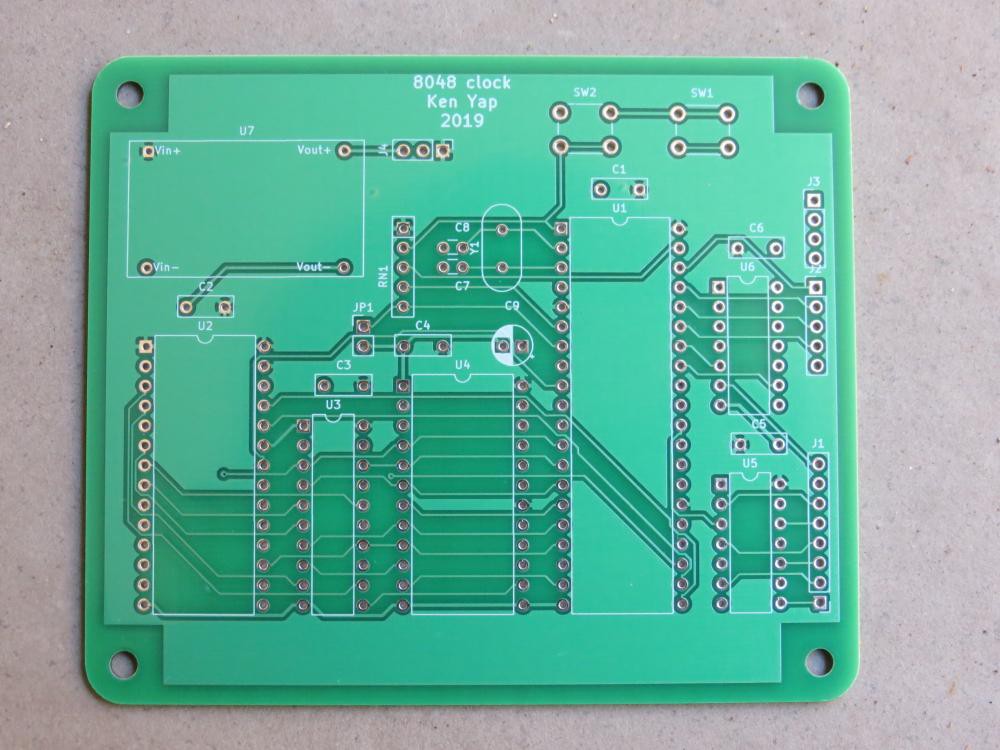

Time to ditch the 2764s

11/08/2024 at 06:25 • 0 comments

© Raimond Spekking / CC BY-SA 4.0 (via Wikimedia Commons), Mitsubishi M5L2764K-5377 , CC BY-SA 4.0

After creating a minor tweak to the firmware for #8042 clock (the PCB version, the breadboard version was disassembled years ago) I needed to burn some 2764 EPROMs with my trusty TL866A. Unfortunately some of the EPROMs couldn't be programmed, but others could. The common factor seemed to be the need for 21V Vpp. Usually the C (for CMOS) chips could be programmed.

I had been able to program these in the past so either my TL866A had developed a fault or the open source minipro software for Linux had a bug. I couldn't find any reports about this in the repo, so that would point to the former. Or hardly anybody programs 21V Vpp EPROMs any more so never hit a bug.

I had already written about ancient 2[57]{16,32} EPROMs that require 25V Vpp, and had concluded that I would not be able to use them. So for these 21V Vpp 2764s, I think the most expedient way forward for a lazy cat is not spend time working out whether my programmer or the minipro software is at fault, or even trying the Windows minipro software in a VM, but just bin these chips. (Or if anybody wants them for the cost of postage, PM me.)

Fortunately my designs already cater for using 27C128 or even 27C256 EPROMs in the same 28-pin socket, and I still have a lot of those, probably more than I'll ever be able to use up, as I'm more ancient than the chips. And anyway the non-CMOS versions of the 2764 are more power-hungry.

-

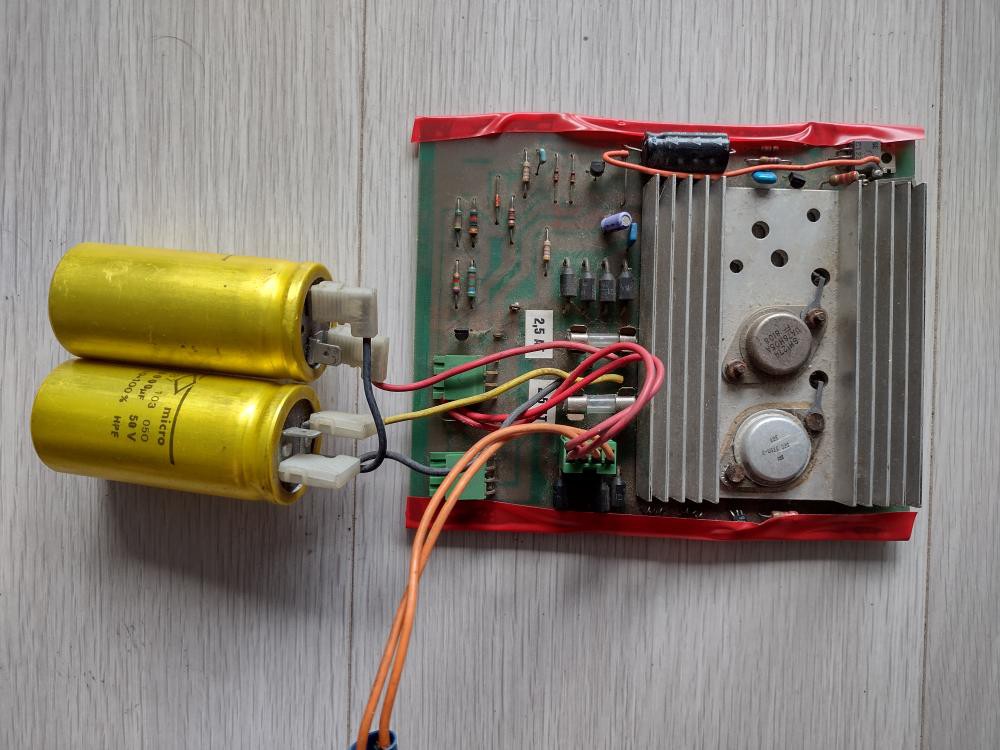

Assembling a 120 W bench power supply

10/20/2024 at 19:38 • 4 comments

I ordered a XY-SK120 buck-boost converter with digital controller with LCD screen from Aliexpress. With it I can dial up any desired voltage and use current limiting to forestall damage when first powering up projects. It has many other features. From the specs it's quite an impressive piece of electronics for its small size. Input can be 6-36 VDC and output 0-36 VDC at up to 6 A and it handles up to 120W.

I chose the cased version. It's more than just the bare converter board with banana sockets in an enclosure. At the back is a cooling fan and a power input panel that takes various sources, including terminal block, barrel socket, some kind of Molex socket, and even USB-3 PD input. A cursory inspection shows that diodes isolate the inputs from each other. These extras account for the higher price.

The fly in the ointment is poor documentation. It would be nice to know how to operate the UI without trial and error. Not even a slip of paper in the box. But a bit of hunting found an instruction manual online. From the modification date, less than 3 months ago, the firmware is still being improved, and in the future it might be possible to update it using the serial interface.

Normally one would use a SMPS or an old laptop power brick for the input. I decided to put to use an old school power supply board possibly from an LA30 Decwriter that the board for #Flashing LEDs from old printer electronics came from. In the board pictured below, only one set of bridge rectifiers and one large capacitor are in use. There are actually two independent power supplies on the board. The low voltage one supplies digital logic via a 5 V regulator, one of the large TO-3 cases. I won't be using that half. The high voltage one supplies the electromechanics. The capacitor is a whopping 10000 µF rated for 50 V so lots of margin. Nominal voltage level was probably around 30 V. A 24 VAC appliance transformer that I was given feeds the board.

For the enclosure I used an old Ryobi timer saved from e-waste. It seems to have been an appendage to unknown industrial equipment. The inside was gutted to fit the PS PCB.

That such a small controller can provide 6 A is a testament to how much the power density of electronics has increased over the years. (But some reviews mention that the cooling fan may be inadequate at high power levels.) The current is more than the old bulky linear power supply can supply. The fuse on the rectifier board is rated at 2.5 A. The transformer is rated at 1.5 A. (Although at lower output voltage, more current can be supplied, as the converter is switching mode.) Anyway this is enough for my needs for the near future.

Oops, I forgot to order 4 mm banana plug cables. Next round then. Can't buy everything in the shops all at once. 😉

Well that takes another tuit off my round tuit list.

-

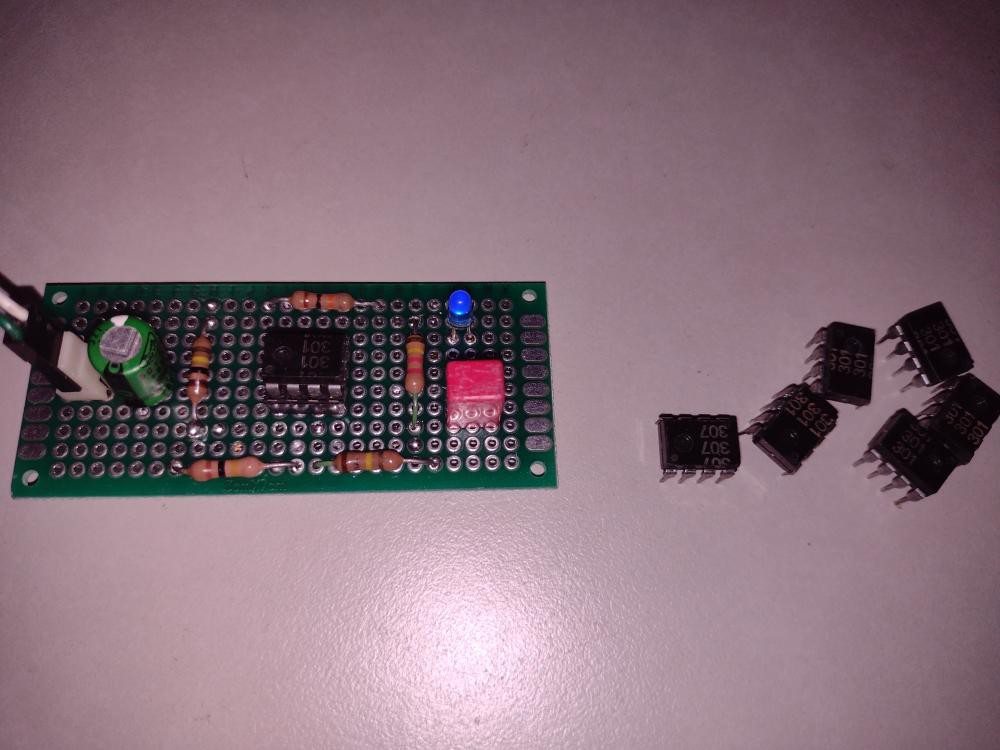

Simple opamp tester

09/26/2024 at 11:07 • 0 comments

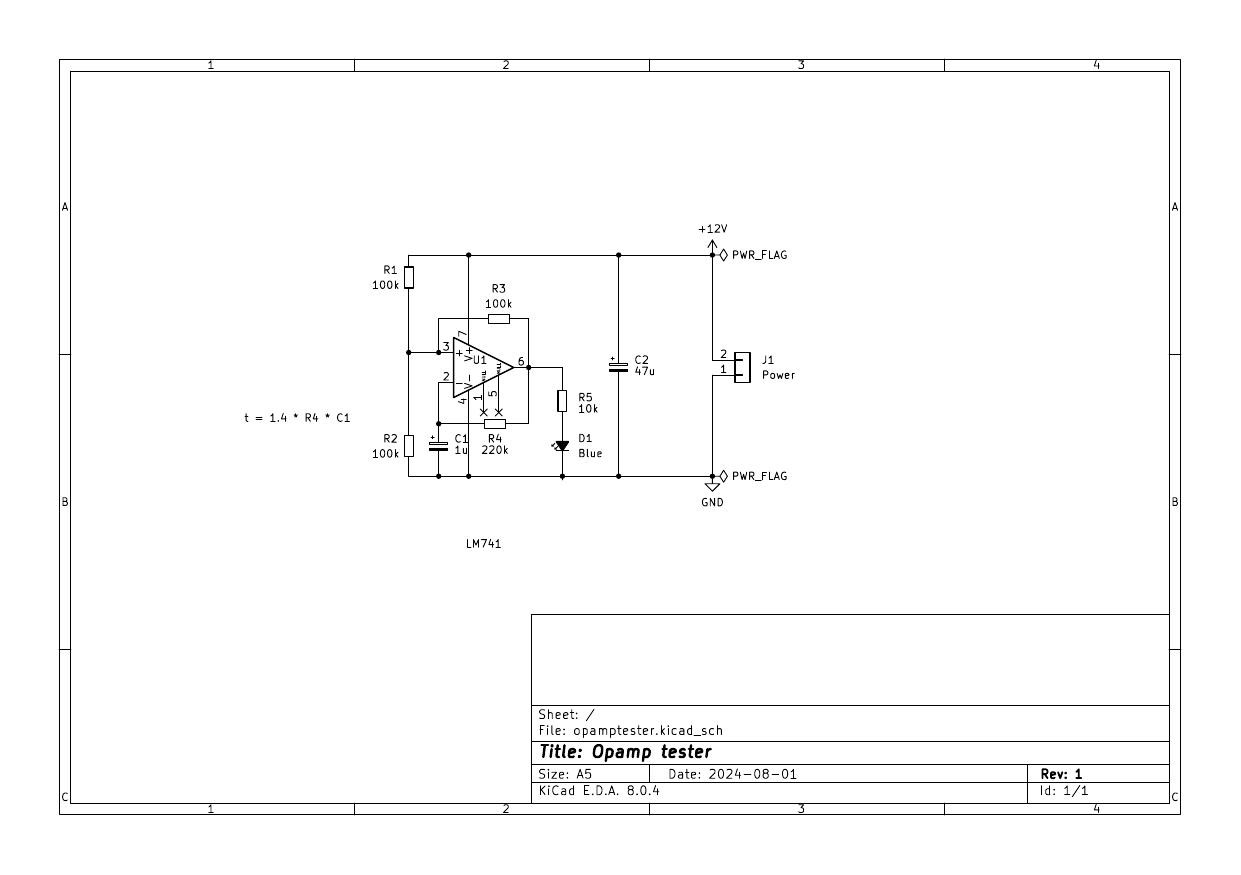

I have many 8-pin opamp ICs such as the venerable 741 in my junk box, some pulls, some from grab bag purchases. I wondered how many of them are working. So I put together a simple circuit to check basic opamp function. I assembled it on perfboard as it's a simple circuit and I only need one.

It's a familiar relaxation oscillator. Normally we need balanced voltage rails for an opamp, but the resistor network R1, R2, and R3 establish upper and lower bounds of roughly ⅓ and ⅔ the supply voltage. The values chosen make the LED to blink at about 3 Hz. The pin numbers are for the 741 and others with the same pinout. It's just a go-nogo check and doesn't test advanced characteristics. The tester found a handful of duds which I can now throw out. So if nothing else, I know that I have lots of blinky ICs in my collection. 😉

-

Trying out JLC's 3D printing service

08/02/2024 at 08:56 • 1 comment

Since JLCPCB lowered its shipping charge to $1.50 for small parcels to me, I wondered if the same applied to JLC's other services. I decided to try out their 3D printing service.

I have wanted a THT resistor lead former for a while. It helps make sure the leads are the right spacing for insertion into PCB holes. But even manufactured ones on Aliexpress cost several dollars each. Daylight robbery for a piece of plastic. I guessed that there would be open designs available and sure enough I found dnewman's design on Thingiverse. I ordered both narrow and wide Imperial size models.

Submission through the web form was straightforward but even just for SLA I was bewildered by a plethora of choice of resin material. A friend explained that they were simply different resins for different use cases. In fact tooltips on the options explain what each is good for. Since the part in question is not load bearing, doesn't have to withstand heat, and doesn't have to be a particular colour, I went for the cheapest beige resin. But even other resin types would not have broken the bank. The order came up to $2.70 including shipping.

There was a bit of a hitch when their engineer warned me about a thin wall < 0.8 mm in the design. It's near the narrow end of the skinny former. I think it means that this feature is in danger of breaking off. I don't have the skill to edit the source files of the design and this isn't a critical part so I told the engineer to let it through.

Progress through production wasn't as fast as for PCBs. I think they don't work on weekends. But there are less steps and it was done in a couple of days then shipped.

This is a cheaper way to get 3D printing done than at my local library where there is a printer, provided I'm willing to wait 10-14 days.

-

MC14450, a tiny chip from half a century ago

07/13/2024 at 10:46 • 0 comments

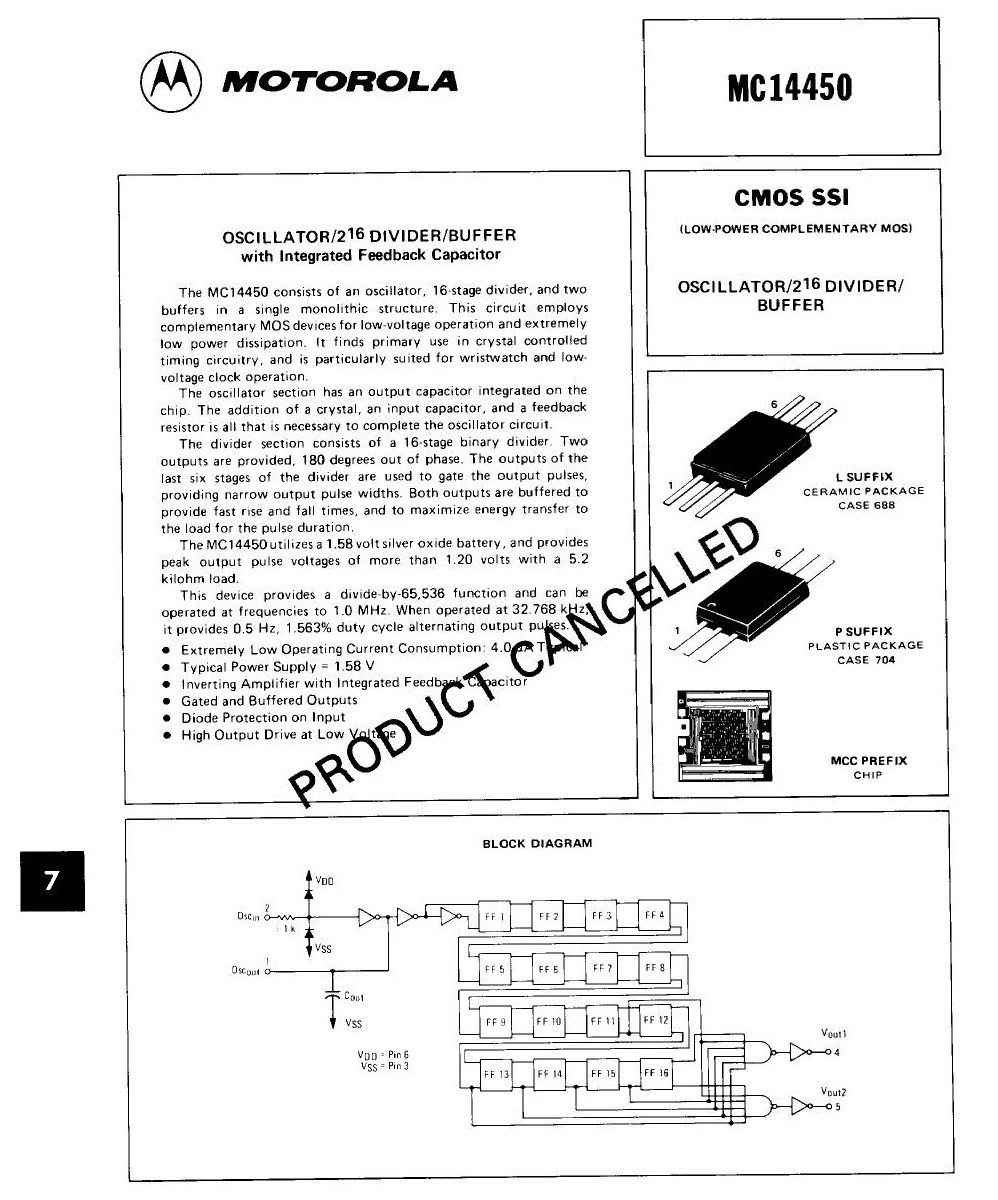

Rummaging through my

junkspare parts box, I found this tiny 6-pin chip in a carrier. Curious, I looked it up and here's the first page of the datasheet.

It is an oscillator and 2^16 divider, from 32768 Hz to ½ Hz, intended to be used in quartz timebase watches with mechanical hands which explains the tiny package and leads. The date code indicates it was produced the 50th week of 1976. An interesting aspect is it runs on 1.5V from a silver oxide cell and at no more than 3.0V.

Oh well, not much use for this almost 50 year old chip except to write a blog page about it. 😉

-

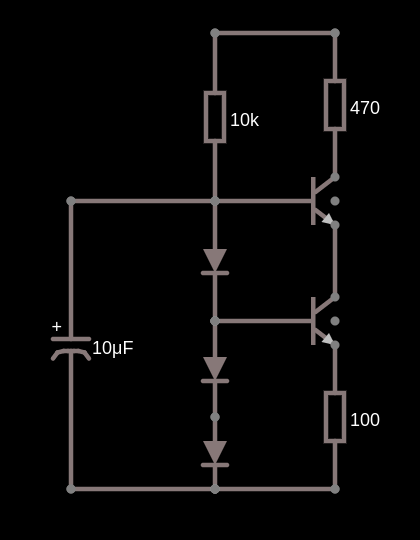

Getting blinky working on the WCH CH32V003F4 development board

07/03/2024 at 10:53 • 2 comments

Motivation

I decided to dip my toes into the current generation of cheap RISC-V MCUs under 20¢ each. The QingKe CH32V003 looked like a good candidate for a basic workhorse MCU. I have some MCUs from the ARM Cortex family like the STM32 and RPI2040 but I have a preference for an open ISA as I think this will drive prices down. I had tried out the GD32V Longan Nano but that was too expensive. The W806 looked promising but that used the Csky architecture which is manufacturer specific, and not much has been heard from them since.

Note that WeActStudio has got into the RISC-V game with the CH5[789]x which can in fact use the same toolchain as the WCH products. The ESP32-C3 is also RISC-V based and of course comes with WiFi and Bluetooth support.

I'm actually late to the game; there are lots of projects on HaD and on the Internet already using the CH32V. I just want to document my initial experiences and maybe help others avoid pitfalls. I'm on Linux but many details are similar on other host OSes.

Ordering

I ordered the kit pictured above for about $10 from the WCH official store on AliExpress which guaranteed me that I would be getting the correct combo. You need the WCH-LinkE to start off, despite any webpages out there talking about programming using the USB-C port. That can only be done if you have installed a bootloader that listens to the USB-C port. Also do not buy the older WCH-Link without the E, it cannot program the 00x series.

Setup

Both Arduino and PlatformIO have support for CH32V. Arduino uses the official gcc 8.2 toolchain and an open source OpenOCD for downloading. PlatformIO uses the xpack distribution of the same software. Later I will explore using command line tools instead of an IDE for development, but it's useful to see what commands an IDE is issuing behind the scenes.

After installing either or both IDEs, there are a couple of udev rule files you need to copy to /etc/udev/rules.d so that you have access to the USB device as an ordinary user (do not do development as root!). You can find them under the openocd directory in either IDE. I had to change the group from plugdev to dialout for my distro. Yeah, it's historical.

Now plug in the WCH-LinkE and you will see a new USB device appear. In my case the device was /dev/ttyACM0.

Instructions say you need to connect GND, 3V3 and SWDIO on the dongle side to GND, VCC, and PD1 on the dev board side. This required a 3 wire pin socket cable which was not included. I found a 4 wire cable from PC days, and fortunately the wires are in the same order on both ends, and 4th pin socket was off the end of the connector pad and didn't connect to anything.

Testing

I fired up the Arduino IDE and selected the CH32V00x target and /dev/ttyACM0 port. I could then get the board info and this showed me the MCU ID in addition to the USB IDs.

I loaded the blink sketch from Examples, compiled and downloaded it. But nothing blinked. I found out from a tutorial that the 2 onboard LEDs are not connected to any port pin. I guess this gives flexibility for development and debugging later. So I had to find another pin socket jumper wire. Which port pin should I connect it to though, in other words what does LED_BUILTIN map to? I looked in the include files in the toolchain and discovered that it's not defined as any port pin. So I edited the sketch to use PD0. When I connected the jumper between pins PD0 and LED1, I got a blinking blue LED. Success!

Ok, that's where I'll leave it as that was my goal for today.

-

Flashing the CH552 dev board from the command line

05/17/2024 at 13:25 • 3 commentsThis is a follow up to https://hackaday.io/page/13802-a-quick-foray-into-the-ch552-mcu

I finally got around to having a use for these cheap and tiny MCU boards.

Instead of using the Arduino CH55x framework by Deqing Sun in my initial exploration, I'm developing using command line tools. Editing and compiling using SDCC is no problem, I've done this for other 8051 projects such as #Adventures with a STC89C52 development board The issue is how to flash the embedded code to the board. The tool I chose is vnproch55x which is maintained by Deqing Sun also. So I just made a link to the binary provided by the Arduino CH55x framework.

However I ended up looking at the code on GitHub also to work out how to invoke it. From observing the output of the Sketch > Upload action, it's called with two additional command line parameters. The full invocation looks like this:

vnproch55x -r 16 -t CH552 blink.hexThe -r parameter sets the number of seconds to retry, the -t parameter chooses the target MCU type, and finally note that utility accepts hex files also, all enhancements to the original vnproch551 by NgoHungCuong. So if you don't have the Arduino CH55x framework installed, Deqing Sun's utility is the one to clone and compile to get an executable utility.

Also confusing the situation was that any sketch uploaded by the Arduino CH55x framework contains a bootloader which makes it appear as /dev/ttyACM0 which is a CDC with USB VID 1209:C550. This confused me because I was expecting the USB VID to be 4348:55E0. When such a CDC bootloader is in place you need to set the serial speed to 1200 baud and drop DTR to make it ready for receiving a sketch. The Arduino IDE does this but to do it from the CLI you can use a short Python script reset.py from the repo Arduino_Loader in GitHub. I made one small change to upgrade it to Python3 since that's the current Python on my Linux system.

However once you have loaded a bare metal sketch, i.e. one that doesn't use a CDC bootloader, it will appear at USB VID 4348:55E0. But I could not get the attention of the board to receive a new sketch. Remembering how similar boards work, I found the sequence.

- First start vnproch55x to read the hex file and start attempting to connect to the board. You now see why I used a generous retry period of 16 seconds.

- Connect the USB cable to the port while holding down the BOOT button (the other one is the RESET) button.

- Release the BOOT button. It will accept a USB connection and receive the code and execute it.

Incidentally the udev rule supplied for the CH55x sets the device mode to 0666. It's better to set it to mode 0660 and owned by the group used for downloads which you should make yourself a member of, in my Linux system it's dialout (I know, not much to do with embedded development, it's historical).

Great! Now I can finish the development of the embedded program and put the board to use.

-

A fugly amplifier

12/26/2023 at 08:09 • 0 comments

My sturdy NAD amplifier developed a fault where the left channel got fainter and fainter. I have the service manual and I think I know where the fault is, but I haven't got a round tuit fixing it. Meanwhile I listen to music all the time so I would miss not having an amplifier. #Playing music remotely with bluetooth was partly a response to the deprivation.

Knowing now that class D amplifiers are small, cheap and powerful, I thought I would buy another, more powerful, amplifier board and retrofit it to an old amplifier case. The amplifier you see came from some garage sale or other, I don't remember. I do remember that I bought it because it offered quadraphonic decoding. For a while in the late 70s, one could buy quadraphonic LP records that squeezed 4 channels onto the 2 channel groove of the vinyl. I had one or two such LPs and only ever heard them in stereo. But by the 2000s, multichannel digital recordings obsoleted the quadraphonic hacks. You can see the 4 power amplifier ICs in this top view of the amplifier.

I thought to put a SMPS inside the case and rewire the selector switch to choose between input sources. The amplifier board is totally disconnected and the volume pots do nothing. I only kept it because the volume pots are soldered on and removing them would leave even more holes in the front panel. (I may later take the pots off the PCB and remove the PCB, leaving the pots bolted on the case just for appearances' sake.)

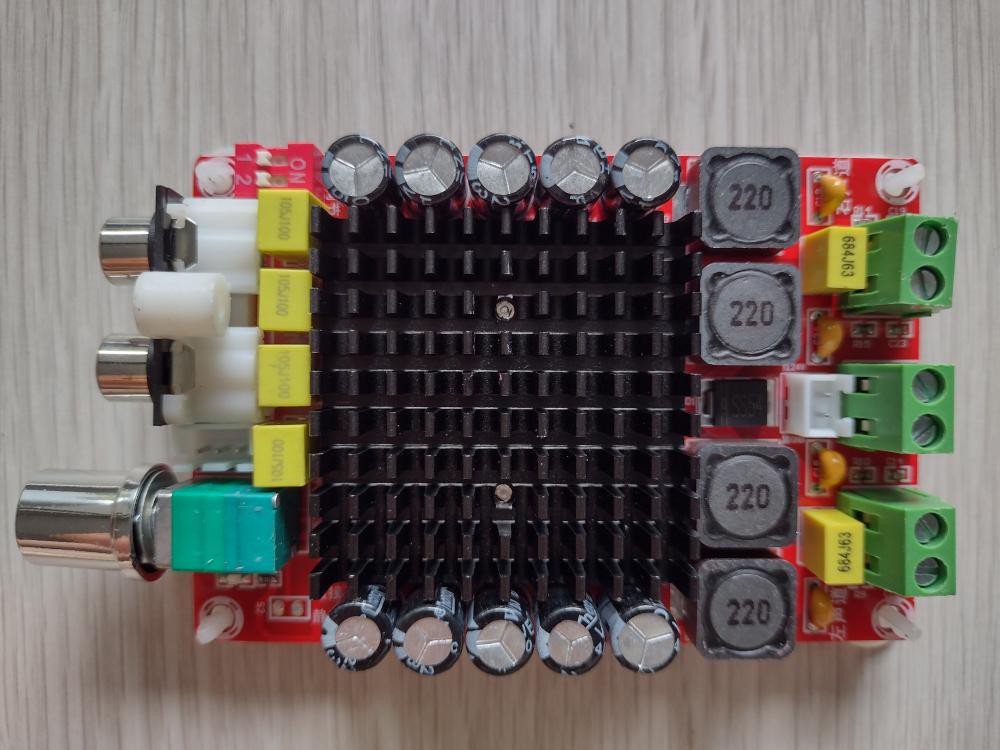

Here's the class D amplifier I bought for about $20 delivered. It takes up to 36V supply, and the SMPS which I think used to feed a laptop or something, can supply 32V. It's based on the TDA7498 chip.

So after a bit of of hacksawing and rewiring, I ended up with the fugly amplifier in the first photo. Fugly because the board is mounted on top of the case. To mount it inside I would have to think of some way to move the volume pot off the board.

Meanwhile I bought a modern AV receiver (not just a stereo amplifier, but multichannel, includes tuners, and even bluetooth input) on sale in the end of year offers so that does duty these days. I'll put this fugly hack to the back of my to do queue and get on with other projects.

-

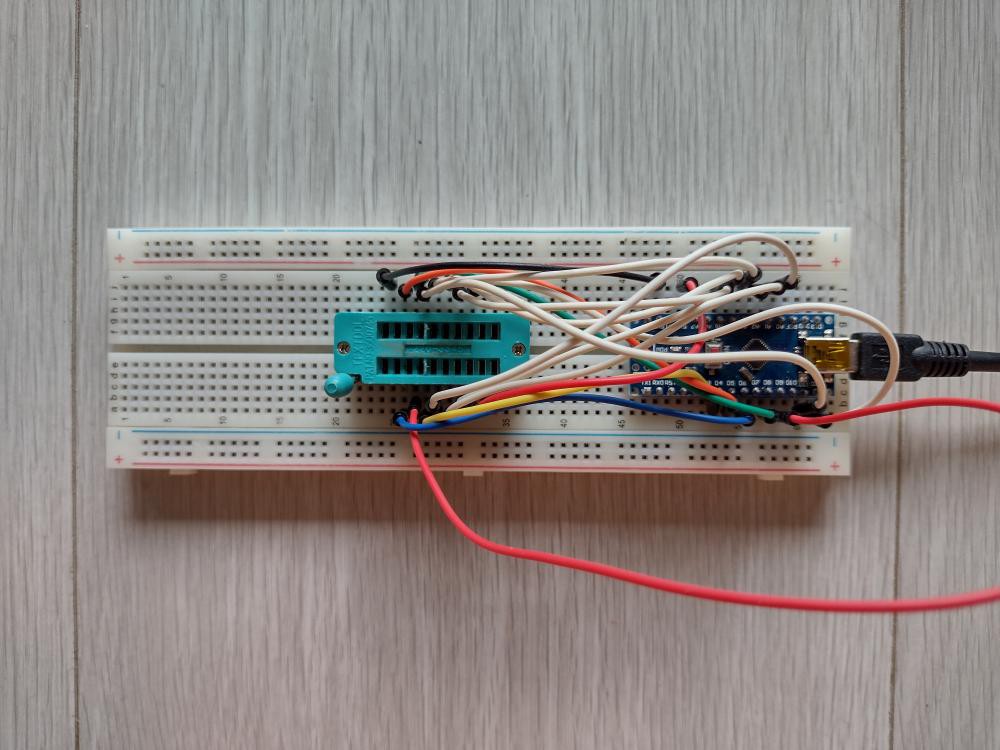

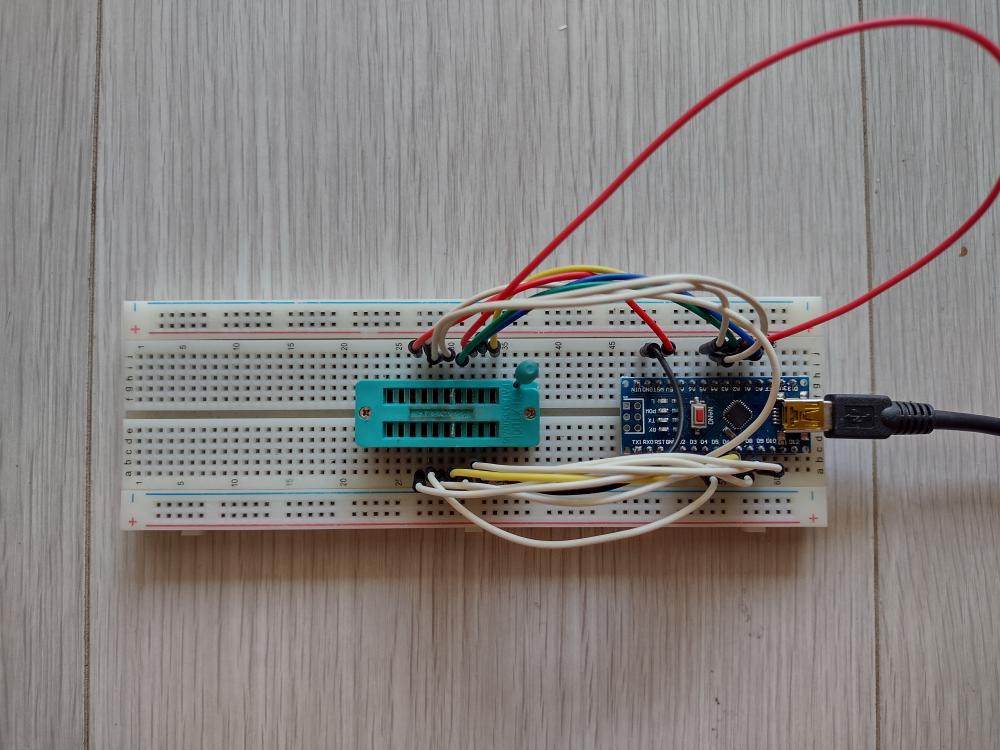

Halving the execution time of an Arduino sketch

12/13/2023 at 08:04 • 0 commentsI have a large pile of 4164 and 41256 1-bit wide DRAM chips from the PC era. Many of them were extracted from sockets or boards. I was curious to know how many are faulty. A web search quickly turned up many designs for Arduino based DRAM testers. Most of them required only a few extra components in addition to an Uno or a Nano. Wiring is also simple so I wired up a tester on breadboard.

(There are complex versions that test a larger range of chips (e.g. additional voltage supplies), and have fancy features like an onboard display, but this was a one-off task. For the same reason I have no interest in any of the published PCB designs for Arduino shields.)

The first design I wired up was this:

This worked well. I didn't even wire up the LEDs because the serial console displays the status. Each chip takes about 80s to test. For succeeding chips I just have to press the reset button on the Nano as the program is already flashed into the MCU. It found a handful of faulty chips. Interesting that a batch of Mostek chips failed the test. Either their specs don't work with this tester, or a process fault ruined the chips over time.

But this circuit didn't handle 41256 chips. So I turned to this design:

The wiring is different. Here they have tried to minimise wire crossings from each side of the Arduino to the chip socket, at the expense of a less logical pin assignment. But it doesn't matter since a table handles the mapping in the sketch.

This also worked well. But with 4 times as many bits the testing time ballooned out to 288s. This meant many minutes waiting. There is only so much surfing I can do on the computer while waiting for tests to complete.

Hacking the sketch

I know that the Arduino library digitalWrite() and digitalRead() routines do a lot behind the scenes and this is reflected in the execution time. The Arduino documentation shows how to do direct I/O on the ports, but discourages it because for most sketches it doesn't matter and the sketch loses readability and portability. But the same page acknowledges there are situations where direct access is warranted. This testing sketch is just such a situation; it does a lot of bit I/O.

So I looked into how to rewrite the sketch to use direct I/O. A goal is to not change the structure of the code but use conditional defines to replace the digitalWrite() and digitalRead() routines.

For digitalRead() on the data out pin there is only one instance that needs to be replaced with inline code to read the pin, so that is easy.

Since writing HIGH or LOW are different code sequences in direct I/O, we define separate macros for the two situations, called dWH and dWL. When the optimisation is disabled, these map to digitalWrite(port, HIGH-or-LOW) and the program runs as before. When optimisation is enabled, these are defined as routines dWH() and dWL(). They use a switch statement to direct to the appropriate code for that pin. To discover the appropriate direct I/O statement one needs to consult the pin table of the Nano. The pins are also labelled in the sketch comments. So the overhead of direct I/O on a pin is a call, switch, and return.

Not all the digitalWrite() calls need to be substituted. Those dealing with the LEDs are not time critical and can be left as-is.

#define FAST_RW #ifndef FAST_RW #define dR_DO() digitalRead(DO) #define dWH(p) digitalWrite((p),HIGH) #define dWL(p) digitalWrite((p),LOW) #else #define dR_DO() (PINB & 1) void dWH(int p) { switch (p) { case XA1: PORTD |= (1 << 2); break; case XA7: PORTD |= (1 << 3); break; case XA5: PORTD |= (1 << 4); break; case XA4: PORTD |= (1 << 5); break; case XA3: PORTD |= (1 << 6); break; case XA6: PORTD |= (1 << 7); break; case CAS: PORTB |= (1 << 1); break; case XA8: PORTC |= (1 << 0); break; case DI: PORTC |= (1 << 1); break; case WE: PORTC |= (1 << 2); break; case RAS: PORTC |= (1 << 3); break; case XA0: PORTC |= (1 << 4); break; case XA2: PORTC |= (1 << 5); break...Read more -

Installing gcc for the 8088 on a RPM based Linux

04/08/2023 at 09:50 • 0 commentsThat's right, there has been a GNU C compiler (gcc-ia16) that generates code for the 16 bit x86 CPUs for quite a few years now, but it's due to the fork by TK Chia that much progress to a usable tool has been made in recent years. It's already in use by various projects, including the ELKS project.

Why would one use gcc-ia16 in preference to other existing free compilers such as Turbo-C (running under DOS, but you could run it in a VM) and Open Watcom, also enjoying a revival in interest? Well with gcc you get the prospect of compliance with a more up to date C standard, plus the possibility of someday compiling C++.

Why am I even tangling with this? I haven't had any 16-bit PCs for I forget how many years. Not even 32-bit only PCs, they are all 64-bit capable. I do have some 8088 chips and might get a round tuit making a SBC board for them. The real reason is I'm bored as I temporarily don't have access to my hardware toys. So I decided to see if I could install gcc-ia16 on my OpenSUSE Linux system.

Now that's definitely possible, because one can compile gcc-ia16 from source. But I'm lazy and decided to see if could adapt the Ubuntu packages, which are in DEB format. I remembered there is a utility called alien, which can convert between various package formats.

First of all alien is not in the official OpenSUSE repos, so I had to go to software.opensuse.org to find a contributed package. That went ok.

Next, I downloaded the DEB packages from the Ubuntu PPA for gcc-ia16. There are heaps of packages there, including versions for 3 Ubuntu releases. Cut to the chase, these are the ones that are needed: gcc-ia16-elf, binutils-ia16-elf, libi86-ia16-elf, and libnewlib-ia16-elf.

So I ran alien on one like this

sudo alien -v -k -r gcc-ia16-elf_6.3.0-20230219.07-ppa230219074~jammy_amd64.debAlien needs to be run as root or it will not be able to assign the correct ownership to the files in the resulting package. The -v shows progress messages, -k preserves the version number, and -r means the output should be a RPM package. Basically alien unpacks the DEB and reassembles it as a RPM. But it also checks the runtime dependencies, such as libraries. Despite being a complex tool, a command line driven compiler usually doesn't need much more than standard C libraries.

First problem, alien couldn't handle the Zstd compression of elements of the DEB. Zstd is a new-fangled compression scheme used in Ubuntu DEBs which replaces the old-fangled Gzip scheme.

I need a newer alien but when I tried to install that, it turns out my Perl isn't recent enough. Grr.

Ok, try another tack. Unpack the DEB, which is actually just a Linux ar archive, and convert the .zst files to .gz files and repack. That worked.

Oops, now it complains that the glibc version that I have on my system, 2.31, isn't recent enough for this application which wanted 2.32. Ok, instead of using the Jammy (Ubuntu 22.04) package, I'll drop back to the Focal (Ubuntu 20.04) package.

sudo alien -v -k -r gcc-ia16-elf_6.3.0-20230219.07-ppa230219074~focal_amd64.debAnd that converted ok.

One of the packages wanted libisl22 when I only had libisl15. This turned out to be the Integer Set Library originally from INRIA. Compilers have to manipulate sets at points during their operation. It turned out that the package comprises a dynamically loaded library and a symbolic link. And nothing required libisl15 so it would be quite safe to install libisl22 side by side and not worry about another application loading the wrong version.

After I converted all the packages just because I'm a bit obsessive, I changed the ownership of the resulting RPMs from root to myself, and made their mtimes the same as the corresponding DEB packages.

Now, would the RPM packages install correctly? I tried:

sudo zypper in gcc-ia16-elf-6.3.0_20230219.07-ppa230219074~focal.x86_64.rpmNotice I used zypper and not rpm, because zypper will detect any dependencies and satisfy them.

One other...

Read more -

A quick foray into the CH552 MCU

11/28/2022 at 02:20 • 0 comments

The CH552 is a very cheap (~$1) enhanced 8051 core MCU by Nanjing Qinheng Microelectronics, It's been on the market for a while and there are breakout board projects based on it, for example #CH552 Dragon , #CHUSBIE552 - CH552 Development board , #CH55xG Tiny on Hackaday alone. An Internet search will find many more. So this is old territory. Seeing cheap WeActStudio CH552 boards on AliExpress for less than $2 prompted me to get a couple to play with, despite being a bit adverse to the 8051 CPU architecture. (A decent C compiler can hide some of the ugliness.) This has the CH552 in a 20 pin package and an impressively small number of glue components. The board is only about the size of old 24 pin 0.6 inch width DIP chips. Even the 5V to 3.3V regulator is on the MCU chip. It's similar to other 20 pin MCU boards like the STM8 budget series.

The previous link is to a Github repo and you may wish to make a local clone to get access to the board details. The datasheets from the manufacturer, in both Chinese and English, are also provided.

One of the attractions of the CH55x series is on-chip support for USB which could come in useful for working with USB devices. In fact the USB connector is USB3, not the older USB2 micro USB connector. Today I just want to get it to blink.

For this I will be using Deqing Sun's CH55xduino, which is an Arduino environment for the CH55x devices. The best place to get it is from the official Arduino repositories, search for ch55x under Boards. This provides a familiar starting point for many people. SDCC, the compiler, isn't a C++ compiler, so the object oriented aspects of some Arduino libraries have to be rewritten in plain C, and user code adapted to suit. CH55xduino has made commendable progress on this front. Later on, I'll probably invoke SDCC directly from Makefiles.

For Linux, CH55sduino suggests installing a udev rule so that you can download code as a normal user. I modified it a bit, the original made the USB port RW to all. Instead I chowned it to the dialout group, which is the suggested group for accounts that need to communicate with serial devices on my Linux distro.

# CH55x bootloader # copy to /etc/udev/rules.d/ SUBSYSTEM=="usb", ATTRS{idVendor}=="4348", ATTRS{idProduct}=="55e0",GROUP="dialout"To get the blink sketch, I went to Examples and chose the CH55x version. One thing has to be edited, the definition for LED_BUILTIN has to be changed to 30, because the WeActStudio board has the LED on this line, by looking at the schematic from their git repo.

So all I had to do was select Upload, and after a while the blue LED duly blinked.

Now that I know it works, it'll go into my collection of MCU breakout boards which I will put to use when I get a round tuit. There seems to be a worldwide shortage of round tuits, but we all have to cope in our own way.

-

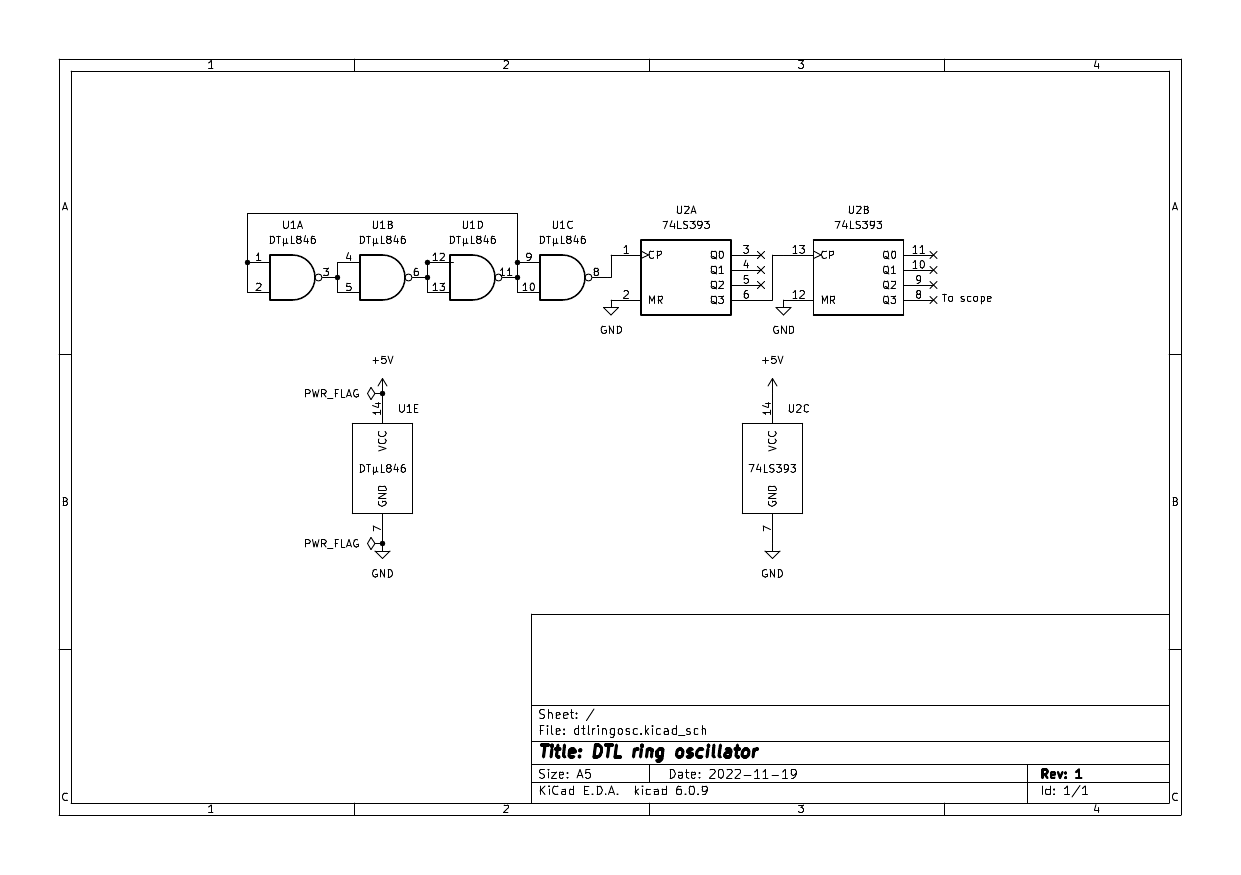

A short experiment with a DTL ring oscillator

11/20/2022 at 10:28 • 1 comment

Following #Ring Oscillators: Fairchild DTL 949 I decided to see if I could make some use of a handful of DTµL 846 quad 2-input NAND chips I have, since it's very easy to wire up a ring oscillator. 3 gates form the oscillator and the fourth buffers the output. I do not have a scope of sufficient bandwidth to measure to 10 MHz so I sent the output to a 74LS393 as a divide by 256 counter. So to get the original frequency, multiply by 256.

The DTL chip was mounted on a repurposed precision IC socket, slightly damaged by a soldering iron. This avoids any stray capacitance from breadboards, but allows different chips to be plugged in. Here are the results of the few good chips I have (the others in my pile had one faulty gate):

- 37 kHz -> 9.5 MHz

- 36 kHz -> 9.2 MHz

- 38 kHz -> 9.7 MHz

The frequency stability is not great, it fluctuates in the short term. In the medium term I noticed it sped up a bit after "warming up". But it's pretty certain that it will not exceed 10 MHz.

So what to do with these oscillators? Where can I use them that doesn't require the accuracy and stability of crystals, which I'm not short of? Perhaps where I don't want the added components for a crystal oscillator. But even ancient MCUs have built-in gates for crystals, requiring only a couple of load capacitors. Modern MCUs even have a builtin RC oscillator mode which is good enough when timing isn't critical. Maybe some kind of coarse timing circuit? But the divisor would be large, so might as well use a MCU again. I'll put that question in the back of my head while I move on to other projects.

Out of interest I tried a 74LS00 chip (which has the same pinout) in the harness and I got 133 kHz -> 34 MHz.

-

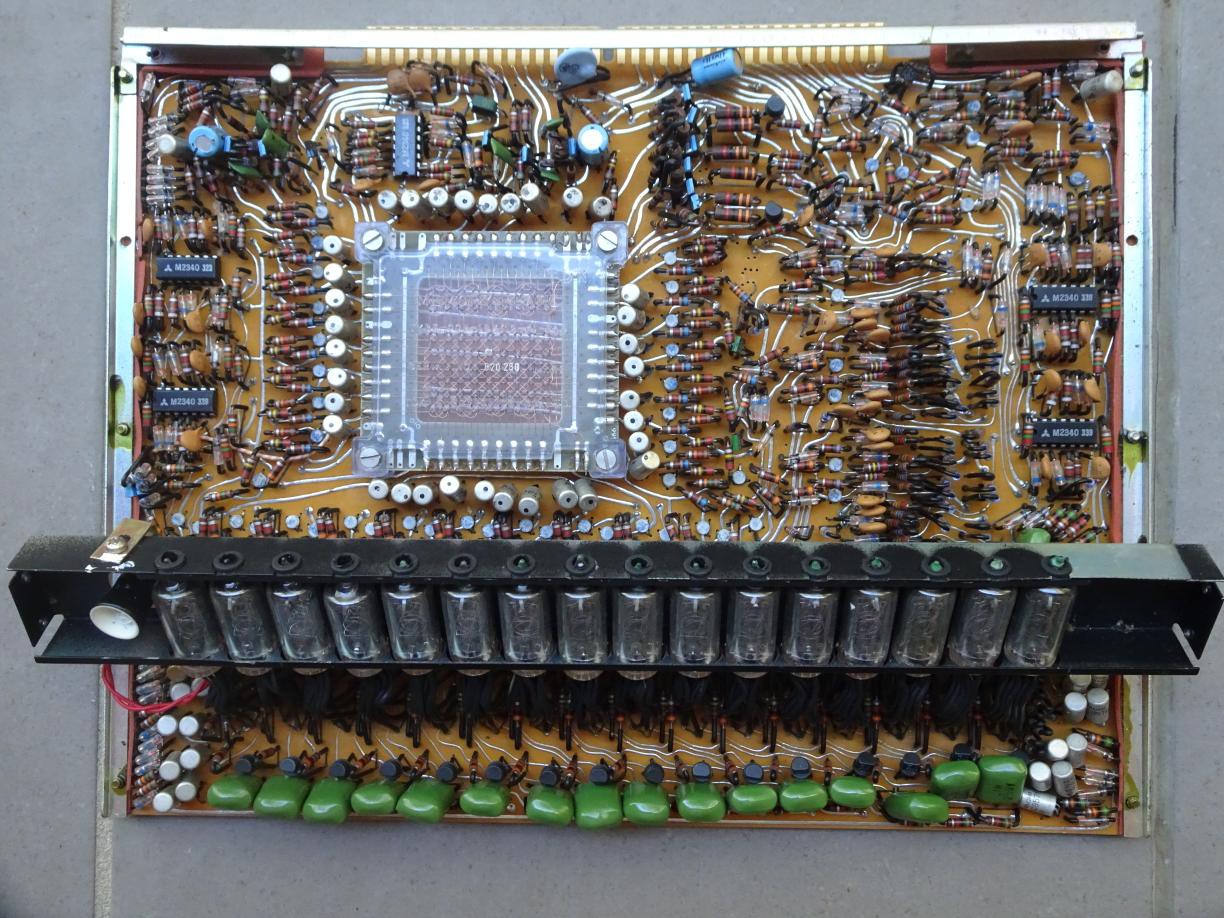

The Soul of an Ancient Calculator

08/30/2022 at 06:45 • 0 comments

Around 1990 I picked up an old Sharp calculator from a flea market because it was only a couple of bucks and had 16 nixies. I believe it was this Sharp calculator model from 1969. I say I believe because at some point when I moved I threw away the case and keyboard, no perceived utility. But that the CS-361 had magnetic core memory fits with the main board I still have.

Well it's a pity I don't have the complete machine because it could have been of interest to a museum. I'm fascinated that it used core memory. I thought it was for microcode storage, but the web page says it was for registers. The microcode probably consists of diode logic. You can also see it has germanium transistors in metal cans and plastic silicon transistors.

No, I'm not going to try to reverse engineer the logic. Just thought I'd publish a picture of the main circuit board before I put the nixies to other uses.

-

A firmware monostable (and other circuit blocks)

05/05/2022 at 08:39 • 2 commentsRecently I was looking to use a 74LS123 dual retriggerable monostable as pulse stretchers. I have used them before in a DTL clock. I only needed a subset of the pins, the /A input for the input pulse and the /Q output for the output pulse. Two additional components, a resistor and a capacitor are needed for each pulse stretcher. Here is the datasheet page with the truth table, only the last 3 rows of the 123 truth table are of interest.

Then it occurred to me that I could use a MCU to do the same job without the R and C. Here's an Arduino simulation:

// // Emulate half of a 74LS123 in firmware // #define NA 2 #define B 3 #define Q 4 #define NQ 5 #define DELAY 1000 // milliseconds void clear() { digitalWrite(Q, LOW); digitalWrite(NQ, HIGH); digitalWrite(LED_BUILTIN, LOW); } void set() { digitalWrite(Q, HIGH); digitalWrite(NQ, LOW); digitalWrite(LED_BUILTIN, HIGH); } void setup() { // put your setup code here, to run once: Serial.begin(115200); pinMode(NA, INPUT_PULLUP); pinMode(B, INPUT_PULLUP); pinMode(Q, OUTPUT); pinMode(NQ, OUTPUT); pinMode(LED_BUILTIN, OUTPUT); clear(); } void loop() { // put your main code here, to run repeatedly: byte a, b, trigger; do { a = digitalRead(NA); b = digitalRead(B); trigger = (!a == b); } while (!trigger); // Serial.println("Triggered"); set(); unsigned long later = millis() + DELAY; while (millis() < later) { a = digitalRead(NA); b = digitalRead(B); trigger = (!a == b); if (trigger) { // Serial.println("Retriggered"); later = millis() + DELAY; } } // Serial.println("Off"); clear(); }Great, I hear you say, you've just written a firmware equivalent for a circuit, so what?

But what if the MCU is an ultra-cheap one like the 3¢ ones discussed over 3 years ago? That's so cheap that you could admit the audacity of thousands of transistors on a chip substituting for maybe 50 transistors on the monostable chip. You could (re)program the MCU for the duration you want. You might not be able to get very short pulses of the order of microseconds, but on the other hand you could have extremely long durations, days even. And it would be far more accurate than an RC network.

Now such MCUs are certainly cheap enough to be 7-segment decoders and the like, but for 3¢ we can contemplate substituting for even simpler circuit blocks such as switch debouncers. Normally you would fold such functionality into the main MCU's firmware, if the product has one. But you could simplify the firmware by splitting out the fuctionality into another chip.

One thing to note is that in practice you want to read in all the inputs in one instruction, so that you don't get race conditions between /A and B changing. This can be done by reading in a port in one go. You can also ensure that all outputs change at the same time by making sure that the Q and /Q lines are on the same port, although output skew is less of an issue for most applications.

In my application I only need /A and /Q so only two I/O lines are needed. So an 8-pin MCU with 6 I/O lines could support 3 such firmware monostables.

-

Bizarre HaD buglet

04/16/2022 at 08:11 • 0 comments

Notice that the details instead of saying "wrote 2 days ago" is in the Chinese translation. This doesn't happen all the time, only sporadicaly, and to other people's pages too. Nothing else is turned into Chinese, only dates. Next time it happens I'll inspect the HTML element to see if it arrived that way from HaD.

-

Is it possible to drive Titan Micro display controllers with an I2C bus?

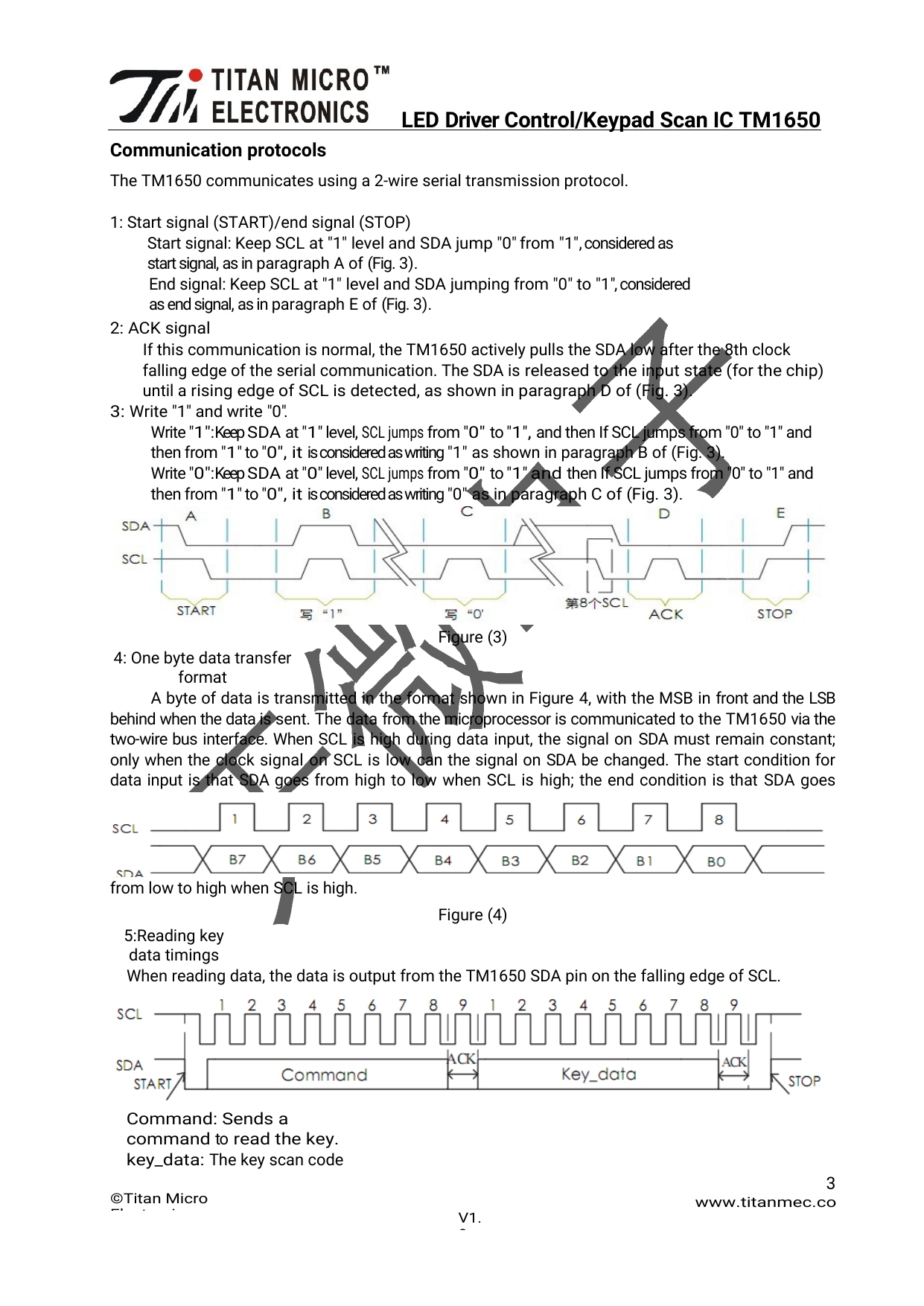

04/14/2022 at 18:00 • 0 commentsMany people have noticed that resemblance to I2C protocol of the protocol used by the Titan Micro series of LED display controller chips, of which the TM1637 is most often seen, on display modules that cost only a dollar or less, not much more than the parts that go into it. These modules are useful for simplifying projects and reducing the number of drive lines needed of the MCU. I myself have written a comparison of the two protocols, I2C and let's call the other TMP.

I saw a suggestion on EEVBlog that TM chips could be driven by a standard I2C bus. Was this a tested idea or speculation, I wondered. I decided to test the idea.

While the low level details of the start and stop conditions are the same, two other aspects need to be handled:

- The bit order in the stream is most significant bit first for I2C and least significant bit first for TMP. This requires that all commands and data to the chip be byte-reversed before use. This isn't as onerous as it sounds. Constants for commands can be reversed in program code. For the display data which is generated from a font table, the table entries can be reversed at coding time. Or one could regard the segment to bit mappings to be reversed. In the program below I have elected to do it with a function to keep things simple.

- TMP doesn't have a slave address, the first byte after the start is a command. So the command would go where the I2C slave address would go. The complication is that in I2C the LSb of the address is the direction bit, 0 for master to slave and 1 for slave to master. We are interested in the former. That means that the LSb has to be 0. Taking into account the byte reversal, this means that only TMP commands below 0x80 can be sent. The silicon is entitled to look at the direction bit and not transmit to the slave if it's not 0.

The previous explains why the following Arduino sketch for scrolling digits doesn't work as expected. The LED display doesn't turn on, and only running a working bit-banging sketch before running this one will the LEDs light up.

The set address command of TMP also doesn't work as it's 0xCn where n is 0..5. At power up n defaults to 0, so all 6 bytes of the data have to be sent otherwise not all the digits can be seen.

// Uno #define SDA A4 #define SCL A5 #include <Wire.h> static uint8_t startnum = 1; static uint8_t display[6]; static const uint8_t font[] = { 0x3f, 0x06, 0x5b, 0x4f, 0x66, 0x6d, 0x7d, 0x07, 0x7f, 0x6f }; static const uint8_t revmap[] = { 0x0, 0x8, 0x4, 0xc, 0x2, 0xa, 0x6, 0xe, 0x1, 0x9, 0x5, 0xd, 0x3, 0xb, 0x7, 0xf }; uint8_t byterev(uint8_t b) { uint8_t lo = b & 0xf; uint8_t hi = b >> 4; return revmap[lo] << 4 | revmap[hi]; } void setdisplay() { Wire.beginTransmission(byterev(0x8f >> 1)); // set brightness (doesn't work) Wire.endTransmission(); } void writedigits() { Wire.beginTransmission(byterev(0x40 >> 1)); // data command (works) Wire.endTransmission(); Wire.beginTransmission(byterev(0xc0 >> 1)); // set address (doesn't work) Wire.write(display, sizeof(display)); Wire.endTransmission(); } void setup() { pinMode(LED_BUILTIN, OUTPUT); pinMode(SDA, OUTPUT); pinMode(SCL, OUTPUT); Wire.begin(); Wire.setClock(100000); setdisplay(); } void loop() { uint8_t first = startnum; for (uint8_t i = 0; i < sizeof(display); i++) { display[i] = byterev(font[first]); first++; if (first >= 10) first = 0; } writedigits(); delay(500); startnum++; if (startnum >= 10) startnum = 0; digitalWrite(LED_BUILTIN, (startnum & 0x1) ? HIGH : LOW); // flash at 0.5 Hz to debug }The video at the top shows the scrolling one should expect to see, albeit on a ESP8266 platform instead of Arduino.

But the send data command does work as it's 0x40. So one solution would be to use bit-banging to initialise the chip, then switch to using the silicon support for I2C for display updates. It would mean slightly more code, but not much for the display update. Here's a slightly modified version of the previous sketch...

Read more -

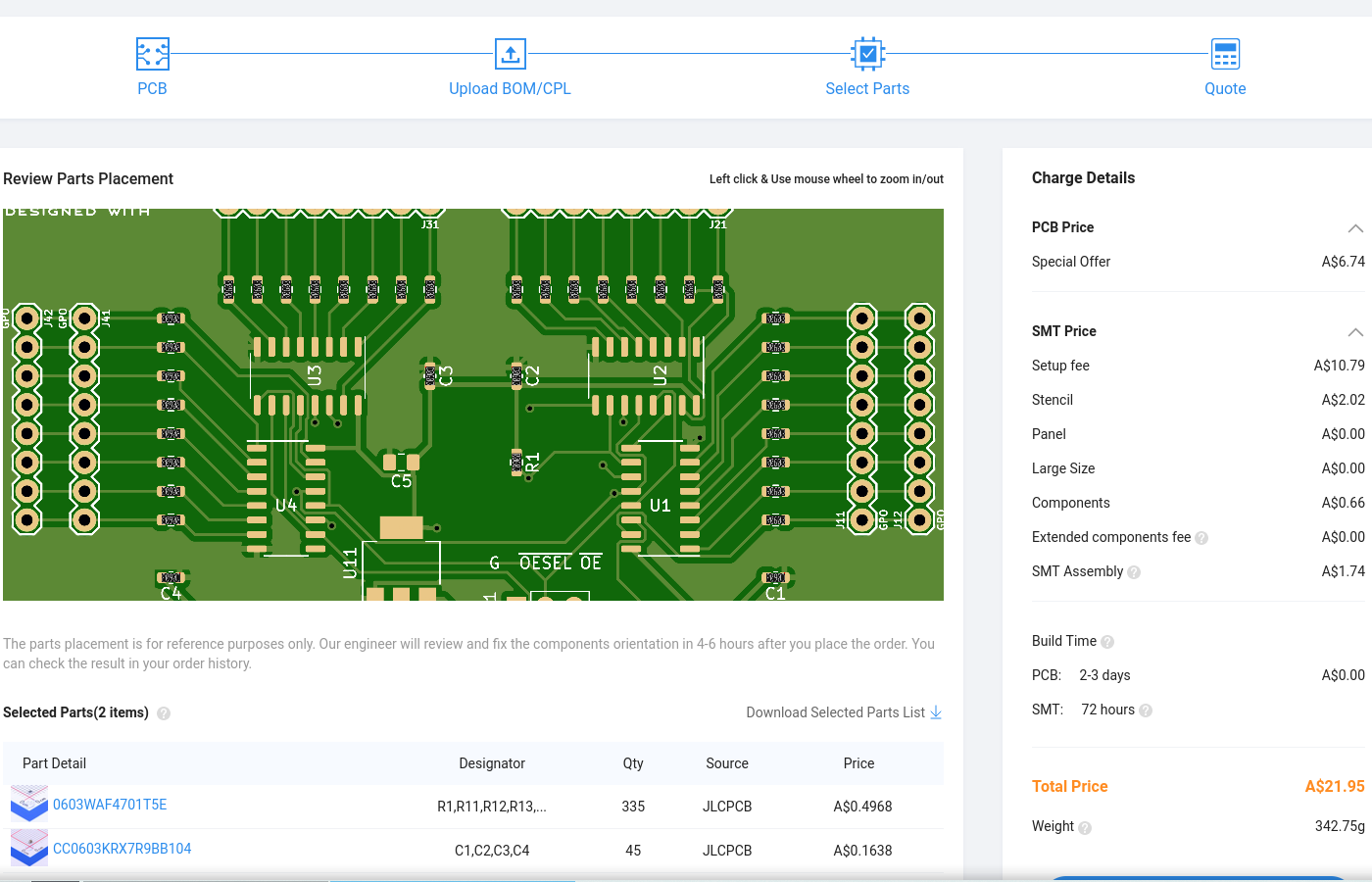

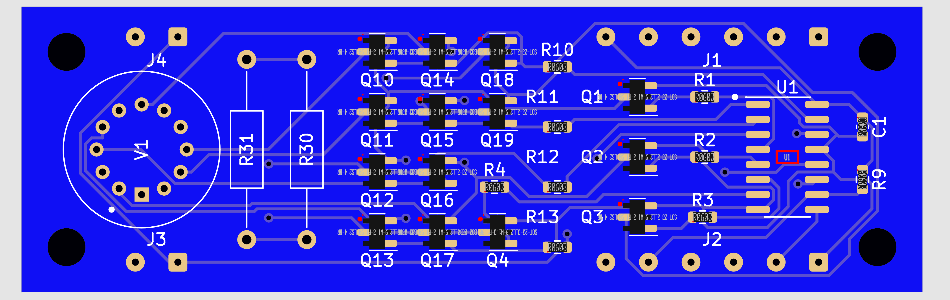

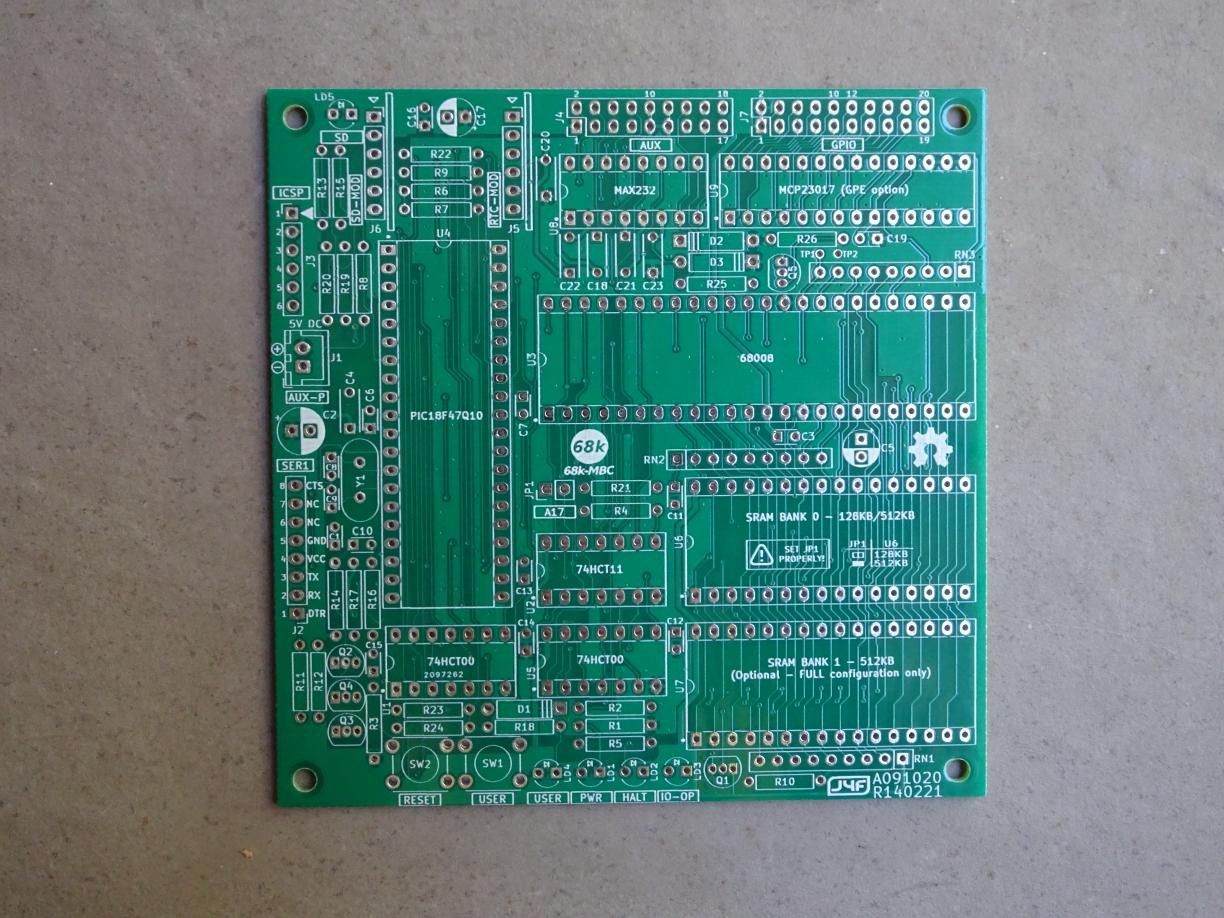

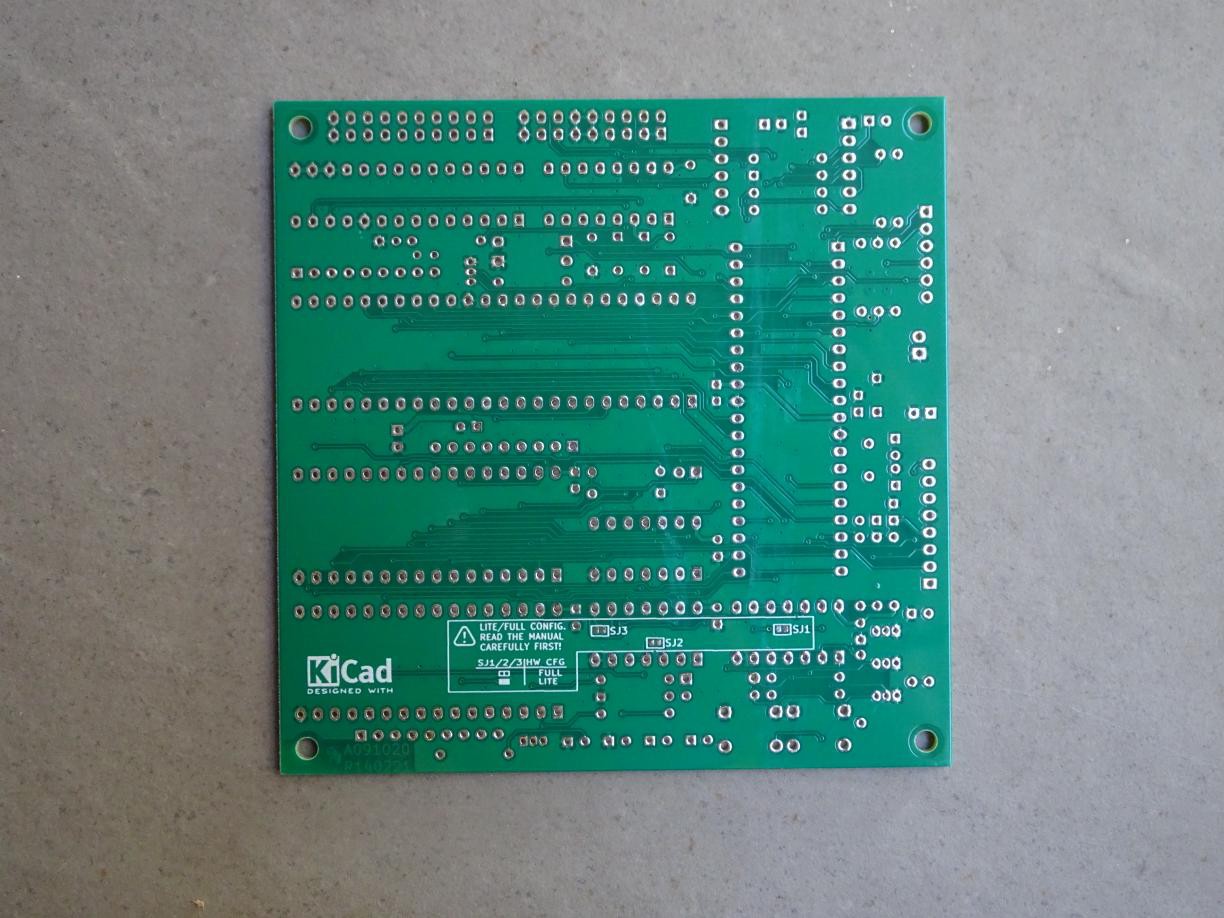

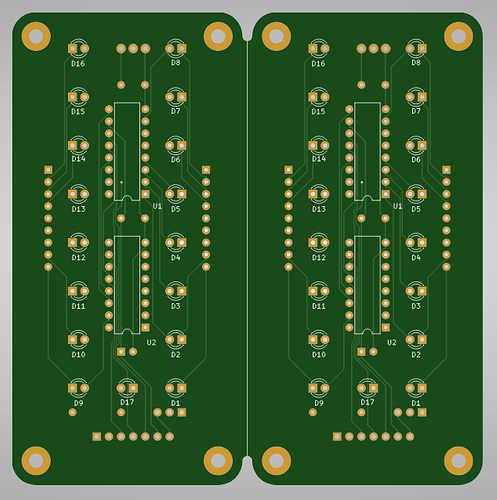

Costing assembly service for my PCB

03/07/2022 at 07:49 • 8 comments

Today I decided to dip my toes into getting a PCB design of mine assembled to avoid a lot of hand soldering. JLCPCB gives out monthly coupons to offset the setup charge so that reduces the total price.

Here's what I found out, in no particular order:

It's quite straightforward to generate the two files required: the Bill Of Materials (BOM) and the Component Placement List (CPL) files, also called POS files, from KiCad. Both are CSV format files. There are many ways to do that. Here's what I did.

The BOM can be generated by the XSLT converter recommended by JLCPCB. This has to be first installed in your scripts directory then registered as a generator for eeschema. But you should also add an extra field to each symbol called LCSC. This is where you put the part number, more further down.

The CPL files (top and bottom) are generated from pcbnew (yes, BOM from eeschema and CPLs from pcbnew, reason is because not all symbol fields are passed on from eeschema, maybe in some future version). After that the header line needs to be changed to JLCPCB's headers, This sed script will do it:

#!/bin/sh exec sed -i '1s/Ref,Val,Package,PosX,PosY,Rot,Side/Designator,Val,Package,Mid X, Mid Y,Rotation,Layer/' "$@"But before you generate the BOM, you need to add the LCSC (a JLCPCB sister company) part numbers. Go to the parts search and find the part numbers you need. For example C23162 is a 0603 profile 4.7k resistor.

JLCPCB has basic parts and extended parts. Basic parts are already in the PCB factory, extended parts have to be ordered from LCSC so an extra fee is levied. Vanilla parts like resistors and capacitors are definitely basic parts. Probably jelly bean transistors, diodes, and common ICs too but see next point.

There is a minimum charge of quantity 20 for each part with headroom of 5 for wastage. They won't credit you for any leftovers. Hence the recommendation to reduce the number of different parts. For example if your circuit has lots of 4.7k resistors already and a particular resistor calls for 3.9k, can you change that to 4.7k?

You upload the Gerber files as usual for PCB fabrication. At the bottom you then select SMT assembly. NB: If you only order 5, you can have 2 assembled and you have to do the rest yourself. So you have to order a minimum of 10 boards if you wish to avoid doing 3 by hand. Only one side of the PCB will be assembled. So put all the SMT components you don't want to do yourself on one side, usually the top. Thus only one CPL file is needed.

You then upload the BOM and the CPL files and a quote will be generated, a sample is in the screenshot. But before you do that you may wish to cull the components in the BOM and CPL files that are not to be assembled. But the web page will filter out those components without a part number anyway.

You can see that the setup fee and stencil cost the most. The components and SMT assembly are really cheap, even for the hundreds that I used in my sample order.

The preview window also shows if your CPL file is correct. The black chips are the components which will be placed by machine and soldered. At some point in your adventures you may encounter this issue:

The transistors are rotated 180° from the correct orientation, and although the IC can barely be seen (due to stock shortage at the time I did this quote), it's 90° wrong too. It all comes down to a mismatch between what is regarded as the normal orientation between KiCad and their database. To fix this you have to edit the orientation column in the CPL file and try again.

Unfortunately you have restart from the Gerber file upload.(May not be necessary.) If you haven't corrected the orientations before the job is started, their engineers will fix the issues and send you a preview for confirmation, so it is strongly encouraged that you provide a mark, such as the filled circle you see near pin 1 of U1 to help them get it right.The coupon is $8 so that brings the cost down to $14....

Read more -

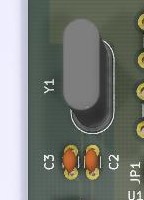

I should pay more attention when assembling

12/24/2021 at 09:33 • 0 comments

I was putting together a few more 8042 boards since the original order netted me 5 PCBs and they were panelised 2 per PCB. One didn't work with the same EPROM as the others. Today I compared it with a working board and noticed that the crystal capacitors were supposed to be like the 3D rendering above, but I had soldered them in rotated 90°. In fact the silkscreen has lines indicating the orientation, and the labels are also a hint. That was dumb of me. A few minutes later it was fixed and worked straight off.

Solved a puzzle, a nice holiday season present for myself! Happy holidays everyone and stay safe!

-

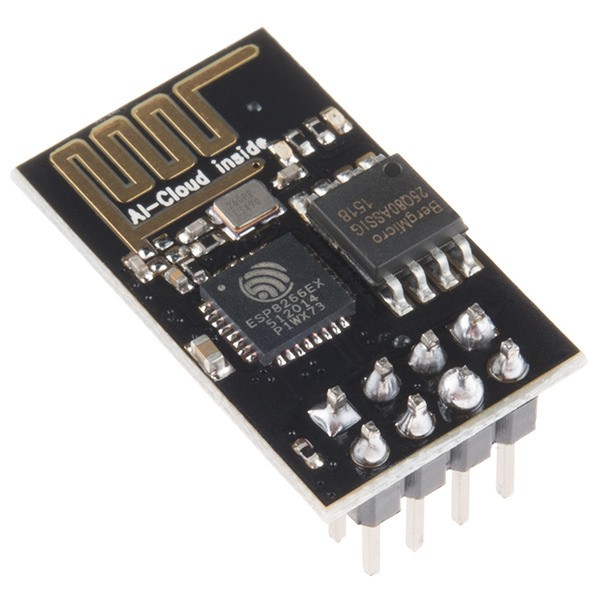

Adventures getting an ESP8266-01 relay module running

12/07/2021 at 12:22 • 0 comments

I bought a relay module and the matching ESP8266-01 WiFi module for a couple of bucks (bargain!), in order to experiment with remote control. In particular I'm thinking of fitting one into an amplifier for remote turn-on. The module is quite small, that photo is larger than life size. It's about the size of a matchbox and perhaps twice as high. The ESP8266-01 fits onto the 8 pin yellow socket in the picture. These are my notes on getting it to work. I will augment this page as I encounter and solve issues.

Sparkfun Electronics, ESP-01, CC BY 2.0

A search for ESP8266-01 will get you quite a few instruction pages. Usually they suggest you start by connecting a serial terminal on an Arduino to it. You could also use a FDTI adaptor. I came across these issues:

Diagrams show that you have to take the EN pin high (3.3V) to allow it to work. But the RST pin must also be taken high or the module may not respond. Later on you should make provision to ground GPIO-0 to flash programs if that's what you want to do.

Beware of "smart left and right quotes" on web pages if you copy and paste commands, in particular the command to register with an AP, giving the SSID and password. You must use the ASCII double quote.

In one Fritzing diagram, hosted by the Arduino site no less, a 5V to 3.3V regulator is shown on the breadboard you'll need to expand some connections like 3V3 and GND. I'm not sure why; the Arduino board, at least the Uno, already has a 5V to 3.3V regulator.

I came across one article discussing ways to expand GPIO. One way is to use an I2C extender. Besides GPIO-0 and 1, Rx and Tx could be used for a total of 4. But such measures are probably unnecessary nowadays; buy a later ESP8266 or ESP32 module with far more I/O pins for not much more money.

Last edited 2021-12-08

-

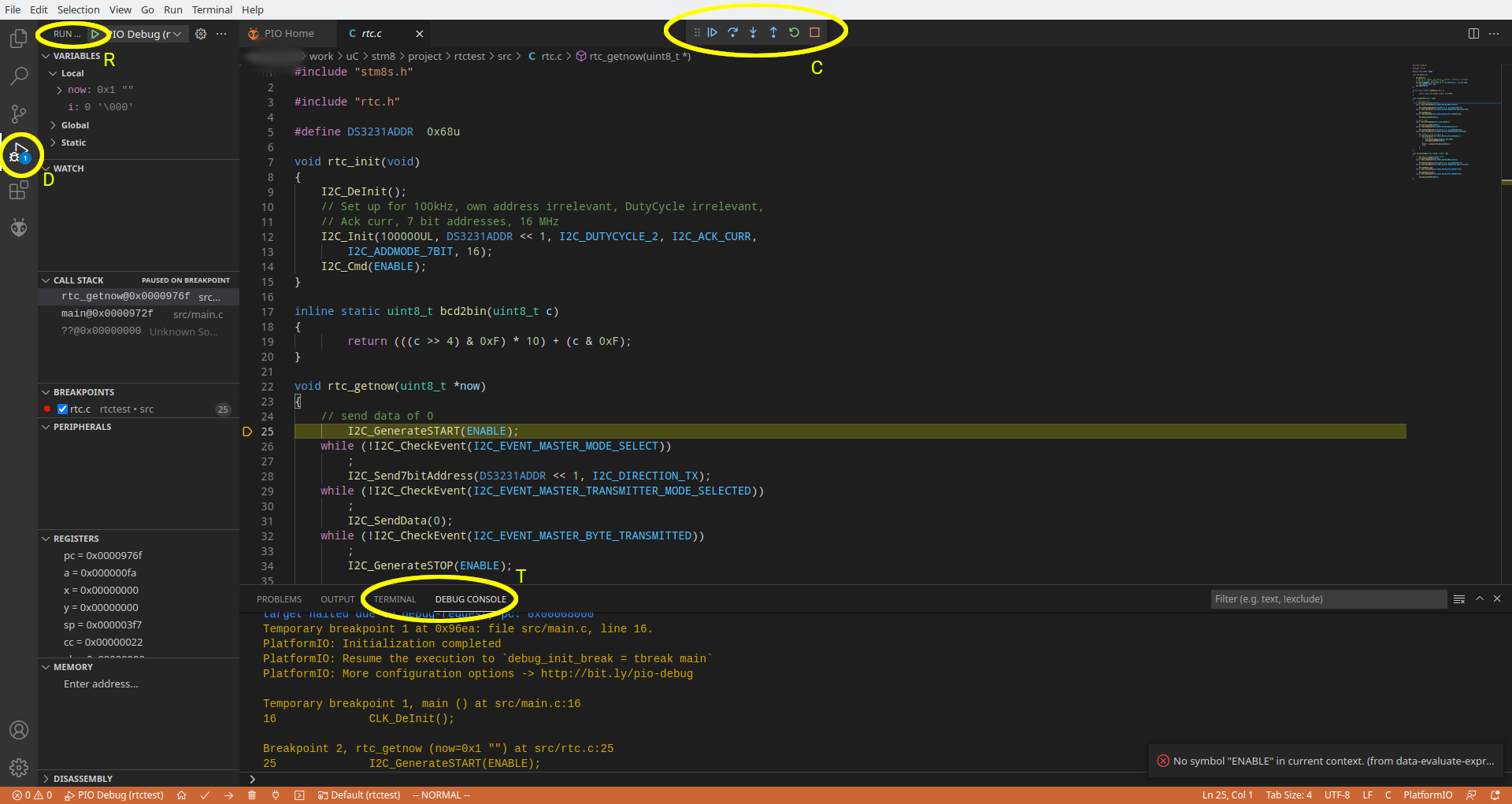

Adventures debugging STM8 with PlatformIO

10/13/2021 at 10:02 • 0 comments

I previously showed how to set up PlatformIO. Now I demonstrate putting PlatformIO to debugging firmware for the STM8. Debugging is where the IDE comes on its own as you can see multiple pieces of information on the screen, unlike a text debug session.

Assuming you have all the build and debug tools installed for STM8 in PlatformIO, and you have the board connected to your host computer with a STlink dongle, then when you open the file explorer to the code you want to debug, and click on icon D, you should get a display like this. As you can see the relevant controls aren't exactly grouped well, they are scattered all over the screen, but you will get used to that. The left column shows the state of the program, including any breakpoints.

To set a breakpoint, right click on the space before the line number and it will allow you set or delete breakpoints. As you can see there's one on line 25.

Start the program with the arrow at R. It will first stop at the beginning of main(), then you can continue using the continue arrow control at C. Here you see we have paused at line 25. You can step into lines or over lines using the controls. These correspond to the gdb commands S and N and can be entered as text at the prompt under the debug console T. However if the program has gone into a loop without hitting any breakpoints, you will have to use the interrupt button at C. This cannot be done from the prompt. You can also restart the session.

Other gdb commands like print [variable] also work, but it's more convenient to watch the variable display in the left column.

One drawback to using debugging from the IDE is that the generated firmware will be larger and may not fit in flash memory if you are near the limits.

-

Addresses need to be doubled in SPL for STM8

10/10/2021 at 22:47 • 0 comments

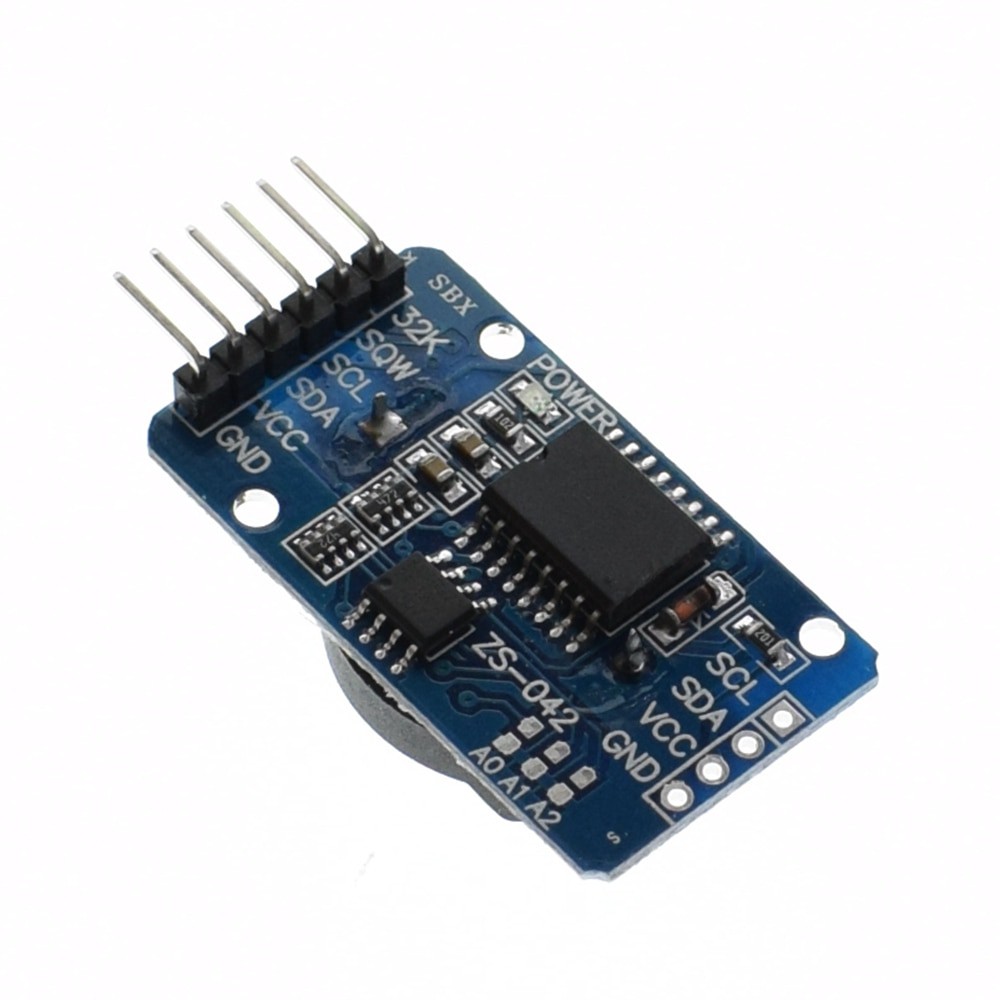

While interfacing a DS3231 RTC to a STM8 development board using the Standard Peripherals Library and PlatformIO (BTW, you don't need to build SPL, it's provided by a PlatformIO package), I fell into a simple trap. I assumed that the address wanted by the I2C functions of the SPL was the one stated by the manufacturer. In the wire protocol this is the top 7 bits of the address byte (0x68 in the case of the DS3221) and the bottom bit indicates the direction of data transfer. However the SPL functions want the address shifted one bit left (or doubled if you prefer). This is obvious when looking at this SPL function.

void I2C_Send7bitAddress(uint8_t Address, I2C_Direction_TypeDef Direction) { /* Check function parameters */ assert_param(IS_I2C_ADDRESS_OK(Address)); assert_param(IS_I2C_DIRECTION_OK(Direction)); /* Clear bit0 (direction) just in case */ Address &= (uint8_t)0xFE; /* Send the Address + Direction */ I2C->DR = (uint8_t)(Address | (uint8_t)Direction); }I assume the SPL writer did this to avoid a runtime left shift of the address parameter, and wanted the SPL user to do this themselves, as the address is usually a constant in the code and the doubling folded by optimisation. Programmers who use the I2C registers directly without SPL will normally take care of this point when setting the address.

Code examples of using I2C with STM8 SPL are a bit thin on the ground, but this is one that helped me.